1. Introduction

The rapid growth in global electric energy demand exhorts the development of sustainable and renewable energy resources [

1]. Solar energy is the most promising resource among all the available options of renewable energy resources due to its abundance, cleanliness, and free availability [

2]. To harvest solar energy, photovoltaic (PV) systems and solar thermal collectors are currently being used [

3]. Solar PV systems have many distinct advantages, such as low maintenance costs due to the absence of any moving parts, quiet operation, no harmful greenhouse gas emissions into the atmosphere, and support for sustainable development. Solar PV technology plays a vital role in sustainable development by reducing the dependence on fast depleting fossil-fueled power plants [

4]. However, the conversion efficiencies of conventional solar cells are inherently lower that further decline at higher cell temperatures [

5]. Integration of optical concentrators and suitable heat dissipation mechanism with such solar cells have great potential to improve their energy conversion performance [

6]. The resulting concentrated PV system produces more output with lesser solar cell material and thus provides the opportunity of net saving in the material and manufacturing cost of solar cells.

The concentrated photovoltaic systems can be subdivided into low, medium, and high concentration systems depending upon their concentration ratios [

7]. Low concentration photovoltaic systems are relatively simple systems that usually employ CPC reflectors, belonging to the family of non-imaging optical concentrators, and can be employed as stationary installations [

8]. On the other hand, medium and high concentrating collectors, categorized as line focusing and point focusing types, utilize imaging type concentrators, which essentially require complex tracking mechanisms for continuous and effective operation [

9].

The compound parabolic concentrators (CPC) were first introduced by Roland Winston [

10] as optical concentrators for thermal as well as PV applications. Later, some other research groups investigated the plausibility of the deployment of these concentrators to solar PV generators for improving their performances. The CPCs have emerged as the best static low concentrating systems for PV applications in the last two decades [

11]. The benefits of the compound parabolic concentrator over other concentrating collectors include higher optical efficiency and the ability to collect both direct and diffuse solar rays [

12]. They do not require active tracking mechanisms, and lesser space is needed for their installation [

13]. Due to these advantages, CPC collectors combined with PV modules are found to be suitable for supplying electricity to domestic as well as small scale industrial/commercial consumers.

Over the last few decades, many researchers have proposed diverse geometries of CPC collectors [

14] for improved optical and electrical performances. Garg and Adhikari [

15] made optical design calculations for a 3× CPC intended for PV/thermal applications. The authors observed the variation of height to aperture as well as the reflector area to aperture area ratios against the concentration ratio of CPC. The CPC height was found to be 1.89 times its aperture width. Some recent research studies about the design of 2D CPC for PV applications are available in the literature [

16,

17]. Khalid et al. [

18] investigated two unique CPC designs having a concentration ratio of 2×, the lowest truncated CPC and the highest truncated CPC, by comparing their optical performances with full CPC using ray-tracing simulations. The authors concluded that the lowest truncated CPC design exhibited better performance in terms of uniform flux distribution and the lowest material consumption. Hadavinia and Singh [

19] used ray-tracing simulations for modeling two geometrically equivalent concentrators viz., V-trough and CPC. The authors demonstrated that truncated CPC had better acceptance of solar radiation beyond its acceptance angle range with a minor reduction in concentration ratio compared to full CPC. Both concentrators were designed for a geometric concentration ratio of “4×”. When compared with an equivalent V-trough, CPC generated 2.4% more power. Lee and Rao [

20] used the fuzzy set theory for performing uncertainty analysis of a CPC-PV collector system located in Miami, USA. The authors performed single objective optimization-based simulations for three different objectives, and the corresponding optimal values of design parameters were obtained using fuzzy analysis technique for each objective. The objective functions included maximization of annual solar energy reaching the receiver surface (f

1) and the lowest monthly incident solar energy (f

2), as well as minimization of total cost of system (f

3), including the cost of reflectors and land. The authors determined the deviations of all three objective functions from their crisp values in the lower and upper bounds and concluded that the width of PV receiver and acceptance angle were the most critical factors that control the deviations in upper bounds as compared to lower bounds.

Some researchers investigated the benefits of integrating CPC collectors with PV modules for amplifying their output power [

21]. Mallick et al. [

22] performed an experiment to compare the performance of an asymmetric CPC having a concentration ratio of 2× with a flat PV module. The results of their research showed that the CPC caused an increment in the ceiling of extreme yield by an amount of 1.61 as compared to that of an analogous module without concentration. Hossain et al. [

23,

24] carried out similar research with the purpose of expanding the productivity of a photovoltaic panel by utilizing CPC. A photovoltaic panel capable of following the sun in the absence of CPC and an analogous panel using CPC and following the sun were examined together under the outside environment in the Malaysian atmosphere. The researchers inferred from the experiment that the productivity of panel using CPC and the sun following arrangement was 1.5 times more than that of its counterpart operating in the absence of concentration and tracking. The application of the sun following mechanism with CPC was found to be a suitable approach for improving the yield of photovoltaic systems. However, the integration of tracking arrangement caused complexity and additional cost of concentrating PV modules. Yang et al. [

25] conducted a comparative analysis to evaluate the energy production of a photovoltaic panel once employing CPC and then in its absence under the climatic conditions of China. The authors concluded that the production of power from a PV panel using CPC was almost double that of its fellow panel without concentration.

To solve the problem of non-uniform flux distribution on the PV module surface due to parabolic reflectors, Paul [

26] presented the design of multi-sectioned CPC consisting of flat reflector sections instead of parabolas. The author designed a total number of eight concentrators having the same concentration ratios but a different number of flat reflectors, starting from one to eight. The comparative analysis revealed that standard CPC exhibited better optical performance within the acceptance angle range. Regarding the uniform flux distribution, the multi-sectioned CPC consisting of seven flat reflectors manifested better performance. However, the comparative cost analysis among various designs was not conducted by the author. To appraise the influence of collector alignment in a CPC-based photovoltaic/thermal system, Lee et al. [

27] employed thin-film solar cells made up of gallium arsenide (GaAs) in a relatively cheaper symmetric mini-CPC made up of plastic. The results thus obtained were compared with those of a flat photovoltaic panel for east–west axis and north–south axis collector orientation. The experiment was performed in natural conditions, and it was shown that the above-mentioned solar cells, when used with CPC oriented in a north–south direction, gathered 68% and 50% more radiation than flat PV panel inclined at a specific angle for hot and cold atmosphere, respectively. This was apparently because of a smaller acceptance angle since the concentrator was oriented opposite to the sun track. On the contrary, the authors inferred that such type of solar cells, when used with CPC oriented in an east–west direction, produced almost double additional power than a flat solar panel for hot and cold weather conditions, respectively. This enhancement resulted mainly due to the orientation of CPC in the same direction as the sun track. The authors also concluded that employing the sun following system augmented the intensification of solar radiation by approximately three times as compared to a flat solar panel having the same area for hot and cold weather.

The optimization of design, and sizing of solar collectors, is inevitable for rendering them a cost-competitive and reliable renewable energy resource [

28]. Many researchers have used response surface methodology for experimental design, modeling, and optimization of different solar energy systems. In a recent study, Rejeb et al. [

29] used the RSM technique for optimizing the design parameters of a hybrid concentrated photovoltaic/thermoelectric generator for maximizing its electrical efficiency. The results generated from the numerical model were further analyzed using RSM. The authors used four parameters as independent factors, namely the product of solar radiation and optical concentration, ambient temperature, electrical load, and leg height of thermoelectric generator, whereas the hybrid system’s efficiency was selected as the response. The authors concluded that response surface modeling is the best tool for studying the combined interactions between input factors and the desired response variable. In another study, Rejeb et al. [

30] evaluated the electrical and thermal performances of a hybrid nanofluid-based photovoltaic/thermal collector using RSM. The authors determined the extent of the significance of input factors by studying the combined effect of input factors on responses. Luo et al. [

31] used an improved algorithm combining successive RSM and simulated annealing for design optimization of a solar power tower consisting of 2650 heliostats located in Spain.

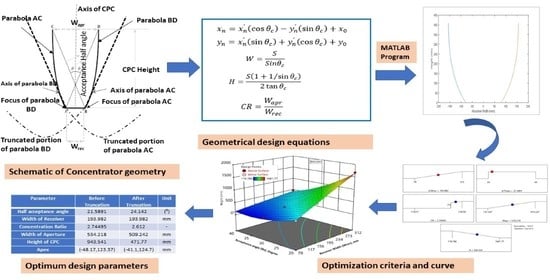

Despite the availability of numerous designs of CPCs for PV applications, little attention has been paid to design optimization and sensitivity analysis involving all design parameters. The present research article presents the design optimization, parametric study, and statistical modeling of CPC concentrator intended for photovoltaic applications leading to its geometric optimization, using response surface modeling technique. The initial focus during the design phase was to achieve desired concentration while still maintaining a stationary installation. The best aperture width and truncation position of CPC were identified. The effect of different truncation positions on the geometric concentration ratio was estimated. Moreover, the acceptance half-angle and receiver width were varied to observe their impact on total CPC height, entry aperture width, and concentration ratio. The synergistic influences of design factors on responses were analyzed using three-dimensional surface plots. The corresponding optimum values of the design parameters of CPC were obtained by using the statistical approach, and the results are presented in this article.

4. Conclusions

The non-imaging compound parabolic concentrators are suitable for low concentrating photovoltaic applications as they can collect both direct and diffuse radiations and do not require continuous tracking. Such collectors are also useful in thermal as well as hybrid PV/thermal applications, whereby they can supply both electricity and process heat for low to medium temperature applications. In this paper, a two-dimensional symmetric CPC with a flat receiver has been designed for PV applications. The reflector profiles were generated by developing a code in the MATLAB program that solves the mathematical equations describing the relationship between design parameters of the CPC. The concentrator was initially designed for an acceptance half-angle of 30° and receiver width of 156 mm to accommodate a single crystalline silicon solar cell. The optical concentration ratio of the resulting CPC was found to be “2×”. The effect of changes in acceptance half-angle on height and aperture width of the CPC was determined. Subsequently, the receiver width was increased to house more solar cells, and its impact on the height and aperture width of the concentrator was observed. The CPC was then truncated for different percentages of full height. The effect of truncation on the aperture width and geometric concentration ratio was evaluated to determine the optimum truncation level.

Detailed statistical analysis and successive geometric optimization were performed using the response surface modeling approach. The resulting 3D surface plots were analyzed to comprehend the combined effect of design factors on the relevant responses. It was concluded that a symmetric 2D CPC with an acceptance half-angle of 21.59° and receiver width of 193.98 mm yielded the optimum geometric dimensions for stationary low concentrating photovoltaic applications. Based on RSM analysis, a truncation level of 50% was selected, which caused only an 8.5% decrease in the geometric concentration ratio. At the same time, half of the reflector material and manufacturing cost were saved. The corresponding optimum values of concentrator height, aperture width, and CR are 471.77 mm, 509.24 mm, and 2.61, respectively, after 50% truncation. The resulting optimized geometrical profile is thereby pertinent for static concentrating solar photovoltaic collectors. Such collectors can reduce the expensive silicon solar cell area for a given electrical yield by employing comparatively low-cost optical concentrators.