Steam Distillation for Essential Oil Extraction: An Evaluation of Technological Advances Based on an Analysis of Patent Documents

Abstract

:1. Introduction

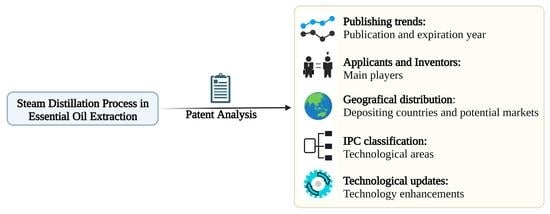

2. Materials and Methods

3. Results and Discussion

| Classification | General Characteristics | Reference |

|---|---|---|

| Dry steam distillation | In dry distillation, steam generated outside the still at moderate pressures is able to pass through the matrix without it coming into direct contact with the water. | [12] |

| Direct steam distillation | Direct steam distillation does not allow the matrix to have direct contact with water as distillation occurs, with steam generated outside the still. Due to this, its components do not easily undergo thermal degradation. | [18] |

| Hydrodistillation (water distillation) | In hydrodistillation, EO extraction occurs through solid–liquid interaction, where the matrix comes into direct contact with water. For this reason, it is important to control the conditions of this process when it is employed, since some EO components may undergo hydrolysis | [19] |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shahin, S.; Kurup, S.; Cheruth, A.-J.; Salem, M. Chemical Composition of Cleome Amblyocarpa Barr. & Murb. Essential Oils under Different Irrigation Levels in Sandy Soils with Antioxidant Activity. J. Essent. Oil Bear. Plants 2018, 21, 1235–1256. [Google Scholar] [CrossRef]

- Guenther, E.; Althausen, D. The Essential Oils; Van Nostrand Company: New York, NY, USA, 1948; ISBN 9780882750736. [Google Scholar]

- Bergman, M.E.; Davis, B.; Phillips, M.A. Medically Useful Plant Terpenoids: Biosynthesis, Occurrence, and Mechanism of Action. Molecules 2019, 24, 3961. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hanif, M.A.; Nisar, S.; Khan, G.S.; Mushtaq, Z.; Zubair, M. Essential Oils. In Essential Oil Research; Springer International Publishing: Cham, Switzerland, 2019; pp. 3–17. [Google Scholar]

- Kumar, S.; Vig, H.; Deshmukh, R. Essential Oils Market. 2020. Available online: https://www.alliedmarketresearch.com/essential-oils-market (accessed on 28 February 2022).

- Essential Oils Market Essential Oils Market by Type (Orange, Lemon, Lime, Peppermint, Citronella, and Others), Application (Food & Beverage, Cosmetics & Toiletries, Aromatherapy, Home Care, Health Care), Method of Extraction, and Region—Global Forecast to 2026. Available online: https://www.marketsandmarkets.com/Market-Reports/essential-oil-market-119674487.html (accessed on 3 March 2022).

- Grand View Research. Essential Oils Market Size, Industry Report, 2021–2028. 2021. Available online: https://www.grandviewresearch.com/industry-analysis/essential-oils-market (accessed on 28 February 2022).

- Elyemni, M.; Louaste, B.; Nechad, I.; Elkamli, T.; Bouia, A.; Taleb, M.; Chaouch, M.; Eloutassi, N. Extraction of Essential Oils of Rosmarinus Officinalis, L. by Two Different Methods: Hydrodistillation and Microwave Assisted Hydrodistillation. Sci. World J. 2019, 2019, 1–6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- de Souza, E.T.; Siqueira, L.M.; Almeida, R.N.; Lucas, A.M.; da Silva, C.G.F.; Cassel, E.; Vargas, R.M.F. Comparison of Different Extraction Techniques of Zingiber Officinale Essential Oil. Braz. Arch. Biol. Technol. 2020, 63. [Google Scholar] [CrossRef]

- Preedy, V.R.; Stratakos, A.C.; Koidis, A. Methods for Extracting Essential Oils. In Essential Oils in Food Preservation, Flavor and Safety; Preedy, V.R., Ed.; Irish Academic Press: San Diego, CA, USA, 2016; pp. 31–38. ISBN 978-0-12-416641-7. [Google Scholar]

- Cordes, E.E.; Jones, D.O.B.; Schlacher, T.A.; Amon, D.J.; Bernardino, A.F.; Brooke, S.; Carney, R.; DeLeo, D.M.; Dunlop, K.M.; Escobar-Briones, E.G.; et al. Environmental Impacts of the Deep-Water Oil and Gas Industry: A Review to Guide Management Strategies. Front. Environ. Sci. 2016, 4, 58. [Google Scholar] [CrossRef]

- Cerpa, M.G.; Mato, R.B.; José Cocero, M. Modeling Steam Distillation of Essential Oils: Application to Lavandin Super Oil. AIChE J. 2008, 54, 909–917. [Google Scholar] [CrossRef]

- Antosz, K.; Machado, J.; Mazurkiewicz, D.; Antonelli, D.; Soares, F. Systems Engineering: Availability and Reliability. Appl. Sci. 2022, 12, 2504. [Google Scholar] [CrossRef]

- Hasinah Johari, S.N.; Hezri Fazalul Rahiman, M.; Adnan, R.; Tajjudin, M. Real-Time IMC-PID Control and Monitoring of Essential Oil Extraction Process Using IoT. In Proceedings of the 2020 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS), Shah Alam, Malaysia, 20 June 2020; pp. 51–56. [Google Scholar]

- Perino, S.; Chemat, F. Green Process Intensification Techniques for Bio-Refinery. Curr. Opin. Food Sci. 2019, 25, 8–13. [Google Scholar] [CrossRef]

- Richa, R.; Kumar, R.; Shukla, R.M. Ultrasound Assisted Essential Oil Extraction Technology: New Boon in Food Industry. SKUAST J. Res. 2020, 22, 78–85. [Google Scholar]

- Masango, P. Cleaner Production of Essential Oils by Steam Distillation. J. Clean. Prod. 2005, 13, 833–839. [Google Scholar] [CrossRef]

- Prado, J.M.; Vardanega, R.; Debien, I.C.N.; de Meireles, M.A.A.; Gerschenson, L.N.; Sowbhagya, H.B.; Chemat, S. Conventional Extraction. In Food Waste Recovery; Elsevier: Amsterdam, The Netherlands, 2015; pp. 127–148. ISBN 9780128003510. [Google Scholar]

- Pateiro, M.; Barba, F.J.; Domínguez, R.; Sant’Ana, A.S.; Mousavi Khaneghah, A.; Gavahian, M.; Gómez, B.; Lorenzo, J.M. Essential Oils as Natural Additives to Prevent Oxidation Reactions in Meat and Meat Products: A Review. Food Res. Int. 2018, 113, 156–166. [Google Scholar] [CrossRef] [PubMed]

- Tongnuanchan, P.; Benjakul, S. Essential Oils: Extraction, Bioactivities, and Their Uses for Food Preservation. J. Food Sci. 2014, 79, R1231–R1249. [Google Scholar] [CrossRef] [PubMed]

- WIPO. Obtaining IP Rights: Patents. Available online: https://www.wipo.int/sme/en/obtain_ip_rights/patents.html (accessed on 24 February 2022).

- WIPO. WIPO Guide to Using Patent Information. Available online: https://www.wipo.int/edocs/pubdocs/en/wipo_pub_l434_3.pdf (accessed on 16 March 2022).

- RMC Education Jiangxi University of TCM. Available online: https://www.rmcedu.com/Jiangxi-university-of-TCM.html (accessed on 17 March 2022).

- D&B Business Directory Dongguan Huaipu Plant Essential Oil Co., Ltd. Available online: https://www.dnb.com/business-directory/company-profiles.dongguan_huaipu_plant_essential_oil_co_ltd.3e3921d616de88752a9eb4e4808c9a3d.html (accessed on 17 March 2022).

- Institute of Medicinal Plant Development Chinese Academy of Medicinal Sciences—Peking Union Medical College Institute of Medicinal Plant Development. Available online: http://www.implad.ac.cn/en/ (accessed on 17 March 2022).

- Barbieri, C.; Borsotto, P. Essential Oils: Market and Legislation. In Potential of Essential Oils; InTech: London, UK, 2018. [Google Scholar]

- Haase, H.; de Araújo, E.C.; Dias, J. Inovações Vistas Pelas Patentes: Exigências Frente Às Novas Funções Das Universidade. Rev. Bras. Inovação 2009, 4, 329. [Google Scholar] [CrossRef]

- Taxt, R.E.; Robinson, D.K.R.; Schoen, A.; Fløysand, A. The Embedding of Universities in Innovation Ecosystems: The Case of Marine Research at the University of Bergen. Nor. Geogr. Tidsskr.—Nor. J. Geogr. 2022, 76, 42–60. [Google Scholar] [CrossRef]

- Tukoff-Guimarães, Y.B.; Kniess, C.T.; Penha, R.; Ruiz, M.S. Patents Valuation in Core Innovation: Case Study of a Brazilian Public University. Innov. Manag. Rev. 2021, 18, 34–50. [Google Scholar] [CrossRef]

- Kamiyama, S.; Sheehan, J.; Martinez, C. Valuation and Exploitation of Intellectual Property; OECD iLibrary: Paris, France, 2006. [Google Scholar]

- Markets and Markets Distillation Systems Market—Global Forecast to 2023. Available online: https://www.marketsandmarkets.com/Market-Reports/distillation-system-market-3730016.html (accessed on 22 March 2022).

- Abert, I.; Besse, C.; Carrara, D.; Grenier, A.; Henry, L. Permeation Enhancer Comprising Genus Curcuma or Germacrone for Transdermal and Topical Administration of Active Agents. US20050244522A1, 30 April 2004. [Google Scholar]

- Bani Correa, C.; de Oliveira Barreto, E.; de Souza Nunes, R.; dos Santos Estevam, C.; Ferreira, S.; Goulart Santana, A.; Santos, R.; Saturinho de Oliveira, J.; Silva de Araujo, S. Microemulsion with Essential Oil of Leaves of Croton Argyrophyllus (Kunth) as Anti-Inflammatory Agent. BR102015005040A2, 6 March 2015. [Google Scholar]

- Haworth, J. Method for Removing Essential Oils and Antioxidants from Extract Products of Lamiaceae Species Using Rolled Film Evaporation. US6450935B1, 13 October 2000. [Google Scholar]

- Mckellip, L.L.; Bing, P.; Trost, B. Method for Extraction of Essential Oils from Plant Material. US5891501A, 25 November 1997. [Google Scholar]

- WIPO. PCT—The International Patent System. Available online: https://www.wipo.int/pct/en/ (accessed on 7 March 2022).

- EPO. Applying for a Patent. Available online: https://www.epo.org/index.html (accessed on 19 March 2022).

- WIPO. International Patent Classification (IPC). Available online: https://www.wipo.int/classifications/ipc/en/ (accessed on 19 March 2022).

- Ding, L.; Li, Y.; Lin, M.; Ni, L.; Wu, Q.; Xu, H.; Zhang, X.; Zou, S. Cinnamomum Camphora Essential Oil Direct Steam Distillation Pot. CN113150873A, 25 May 2021. [Google Scholar]

- Gao, Z.; Huang, Y.; Pang, J.; Wu, Z.; Xie, J.; Zhang, G.; Zheng, J. Device for Extracting Essential Oil in Peel of Passion Fruit and Use Method Thereof. CN113073008A, 13 April 2021. [Google Scholar]

- Han, S.; Hu, B.; Kong, W.; Li, H.; Liu, F. Flower Essential Oil Distiller and Continuous Distilling and Extracting Device. CN112029589A, 21 September 2020. [Google Scholar]

- Fan, Z.; Han, S.; Kong, W.; Li, Y.; Liu, F.; Yang, Z.; Zhang, Y. A Woody Oil Continuous Steam Distillation Extraction Device and Its Device System. CN108517258A, 4 June 2018. [Google Scholar]

- Ji, W. A Fractional Extraction Method and Device for Sandalwood Essential Oil. CN106833901A, 3 March 2017. [Google Scholar]

- Liang, H. An Extraction Technique for Agilawood Essential Oil and Device. CN105925377A, 24 June 2016. [Google Scholar]

- Ge, B.; Liu, P.; Lu, D.; Yin, W.; Yin, Y.; Zhang, M. An Essential Oil Extracting Device. CN214115463U, 24 November 2021. [Google Scholar]

- Jin, J. High-Efficiency Plant Essential Oil Distilling and Extracting Device. CN212152220U, 30 April 2020. [Google Scholar]

- Machado, C.A.T.; Lepikson, H.A.; de Andrade, M.A.N.; da Silva, P.R.C. Essential Oil Steam Distillation: Manufacturing 4.0. J. Bioeng. Technol. Appl. Health 2021, 4, 95–99. [Google Scholar] [CrossRef]

- Machado, C.A.T.; Lepikson, H.A.; de Andrade, M.A.N.; Silva, P.R.C. da Essential Oil Extraction: Being Green and Emerging Technologies. In Proceedings of the Blucher Engineering Proceedings; Editora Blucher: São Paulo, Brazil, 2021; pp. 321–326. [Google Scholar]

- Machado, C.A.T.; Lepikson, H.A.; de Andrade, M.A.N.; Ferreira, Y.T.S.; Vasconcelos, S.F.S. Essential Oil Extraction Industry: Exploring the Strategic Technology Dimension. In Proceedings of the Blucher Engineering Proceedings; Editora Blucher: São Paulo, Brazil, 2020; pp. 567–575. [Google Scholar]

| Item | IPC Code | Definition |

|---|---|---|

| 1 | A61P 31/04 | Medical or veterinary science; hygiene, specific therapeutic activity of chemical compounds or medicinal preparations; anti-infectives, i.e., antibiotics, antiseptics, chemotherapeutics—antibacterial agents. |

| 2 | A61P 29/00 | Medical or veterinary science; hygiene, specific therapeutic activity of chemical compounds or medicinal preparations—noncentral analgesic, antipyretic or anti-inflammatory agents, e.g., antirheumatic agents; non-steroidal anti-inflammatory drugs (NSAIDs). |

| 3 | A61Q 19/02 | Medical or veterinary science; hygiene, specific use of cosmetics or similar toilet preparations—preparations for care of the skin. |

| 4 | A61K 8/97 | Medical or veterinary science; hygiene, preparations for medical, dental, or toilet purposes—from algae, fungi, lichens, or plants and from derivatives thereof. |

| 5 | C11B 9/00 | Animal or vegetable oils, fats, fatty substances, or waxes and fatty acids from these substances; detergents; candle production, e.g., by pressing raw materials or by extraction from waste materials, refining or preserving fats, fatty substances, e.g., lanolin, fatty oils, or waxes; essential oils; perfumes—essential oils and perfumes. |

| 6 | A61Q 19/08 | Medical or veterinary science; hygiene, specific use of cosmetics or similar toilet preparations, preparations for care of the skin—anti-ageing preparations. |

| 7 | A61K 8/9789 | Medical or veterinary science; hygiene, preparations for medical, dental, or toilet purposes, cosmetics or similar toilet preparations—magnoliopsida [dicotyledons]. |

| 8 | A61Q 19/00 | Medical or veterinary science; hygiene, specific use of cosmetics or similar toilet preparations—preparations for care of the skin. |

| 9 | A61K 8/92 | Medical or veterinary science; hygiene, preparations for medical, dental, or toilet purposes, cosmetics or similar toilet preparations—oils, fats, or waxes and derivatives thereof, e.g., hydrogenation products. |

| 10 | C11B 9/02 | Animal or vegetable oils, fats, fatty substances, or waxes and fatty acids there from; detergents; candle production, e.g., by pressing raw materials or by extraction from waste materials, refining or preserving fats, fatty substances, e.g., lanolin, fatty oils, or waxes; essential oils; perfumes for essential oils; perfumes—recovery or refining of essential oils from raw materials. |

| Item | Classification | Number of Documents |

|---|---|---|

| 1 | Human and animal healthcare; cosmetics; repellent; taste improvement; disinfectant; sterilizing agent; acaricide; skin and acne care; tobacco flavoring; beverage additive; air freshener; food preservative; laundry fragrance. | 320 |

| 2 | Raw material preparation and product post treatment (membrane; purification; fractioning; ultrasound; fermentation; concentration; mechanical expression). | 33 |

| 3 | Extraction with organic solvents; use of surfactants; vacuum; salt solution. | 29 |

| 4 | Mechanically improved distiller; flow improvement; optimized procedures. | 27 |

| 5 | Multipurpose steam distillation with solvents or ultrasonic pretreatment. | 25 |

| 6 | Focus on raw materials (for example, pistachio; mandarin; garlic; green tea; oak bark; passion fruit; cinnamon; lavender; cardamomum; angelica; camphor). | 20 |

| 7 | Supercritical state CO2 and subcritical state water. | 12 |

| 8 | Focus on hydrosol and fragrant water. | 5 |

| 9 | Others were as follows: paper additive; fire retardant; air cleaner (bactericide); fuel additive; natural colorant; fertilizer; silicon rubber additive. | 14 |

| 10 | Microbial contact to improve yield. | 2 |

| 11 | Dry extract. | 1 |

| 12 | Steam pressure control. | 1 |

| 13 | Analytical method. | 1 |

| Publication Number | Applicant | Inventor | Description | Overview (Strengths and Weaknesses Analysis) |

|---|---|---|---|---|

| CN113150873A | Fujian Agriculture and Forestry University Fujian Tianwu Forestry Development Co., Ltd. (Fuzhou, China) Quanzhou Mingdao Agriculture and Forestry Development Co., Ltd. (Quanzhou, China) | Ding, L. Li, Y. Lin, M. Ni, L. Wu, Q. Xu, H. Zhang, X. Zou, S. | This patent consists of a split body distillation vessel to ease the loading and unloading operation. The steam outlet, just before the condensation process, was designed to allow a smooth flow [39]. | The strength of this mechanical proposition lies in the practicality and time reduction of its loading and unloading operations. It also makes the cleaning between batches easier. |

| CN113073008A | Zhangzhou Institute of Technology (Zhengzhou, China) | Gao, Z. Huang, Y. Pang, J. Wu, Z. Xie, J. Zhang, G. Zheng, J. | This patent consists of a multilayer plate distillation vessel. These plates are rotated by an electrical driver aiming at avoiding the contact among the passion fruit peels, which decreases the contact with steam [40]. | The relative movement among the layers allow the steam flow to more efficiently contact the passion fruit peels. This mechanical improvement presents the potential to increase yield and reduce extraction time. Nevertheless, the controlling actions from a properly programmed process computer would improve this endeavor. |

| CN112029589A | Yingkou Chenguang Plant Extraction Equipment Co., Ltd. (Yingkou, China) | Han, S. Hu, B. Kong, W. Li, H. Liu, F. | This patent consists of a horizontal fresh-flower extractor with a belt conveyor that claims to be a continuous extraction system. It moves the raw material inside the distiller [41]. | A continuous system, applied to fresh flowers. It is an interesting way of controlling the residence time inside that main equipment. Basic controllers such as timers and position switches should be part of the invention. However, the main command from a process control computer could be helpful in this system. |

| CN108517258A | Yingkou Chenguang Plant Extraction Equipment Co., Ltd. (Yingkou, China) | Fan, Z. Han, S. Kong, W. Li, Y. Liu, F. Yang, Z. Zhang, Y. | This patent is a continuous distillation system for woody material with several plates for raw material accommodation [42]. | Specifically for wood material extraction, this idea brings interesting propositions for exposing the raw material to the steam flow. It is, nevertheless, a mechanically improved system without mentioning process control attributes. |

| CN106833901A | Request by inventor | Ji, W. | This patent consists of a rolling hydro-distillation extraction device, where the sandalwood plant material is fed and during the process alternates between immersed in the water and exposed to steam, with the aim of improving yield [43]. | The idea of a rotating distillation vessel brings a new geometry to the conventional process. It is, nevertheless, a mechanical change. The application of digital smart technologies is not mentioned. |

| CN105925377A | Mo, Z. | Liang, H. | This patent brings an extraction device for agarwood EO, with rotating perforated plates to extract via steam distillation and compression between the plates [44]. | As this idea is designed to extract essential oil from agarwood, the mechanical improvement of the pressing device is interesting. The liquid from this pressing is hot and eases the EO extraction. The equipment is mechanically improved and dedicated to wood extraction. |

| CN214115463U | Hubei Weilaijiayuan High-Tech Agriculture Co., Ltd. (Wuhan, China) | Ge, B. Liu, P. Lu, D. Yin, W. Yin, Y. Zhang, M. | This patent is a utility model. It consists of a distillation device composed of two layers. Its claims are related to improving productivity and reducing process time by obtaining both the light fractions, from the upper part of the device, and the heavier fractions from the bottom part. Both extractions are mixed to deliver the whole essential oil [45]. | Even though this system pursues higher yields and, as a consequence of reduced time, better quality, it consists of a mechanically changed distillation vessel. This means that technological control elements were not applied by the author. |

| CN212152220U | Zhejiang Jinghui Cosmetics Co., Ltd. (Yiwu, China) | Jin, J. | This patent is a utility model. It claims to have performance improvements with the use of compressed air to clean the holes in the perforated plate where the steam passes [46]. | This is an interesting idea where the full passage of steam, provided by compressed air blowing the herb, indeed improves the extraction efficiency. Despite the possibility of undesired effects, such as oxidation of the plant material (to be proven by analysis), the proposition, if it would be properly commanded by process controllers, moves the raw material within the distillation vessel and fixes the channeling effects. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Machado, C.A.; Oliveira, F.O.; de Andrade, M.A.; Hodel, K.V.S.; Lepikson, H.; Machado, B.A.S. Steam Distillation for Essential Oil Extraction: An Evaluation of Technological Advances Based on an Analysis of Patent Documents. Sustainability 2022, 14, 7119. https://doi.org/10.3390/su14127119

Machado CA, Oliveira FO, de Andrade MA, Hodel KVS, Lepikson H, Machado BAS. Steam Distillation for Essential Oil Extraction: An Evaluation of Technological Advances Based on an Analysis of Patent Documents. Sustainability. 2022; 14(12):7119. https://doi.org/10.3390/su14127119

Chicago/Turabian StyleMachado, Carlos Alberto, Fabricia Oliveira Oliveira, Matheus Antônio de Andrade, Katharine Valéria Saraiva Hodel, Herman Lepikson, and Bruna Aparecida Souza Machado. 2022. "Steam Distillation for Essential Oil Extraction: An Evaluation of Technological Advances Based on an Analysis of Patent Documents" Sustainability 14, no. 12: 7119. https://doi.org/10.3390/su14127119

APA StyleMachado, C. A., Oliveira, F. O., de Andrade, M. A., Hodel, K. V. S., Lepikson, H., & Machado, B. A. S. (2022). Steam Distillation for Essential Oil Extraction: An Evaluation of Technological Advances Based on an Analysis of Patent Documents. Sustainability, 14(12), 7119. https://doi.org/10.3390/su14127119