1. Introduction

As a polymer modifier with excellent performance, styrene-butadiene-styrene (SBS) has been extensively utilized in asphalt pavement of high-grade highways in China [

1,

2,

3]. No matter under high or low temperatures, it has the advantages of sufficient durability and satisfactory elastic resilience. However, enormous SBS-modified pavements have drawn near to or have entered into the overhaul period in China, especially being subject to the excessive and overloaded vehicles. The disposal of reclaimed SBS-modified pavements (RAP-SBS) is a protruding complication during the maintenance of SBS modified pavements, given the vast amount of pavements built in the past decades. According to the relative standard in China, the recommended percentages of reclaimed asphalt pavements (RAP) in the hot mix plant recycling are 15–30%, while the percentages in practical engineering are mostly controlled at about 25%. Consequently, the properties and applicability of recycled asphalt mixtures incorporating high-content (more than 30%) RAP-SBS have become a crucial study to promote the sustainability of asphalt pavements.

For a recycled mixture, the performance degradation of aged asphalt is the principle obstruction to incorporating high-content RAP into new asphalt pavement. As RAP content increases, the blended asphalt is observed to be harder, increases in elasticity, and decreases in viscosity, which may cause premature distress such as fatigue failure and low temperature cracking [

4]. To resolve this problem, a rejuvenating agent (RA) is widely adopted to restore the performance of aged asphalt in RAP and improve the state of intermingling of aged and virgin asphalt binder [

5,

6]. For recycled asphalt mixtures with different RAP content and type of recycling, the appropriate type of RA and the corresponding dosage should be carefully determined. There have been a considerable number of studies focused on the RA applied in HMA [

7,

8], and many studies have been conducted toward rejuvenating SBS modified asphalt binders [

9,

10]. Previous studies indicated that a compound RA with appropriate ingredients and proportion is able to entirely renovate the long-term aged SBS modified asphalt to its virgin state in terms of penetration, ductility, and softening point, as well as improving the performance at both low and high temperature [

11,

12,

13,

14,

15]. However, the suitable type and corresponding dosage of RA to incorporate into the recycled asphalt mixture and its influence on the viscoelasticity remains further exploration, especially when RAP-SBS content extends beyond 50%.

Because of the presence of SBS, there are many dissimilarities between RAP and RAP-SBS, which contribute to the uncertainties in recycling RAP-SBS [

16,

17,

18]. As a result of it, the incorporation of high-content RAP-SBS remarkably converts the properties of recycled mixtures. Performances including crack resistance [

19], rutting resistance [

20,

21], and moisture susceptibility [

3,

19] of recycled mixtures with RAP-SBS have been investigated systematically. In general, recycled mixtures with a high content of RAP-SBS exhibit poor moisture susceptibility and low-temperature cracking resistance, which can be improved by adding RA with appropriate content, while the investigation towards its material nature, i.e., viscoelasticity, remains extending. Compared with hot mixture asphalt, the phase angle peak of recycled asphalt mixtures incorporating RAP-SBS decreases and can be reached earlier, which is more conspicuous when loading frequency and the dosage of RAP-SBS increases [

22]. On the other hand, it has been explored that the dynamic modulus of recycled mixtures increases with the reduction of RA content and the increase in RAP-SBS content [

3].

However, in the previous studies, the range of RAP-SBS content variation was not set sufficiently, and there is a lack of investigation towards the change of recommended RAP-SBS content under the effect of long-term aging (LOTA) and incorporating RA. Additionally, the model adopted to evaluate the viscoelasticity of it is required to be innovated.

In this paper, two indicators, dynamic modulus and phase angle, were selected to characterize the viscoelasticity of asphalt mixtures. A mass of investigations has been conducted adopting various models to develop master curves, including the Christensen–Anderson (CA) model [

23,

24], the Sigmoidal model [

25,

26,

27], the Havriliak–Negami (HN) model [

28,

29,

30], etc. Modifying on the basis of the CA model, the Christensen–Anderson–Marasteanu (CAM) model was proposed by Marasteanu and Anderson, which was originally used to develop master curve for asphalt binder [

31]. Compared with the above models, the CAM model provides a superior fit of the complex modulus master curve with a wide frequency range, especially for the polymer-modified asphalt binder [

32,

33]. Apart from it, the CAM model is also utilized to develop master curves of asphalt mixtures in terms of dynamic modulus widely [

34,

35,

36]. However, there is still a lack of investigation towards the feasibility and effectiveness of fitting a master curve of recycled mixtures with the CAM model, especially with high RAP-SBS content.

In summary, previous studies focused on recycled mixtures with less than 30% RAP-SBS, and even though there have been a number of studies on the performance of recycled asphalt with high RAP-SBS content recently, further research is still needed, especially with 70% RAP-SBS content. Applicable RA for recycled mixtures with high RAP-SBS content has been investigated, while previous studies have not reached a consensus on the suitable type and the corresponding dosage of RA, and there is a lack of investigation towards the variation of viscoelasticity of recycled mixtures with high RAP-SBS content under the combined action of RA and LOTA. The CAM model has been widely adopted to develop master curve for asphalt mixture because of its reliability, while there is no study to prove its applicability for a recycled mixture with high RAP-SBS content. For the concerns of promoting service life of hot-mix recycled asphalt mixture, the content of RAP-SBS should be carefully selected according to specific pavement characteristics (including temperature, designed speed, and construction cost). To this end, this paper aims to explore the suitable RAP-SBS content for pavements with different characteristics according to its viscoelasticity, which is urgently needed from a practical level, and it is also the main embodiment of innovation in this paper.

3. Materials and Methods

3.1. Materials

RAP-SBS used in this study was acquired in Beijing, and Abson method (ASTM D 1856) was conducted to reclaim asphalt from RAP-SBS. The aging of SBS modified asphalt was simulated with thin film oven test (TFOT). The aged asphalt content of RAP-SBS by mass was tested to be 3.6% with Abson Method according to ASTM D1856.

To enhance the performance of aged asphalt, a kind of rejuvenating agent (RA) was selected and procured from Sobute Ltd. in China, which was developed with an aim to increase RAP content in recycled mixtures. RA adopted in this paper is reddish-brown in color, whose main performance indexes were tested according to ASTM D4552 (TFOT was conducted according to ASTM D2872).

For the purpose of excluding the influence of aggregate gradation on the performance of mixtures with different dosages of RAP-SBS (0%, 30%, 50%, 70%), separate calculations were made for each mixture to ensure the consistency and coherence of the gradation. In this paper, the RAP-SBS content refers to the ratio of RAP-SBS to recycled mixture by mass. According to ASTM D1559, the Marshall methodology is adopted, and the aggregate gradation of each mixture is set separately.

This paper investigated the effect of RA on recycled asphalt mixtures incorporating high-content RAP-SBS, which affects the optimum asphalt content (OAC) for each mixture. The OAC of each mixture, including aged asphalt and virgin asphalt, was determined according to the Marshall methodology, considering volume of asphalt (VA), voids in mineral aggregates (VMA), voids filled with asphalt (VFA), Marshall stability (MS), and flow value (FV).

3.2. Dynamic Modulus Test

Dynamic modulus test (DM) was processed with an AMPT according to AASHTO T342, which was conducted at frequencies of 25, 10, 5, 1, 0.5, and 0.1 Hz at 4 °C, 20 °C, and 40 °C.

According to the current Chinese standard (JTG/T 5521), recycled mixtures were mixed with the following steps: 1. add RAP-SBS into a preheated mixing pot and incorporate RA; 2. add virgin fine aggregate and coarse aggregate; 3. add virgin asphalt; 4. add virgin filler. The material should be mixed evenly in each step, and the total mixing time is about 3 min. In this research, the Superpave gyratory compactor (SGC) method was adopted to fabricate specimens 17 cm in height and 15 cm in diameter at 7 ± 0.5% air voids; by coring, the specimens were trimmed to 15 cm in height and 10 cm in diameter to fit the mold of AMPT. Three replicate specimens were tested for each type of mixture.

3.3. Long-Term Aging Test

Chinese current standard (JTG E20) adopts the long-term aging methods for asphalt mixtures proposed by SHRP, which is regarded as a reliable method to simulate the performance of asphalt pavement after 5–7 years and it has been conducted extensively in previous studies [

39,

40]. It was adopted in this study to investigate the long-term aged properties of recycled mixtures with a thin film oven. The specific steps are as follows: (1) after mixing, place recycled mixtures in an oven with trays at 135 °C for 4 h, and stir the recycled mixtures with a shovel once an hour; (2) fabricate specimens for DM test with recycled mixtures as the same method in

Section 3.2; (3) heat the specimens in the oven at 85 °C for 120 h; (4) place the specimens at room temperature for 24 h and conduct DM test.

3.4. Statistical Analysis

One-way ANOVA is applied to evaluate the sensitivities of dynamic modulus and phase angle on RAP-SBS content, the incorporation of RA, and LOTA. The significance level α is set as 0.05, and the p-value of each factor is calculated and compared with α to investigate whether it has a significant impact on the test results.

As a viscoelasticity material, asphalt mixture exhibits different performances at different loading frequencies and temperatures. As a result of it, the ANOVA was conducted at 10 Hz and 20 °C according to the most common applying situation for pavements in China.

5. Conclusions

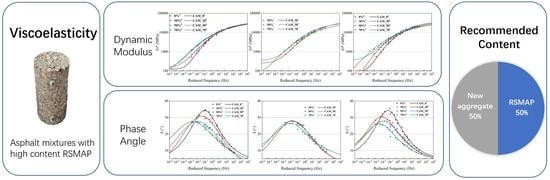

In this study, the viscoelasticity of recycled mixtures with high-content (more than 30%) RAP-SBS was investigated in terms of dynamic modulus and phase angle with AMPT. The effect of different factors on the viscoelasticity was evaluated with CAM model and ANOVA, including RAP-SBS content, temperatures, and loading frequencies, with or without RA and LOTA. The results can be drawn as follow:

According to the results of dynamic modulus test, the elastic component of recycled asphalt mixture elevated with the increasing of RAP-SBS content and loading frequency; as a result of it, the high-temperature stability of it enhances but it is prone to cracking at low temperatures; while when the dosage of RAP-SBS is set to 50%, the recycled mixtures exhibited satisfactory resistance to deformation in both cases.

CAM model is not only applicable to fit the dynamic modulus and phase angle master curves of conventional asphalt mixtures but is also able to develop master curves of recycled asphalt mixtures with high RAP-SBS content. For recycled asphalt mixtures with high RAP-SBS content, the incorporation of RA improved the resistance to deformation and reduced the loss of viscous components of it, reflecting protruding anti-aging properties. Besides, compared with LOTA and the incorporation of RA, RAP-SBS content of recycled mixtures is observed to have a more significant influence on the viscoelasticity and it should be one of the first parameters to be determined.

In conclusion, the recycled asphalt mixtures with high-content RAP-SBS exhibited greater viscoelasticity than control mixtures. For the general situation, 50% RAP-SBS is recommended to incorporate in recycled mixtures to ensure the satisfactory performance of asphalt pavements from the aspect of viscoelasticity. As for pavements with slower design speed, the dosage of RAP-SBS can be considered to increase from 50% to 70% after verifying that other performances meet the specification requirements.

Further investigation into recycled mixtures with hig-content RAP-SBS remains to be explored, including aged performance, low-temperature resistance, and fatigue performance. What is more, the study about the type and dosage of RA embraced in it is of great engineering value.