1. Introduction

Ocean wave energy is a renewable energy source with high energy density and great potential. Ocean waves have higher energy density as they are deeper offshore. The water particles here draw a circular orbital trajectory. Conversely, and the lower the depth of water, the closer the ocean is, the lower the energy density of the waves, and the water particles have the orbitals of long transverse orbits. That is, as the water depth decreases, the energy distribution in the horizontal direction becomes larger. In the shallow sea, furthermore, the irregularity of the waves becomes larger depending on the terrain of the sea floor [

1,

2].

Depending on the characteristics of the waves due to these water depths, the power generation mechanism from waves varies greatly depending on the place where the wave energy converter (WEC) is installed [

3,

4]. It is advantageous to use the heave motion in the deep sea, and point absorber types such as OPT PowerBuoy [

5], Wavebob [

6], and CETO [

7] have been studied to maximize vertical energy absorption. The attenuator-types WEC resembling the inverted oscillator such as Oyster [

8,

9] and WaveRoller [

10] are advantageous for absorbing energy mainly in the surge direction. It is therefore suitable for areas with lower depths than the target area of the point absorber. The coastal installation of WEC is led by the fixed-structure oscillating water column (OWC) types that were built in Norway (in Toftestallen, near Bergen, 1985, [

3]), Japan (Sakata, 1990, [

11,

12]), India (Vizhinjam, near Trivandrum, Kerala state, 1990, [

13]), Portugal (Pico, Azores, 1999, [

14]), UK (the LIMPET plant in Islay Island, Scotland, 2000, [

15]), Spain (breakwater OWC, Mutriku, Northern Spain, 2008, [

16]), and Italy (U-OWC, Civitavecchia, 2012 [

17,

18]). Recently, moving from the experience of the offshore over-topping devices (OTD) Wavedragon [

19] and the Sea-wave Slot-cone Generator [

20], an onshore OTD has been built in Italy [

21]. Fixed-structure OWCs and OTDs have good accessibility and maintainability, but there are topographical constraints where the wave energy density should be high and the civil construction should be possible.

The distinction by such depth or distance from the land determines the motion mechanism. In addition, the more distant the sea, the higher the cost of the facilities required for electric transmission to areas where electricity is mainly consumed. There is another alternative to electric transmission. The CETO and Oyster WECs pump the seawater to the land that drives the generator, so the sea water pipe replaces the electric transmission cable. In this case, it is very advantageous for maintenance of the generator since the generator is located on the land. That is, the way to transfer energy to the land is also a main factor in determining the mechanism of wave power generation.

Meanwhile, one of the areas where the introduction of wave power is difficult is the area where the water depth is shallow and wave irregularity is large. In this area, it is difficult to design the mechanism of conversion process from wave to mechanical energy; however, accessibility on land is comparatively good, and it is distributed all over the world. There is a need for a WEC capable of targeting these areas. It is expected that such areas will need a strategy of securing the desired capacity by installing multiple WECs with small capacity rather than a single large capacity WEC, and the cost of a single device should be cheap.

The off-grid islands have a great need for the development of these wave devices, where there is no power supply from the mainland. According to reports from the Korea Electric Power Corporation (KEPCO), electric power costs in these areas are eight times higher than those on the land [

22]. In many of these areas, the required amount of electric power is often small, such as several tens of kilowatts. Therefore, a small capacity wave generator is more suitable for these areas.

The wave power company

INGINE has created a wave power generator called

INWAVE, which is a wave generator suitable for coasts with shallow water depths and wave irregularities [

23]. This is a multi-tight moored moving object, sharing similar concepts with Fred Olsen’s Lifesaver WEC [

24]. However, unlike Lifesaver,

INWAVE has a reinforced mechanism to cope with the wave force in a horizontal direction as the installation depth is low. It is also advantageous for maintenance because the PTO module is located on the coast.

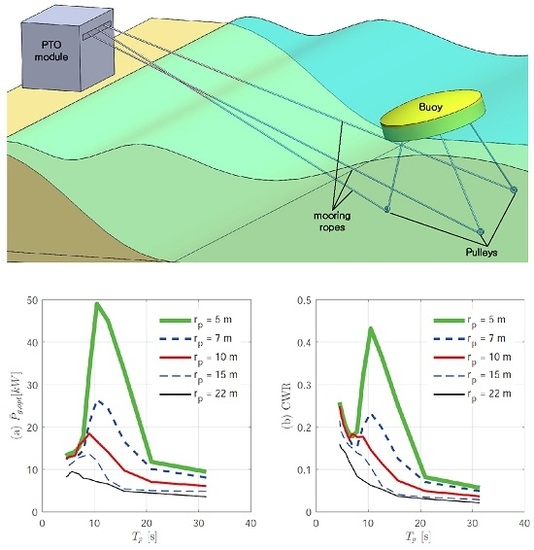

It mainly consists of a buoy, subsea pulleys, and a power take off (PTO) module as shown in

Figure 1. Three mooring ropes are attached to three points on the bottom of the buoy and also connected to three counterweights in the PTO module via subsea pulleys on the sea-bed. The counterweight moves only vertically and this provides restoring force to the buoy, and the buoy performs six degrees of freedom movement of heave, surge, sway, roll, pitch, and yaw within a certain range. In addition, the tension prevents the rope from sagging and serves to transfer the kinetic energy of the buoy to the PTO module. As the buoy moves, the three ropes reciprocate and also the rope pulleys in the PTO module that rotate back and forth share one shaft and transmit unidirectional rotary motion to the common shaft through their ratchet gears. This rotational energy is then converted into electrical energy by the electric generator. When the buoy is pulling the rope, the tension of the rope raises the counterweight while transmitting power to the common shaft through the ratchet gear. On the other hand, when the buoy is no longer pulling the rope, the tension is provided by the counterweight, which pulls the buoy back to its equilibrium position. However, during this time, the ratchet gear cuts off the work of the counterweight, so there is no power transmitted to the common shaft.

The two-dimensional modeling and simulation of

INWAVE has been presented in a previous paper [

25]. This modeling assumes that only two ropes are connected between the buoy and the PTO module unlike the actual plant, and only surge, heave, and pitch motions of the buoy were considered while sway, roll, and yaw motions were ignored as a limitation of the two-dimensional analysis. In this paper, a three-dimensional model of the

INWAVE device is presented, which considers the six degree motion of the buoy and the three mooring rope’s connections in order to overcome previous assumptions. To build this dynamic model, the geometric relationship between the behavior of the buoy and the ropes in the three-dimensional space was identified, and, based on this, we derived the overall dynamics by combining the hydrodynamic coefficients for the buoy using an ANSYS AQWA simulator [

26] and the PTO module based on the Newtonian mechanics and linear wave theory (LWT) [

27,

28]. Next, we carried out simulations under regular wave conditions with varying wave periods to analyze the effects of the mooring rope angle, counterweight’s mass, and wave incidence angle, which are the most important factors that influence the system output. Then, for objective efficiency comparison with other WECs, we analyzed the theoretical performance of the device by calculating the capture width ratio (CWR) that is the average power output of the device divided by wave energy density and the diameter of the buoy under irregular wave conditions based on the joint north sea wave project (JONSWAP) wave spectrum model.

2. Geometrical Relationship between Buoy and Ropes in Three-Dimensional Space

Consider a buoy in the sea with a depth of

h, where the buoy radius and draft are

R and

d, respectively. The behavior of the buoy is given by

corresponding to surge (

x), sway (

y), heave (

z), roll (

), pitch (

), and yaw (

), respectively, since the wave propagates in the

x-direction. The top view of the buoy, subsea pulleys, and rope connection points are shown in

Figure 2. An actual device is installed near the breakwater. Unfortunately, ANSYS AQWA, which is a computational fluid dynamics simulator to obtain the hydrodynamics, assumes a flat undersea surface and does not provide an effect on reflected waves. Hence, it is assumed that the buoy is installed on open sea.

At the bottom of the buoy, the ropes are connected at a distance of , and the connection points make an angle of 120 with each other. At the bottom surface of the sea, the three subsea pulleys are each located at a distance of from the center and are arranged at an angle of 120 with respect to each other.

In the equilibrium state, since the forces exerted on the buoy are only the tensions of the ropes exerted by the counterweight and buoyancy in the heave direction, the center of the subsea pulley and the buoy are placed on the

z-line, and each pulley and rope connection point are placed on the same line from the center. Since the buoy is

z-axis symmetry, the direction of wave propagation only affects the the rope connection points. Hence it is assumed that the wave direction is heading to the

x-direction as seen in

Figure 2 and the relative angle between the wave direction and the rear pulley is defined as

, which has a value of –60

to 60

, but is limited to a range of 0

to 60

by symmetry.

The dynamic model of the device includes the influence of the rope tensions; hence, the geometric analysis between the rope connection point and subsea pulley is necessary. First, the positions of rope connection points and the subsea pulleys must be defined in three dimensions. For convenience, let the position of

ith rope connection point and subsea pulley point be

and

, respectively. These points can be derived using the homogeneous transformation matrices

and

as follows [

29]:

where

,

,

, and

are defined as

and

are the last column vectors of

and

that can be expressed as follows:

where

(for

i = 1, 2, 3). From this relationship, the

ith rope vector

is given by

The

ith length of the rope

, the speed of the rope

(or

), and the acceleration of the rope

(or

) are expressed as follows:

Let

; then, Equation (

12) becomes

where

3. Dynamics of the Buoy and Rope Tension

The equations of buoy motion in surge, sway, heave, roll, pitch, and yaw directions can be expressed in Newtonian mechanics based on the LWT [

27,

28]. These six equations representing each axis are influenced by the excitation force due to waves, radiation damping caused by buoy motion, buoyancy, and rope tensions. The six equations are expressed as one vector equation that can be expressed as [

25,

27]:

Here,

is the mass matrix consisting of buoy mass, buoy inertia, and added mass,

is the radiation damping force vector, and

is the buoyancy spring coefficient matrix.

is the

ith matrix of the rope tension effect on the buoy and

is the tension applied to the

ith rope.

is the excitation force vector.

can be expressed as

where ⊗ represents a cross product.

and

are given as [

25]

where

,

,

, and

represent the buoy’s masses and inertia of the

x-,

y-, and

z-axes, respectively. Furthermore,

,

,

,

,

, and

are the added masses and inertia at infinity for the buoy’s surge, sway, heave, roll, pitch, and yaw motions, respectively.

and g denote the sea water density and the gravitational acceleration, respectively. is a diagonal matrix.

As described above, the wave direction is limited to the

x-direction and it yields the excitation forces of surge, heave, and pitch, only acting on the buoy due to the buoy’s symmetry, and other components are omitted. The excitation force vector

can be computed as a convolution of the water surface elevation

and impulse response function from the frequency domain results.

denotes the time shift for convolution:

where

,

, and

denote the excitation kernel functions for surge, heave, and pitch, respectively, which can be obtained by the following formula:

where

is the excitation force in the frequency domain and

is the phase shift of the excitation force, which is

, 0, and

for surge, heave, and pitch, respectively. This phase shift is necessary for the same reason that water particles by the waves cause the orbital motion [

1].

Similarly, the radiation damping force, which is a resistance component, can be obtained by convolution of the buoy’s velocity and radiation kernel function as follows [

30]:

where

Here, , and and denote radiation damping and added mass in the frequency domain, respectively. It is assumed that there is no resistance in the yaw direction because this part is disk-shaped.

4. PTO Modeling

Figure 3 is a simplified representation of the configuration of the PTO module. In the PTO module, three mooring ropes hang on rope pulleys and three counterweights are attached to the end of the ropes to provide constant tension equal to their weight. The rope pulley has a ratchet gear module that only transmits torque to the common shaft when the rope is pulled by the buoy. The rotation of this shaft is increased by the gear ratio

and transmitted to the generator. The angle and angular velocity of the

ith rope pulley are

and

, respectively, while that of the common shaft and generator are

and

, and

and

, respectively. Then, these variables have the following relationship:

where

is the

ith pulley radius. Assuming that there is no inertia of the shaft and pulleys, the dynamics of the generator are given as follows:

where

is the generator inertia,

is the torque transmitted by the

ith pulley, and

is the induced torque applied by the generator and is given as

where

is the generator damping coefficient that can be controlled using an inverter at the rear end of the generator. The instantaneous output from the generator is defined as

The ratchet gears continuously supply and block the torque from the rope pulley to the common shaft. When the torque is transmitted, the rope pulley and the common shaft are coupled and driven as one part, and when the torque is not transmitted, the two parts move independently. At the moment when the rope pulley and the common shaft are combined, the analysis is linked to their physical properties such as the strength and elastic modulus and is difficult to model using Newtonian mechanics. Therefore, to solve this problem, we introduced a virtual spring concept in the ratchet module in our previous paper [

25]. This spring occurs at the moment of contact between the pulley and the common shaft, momentarily stores the compressed force as potential energy, and gradually transfers this energy to the shaft without power loss. Then, as soon as negative torque is transmitted through the spring, the pulley and the common shaft are separated. This process can be expressed as follows:

where

is the spring coefficient of the virtual spring,

and

is the time of contact (

). Then, when

, the contact between the ratchet and the shaft is released.

The dynamic equation of the counterweight, including the transmitted torque to the shaft, is as follows:

The power transfer efficiency of the ratchet gear to the generator during one wave peak period

is defined as follows:

Substituting Equations (

13) and (

30) into Equation (

16) yields the combined dynamics of the buoy-counterweights as

Combining Equation (

32) with Equations (

26) and (

29) completes the final dynamic system in which the wave elevation

and constant

in the time domain are the input states and the motions of the buoy

and the PTO

are the output states.

5. Simulation and Analysis under Regular Wave Condition

Currently, a prototype installed on Jeju Island has a buoy diameter of 5 m and the maximum power is obtained in a period between 2.5 and 4.5 s [

25]. However, the wave period of the area under consideration for installation is 7 to 12 s. By the simulation of buoys with various geometries, it was found that a diameter of 12 m is suitable for the target area. Therefore, in this paper, a simulation is performed based on a buoy with a diameter of

and a draft of

.

In order to perform simulation on the WEC system, we need the hydrodynamic data such as excitation force, radiation damping, and added mass in the frequency domain. The ANSYS AQWA simulator was used to obtain the data [

26]. A disk-shaped buoy with a diameter of

and a draft of

was applied floating on a sea with a depth (

h) of 10 m; the acquired data are shown in

Figure 4. This simulator is based on LWT and assumes incompressible, irrotational flow with small amplitude motion [

27,

28]. Therefore, the simulation only considers the case of 1 m wave height (

).

By substituting this data into Equations (

21) and (

23), we obtain the kernel functions, and then substituting the wave elevation

and the excitation kernel function

into Equation (

20) yields the excitation force in the time domain. As mentioned in the previous section, the overall dynamic equation consisting of Equation (

32) with Equations (

26) and (

29) is analyzed in the time domain using the fourth-order Runge–Kutta method [

31].

In the modeling of

INWAVE, the influence of the rope is included in

. Since this matrix has nonlinearities including the trigonometric function, the analysis of the overall modeling is impossible in the frequency domain. Therefore, the simulation under the regular wave condition in the time domain was carried out to analyze the exact dynamic behavior of the device with the characteristics of the power output. The following sine wave was generated for regular wave condition:

where

and

are the significant wave height and peak wave frequency, respectively.

The output power

of the WEC is sensitive to generator damping load

. We substitute

between

and

, and denote

when the average of the maximum output power from generator

is obtained. The data for all parameters required to perform the simulation are listed in

Table 1. In order to observe the characteristics of each wave frequency,

was fixed at 1 m and

was assigned at intervals of 0.1 rad/s between 0.2 and 1.4 rad/s. The total sampling time was

where

, and only the results within

to

were recorded in order to exclude the data in the transient segment. Except for

defined in Equation (

31), the mean value (

) and standard deviation (

) used the data in this interval.

The

INWAVE device has all the states intertwined because the buoy moves in six degrees of freedom and three ropes are connected to the single generator. Therefore, it is hard to obtain the perfect periodicity of the states according to the wave period even in regular wave conditions. In the case of

,

,

Nm·s/rad,

30

, and

(

) as presented in

Table 1, while the simulation results are shown in

Figure 5.

Figure 5b shows that the surge, heave, and pitch motions of the buoy have periodicity with the wave period and out of these parameters, the surge has the highest amplitude. In

Figure 5c–e, however, the angular speeds of the rope pulley and generator, rope tensions, and power output do not have repeated patterns. In

Figure 5c, the angular velocity of the generator follows the highest value of the angular velocity of the rope drum, but not perfectly. Even then, the average efficiency of the ratchet in

Figure 5f is approximately 1. Accordingly, it can be estimated that there is no power loss in the ratchet transmission. The rope tension in

Figure 5d only increases when the power is transferred; otherwise, it acts on the rope only as much as the counterweight’s mass.

As can be seen in

Figure 5, the device has a strong nonlinearity and cannot be directly analyzed in the frequency domain. Therefore, we resolved to understand the behavior and performance of the device by taking the average data for a long period of time in the time domain while varying several parameters such as the pulley position

, mass of the counterweight

, and the wave direction

.

5.1. Influence of Subsea Pulley Position

The simulation was carried out where the rope connection points at the bottom of the buoy were fixed at

and the position of the subsea pulley

was selected from 5, 7, 10, 15, and 22

. The mooring rope’s angle corresponding to

with the sea floor is given in

Table 2 and

Figure 6 shows the rendered image of the buoy and ropes with

according to

. In the case of

, the rope tension acts on the buoy only in the vertical direction, and as

increased, the horizontal component of the rope tension acting on the buoy also increased.

Figure 7 shows simulation results of the average maximum power output

and the corresponding damping load

at various

values that can be obtained at each wave period. In the graph, the case of

showed the highest average power and the power decreased as

increased. In addition, it can be seen that the wave period of the peak power output slightly decreased while the

increased. The smaller the

, the larger the lateral force tension generated, which affects the resonance period.

also influences how efficiently the movement of the buoy is transmitted to the displacement of the rope. As the rope connection point moved in the tangential direction around the subsea pulley, the change in the length of the rope decreased, so that the transmission rate of the kinetic energy was reduced. Therefore, we define a rope kinematic efficiency factor

in order to determine the effectiveness of transmitting the buoy’s motion to the rope’s displacement, which can be defined by the ratio of the absolute value of the rope connection point speed to the speed of the rope length. This can be expressed as follows:

As the efficiency was very close to 1, the movement of the rope connection point was effectively transmitted to the change in the length of the rope.

For a more accurate analysis, we compared the power output, behavior of the buoy, and displacement of the rope for variations in

values between 5 and 22 m as seen in

Table 2 at

4.49, 8.98, and 12.57 s; the results are shown in

Figure 8.

Figure 8a shows the optimal mean power and

Figure 8b–d show the normalized standard deviation

in the direction of surge, heave and pitch, which denotes the standard deviation of the displacement divided by the amplitude of the wave.

Figure 8e,f show

of ropes 1 and 2, respectively. Since

, the motion of rope 3 is the same as that of rope 2, and it is omitted.

Figure 8g,h are the motion transfer efficiencies of the rope. First, let us consider the results for

7.85 and 15.71 s in order to analyze the concentration of power output in 7–15 s of the wave period.

In

Figure 8a, the power output tends to decrease as

increased and the result is similar to

In

Figure 8b, it can be seen that

is overwhelmingly higher than

and

in

Figure 8c,d, respectively. This means that the output of the device depends mostly on the surge movement. It seems to be a good choice to choose

m in order to maximize the motion in the surge direction, but the opposite tendency can be seen from

Figure 8e–h. In

Figure 8e,f, when

15.71 s, it can be seen that

increased with increasing

until

15 m because the increasing rate of

is higher than the decreasing rate of

. The dynamic modeling so far considered did not take into account resistances other than radiation damping such as friction and viscosity. If all resistive components were considered, a large

as shown in

Figure 8b cannot be expected. Therefore, the actual model should select

considering both the effects of surge displacement and the motion transfer efficiency of the rope. In addition, the case of

4.49 s is different from

15.71 and 7.85 s. It should be noted that

Figure 8g,h,

showed a very high

near 5 m. This is because the pitching motion increased as

decreased, which affects the normal direction movement of the rope rather than the surge and heave.

5.2. Influence of Counterweight

In order to evaluate the effect of the counterweight, we carried out a simulation for the case when

10 m was fixed and

was set to 500, 1000, 2000, and 4000 kg. The other parameters remained the same as shown in

Table 1.

Figure 9 shows the maximum power output

and the corresponding

. As

increased,

generally increased, but the extent of the increase gradually decreases. The increase in the power output by the counterweight was prominent in the long period, and the effect was small in the short period. In addition, as

increased, the peak of the output shifts slightly to the smaller period, but this tendency is not noticeable.

5.3. Influence of Wave Direction

In order to analyze the influence of the direction of the wave, the average power output and the standard deviation were calculated for various wave directions such as

10

, 20

, 30

, 40

, 50

, when

m,

Nm·s/rad.

Figure 10 shows the results of the power output with varying wave direction for

15.71, 7.85, and 4.49 s, where the thick green line is the average output and the red line is the standard deviation. When

15.71 s, the average power and standard deviation decreased slightly at approximately 20–30

, although this is not significant. When

7.85 s, the average power and standard deviation increased by approximately 30% at

30

. In the case of

4.49 s, the average output and standard deviation decrease by approximately 20% as the angle increased. Synthetically, consistent trends could not be derived, so we could not identify meaningful effects of the wave direction.

6. Simulation and Analysis under JONSWAP Irregular Wave Condition

In this section, let us compare the optimal average power for an irregular wave condition with the theoretical wave energy density. We chose the JONSWAP wave model because the target area where the

INWAVE device has been installed has

of the JONSWAP spectrum [

32,

33]. When the significant wave height is

and the peak period is

, it is expressed in the frequency domain with wave angular frequency

as

where

The wave power per unit crest length is defined as

where

and

Here, the wave number

(

is the wave length) is obtained from

When discussing the performance of many wave power systems, the availability and presentation of data vary greatly between sources. Therefore, many devices use a capture width ratio (CWR) to objectively compare the conversion efficiency. For a cylindrical buoy, the CWR is the average power output divided by

and the diameter of the buoy and is expressed as [

34]:

For time series calculations, the spectral distribution in Equation (

35) is discretized as the sum of a large number

N of regular waves and written as

Here,

, where

is the lowest frequency,

is a small frequency interval,

and the spectrum does not contain a significant amount of energy outside the frequency range

.

and

are the amplitude of the wave component of order

n and the initial phase randomly chosen in the interval

, respectively. This wave elevation

is substituted into Equation (

20), and the simulation was carried out with the equivalent parameters in

Table 1.

The average power output under irregular waves in

Figure 11a was lower than that of the regular wave, but its pattern is similar to that of the regular wave. When

5 m, the highest power output was obtained and the output power gradually decreased as

increased. The CWR shown in

Figure 11 exhibited a similar pattern, having a peak of 0.43 at

m, and the peak gradually disappeared as the

increased. In addition, it can be seen that the CWR was much lower at a wider spectrum than in our previous paper [

25]. This is a characteristic of the general point observer that can be seen as the diameter of the buoy increases.

Figure 12 shows the standard deviations of the buoy’s behavior in each direction, the standard deviation of the rope motion, and the motion transfer efficiency of the rope, which were also similar to that of the regular waves shown in

Figure 8. At

15.71 and 7.85 s, the surge showed the greatest movement, and it decreased rapidly as

decreased. In addition, the efficiency of the rope increased as

increased, similar to the results of the regular wave condition.

7. Conclusions

In this study, we derived the three-dimensional dynamics of the INWAVE device and carried out simulations in time domain under regular and irregular wave conditions while varying various parameters such as the subsea pulley position, the counterweight’s mass, and the wave direction. The analysis of the results show that the distance between the subsea pulleys significantly affects the behavior of the buoy, the displacement of the rope, and the shape of the power output. The smaller the value of , that is, as the mooring angle approached 90, the dynamic behavior of the buoy became higher; however, the motion transfer efficiency of the rope decreased. This is because a large mooring angle leads to higher movements of the rope in the tangential direction, which decreases the effect on the rope length change. Since the dynamic behavior of the actual buoy motion would be greatly reduced by the unconsidered resistance factors, it may be better to consider the motion transfer efficiency of the rope more than increasing the dynamic behavior of the buoy. It is expected that the actual rope mooring angle would be between 45 and 60.

The effect of the counterweight increased the power output as the mass increased, but the extent of the increase in the output gradually decreased. Therefore, it was concluded that this factor does not affect the output as much as the subsea pulley position. The mass of the counterweight serves to restore the buoy to its origin. Therefore, it is necessary to cope with the drift and to confine the region of the buoy motion within a certain boundary even in extreme wave conditions. In addition, since the basic tension of the rope is determined according to the weight of the counterweight, which also determines the specifications of mechanical components such as the rope thickness and the rope drum size, a suitable value of the counterweight cannot be selected simply by setting the performance of the power output.

In Korea, due to the monsoon effect between Eurasia and the Pacific Ocean, the Northwest and the Southwest monsoons are dominant in winter and summer, respectively. Waves also have different seasonal direction due to these winds. Thus, it is very important to analyze the influence of the direction of propagation of the wave. However, the simulation results did not yield a meaningful conclusion. This implies that when choosing the position of the subsea pulley, the influence of the traveling angle of the waves can be given less consideration.

Currently, there are three full-scale prototype devices installed on Jeju Island, Korea as a test run [

23]. The diameter and draft of the buoy are 5 and 0.5 m, respectively. Three mooring ropes have an angle of 60

with the sea floor. The average sea depth is 3 m. At the end of the each rope, a 250 kg counterweight is attached. A speed increaser module in the PTO module increases the angular velocity of the rope drum by 35 times and transfers it to the 20 kW AC generator. The generated power from the generator is converted into stable AC and is transmitted to the grid through the AC/DC converter and the DC/AC inverter to be transmitted.

The most important element of this device is the rope. The rope is constantly weighed by the counterweight, and it continually contacts with the subsea pulley and the rope. Therefore, it is important to secure durability against salt water and friction. As seen in the simulation results, the maximum tension on the rope is determined by the load on the generator rather than the counterweight. Therefore, the determination of the load of the generator has a significant influence on the maximum power generation and the durability of the rope. There are currently ongoing optimization processes to ensure mechanical durability and high efficiency by testing various rope materials and various control logic in the equivalent three prototypes. The optimization process will be discussed later in the paper.

We expect that, in the near future, it will be possible to compare and verify theoretically obtained characteristics using actual data. We will also present a simulation that reflects the actual characteristics of the machine components, such as backlash and friction in the gear modules, and nonlinearity in the generator.