Mapping Asphaltic Roads’ Skid Resistance Using Imaging Spectroscopy

Abstract

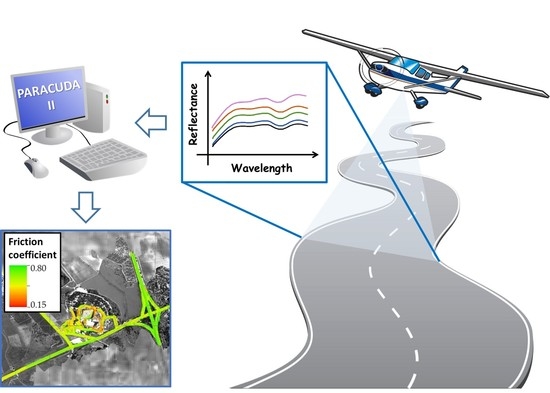

:1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. Hyperspectral Data

2.3. Friction Data

2.4. Hyperspectral Data Processing

2.5. Modelling

3. Results

3.1. Data Exploration

3.2. Modelling Procedure

3.2.1. Outlier Detection

3.2.2. Model Development

3.2.3. Prediction Results

3.2.4. Spectral Assignments Analysis

3.3. Mapping

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Asi, I.M. Evaluating skid resistance of different asphalt concrete mixes. Build. Environ. 2007, 42, 325–329. [Google Scholar] [CrossRef]

- Pardillo Mayora, J.M.; Jurado Piña, R. An assessment of the skid resistance effect on traffic safety under wet-pavement conditions. Accid. Anal. Prev. 2009, 41, 881–886. [Google Scholar] [CrossRef] [PubMed]

- The Little Book of Tire Pavement Friction | Tire | Road Surface. Available online: https://www.scribd.com/document/336106494/The-Little-Book-of-Tire-Pavement-Friction (accessed on 21 February 2018).

- Herold, M.; Roberts, D. Spectral characteristics of asphalt road aging and deterioration: Implications for remote-sensing applications. Appl. Opt. 2005, 44, 4327–4334. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-J.; Amirkhanian, S.N.; Kim, K.W. Laboratory evaluation of the effects of short-term oven aging on asphalt binders in asphalt mixtures using HP-GPC. Constr. Build. Mater. 2009, 23, 3087–3093. [Google Scholar] [CrossRef]

- Robinson, H.L. Polymers in Asphalt; Rapra Technology: Shawbury, UK, 2004. [Google Scholar]

- Al-Assi, M.; Kassem, E. Evaluation of Adhesion and Hysteresis Friction of Rubber–Pavement System. Appl. Sci. 2017, 7, 1029. [Google Scholar] [CrossRef]

- Wallingford, J.G.; Greenlees, B.; Christoffersen, S. Tire-Roadway Friction Coefficients on Concrete and Asphalt Surfaces Applicable for Accident Reconstruction; SAE Technical Paper: Warrendale, PA, USA, 1990. [Google Scholar]

- Gustafsson, F. Monitoring tire-road friction using the wheel slip. IEEE Control Syst. 1998, 18, 42–49. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Tartaglino, U.; Albohr, O.; Tosatti, E. Rubber friction on wet and dry road surfaces: The sealing effect. Phys. Rev. B 2005, 71, 035428. [Google Scholar] [CrossRef]

- Lin, Y.; Hyyppa, J.; Jaakkola, A. Mini-UAV-Borne LIDAR for Fine-Scale Mapping. IEEE Geosci. Remote Sens. Lett. 2011, 8, 426–430. [Google Scholar] [CrossRef]

- Chen, X.; Kohlmeyer, B.; Stroila, M.; Alwar, N.; Wang, R.; Bach, J. Next Generation Map Making: Geo-referenced Ground-level LIDAR Point Clouds for Automatic Retro-reflective Road Feature Extraction. In Proceedings of the 17th ACM SIGSPATIAL International Conference on Advances in Geographic Information Systems (GIS ’09), Seattle, WA, USA, 4–6 November 2009; ACM: New York, NY, USA, 2009; pp. 488–491. [Google Scholar]

- Pascucci, S.; Bassani, C.; Palombo, A.; Poscolieri, M.; Cavalli, R. Road Asphalt Pavements Analyzed by Airborne Thermal Remote Sensing: Preliminary Results of the Venice Highway. Sensors 2008, 8, 1278–1296. [Google Scholar] [CrossRef] [PubMed]

- Mei, A.; Manzo, C.; Bassani, C.; Salvatori, R.; Allegrini, A. Bitumen removal determination on asphalt pavement using digital imaging processing and spectral analysis. Open J. Appl. Sci. 2014, 4, 366. [Google Scholar] [CrossRef]

- Herold, M.; Roberts, D.; Noronha, V.; Smadi, O. Imaging spectrometry and asphalt road surveys. Transp. Res. Part C Emerg. Technol. 2008, 16, 153–166. [Google Scholar] [CrossRef]

- Carmon, N.; Ben-Dor, E. Rapid Assessment of Dynamic Friction Coefficient of Asphalt Pavement Using Reflectance Spectroscopy. IEEE Geosci. Remote Sens. Lett. 2016, 13, 721–724. [Google Scholar] [CrossRef]

- Dynatest | Pavement Evaluation & Consulting | HFT. Available online: https://www.dynatest.com/hft (accessed on 4 January 2018).

- Brook, A.; Ben-Dor, E. Supervised vicarious calibration (SVC) of hyperspectral remote-sensing data. Remote Sens. Environ. 2011, 115, 1543–1555. [Google Scholar] [CrossRef]

- Kruse, F. Comparison of ATREM, ACORN, and FLAASH Atmospheric Corrections using Low-Altitude AVIRIS Data of Boulder, Colorado. In Proceedings of the 13th JPL Airborne Geosciences Workshop, Pasadena, CA, USA, 31 March–2 April 2004. [Google Scholar]

- Carmon, N.; Ben-Dor, E. An Advanced Analytical Approach for Spectral-Based Modelling of Soil Properties. Int. J. Emerg. Technol. Adv. Eng. 2017, 7, 90–97. [Google Scholar]

- Kopačková, V.; Ben-Dor, E.; Carmon, N.; Notesco, G. Modelling Diverse Soil Attributes with Visible to Longwave Infrared Spectroscopy Using PLSR Employed by an Automatic Modelling Engine. Remote Sens. 2017, 9, 134. [Google Scholar] [CrossRef]

- Gholizadeh, A.; Carmon, N.; Klement, A.; Ben-Dor, E.; Borůvka, L. Agricultural Soil Spectral Response and Properties Assessment: Effects of Measurement Protocol and Data Mining Technique. Remote Sens. 2017, 9, 1078. [Google Scholar] [CrossRef]

- Minasny, B.; McBratney, A.B. A conditioned Latin hypercube method for sampling in the presence of ancillary information. Comput. Geosci. 2006, 32, 1378–1388. [Google Scholar] [CrossRef]

- Latin Hypercube Sampling for Stochastic Finite Element Analysis. J. Eng. Mech. 1061, 128. [CrossRef]

- Wold, S.; Sjöström, M.; Eriksson, L. PLS-regression: a basic tool of chemometrics. Chemom. Intell. Lab. Syst. 2001, 58, 109–130. [Google Scholar] [CrossRef]

- Gowen, A.A.; Downey, G.; Esquerre, C.; O’Donnell, C.P. Preventing over-fitting in PLS calibration models of near-infrared (NIR) spectroscopy data using regression coefficients. J. Chemom. 2011, 25, 375–381. [Google Scholar] [CrossRef]

- Gomez, C.; Lagacherie, P.; Coulouma, G. Continuum removal versus PLSR method for clay and calcium carbonate content estimation from laboratory and airborne hyperspectral measurements. Geoderma 2008, 148, 141–148. [Google Scholar] [CrossRef]

- Schwartz, G.; Ben-Dor, E.; Eshel, G. Quantitative Assessment of Hydrocarbon Contamination in Soil Using Reflectance Spectroscopy: A “Multipath” Approach. Appl. Spectrosc. 2013, 67, 1323–1331. [Google Scholar] [CrossRef] [PubMed]

- Ben-Dor, E. Quantitative remote sensing of soil properties. Adv. Agron. 2002, 75, 173–243. [Google Scholar]

- Hunt, G.R.; Salisbury, J.W. Visible and near infrared spectra of minerals and rocks. II. Carbonates. Mod. Geol. 1971, 2, 23–30. [Google Scholar]

- Smith, M.O.; Johnson, P.E.; Adams, J.B. Quantitative determination of mineral types and abundances from reflectance spectra using principal components analysis. J. Geophys. Res. Solid Earth 1985, 90, C797–C804. [Google Scholar] [CrossRef]

| Optical Properties | VNIR | SWIR |

|---|---|---|

| Detector Type | CMOS | MCT |

| Spectral Range | 380–970 nm | 970–2500 nm |

| Spectral Resolution | ≤4.5 nm | ≤12 nm |

| Spectral Pixels | 348 | 246 |

| Spatial Pixels | 1024 | 1024 |

| F-Number | 2.4 | |

| FOV | 40° | |

| IFOV | 0.039° | |

| Group Rank | Minimum | Maximum | n | Color Code 1 |

|---|---|---|---|---|

| A | 0.077 | 0.383 | 272 | Red |

| B | 0.383 | 0.522 | 276 | Magenta |

| C | 0.522 | 0.593 | 274 | Green |

| D | 0.593 | 0.664 | 274 | Blue |

| E | 0.664 | 0.796 | 274 | Black |

| Feature ID | Wavelength (nm) | Sign Indication | Possible Assignment |

|---|---|---|---|

| 1 | 726 | Positive | Metal Oxides/Surface Texture |

| 2 | 1095 | Positive | Hygroscopic Water |

| 3 | 1706 | Negative | Organic Compounds/Polymers |

| 4 | 2229 | Positive | Clay Minerals |

| 5 | 2340 | Positive | Calcium Carbonate |

| 6 | 2381 | Negative | Organic Compounds/Polymers |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carmon, N.; Ben-Dor, E. Mapping Asphaltic Roads’ Skid Resistance Using Imaging Spectroscopy. Remote Sens. 2018, 10, 430. https://doi.org/10.3390/rs10030430

Carmon N, Ben-Dor E. Mapping Asphaltic Roads’ Skid Resistance Using Imaging Spectroscopy. Remote Sensing. 2018; 10(3):430. https://doi.org/10.3390/rs10030430

Chicago/Turabian StyleCarmon, Nimrod, and Eyal Ben-Dor. 2018. "Mapping Asphaltic Roads’ Skid Resistance Using Imaging Spectroscopy" Remote Sensing 10, no. 3: 430. https://doi.org/10.3390/rs10030430

APA StyleCarmon, N., & Ben-Dor, E. (2018). Mapping Asphaltic Roads’ Skid Resistance Using Imaging Spectroscopy. Remote Sensing, 10(3), 430. https://doi.org/10.3390/rs10030430