Damage Detection Based on 3D Point Cloud Data Processing from Laser Scanning of Conveyor Belt Surface

Abstract

:1. Introduction

1.1. Belt Conveyor Maintenance

1.2. Laser Scanning

1.3. Motivation

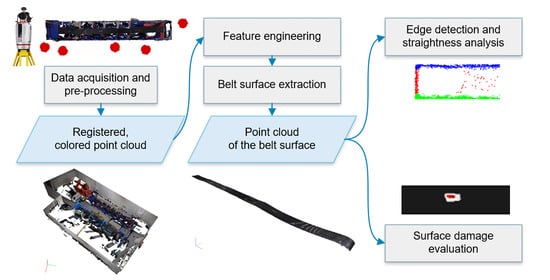

- extracting only point representing the belt surface from the full point cloud of the surroundings,

- detecting and evaluating local damage to the belt surface,

- identifying belt edges defects and analysing edge straightness.

2. Materials and Methods

2.1. Methodology of Conveyor Belt Geometry Measurement

2.1.1. Data Acquisition

2.1.2. Point Cloud Data Pre-Processing

2.1.3. Point Cloud Supervised Classification and Segmentation

2.2. Belt Geometry Condition Monitoring

2.2.1. Belt Surface Damage Detection

2.2.2. Belt Edges Condition Evaluation

2.3. Test Environment

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wodecki, J.; Zdunek, R.; Wyłomańska, A.; Zimroz, R. Local fault detection of rolling element bearing components by spectrogram clustering with Semi-Binary NMF. Diagnostyka 2017, 18, 3–8. [Google Scholar]

- Wodecki, J.; Michalak, A.; Zimroz, R.; Wyłomańska, A. Separation of multiple local-damage-related components from vibration data using Nonnegative Matrix Factorization and multichannel data fusion. Mech. Syst. Signal Process. 2020, 145. [Google Scholar] [CrossRef]

- Obuchowski, J.; Wylomańska, A.; Zimroz, R. Recent developments in vibration based diagnostics of gear and bearings used in belt conveyors. Appl. Mech. Mater. 2014, 683, 171–176. [Google Scholar] [CrossRef]

- Gładysiewicz, L.; Król, R.; Kisielewski, W. Measurements of loads on belt conveyor idlers operated in real conditions. Meas. J. Int. Meas. Confed. 2019, 134, 336–344. [Google Scholar] [CrossRef]

- Król, R.; Kisielewski, W.; Kaszuba, D.; Gładysiewicz, L. Testing belt conveyor resistance to motion in underground mine conditions. Int. J. Min. Reclam. Environ. 2017, 31, 78–90. [Google Scholar] [CrossRef]

- Molnar, V.; Fedorko, G.; Honus, S.; Andrejiova, M.; Grincova, A.; Michalik, P.; Palenčár, J. Research in Placement of Measuring Sensors on Hexagonal Idler Housing with regard to Requirements of Pipe Conveyor Failure Analysis. Eng. Fail. Anal. 2020, 116, 104703. [Google Scholar] [CrossRef]

- Molnár, V.; Fedorko, G.; Homolka, L.; Michalik, P.; Tučková, Z. Utilisation of measurements to predict the relationship between contact forces on the pipe conveyor idler rollers and the tension force of the conveyor belt. Measurement 2019, 136, 735–744. [Google Scholar] [CrossRef]

- Kozłowski, T.; Wodecki, J.; Zimroz, R.; Błażej, R.; Hardygóra, M. A Diagnostics of Conveyor Belt Splices. Appl. Sci. 2020, 10, 6259. [Google Scholar] [CrossRef]

- Blazej, R.; Jurdziak, L.; Zimroz, R. Novel approaches for processing of multi-channels NDT signals for damage detection in conveyor belts with steel cords. Key Eng. Mater. 2013, 569–570, 978–985. [Google Scholar] [CrossRef]

- Kozłowski, T.; Błażej, R.; Jurdziak, L.; Kirjanów-Błażej, A. Magnetic methods in monitoring changes of the technical condition of splices in steel cord conveyor belts. Eng. Fail. Anal. 2019, 104, 462–470. [Google Scholar] [CrossRef]

- Błażej, R.; Jurdziak, L.; Kozłowski, T.; Kirjanów, A. The use of magnetic sensors in monitoring the condition of the core in steel cord conveyor belts—Tests of the measuring probe and the design of the DiagBelt system. Meas. J. Int. Meas. Confed. 2018, 123, 48–53. [Google Scholar] [CrossRef]

- Błazej, R.; Jurdziak, L.; Kirjanów, A.; Kozłowski, T. A device for measuring conveyor belt thickness and for evaluating the changes in belt transverse and longitudinal profile. Diagnostyka 2017, 18, 97–102. [Google Scholar]

- Valis, D.; Mazurkiewicz, D.; Forbelska, M. Modelling of a transport belt degradation using state space model. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 949–953. [Google Scholar]

- Doroszuk, B.; Król, R. Analysis of conveyor belt wear caused by material acceleration in transfer stations. Min. Sci. 2019, 26, 189–201. [Google Scholar] [CrossRef]

- Bajda, M.; Błażej, R.; Hardygóra, M. Optimizing splice geometry in multiply conveyor belts| with respect to stress in adhesive bonds. Min. Sci. 2018, 25, 195–206. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, X. Optimal control of operation efficiency of belt conveyor systems. Appl. Energy 2010, 87, 1929–1937. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, T. The Research of Distribute Temperature Monitoring System Early Warning Fire in Coal Belt Conveyor. Adv. Mater. Res. 2012, 548, 890–892. [Google Scholar] [CrossRef]

- Sawicki, M.; Zimroz, R.; Wyłomańska, A.; Obuchowski, J.; Stefaniak, P.; Żak, G. An Automatic Procedure for Multidimensional Temperature Signal Analysis of a SCADA System with Application to Belt Conveyor Components. Procedia Earth Planet. Sci. 2015, 15, 781–790. [Google Scholar] [CrossRef] [Green Version]

- Michalik, P.; Zajac, J. Use of thermovision for monitoring temperature conveyor belt of pipe conveyor. Appl. Mech. Mater. 2014, 683, 238–242. [Google Scholar] [CrossRef]

- Liu, X.; Pang, Y.; Lodewijks, G.; He, D. Experimental research on condition monitoring of belt conveyor idlers. Measurement 2018, 127, 277–282. [Google Scholar] [CrossRef]

- Zimroz, R.; Hutter, M.; Mistry, M.; Stefaniak, P.; Walas, K.; Wodecki, J. Why Should Inspection Robots be used in Deep Underground Mines? In Proceedings of the 27th International Symposium on Mine Planning and Equipment Selection—MPES 2018; Widzyk-Capehart, E., Hekmat, A., Singhal, R., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 497–507. [Google Scholar]

- Carvalho, R.; Nascimento, R.; D’Angelo, T.; Delabrida, S.; Bianchi, A.G.C.; Oliveira, R.A.; Azpúrua, H.; Uzeda Garcia, L.G. A UAV-Based Framework for Semi-Automated Thermographic Inspection of Belt Conveyors in the Mining Industry. Sensors 2020, 20, 2243. [Google Scholar] [CrossRef] [Green Version]

- Szrek, J.; Wodecki, J.; Błażej, R.; Zimroz, R. An Inspection Robot for Belt Conveyor Maintenance in Underground Mine—Infrared Thermography for Overheated Idlers Detection. Appl. Sci. 2020, 10, 4984. [Google Scholar] [CrossRef]

- Zimroz, R.; Hardygóra, M.; Blazej, R. Maintenance of Belt Conveyor Systems in Poland—An Overview. In Proceedings of the 12th International Symposium Continuous Surface Mining—Aachen 2014; Niemann-Delius, C., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 21–30. [Google Scholar]

- Blazej, R.; Zimroz, R.; Jurdziak, L.; Hardygora, M.; Kawalec, W. Conveyor belt condition evaluation via non-destructive testing techniques. In Mine Planning And Equipment Selection; Springer: Cham, Switzerland, 2014; pp. 1119–1126. [Google Scholar]

- Chauve, A.; Mallet, C.; Bretar, F.; Durrieu, S.; Deseilligny, M.P.; Puech, W. Processing full-waveform lidar data: Modelling raw signals. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2006, 36.3/W52, 102–107. [Google Scholar]

- Fregonese, L.; Barbieri, G.; Biolzi, L.; Bocciarelli, M.; Frigeri, A.; Taffurelli, L. Surveying and monitoring for vulnerability assessment of an ancient building. Sensors 2013, 13, 9747–9773. [Google Scholar] [CrossRef] [PubMed]

- Alba, M.; Fregonese, L.; Prandi, F.; Scaioni, M.; Valgoi, P. Structural monitoring of a large dam by terrestrial laser scanning. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2006, 36, 6. [Google Scholar]

- Muszynski, Z.; Milczarek, W. Application of terrestrial laser scanning to study the geometry of slender objects. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 42–69. [Google Scholar] [CrossRef] [Green Version]

- Wehr, A.; Lohr, U. Airborne laser scanning—An introduction and overview. ISPRS J. Photogramm. Remote Sens. 1999, 54, 68–82. [Google Scholar] [CrossRef]

- Bellian, J.A.; Kerans, C.; Jennette, D.C. Digital outcrop models: Applications of terrestrial scanning lidar technology in stratigraphic modeling. J. Sediment. Res. 2005, 75, 166–176. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Lozano, J.; Gutiérrez-Alonso, G.; Fernández-Morán, M.Á. Using airborne LiDAR sensing technology and aerial orthoimages to unravel roman water supply systems and gold works in NW Spain (Eria valley, León). J. Archaeol. Sci. 2015, 53, 356–373. [Google Scholar] [CrossRef]

- Dubayah, R.O.; Drake, J.B. Lidar remote sensing for forestry. J. For. 2000, 98, 44–46. [Google Scholar]

- Rosell, J.; Sanz, R. A review of methods and applications of the geometric characterization of tree crops in agricultural activities. Comput. Electron. Agric. 2012, 81, 124–141. [Google Scholar] [CrossRef] [Green Version]

- Weitkamp, C. (Ed.) Lidar: Range-Resolved Optical Remote Sensing of the Atmosphere; Springer: New York, NY, USA, 2006. [Google Scholar]

- Cheng, Y.; Wang, G.Y. Mobile robot navigation based on lidar. In Proceedings of the 2018 Chinese Control And Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 1243–1246. [Google Scholar]

- Biber, P.; Andreasson, H.; Duckett, T.; Schilling, A. 3D modeling of indoor environments by a mobile robot with a laser scanner and panoramic camera. In Proceedings of the 2004 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) (IEEE Cat. No. 04CH37566), Sendai, Japan, 28 September–2 October 2004; Volume 4, pp. 3430–3435. [Google Scholar]

- Zhang, W.; Yang, D. Lidar-Based Fast 3D Stockpile Modeling. In Proceedings of the 2019 International Conference on Intelligent Computing, Automation and Systems (ICICAS), Chongqing, China, 6–8 December 2019; pp. 703–707. [Google Scholar]

- Duff, E. Automated volume estimation of haul-truck loads. In Proceedings of the Australian Conference on Robotics and Automation, Melbourne, Australia, 30 August–1 September 2000; CSIRO: Melbourne, Australia, 2000; pp. 179–184. [Google Scholar]

- Kukutsch, R.; Konicek, P.; Waclawik, P.; Ptáček, J.; Kajzar, V. Possibility of convergence measurement of gates in coal mining using terrestrial 3D laser scanner. J. Sustain. Min. 2015, 14. [Google Scholar] [CrossRef] [Green Version]

- Kajzar, V. Verifying the possibilities of using a 3D laser scanner in the mining underground. Acta Geodyn. Geomater. 2015, 51–58. [Google Scholar] [CrossRef] [Green Version]

- Zeng, F.; Wu, Q.; Chu, X.; Yue, Z. Measurement of bulk material flow based on laser scanning technology for the energy efficiency improvement of belt conveyors. Measurement 2015, 75, 230–243. [Google Scholar] [CrossRef]

- Fengyun, G.; Hongquan, X. Status and development trend of 3D laser scanning technology in the mining field. In Proceedings of the 2013 the International Conference on Remote Sensing, Environment and Transportation Engineering (RSETE 2013), Nanjing, China, 26–28 July 2013; Atlantis Press: Paris, France, 2013; pp. 405–408. [Google Scholar] [CrossRef]

- Neumann, T.; Ferrein, A.; Kallweit, S.; Scholl, I. Towards a mobile mapping robot for underground mines. In Proceedings of the 2014 PRASA, RobMech and AfLaI Int. Joint Symposium, Cape Town, South Africa, 27–28 November 2014. [Google Scholar]

- Grilli, E.; Menna, F.; Remondino, F. A review of point clouds segmentation and classification algorithms. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, 42, 339. [Google Scholar] [CrossRef] [Green Version]

- Strom, J.; Richardson, A.; Olson, E. Graph-based segmentation for colored 3D laser point clouds. In 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems; IEEE: Piscataway, NJ, USA, 2010; pp. 2131–2136. [Google Scholar]

- Reymann, C.; Lacroix, S. Improving LiDAR point cloud classification using intensities and multiple echoes. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–3 October 2015; pp. 5122–5128. [Google Scholar]

- Weinmann, M.; Jutzi, B.; Hinz, S.; Mallet, C. Semantic point cloud interpretation based on optimal neighborhoods, relevant features and efficient classifiers. ISPRS J. Photogramm. Remote Sens. 2015, 105, 286–304. [Google Scholar] [CrossRef]

- Weinmann, M.; Weinmann, M.; Mallet, C.; Brédif, M. A classification-segmentation framework for the detection of individual trees in dense MMS point cloud data acquired in urban areas. Remote Sens. 2017, 9, 277. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Q.Y.; Park, J.; Koltun, V. Open3D: A Modern Library for 3D Data Processing. arXiv 2018, arXiv:1801.09847. [Google Scholar]

- Géron, A. Hands-on Machine Learning with Scikit-Learn, Keras, and TensorFlow: Concepts, Tools, and Techniques to Build Intelligent Systems; O’Reilly Media: Sebastopol, CA, USA, 2019. [Google Scholar]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining (KDD ’16), San Francisco, CA, USA, 13–17 August 2016; ACM: New York, NY, USA, 2016; pp. 785–794. [Google Scholar] [CrossRef] [Green Version]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for point-cloud shape detection. Comput. Graph. Forum 2007, 26, 214–226. [Google Scholar] [CrossRef]

- Huber, P.J. Robust Statistics; Wiley: Hoboken, NJ, USA, 2004; Volume 523. [Google Scholar]

- Schubert, E.; Sander, J.; Ester, M.; Kriegel, H.P.; Xu, X. DBSCAN revisited, revisited: Why and how you should (still) use DBSCAN. ACM Trans. Database Syst. (TODS) 2017, 42, 1–21. [Google Scholar] [CrossRef]

- Barnes, R. RichDEM: Terrain Analysis Software. 2016. Available online: http://github.com/r-barnes/richdem (accessed on 31 October 2020).

- Zhou, G.; Sun, Z.; Fu, S. An efficient variant of the priority-flood algorithm for filling depressions in raster digital elevation models. Comput. Geosci. 2016, 90, 87–96. [Google Scholar] [CrossRef]

- Ahmed, S.M.; Tan, Y.Z.; Chew, C.M.; Al Mamun, A.; Wong, F.S. Edge and corner detection for unorganized 3D point clouds with application to robotic welding. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 7350–7355. [Google Scholar]

- Reynolds, D.A. Gaussian Mixture Models. Encycl. Biom. 2009, 741. [Google Scholar]

- Fedorko, G.; Molnar, V.; Marasova, D.; Grincova, A.; Dovica, M.; Zivcak, J.; Toth, T.; Husakova, N. Failure analysis of belt conveyor damage caused by the falling material. Part II: Application of computer metrotomography. Eng. Fail. Anal. 2013, 34, 431–442. [Google Scholar] [CrossRef]

- RIEGL VZ-400i Datasheet. 2019. Available online: http://www.riegl.com/uploads/tx_pxpriegldownloads/RIEGL_VZ-400i_Datasheet_2020-10-06.pdf (accessed on 31 October 2020).

- McKinney, W. Data Structures for Statistical Computing in Python. In Proceedings of the 9th Python in Science Conference, Austin, TX, USA, 28–30 June 2010; pp. 51–56. [Google Scholar]

- Hunter, J.D. Matplotlib: A 2D graphics environment. Comput. Sci. Eng. 2007, 9, 90–95. [Google Scholar] [CrossRef]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2020. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- de la Iglesia Castro, D. PyntCloud. 2019. Available online: https://github.com/daavoo/pyntcloud (accessed on 31 October 2020).

- pptk—Point Processing Toolkit. 2018. Available online: https://github.com/heremaps/pptk (accessed on 31 October 2020).

| Local 3D Shape Descriptor | Definition |

|---|---|

| sum of eigenvalues | |

| planarity | |

| linearity | |

| anisotropy | |

| omnivariance | |

| eigenentropy | |

| first principal component | |

| second principal component | |

| third principal component (curvature) | |

| verticality |

| Class | Precision | Recall | |

|---|---|---|---|

| belt surface points | 0.992 | 0.983 | 0.988 |

| other points | 0.999 | 1.000 | 1.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trybała, P.; Blachowski, J.; Błażej, R.; Zimroz, R. Damage Detection Based on 3D Point Cloud Data Processing from Laser Scanning of Conveyor Belt Surface. Remote Sens. 2021, 13, 55. https://doi.org/10.3390/rs13010055

Trybała P, Blachowski J, Błażej R, Zimroz R. Damage Detection Based on 3D Point Cloud Data Processing from Laser Scanning of Conveyor Belt Surface. Remote Sensing. 2021; 13(1):55. https://doi.org/10.3390/rs13010055

Chicago/Turabian StyleTrybała, Paweł, Jan Blachowski, Ryszard Błażej, and Radosław Zimroz. 2021. "Damage Detection Based on 3D Point Cloud Data Processing from Laser Scanning of Conveyor Belt Surface" Remote Sensing 13, no. 1: 55. https://doi.org/10.3390/rs13010055

APA StyleTrybała, P., Blachowski, J., Błażej, R., & Zimroz, R. (2021). Damage Detection Based on 3D Point Cloud Data Processing from Laser Scanning of Conveyor Belt Surface. Remote Sensing, 13(1), 55. https://doi.org/10.3390/rs13010055