Performance Evaluation of Vibrational Measurements through mmWave Automotive Radars †

Abstract

:1. Introduction

1.1. Radar micro-Doppler Effect for a Vibrating Target

1.2. Related Work

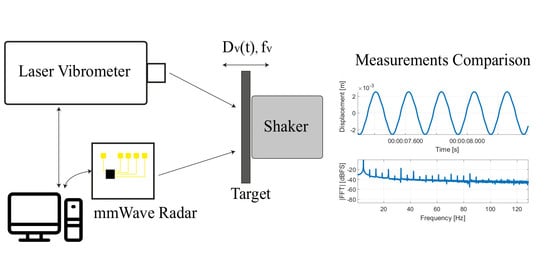

2. Materials and Methods

2.1. Materials

- Idle Time: time required for the ramp generator to return to its original state;

- ADC Valid Start Time: idle time used to remove data in the very beginning of the ramp. This way we can improve system linearity and reduce distortion in the beat signal;

- ADC Sampling Time: amount of time during which ADC samples the beat signal;

- Used Radar Bandwidth: effective Radar bandwidth after the initial part of the ramp has been removed.

2.2. Radar Signal Processing

- is target distance from the Radar in meters;

- is the target displacement in time;

- is the initial chirp wavelength;

- is the central chirp wavelength.

- is the minimum detectable phase;

- is the minimum target displacement able to generate a phase variation.

- the Fast-Time axis: samples of a single chirp;

- the Spatial Sampling axis: samples collected from different ADCs;

- the Slow-Time axis: samples from different chirps.

3. Experimental Tests

4. Results

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FMCW | Frequency Modulated Continuous Wave |

| MIMO | Multiple In Multiple Out |

| ADC | analog-to-digital converter |

| FPGA | Field Programmable Gate Array |

| RF | Radio Frequency |

| DSP | Digital Signal Processor |

| LVDS | Low Voltage Differential Signaling |

| FFT | Fast Fourier Transform |

| ADAS | Advanced Driver Assistance System |

| SAR | Synthetic Aperture Radar |

| PCB | Printed Circuit Board |

References

- Ciattaglia, G.; De Santis, A.; Disha, D.; Spinsante, S.; Castellini, P.; Gambi, E. Performance Evaluation of Vibrational Measurements Through mmWave Radars. In Proceedings of the IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Pisa, Italy, 22–24 June 2020; pp. 160–165. [Google Scholar]

- Recommendation ITU-R M.2057-1. Systems Characteristics of Automotive Radars Operating in the Frequency Band 76–81 GHz for Intelligent Transport Systems Applications. Available online: https://www.itu.int/rec/R-REC-M.2057-1-201801-I/en (accessed on 30 November 2020).

- Recommendation ITU-R M.1452-2. Millimeter Wave Vehicular Collision Avoidance Radars and Radiocommunication Systems for Intelligent Transport System Applications. Available online: https://www.itu.int/rec/R-REC-M.1452/en (accessed on 30 November 2020).

- Agiwal, M.; Roy, A.; Saxena, N. Next generation 5G wireless networks: A comprehensive survey. IEEE Commun. Surv. Tutor. 2016, 18, 1617–1655. [Google Scholar] [CrossRef]

- Ramasubramanian, K.; Ramaiah, K. Moving from legacy 24 GHz to state-of-the-art 77-GHz Radar. Atzelektronik Worldw. 2018, 13, 46–49. [Google Scholar] [CrossRef]

- Zhang, G.; Li, H.; Wenger, F. Object Detection and 3d Estimation Via an FMCW Radar Using a Fully Convolutional Network. In Proceedings of the 2020 IEEE International Conference on Acoustics Speech and Signal Processing (ICASSP), Barcelona, Spain, 4–8 May 2020; pp. 4487–4491. [Google Scholar]

- Song, H.; Hyun-Chool, S. Classification and Spectral Mapping of Stationary and Moving Objects in Road Environments Using FMCW Radar. IEEE Access 2020, 8, 22955–22963. [Google Scholar] [CrossRef]

- Patole, S.M.; Torlak, M.; Wang, D.; Ali, M. Automotive radars: A review of signal processing techniques. IEEE Signal Process. Mag. 2020, 34, 22–35. [Google Scholar] [CrossRef]

- Scheer, J.; William, A.H. Principles of Modern Radar; SciTech Pub.: Raleigh, NC, USA, 2010. [Google Scholar]

- Hasch, J.; Topak, E.; Schnabel, R.; Zwick, T.; Weigel, R.; Waldschmidt, C. Millimeter-wave technology for automotive radar sensors in the 77 GHz frequency band. IEEE Trans. Microw. Theory Tech. 2012, 60, 845–860. [Google Scholar] [CrossRef]

- Curry, G.R. Radar System Performance Modeling; Artech House: Norwood, MA, USA, 2005. [Google Scholar]

- MIMO Radar. Available online: https://www.ti.com/lit/an/swra554a/swra554a.pdf?ts=1609159599601 (accessed on 29 December 2020).

- Senigagliesi, L.; Ciattaglia, G.; De Santis, A.; Gambi, E. People Walking Classification Using Automotive Radar. Electronics 2020, 9, 588. [Google Scholar] [CrossRef] [Green Version]

- Parker, K.J.; Robert, M.L.; Huang, S.-R. Method and Apparatus for Using Doppler Modulation Parameters for Estimation of Vibration Amplitude. U.S. Patent No. 5,086,775, 11 February 1992. [Google Scholar]

- Chen, V.C.; Li, F.; Ho, S.S.; Wechsler, H. Micro-Doppler effect in radar: Phenomenon, model, and simulation study. IEEE Trans. Aerosp. Electron. Syst. 2006, 42, 2–21. [Google Scholar] [CrossRef]

- Chen, V.C.; Li, F.; Ho, S.S.; Wechsler, H. Analysis of micro-Doppler signatures. IEEE Proc. Radar Sonar Navig. 2003, 150, 271–276. [Google Scholar] [CrossRef]

- Zeintl, C.; Eibensteiner, F.; Langer, J. Evaluation of FMCW Radar for Vibration Sensing in Industrial Environments. In Proceedings of the 29th IEEE International Conference Radioelektronika (RADIOELEKTRONIKA), Pardubice, Czech Republic, 16–18 April 2019. [Google Scholar]

- Thayananthan, T.; Stanković, L.J.; Djurović, I. Micro-Doppler-based target detection and feature extraction in indoor and outdoor environments. J. Frankl. Inst. 2008, 345, 700–722. [Google Scholar]

- Ding, L.; Ali, M.; Patole, S.; Dabak, A. Vibration parameter estimation using FMCW Radar. In Proceedings of the IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Shanghai, China, 20–25 March 2016; pp. 2224–2228. [Google Scholar]

- Clemente, C.; Balleri, A.; Woodbridge, K.; Soraghan, J.J. Developments in target micro-Doppler signatures analysis: Radar imaging, ultrasound and through-the-wall radar. Eurasip J. Adv. Signal Process. 2013, 2013, 47. [Google Scholar] [CrossRef] [Green Version]

- Chen, V.C.; Tahmoush, D.; William, J.M. Radar Micro-Doppler Signatures: Processing and Applications; Institution of Engineering and Technology: London, UK, 2014. [Google Scholar]

- Piotrowsky, L.; Siska, J.; Schweer, C.; Pohl, N. Using FMCW Radar for Spatially Resolved Intra-Chirp Vibrometry in the Audio Range. In Proceedings of the 2020 IEEE/MTT-S International Microwave Symposium (IMS), Atlanta, GA, USA, 4–6 August 2020; pp. 791–794. [Google Scholar]

- Moll, J.; Salman, R.; Pozdniakov, D.; Nuber, A.; Friedman, H.; Arnold, P.; Krozer, V. Motion sensing of a wind turbine prototype using a bistatic FMCW Doppler radar sensor. In Proceedings of the 11th German Microwave Conference (GeMiC), Cottbus, Germany, 9–11 March 2018; pp. 99–102. [Google Scholar]

- Campbell, J.B.; Pérez, F.; Wang, Q.; Santhanam, B.; Dunkel, R.; Doerry, A.W.; Hayat, M.M. Remote vibration estimation using displaced-phase-center antenna sar for strong clutter environments. IEEE Trans. Geosci. Remote Sens. 2018, 56, 2735–2747. [Google Scholar] [CrossRef]

- Sparr, T.; Bard, K. Micro-Doppler analysis of vibrating targets in SAR. IEEE Proc. Radar Sonar Navig. 2003, 150, 277–283. [Google Scholar] [CrossRef] [Green Version]

- Muñoz-Ferreras, J.M.; Wang, J.; Peng, Z.; Li, C.; Gómez-García, R. Fmcw-radar-based vital-sign monitoring of multiple patients. In Proceedings of the 2019 IEEE MTT-S International Microwave Biomedical Conference (IMBioC), Nanjing, China, 6–8 May 2019; Volume 1, pp. 1–3. [Google Scholar]

- He, M.; Nian, Y.; Gong, Y. Novel signal processing method for vital sign monitoring using FMCW Radar. Biomed. Signal Process. Control 2017, 33, 335–345. [Google Scholar] [CrossRef]

- Ciattaglia, G.; Senigagliesi, L.; De Santis, A.; Ricciuti, M. Contactless measurement of physiological parameters. In Proceedings of the IEEE 9th International Conference on Consumer Electronics (ICCE-Berlin), Berlin, Germany, 8–11 September 2019; pp. 22–26. [Google Scholar]

- Li, C.; Cummings, J.; Lam, J.; Graves, E.; Wu, W. Radar remote monitoring of vital signs. IEEE Microw. Mag. 2019, 10, 47–56. [Google Scholar] [CrossRef]

- Broquetas, A.; Aguasca, A.; Martinez, A.; Tomás, R. Structural health monitoring with 94 GHz Radar. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium, Valencia, Spain, 22–27 July 2018; pp. 7982–7985. [Google Scholar]

- Gambi, E.; Ciattaglia, G.; De Santis, A. Automotive Radar Application for Structural Health Monitoring. Wit Trans. Built Environ. 2019, 189, 79–89. [Google Scholar]

- Alva Bañuelos, R.E.; González Drigo, J.R.; Luzi, G.; Caselles Magallón, J.O.; Pujades Beneit, L.; Vargas Alzate, Y.F.; Pinzón Ureña, L. Remote ambient vibration measurements with real aperture radar to estimate buildings dynamic properties. In Proceedings of the 7th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, Crete, Greece, 24–26 June 2019; pp. 1797–1808. [Google Scholar]

- Nakagawa, T.; Hyodo, A.; Kogo, K.; Kurata, H.; Osada, K.; Oho, S. Contactless liquid-level measurement with frequency-modulated millimeter wave through opaque container. IEEE Sens. J. 2012, 13, 926–933. [Google Scholar] [CrossRef]

- Prabhakara, A.; Singh, V.; Kumar, S.; Rowe, A. Osprey: A mmWave approach to tire wear sensing. In Proceedings of the 18th International Conference on Mobile Systems, Applications, and Services, Toronto, ON, Canada, 29 June–3 July 2020; pp. 28–41. [Google Scholar]

- Coppi, F.; Gentile, C.; Paolo Ricci, P. A software tool for processing the displacement time series extracted from raw radar data. AIP Conf. Proc. 2010, 1253, 190–201. [Google Scholar]

- Kim, H.; Jeong, J. Non-Contact Measurement of Human Respiration and Heartbeat Using W-band Doppler Radar Sensor. Sensors 2020, 20, 5209. [Google Scholar] [CrossRef]

- Moll, J.; Bechtel, K.; Hils, B.; Krozer, V. Mechanical vibration sensing for structural health monitoring using a millimeter-wave doppler radar sensor. In Proceedings of the 7th European Workshop on Structural Health Monitoring, IFFSTTAR, Nantes, France, 8–11 July 2014. [Google Scholar]

- Malešević, N.; Petrović, V.; Belić, M.; Antfolk, C.; Mihajlović, V.; Janković, M. Contactless Real-Time Heartbeat Detection via 24 GHz Continuous-Wave Doppler Radar Using Artificial Neural Networks. Sensors 2020, 20, 2351. [Google Scholar] [CrossRef] [Green Version]

- Mehrdad, M.; Tavassolian, N. Accurate Doppler radar-based cardiopulmonary sensing using chest-wall acceleration. IEEE J. Electromagn. Microwaves Med. Biol. 2018, 3, 41–47. [Google Scholar]

- Rothberg, S.J.; Allen, M.S.; Castellini, P.; Di Maio, D.; Dirckx, J.J.J.; Ewins, D.J.; Steger, H. An international review of laser Doppler vibrometry: Making light work of vibration measurement. Opt. Lasers Eng. 2017, 99, 11–22. [Google Scholar] [CrossRef] [Green Version]

- Shrestha, A.; Kumar, R.; Dornuf, F.; Moll, J.; Krozer, V.; Schmidt, M. Remote Mechanical Vibration Sensing: A Comparison Between CW-Doppler Radar and Laser-Doppler Vibrometer Measurements. In Proceedings of the 11th International Workshop on Structural Health Monitoring, Stanford, CA, USA, 17–19 October 2017; pp. 415–421. [Google Scholar]

- Monti-Guarnieri, A.; Falcone, P.; d’Aria, D.; Giunta, G. 3D Vibration Estimation from Ground-Based Radar. Remote Sens. 2018, 10, 1670. [Google Scholar] [CrossRef] [Green Version]

- Gentile, C. Vibration measurement by radar techniques. In Proceedings of the 8th International Conference on Structural Dynamics, Athens, Greece, 23–26 November 2020; pp. 92–103. [Google Scholar]

- AWR1642 Evaluation Module (AWR1642BOOST) Single-Chip mmWave Sensing Solution. Available online: http://www.ti.com/product/AWR1642. (accessed on 30 November 2020).

- Jian, L.; Stoica, P. MIMO Radar Signal Processing; Wiley: New York, NY, USA, 2009; Volume 7. [Google Scholar]

- DCA1000EVM Data Capture Card. Available online: http://www.ti.com/tool/DCA1000EVM (accessed on 30 November 2020).

- Xiong, Y.; Peng, Z.; Xing, G.; Zhang, W.; Meng, G. Accurate and Robust Displacement Measurement for FMCW Radar Vibration Monitoring. IEEE Sens. J. 2017, 18, 1131–1139. [Google Scholar] [CrossRef]

| Radar Type | Long-Range Radars | Medium-Range Radars | Short-Range Radars |

|---|---|---|---|

| Range [m] | 10–250 | 1–100 | 0.15–30 |

| Azimuthal feld of view [deg.] | |||

| Elevation feld of view [deg.] | |||

| Sample Applications | Automotive cruise control | Lane change assist | Park assist |

| Parameter | Value |

|---|---|

| Idle Time | 100 s |

| ADC Valid Start Time | 6 s |

| ADC Sampling Time | 63 s |

| Used Radar Bandwidth | 3.99 GHz |

| 976 s |

| Voltage [V] | Frequency [Hz] |

|---|---|

| 1.5, 1, 0.5, 0.25, 0.125 | 21.5 |

| 1.5, 1, 0.5, 0.25, 0.125 | 13 |

| 1.5, 1, 0.5, 0.25, 0.125 | 4.7 |

| Signal Gen. | Vibrometer | Radar |

|---|---|---|

| Frequency [Hz] | [Hz] | [Hz] |

| 21.5 | 21.56 | 21.49 |

| 13 | 13 | 13.13 |

| 4.7 | 4.7 | 4.69 |

| Signal Gen. | Vibrometer | Radar | ||

|---|---|---|---|---|

| Frequency [Hz], Voltage [V] | [mm] | [mm] | [mm] | [mm] |

| 21.5, 1.5 | 1.69 | 1.83 | 0.015 | 0.14 |

| 21.5, 1 | 1.08 | 1.15 | 0.004 | 0.07 |

| 21.5, 0.5 | 0.57 | 0.61 | 0.003 | 0.04 |

| 21.5, 0.25 | 0.28 | 0.32 | 0 | 0.04 |

| 21.5, 0.12 | 0.14 | 0.16 | 0 | 0.02 |

| 13, 1.5 | 2.50 | 2.88 | 0.005 | 0.38 |

| 13, 1 | 1.66 | 1.95 | 0.016 | 0.29 |

| 13, 0.5 | 0.83 | 0.92 | 0.001 | 0.09 |

| 13, 0.25 | 0.41 | 0.49 | 0.004 | 0.08 |

| 13, 0.125 | 0.20 | 0.25 | 0 | 0.05 |

| 4.7, 1.5 | 6.83 | 7.20 | 0 | 0.37 |

| 4.7, 1 | 4.62 | 4.96 | 0.012 | 0.34 |

| 4.7, 0.5 | 2.28 | 2.53 | 0.008 | 0.25 |

| 4.7, 0.25 | 1.12 | 1.16 | 0 | 0.04 |

| 4.7, 0.125 | 0.55 | 0.64 | 0.001 | 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciattaglia, G.; De Santis, A.; Disha, D.; Spinsante, S.; Castellini, P.; Gambi, E. Performance Evaluation of Vibrational Measurements through mmWave Automotive Radars. Remote Sens. 2021, 13, 98. https://doi.org/10.3390/rs13010098

Ciattaglia G, De Santis A, Disha D, Spinsante S, Castellini P, Gambi E. Performance Evaluation of Vibrational Measurements through mmWave Automotive Radars. Remote Sensing. 2021; 13(1):98. https://doi.org/10.3390/rs13010098

Chicago/Turabian StyleCiattaglia, Gianluca, Adelmo De Santis, Deivis Disha, Susanna Spinsante, Paolo Castellini, and Ennio Gambi. 2021. "Performance Evaluation of Vibrational Measurements through mmWave Automotive Radars" Remote Sensing 13, no. 1: 98. https://doi.org/10.3390/rs13010098

APA StyleCiattaglia, G., De Santis, A., Disha, D., Spinsante, S., Castellini, P., & Gambi, E. (2021). Performance Evaluation of Vibrational Measurements through mmWave Automotive Radars. Remote Sensing, 13(1), 98. https://doi.org/10.3390/rs13010098