1. Introduction

Landsat-8 (previously known as the Landsat Data Continuity Mission, LDCM), a joint NASA/USGS mission, was launched on 11 February 2013, with two instruments that are operated simultaneously, but independently: (1) the Operational Land Imager (OLI) that images in the visible, near-infrared and short-wave infrared; and (2) the Thermal Infrared Sensor (TIRS), a two-channel thermal imager. The goal of the LDCM was to continue the collection, archiving and distribution of multispectral imagery, affording global, synoptic and repetitive coverage of the Earth’s land surfaces at a scale where natural and human-induced changes can be detected, differentiated, characterized and monitored over time. As the successor to the earlier Landsat satellites, the intent was to provide data into the future that is sufficiently consistent with previous Landsat data to allow the detection and quantitative characterization of land surface changes and to permit studies of land cover and land use change over multi-decadal periods. The data products are provided to the general public on a nondiscriminatory basis and at no cost to the users. The mission will provide Landsat data to the USGS National Satellite Land Remote Sensing Data Archive (NSLRSDA) at the USGS Earth Resources Observation and Science Center (EROS). This archive constitutes the longest continuous record of the Earth’s surface as seen from space. In keeping with the Landsat continuity directive, the LDCM specifications, including ground resolution, swath width, radiometric and geometric accuracy and precision, and channel spectral bandwidths are compatible with the heritage Landsat specifications. It is important to note that, though thermal instruments have been on Landsat Mission satellites since Landsat 4, TIRS was not on the original manifest for LDCM. It was added quite late in the mission definition timeline, and as a result, the time from TIRS Systems Requirements Review (SRR) to when it was delivered to the spacecraft was only about three years. This is about one year shorter than a normal delivery schedule, and because of this, the TIRS schedule was always a significant driving force.

Both instruments introduced an operating concept new to the Landsat program, pushbroom sensor operation, in which rows of detectors for each channel are swept in the along-track direction by spacecraft motion. For each channel, an image is built-up by concatenating successive single-row measurements. Previous Landsat instruments used whiskbroom operations, in which a few detectors for each channel are swept across track by a system of moving mirrors as the spacecraft travels in the along-track direction. Because, in a pushbroom sensor, each spatial element has its own detector, integration times can be much longer, which leads to improved signal-to-noise performance. Furthermore, unlike in whiskbroom sensors, there is no need for a large, continuously-moving scan mirror or for the scan line corrector, eliminating sources of jitter and possible failure modes. The TIRS focal plane consists of three quantum well infrared photodetector (QWIPs) arrays, a technology flown for the first time on Landsat 8. A segmented filter assembly placed directly over the QWIP arrays provides the spectral band pass.

The TIRS instrument continually gathers image data, but these data are recorded and brought to the ground only on command. Typically, TIRS data are acquired simultaneously with OLI images, but occasionally, at night and in some calibration modes, TIRS data are collected alone. The OLI and TIRS datasets are merged onboard, downlinked in a single data stream and processed into a single product. In addition to normal, nadir-pointed viewing, OLI and TIRS data may be collected in off-nadir viewing geometries and in calibration modes, including lunar viewing and flat fielding modes (the so-called side slither mode in which the field of view is rotated by 90 degrees with respect to its normal mode).

Landsat-8 collects and archives the global, synoptic and repetitive OLI and TIRS imagery and electronically distributes data products to the general public on a no-cost basis [

1]. The USGS Earth Resources Observation Systems (EROS) Data Center is responsible for the ground system, including the Ground Network Element, the Mission Operations Element and the Data Processing and Archive System (DPAS). The DPAS consists of several subsystems that produce the Level 0 data and associated metadata and generate the Level 1 radiometrically calibrated and orthorectified images of the Earth’s surface, which are located with respect to the standard Worldwide Reference System 2 (WRS2) grid [

2,

3]. It also includes the Image Assessment System (IAS) developed for OLI and TIRS. The IAS operationally monitors, characterizes and updates the calibrations of the two sensors. The processing algorithms were developed by NASA Goddard and USGS calibration and validation teams.

Requirements Overview

TIRS has nearly 1000 requirements, including detailed performance specifications, spacecraft accommodation, reliability testing, environmental testing, and more [

4]. Indeed, there are several hundred performance requirements that cover topics, such as noise, spectral uniformity, banding, streaking, specific spatial characteristics of the instrument function and their temporal stability. With the exception of a stray light exceedance, to be discussed below (and in more detail in [

5]), all requirements were met, in some cases with minor waivers. In what follows, only the basic spatial, spectral and noise requirements are discussed. More detail is given in the other papers in this issue [

6,

7,

8].

TIRS has 100-m spatial resolution, not as fine as the ETM+ on Landsat 7 at 60 m, but higher than the TM sensors with their 120-m thermal band resolution. The 100-m resolution reduces the number of cross-track pixels needed, which aided in meeting the pressing schedule and was determined to be sufficient for TIRS’s primary applications, which include agricultural irrigation studies. As defined in [

9,

10] and shown in

Table 1, the two spectral channels, centered near 10.9 and 12 microns, essentially double sample the single thermal band in the heritage TM/ETM+ systems. The two channels were chosen to allow the use of a “split-window” approach (see, e.g., [

11] and the references therein) to compensate for the effects of the atmosphere in converting measured at-satellite radiances into surface temperatures.

Table 1.

TIRS band definitions and maximum allowed radiance error.

Table 1.

TIRS band definitions and maximum allowed radiance error.

| Landsat Channel | Thermal Band | 50% Lower Band Edge (µm) | 50% Upper Band Edge (µm) | Center Wavelength (µm) | NEdL

Maximum Allowed Radiance Error W/(m2 sr µm) |

|---|

| 10 | 1 | 10.6 | 11.2 | 10.9 | 0.059 (0.4 K at 300 K) |

| 11 | 2 | 11.5 | 12.5 | 12 | 0.049 (0.4 K at 300 K) |

To produce the 185-km swath width of TIRS, 1850 pixels are required for each row in each channel. At a ground speed of 7 km/s, it requires approximately 0.014 s to move 100 m, and 70 frames are taken in each second for each channel. TIRS uses a 3.49-millisecond integration time, and the resultant 25-m image motion, when convolved with the instrument spatial function, does not excessively broaden the spatial resolution. This integration time was chosen to give maximum signal-to-noise performance, while still not saturating at the required high temperature target limit of 360 K. The 10.9-micron channel saturates for target temperatures of about 400 K, while the 12-micron channel saturates at about 370 K. Twelve-bit digitization is used to produce precise temperature measurements over the required range of 240 to 360 K. Pre-launch measurements and in-flight results have shown that temperatures of 180 K (or even less) may be measured with a high signal-to-noise ratio.

Figure 1, taken from [

12], shows a comparison of the TIRS spectral bandwidths with those of previous Landsat thermal channels.

Figure 1.

Comparison of the relative spectral response of the Landsat 8/LDCM TIRS thermal channels with those of previous Landsat instruments. The TIRS channels span the same spectral region as the previous versions.

Figure 1.

Comparison of the relative spectral response of the Landsat 8/LDCM TIRS thermal channels with those of previous Landsat instruments. The TIRS channels span the same spectral region as the previous versions.

2. Design Overview

Structurally, the TIRS consists of the sensor unit, including the telescope assembly, focal plane assembly (FPA) and focal plane electronics (FPE), two-stage cryocooler, blackbody calibrator, scene select mechanism (SSM), Earth shield, radiators and heat pipes, and two electronics boxes, the main electronics box (MEB) and the cryocooler electronics (CCE). The MEB provides command, telemetry and image data interfaces to the spacecraft, provides power to and controls all functions of the instrument, controls the thermal zones on the instrument (except the cryocooler) and commands the cryocooler electronics. The CCE provides power to the cryocooler and controls its operations and temperature. The FPE provides power and clocking to the three QWIP arrays, and it digitizes the image data. Once every observational period (up to 43 minutes long), the SSM rotates the field of view (FOV) from the ground to the blackbody calibrator and to deep space and then back to the ground. This allows any variation in the instrument thermal background radiance to be removed from the measured radiance and provides regular verification of the calibration response.

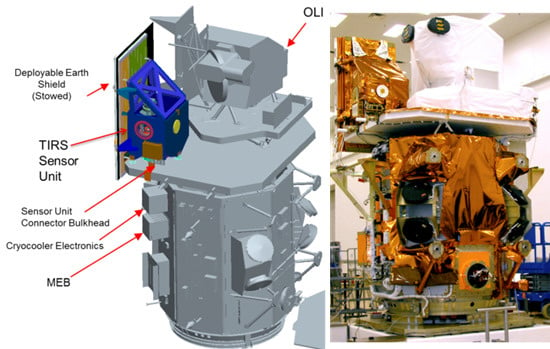

Figure 2 shows a schematic of the TIRS instrument with the main components identified, and

Figure 3 shows a drawing of the TIRS and OLI on the spacecraft next to a picture of the spacecraft prior to launch. To meet its 3.25-year operational lifetime requirement, TIRS employs selective redundancy based on engineering best judgment and validated by analyzing fault trees and performing a failure mode effects analysis (FMEA). In particular, the FPE and SSM have redundant A and B sides, as do some of the other functions of the MEB.

Figure 2.

Block diagram showing the interfaces among the major parts of TIRS, including the light paths. SCA A, SCA B and SCA C , the three QWIP sensor chip assemblies (SCA); TMU, thermal-mechanical unit; HSI, high speed interface; L1–L4, the four lens elements; CDH, command and data handling. The other acronyms are defined in the text above.

Figure 2.

Block diagram showing the interfaces among the major parts of TIRS, including the light paths. SCA A, SCA B and SCA C , the three QWIP sensor chip assemblies (SCA); TMU, thermal-mechanical unit; HSI, high speed interface; L1–L4, the four lens elements; CDH, command and data handling. The other acronyms are defined in the text above.

The f/1.64, 178-mm focal length TIRS telescope uses a temperature-stabilized four-element refractive lens assembly, three germanium (Ge) elements and one zinc selenide (ZnSe) element, to produce nearly diffraction-limited images at the focal plane. The lens elements were fabricated by Nu-Tek Precision Optical Corp. of Aberdeen, MD. All but two of the surfaces are spherical, which simplified fabrication. The lenses were assembled at GSFC. To reduce the thermal background, the TIRS optics are cooled to a temperature between 180 and 190 K using a radiative cooler, and the temperature is stabilized to ~0.1 K using heaters controlled by the MEB. The optics temperature directly affects the focus of the lens, because the Ge index of refraction is a strong function of temperature. The 10-degree temperature range of the optics provides a means of adjusting the focus [

9,

10].

Figure 3.

Drawing showing the location of various TIRS components on the spacecraft (left) and a picture of TIRS and OLI on the spacecraft prior to encapsulation (right).

Figure 3.

Drawing showing the location of various TIRS components on the spacecraft (left) and a picture of TIRS and OLI on the spacecraft prior to encapsulation (right).

Figure 4.

(Left) TIRS sensor unit with Earth shield deployed and showing FOVs. (Right) Drawing of the optical system, including the SSM, the four lens elements and the focal plane assembly. At the bottom, the cryocooler and the heat straps used to cool the FPA are shown. The blackbody calibration source is shown with its attached radiator.

Figure 4.

(Left) TIRS sensor unit with Earth shield deployed and showing FOVs. (Right) Drawing of the optical system, including the SSM, the four lens elements and the focal plane assembly. At the bottom, the cryocooler and the heat straps used to cool the FPA are shown. The blackbody calibration source is shown with its attached radiator.

The focal plane enclosure is cooled to ~100 K, using the first stage of the cryocooler. This further reduces the background thermal level, improving the sensitivity. The focal plane assembly is cooled to about 39 K by the second stage of the two-stage mechanical cryocooler controlled by the CCE. The focal plane temperature is stable to better than 0.05 K, which reduces the noise added by the variability of the dark signal to a very low level. The blackbody calibrator temperature is controlled by the MEB and can be set from 270 to 330 K with an accuracy of 0.1 K. The calibrator was referenced to a NIST traceable calibration standard during ground testing (see

Section 3 below).

Figure 4 shows a drawing of the TIRS sensor unit with the various fields of view and a model of the TIRS optical system, including the SSM, the four lens elements and the focal plane assembly.

The radiators required to cool the optics and to dump the heat generated by the cryocooler are protected from heating by the Earth by an Earth shield that was deployed soon after launch.

2.1. Focal Plane

The TIRS focal plane uses three 512-pixel by 640-pixel QWIP arrays arranged in a staggered configuration to provide the 1850 cross-track pixels required to cover the 185 km FOV at 100-m resolution. The 25 μm × 25 μm pixels have an IFOV of 141 μradians. Two spectral filters mounted 300 µm above each QWIP produce the spectral shapes shown in

Figure 1. The filters were fabricated by Materion Barr Precision Optics and Thin Film Coatings using an ion-assisted deposition process.

Figure 5 shows pictures of the focal plane, both before and after the filters are installed.

Figure 5.

The TIRS flight focal plane with the three QWIP arrays exposed (left) and the focal plane with the filter assembly installed (right). The six filter segments (two over each array) are clearly visible on the right. The filter assembly is coated on both the top and the bottom with a “black mirror” coating that is less than 5% reflective over the roughly 9–14-μm spectral range over which the QWIPs are active. The coating, which appears greenish in the photo below, limits scattering into the active area of the array.

Figure 5.

The TIRS flight focal plane with the three QWIP arrays exposed (left) and the focal plane with the filter assembly installed (right). The six filter segments (two over each array) are clearly visible on the right. The filter assembly is coated on both the top and the bottom with a “black mirror” coating that is less than 5% reflective over the roughly 9–14-μm spectral range over which the QWIPs are active. The coating, which appears greenish in the photo below, limits scattering into the active area of the array.

The QWIP design and fabrication process was a collaborative effort among GSFC, The U.S. Army Research Laboratory (USARL, Adelphi, MD, USA) and QmagiQ (Nashua, NH, USA). All three entities worked on modelling and defining the superlattice growth recipe. The thickness of the gallium arsenide (GaAs) quantum wells and the aluminum gallium arsenide (AlGaAs) barrier layers and the concentration of aluminum in the AlGaAs primarily determine the band structure in the wells and, hence, the spectral response of the detector material [

13,

14]. This design was provided to a fabrication house, which deposited 20 alternating layers of GaAs quantum wells and AlGaAs barriers using molecular beam epitaxy (MBE). The resulting detector wafers were sent to QmagiQ, which processed the wafers into arrays up to the point of indium bump fabrication using photolithography, reactive ion etching and vacuum deposition processes. This included etching a periodic structure into the surface of each pixel to form a scattering grating. Each QWIP array was then completed by hybridizing the detector layer to a read-out integrated circuit (ROIC) using an indium bump bonding process. The ROIC contains the integrated electronics that detect the photo-generated electrons and converts the electrons into a voltage. This voltage is proportional to the number of detected photons. Indigo ISC9803 ROICs were used. The hybridization was done at GSFC, where the wafers were diced, most of the substrate was removed and the remaining two-micron layer was polished; the indium bumps were defined and deposited on both the detector layers and the ROICs; the bonding was accomplished, and the epoxy underfill was applied.

The QWIP/ROIC hybrid was then bonded to a custom-developed silicon substrate that contains metal traces. The QWIP hybrids were wire bonded to the traces on the silicon substrate, and this subassembly was attached to an invar baseplate. Also mounted on the baseplate were two printed circuit (PC) boards located at either end of the silicon substrate. Wire bonds connected the silicon substrate traces to these PC “daughter” boards. Connectors on these daughter boards provided the interface between the QWIP hybrids and the FPE.

Because the QWIP detector layer fabrication process is well controlled, the pixels have a very uniform spectral response across each array. Similarly, the pixel response is very stable over time, and there are very few unresponsive or “bad” pixels. These characteristics make the QWIPs excellent sensors in high flux applications, where relatively low quantum efficiency (<1% in the case of TIRS) is not a problem, but where accurate and stable radiometric performance is required.

Figure 6 shows a schematic of the TIRS focal plane with the 36-row un-vignetted active areas under the filters shown. The areas of the hybrids not directly under the filters are shielded from illumination. The filters are wider than the QWIP arrays to reduce scattering from the filter holder edges into the active areas of the arrays. In each of the 70 samples produced per second, six rows are read out from each array: two illuminated rows from the un-vignetted region under each filter (four rows altogether) and two dark rows from an area on the hybrid that is far removed from the filters. The pixels from the illuminated rows in each channel in each hybrid are projected onto the Worldwide Reference System-2 grid. Should a detector fail in a pushbroom instrument, like TIRS, a complete image column of data would be lost. Capturing two rows from each infrared channel on each hybrid allows the ground processing software to combine the two rows into a single “effective” 1850-pixel row that has no inoperable pixels and covers the entire 185-km swath. The dark pixels are read out to provide a measure of the dark current of the QWIP hybrids. This is done to mitigate the effect of variable dark current on the image data in the unlikely event that the temperature of the focal plane is not controlled to sufficient precision by the CCE. Under normal conditions, the dark pixels are not used in data processing.

Figure 6.

Focal plane layout schematic showing the infrared band locations on the QWIP arrays. The dark area between the filters eliminates scattering between the bands. The first and last seven columns of each array are not used to form the swath. Between that and the fact that there is an overlap area on the ground “seen” by each array, the 1920 total row pixels (3 × 640) are reduced to 1850 pixels.2.2. Electronics

Figure 6.

Focal plane layout schematic showing the infrared band locations on the QWIP arrays. The dark area between the filters eliminates scattering between the bands. The first and last seven columns of each array are not used to form the swath. Between that and the fact that there is an overlap area on the ground “seen” by each array, the 1920 total row pixels (3 × 640) are reduced to 1850 pixels.2.2. Electronics

The arrays receive clock signals and biases from the focal plane electronics (FPE). The FPE contains an application-specific integrated circuit (ASIC) chip to gather image data from the QWIP arrays. The System for Image Digitization, Enhancement, Control and Retrieval (SIDECAR) ASIC controls the read pattern on the hybrids and performs analog-to-digital conversion of the image data. The FPE adds header information, formats these data and sends them to the MEB. The MEB packetizes the digitized image data and forwards the packets to the spacecraft communications system to downlink.

The MEB controls the scene mirror position and provides mirror position data to the spacecraft for incorporation into the telemetry. The scene mirror can be positioned with an accuracy better than 10 μradians (3σ) to meet the geodetic requirement that pixel location on the ground be known to 18 m (27 μradians).

The FPE, ASIC and CCE software are loaded from electrically-erasable, programmable, read-only memory (EEPROM), which can be updated from the ground. The MEB uses field-programmable gate arrays (FPGA) for its operations.

3. TIRS Calibration and Pre-Launch Performance

Calibration was performed at the component, subsystem and instrument level throughout the TIRS fabrication process. Comprehensive requirement verification and calibration measurements were made at the instrument level in a thermal vacuum environment prior to shipment of the TIRS for integration with the spacecraft. These latter measurements employed in-chamber calibration equipment with several variable temperature sources for radiometric calibration, which also allowed the spatial and spectral characteristics of the instrument to be characterized by a variety of techniques. In particular, the calibration equipment included a blackbody cavity source in an Infrared Source Module (IRSM) and a flood source. The latter underwent NIST-traceable laboratory calibration that showed it to be equivalent to a blackbody with an emissivity of 0.992 with an uncertainty of <0.3% at all calibration temperatures required for TIRS [

15]. This was the source used to obtain the TIRS radiometric calibration.

The IRSM source is behind a target wheel with apertures ranging in size from a quarter of a pixel to tens of pixels and shapes including circles, squares and extended slits. The output of this source illuminates an off-axis parabola and the aperture can be moved in the X,Y direction in the focal plane of the parabola, as well as in the Z-direction in and out of the parabola’s focal plane. The output of the OAP is directed into the aperture of the TIRS instrument by a steering mirror. This optical system allows one to produce target wavefronts equivalent to distant objects at various incidence angles on the TIRS optics. With this functionality, the IRSM and steering mirror allow one to determine the instrument focus, its boresight and the details of the instrumental spatial response. In addition, it allows scattering, streaking, banding, ghosting and distortion characteristics to be investigated and characterized. The calibration equipment structures are cooled to temperatures below 100 K, so that at the TIRS wavelengths, the background illumination produced by them is negligible. Finally, the IRSM module, which is flanked by two sets of “periscope” mirrors, may be moved to place the output of the second “periscope” mirror set at the OAP focal point. In this way, light sources from outside the chamber can be directed through the OAP/steering mirror system to the instrument input aperture. With the output of a grating spectrometer as the external source, this is the configuration used to verify the spectral shape of the two TIRS channels at various places on all three arrays.

Figure 7 shows a drawing of the calibration equipment and an example of the light path (in the external source configuration), while

Figure 8 shows photographs of it.

Figure 7.

(Left) Drawing of the TIRS calibration equipment as placed in the chamber to illuminate TIRS. The various acronyms are defined in the text. In this drawing, which shows the light path for an external source, some of the coverings have been removed for clarity. (Right) Detail of the OAP optical system showing the field mirror that directs light from the IRSM to the OAP.

Figure 7.

(Left) Drawing of the TIRS calibration equipment as placed in the chamber to illuminate TIRS. The various acronyms are defined in the text. In this drawing, which shows the light path for an external source, some of the coverings have been removed for clarity. (Right) Detail of the OAP optical system showing the field mirror that directs light from the IRSM to the OAP.

Figure 8.

(Left) Picture of the TIRS calibration system before it was put into the thermal vacuum test chamber. (Right) The grating monochromator system used to verify that the spectral shape of a representative set of pixels was consistent with the product of the component level measurements.

Figure 8.

(Left) Picture of the TIRS calibration system before it was put into the thermal vacuum test chamber. (Right) The grating monochromator system used to verify that the spectral shape of a representative set of pixels was consistent with the product of the component level measurements.

Based on data taken using this system, all performance requirements were met with a few minor exceptions. Waivers were granted for these exceptions, because modeling studies indicated that they would not impact the TIRS data quality. Calibration coefficients were obtained for all pixels in the ~36-row un-vignetted areas of the arrays under the filters. Similarly, 36 rows of dark pixels were obtained for each array. In the normal mode used in-flight, only two rows of pixels under each filter and in the dark areas are obtained. These are the so-called science rows. All pixels in the science rows go through the entire calibration sequence, including georectification. For all locations, either row is fully operational (

i.e., all pixels in the row are usable), and the image data for a given channel is based on the first science row of pixels.A high level summary of the overall pre-launch performance is presented below. In summary, the analog signals output by the QWIP pixels, which correspond to the illumination levels, are converted to digital numbers by the ASIC. The illumination levels correspond to the input radiance, which is provided by the calibrated sources. There are non-linearities designed in the QWIP arrays to increase their sensitivity at low light levels. In particular, the output capacitance changes at ~15% of the full well, so that the slope (V/e-) is about four-times higher in the region from 0% to 15% of the full well than it is from 15% to 100% of the full well (see [

6] for more details). The first step in the conversion to radiance, therefore, is to linearize the digital output from the arrays for each frame. In this process, all signals are referenced to the slope in the region up to ~10% of the full well. After linearization, the cold background values are subtracted from the values obtained during the nadir calibration observations. The difference represents the calibrated target signal.

Radiometric accuracy: The radiometric calibration was performed using the flood source described above. Required calibrations were obtained at flood source temperatures of 240, 250, 270, 290, 300, 320, 330, 345 and 360 K. At each temperature, the linearized, background-subtracted digital counts generated at each pixel were associated with the calibrated radiance from the flood source. Measurements were made using both the A and B redundant sides of the TIRS electronics over the range of temperatures expected in-flight for the MEB, the FPE and other system components. Each pixel in the active areas of the arrays has a calibration table relating background-subtracted linearized counts to radiance (and brightness temperature) at the flood source temperatures above. The sampling temperatures were chosen such that in no case was there a difference of more than 0.4% between a linear extrapolation of radiances between two temperatures and an extrapolation using the channel integrated product of τl(λ)* τf(λ)*QE(λ). Here, τf(λ) is the filter transmission as a function of wavelength, τl(λ) is the lens transmission and QE(λ) is the QWIP quantum efficiency. Given this and the better than 0.3% accuracy of the flood source calibration, the requirements of 2% accuracy for temperatures between 260 and 330 K and 4% for the rest of the range from 240 to 360 K are easily met. Final verification of the radiometric accuracy is taking place on-orbit through vicarious calibration methods [

16,

17].

Noise or NedL: The noise equivalent radiance change is the root mean square (RMS) radiance change over the 30 seconds it takes to obtain a single 185-km × 180-km WRS2 image frame. The required performance is shown in

Table 1.

Figure 9 shows the results obtained during thermal vacuum testing at 240 K and 360 K, the limits of the required target temperature. As may be seen from this figure, the requirement is easily met by all pixels and with a margin of a factor of five or more for the vast majority. There is also a requirement that the drift over the maximum 44-minute span between deep space looks is <0.7%. This requirement is also met by all pixels with a margin of at least a factor of two.

Figure 9.

Noise performance in terms of NEdL and NEdT (noise equivalent temperature change) for the science pixels at 240 K (top) and 360 K (bottom) measured during thermal vacuum testing. Similar results were found for all flood source temperatures and at all instrument temperature conditions.

Figure 9.

Noise performance in terms of NEdL and NEdT (noise equivalent temperature change) for the science pixels at 240 K (top) and 360 K (bottom) measured during thermal vacuum testing. Similar results were found for all flood source temperatures and at all instrument temperature conditions.

Spatial: The TIRS spatial performance was measured during thermal vacuum testing using a variety of IRSM target sources and stepping the steering mirror in sub-pixel steps. The requirements on the instrument spatial performance were levied primarily on the relative edge response (RER, also called the edge response slope) and half edge extent (HEE). These are best defined by reference to

Figure 10. As may be seen from this figure, the RER is the ratio of 0.2 to the ground track distance it takes for the instrument response to drop from 60% to 40%. The requirement that RER be greater than 0.007 means this distance must be 28 m or less. The HEE is the ground track distance it takes for the instrument response to drop from 90% to 10%. The requirement is that it takes 150 m or less. Generally, the TIRS RERs were somewhat smaller than required (0.0062 to 0.0068) and the HEEs were somewhat larger (180 to 220 m). However, as the representative measured instrument response function in

Figure 10 shows, there is little overshoot or ripple in the TIRS channels, and the TIRS spatial response still meets science measurement needs. Therefore, waivers were granted for the RER and HEE exceedances, which may, or may not, be due to the calibration setup (see [

8] for a more complete description of the spatial measurements).

Figure 10.

(Left) Graphics demonstrating the definition of RER and HEE. (Right) Measured instrument response for a representative pixel in the 12-micron channel (TIRS Channel 11). In the graph, each pixel represents 100 m.

Figure 10.

(Left) Graphics demonstrating the definition of RER and HEE. (Right) Measured instrument response for a representative pixel in the 12-micron channel (TIRS Channel 11). In the graph, each pixel represents 100 m.

Geometric: The geometric (pointing) performance was also measured using the IRSM and steering mirror. The various geometric pointing and stability requirements, as defined in the original requirements matrix, were met with the exception of the measured pointing stability as the instrument temperature was varied over its qualification range. This parameter performed slightly worse than specified in the requirements document. The stability requirement, however, was near the limits of measurement capability, and chamber vibrations and ground support equipment effects contributed to the apparent instability. In [

7], a detailed description of the geometric performance using both pre-flight and on-orbit data is presented. There is no measureable on-orbit effect of the temperature-induced pointing instability measured in ground testing.

Spectral: The spectral characteristics of the fully-assembled instrument were measured using the out-of-chamber monochromator. These instrument-level measurements were consistent with the product of the component-level measurements. All spectral requirements are met, although there are some very minor deficiencies in the pixel average response and the in-band spectral variation that required waivers. These are mitigated by the spectral uniformity of the atmosphere and the surface in the TIRS spectral bands, and no science impact is expected, or seen, in-flight.

Scattering, banding, streaking, ghosting, stray light, etc.: These parameters were measured using the IRSM with a combination of targets and beam positions with the steering mirror to simulate both in-field and out-of-field illumination angles. Additionally, the flood source was used in off-axis positions to simulate a large out-of-FOV target (i.e., the part of the Earth not in TIRS’s 15-degree FOV). All of the performance requirements were met. In some cases, the calibration equipment was not capable of directly illuminating the optics without vignetting. In those cases, an attempt was made to use the SSM to rotate the FOV a few degrees. However, this was not the way the SSM is used in flight, so it was difficult to interpret the results. There were no indications of significant difficulties.

Once on-orbit, however, some anomalous results were obtained when comparing to temperatures of buoys in several bodies of water [

16]. That, combined with out-of-field ghosting observed during lunar observations [

5], indicated that there was a difficulty caused by the out-of-FOV signal. As it turns out, the total ghosting appears to come from an annulus a few degrees wide, at a radius of ~15 degrees from the boresight. The particular geometry of the ghosting signal seen by a given pixel varies slowly as a function of position in the focal plane. For a uniform field, the ghost signal is only a few percent of the direct signal (about 2% for Channel 10 and 4% for Channel 11). The primary effect of the ghosting is to introduce a positive bias in the measured radiances. When the out-of-FOV radiance is significantly higher than the within-FOV radiance, the effect on brightness temperature can be larger, and the observed radiances can become non-uniform. Detailed optical modeling has indicated that the effect is caused by scattering from a supporting structure above the third lens. The modeling has produced a map of the ghosting source for each pixel. Work is ongoing that indicates a correction algorithm is feasible [

5], and a numerical correction algorithm is being implemented. It is important to note that for most regions, the ghosting is not problematic for applications, such as evapotranspiration studies, where local gradients are being assessed and the bias is subtracted out.

4. On-Orbit Calibration Methods

The existing suite of thermal data calibration and validation tools is applied to the TIRS data collected on-orbit, and vicarious calibration continues to play an important role. The IAS has been updated to process pushbroom data, after proving the concept with data from the Earth Observer-1 advanced land imager (ALI), also a pushbroom instrument [

18]. Additionally, there are new capabilities on Landsat-8 for calibration and for validation of TIRS.

Table 2 lists the types of calibrations that are being used by TIRS on-orbit. Although some of the calibration parameters have changed a bit from their ground-based values [

6,

7,

8,

16,

17], TIRS performance has been very stable [

17] since its initial turn on in orbit.

For normal radiometric calibration, the SSM rotates the FOV from a nadir Earth view to the on-board blackbody calibrator for 60 s and then to deep space for 60 s. This is done twice each orbit, before the first imaging interval and after the last imaging interval (the Landsat 4–7 thermal bands performed similar calibrations twice each data line). TIRS is capable of imaging up to 35 minutes between calibration sequences. The data acquired during these calibration cycles is used during ground processing to correct offsets and gains that may vary over time.

Table 2.

TIRS on-orbit calibration data types and their application.

Table 2.

TIRS on-orbit calibration data types and their application.

| | Detector-to-Detector Relative Calibration | Long Term Stability (Change Monitoring) | Absolute Calibration (Geophysical Parameter Retrieval) | Stray Light Effects |

|---|

| Dark (Deep Space) | X | X | X | |

| Blackbody | X | X | X | |

| Vicarious Sites | | X | X | X |

| Side Slither | X | | | X |

| | Band-to-Band Registration (within and between sensors) | Geodetic Accuracy | Focus | Stray Light Effects |

| Geometric Super-sites | X | X | | |

| Focus Check Sites | | | X | |

| Lunar Scans | | | | X |

The normal calibration sequence described above is replaced on a periodic basis by two other calibration modes: (1) an integration time sweep calibration during the blackbody portion of the normal calibration; and (2) a series of normal calibrations during a blackbody temperature sweep. If required, a stability calibration may be performed in which the normal calibration sequence is repeated every five minutes, for a total of 10-times across 50 minutes.

Since TIRS typically images coincidentally with the OLI, TIRS collects data over the OLI radiometric, geometric and focus check calibration sites, as well as during long land collects and OLI side slither collects. TIRS-driven acquisitions include ocean and night collects. The IAS performs long-term trending, characterization and calibration of the TIRS data and updates the processing parameters as needed.