Scale-up of Aflatoxin Purification by Centrifugal Partition Chromatography

Abstract

:1. Introduction

2. Results

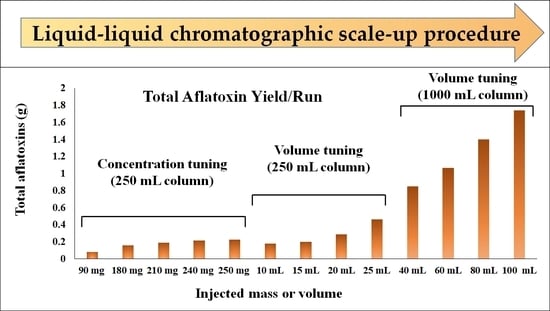

2.1. Determining the Maximum Loading Capacity on a 250 mL Rotor

2.2. Linear Scale-up of the Purification to a 1000 mL Column

2.3. Product Purity

2.4. Yield of the Entire Scale-up Procedure

3. Discussion

4. Conclusions

5. Materials and Methods

5.1. Chemicals and Solvents

5.2. Preparation of the Crude Extract

5.3. Centrifugal partition chromatography

5.4. HPLC-UV Analyses

5.5. Final clean-up of AFs

5.6. HPLC-HRMS analyses

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sargenat, K.; Sheridan, A.; O’Kelly, J. Toxicity associated with certain samples of groundnuts. Nature 1961, 192, 1096–1097. [Google Scholar] [CrossRef]

- Nakai, V.K.; Rocha, L.O.; Goncalez, E.; Fonseca, H.; Ortega, E.M.M.; Corrêa, B. Distribution of fungi and aflatoxins in a stored peanut variety. Food Chem. 2008, 106, 285–290. [Google Scholar] [CrossRef]

- Rustom, I.Y.S. Aflatoxin in food and feed: Occurrence, legislation and inactivation by physical methods. Food Chem. 1997, 59, 57–67. [Google Scholar] [CrossRef]

- Varga, J.; Baranyi, N.; Chandrasekaran, M.; Vágvölgyi, C.; Kocsubé, S. Mycotoxin producers in the Aspergillus genus: An update. Acta Biol. Szeged. 2015, 59, 151–167. [Google Scholar]

- Calderari, T.O.; Iamanaka, B.T.; Frisvad, J.C.; Pitt, J.I.; Sartori, D.; Pereira, J.L.; Fungaro, M.H.; Taniwaki, M.H. The biodiversity of Aspergillus section Flavi in brazil nuts: From rainforest to consumer. Int. J. Food Microbiol. 2013, 160, 267–272. [Google Scholar] [CrossRef]

- Nesbitt, B.F.; O’Kelly, J.; Sargeant, K. Aspergillus flavus and Turkey X disease: Toxic metabolites of Aspergillus flavus. Nature 1962, 195, 1062–1063. [Google Scholar] [CrossRef]

- Hartley, R.D.; Nesbitt, B.F.; O’Kelly, J. Toxic metabolites of Aspergillus flavus. Nature 1963, 198, 1056–1058. [Google Scholar] [CrossRef]

- World Health Organization; International Agency for Research on Cancer. Aflatoxins. In IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; IARC Press: Lyon, France, 1993; Volume 56, pp. 245–395. [Google Scholar]

- Stubblefield, R.D.; Shotwell, O.L.; Shannon, G.M. Aflatoxins B1, B2, G1 and G2: Separation and purification. J. Am. Oil Chem. Soc. 1968, 45, 686–688. [Google Scholar] [CrossRef]

- De Jesus, A.E.; Gorst-Allman, C.P.; Horak, R.M. Large-scale purification of the mycotoxins aflatoxin B1, B2 and G1. J. Chromatogr. A 1988, 450, 101–104. [Google Scholar] [CrossRef]

- Stubblefield, R.D.; Shotwell, O.L. Reverse phase analytical and preparative high pressure liquid chromatography of aflatoxins. J. Assoc. Off. Anal. Chem. 1977, 60, 784–790. [Google Scholar] [CrossRef]

- Tiebach, R.K.D.; Schram, M. Application of preparative HPLC in the chemical analysis of food ingerdients. Chromatographia 1980, 13, 403–407. [Google Scholar] [CrossRef]

- Endre, G.; Hegedüs, Z.; Turbat, A.; Škrbić, B.; Vágvölgyi, C.; Szekers, A. Separation and purification of aflatoxins by centrifugal partition chromatography. Toxins 2019, 11, 309. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heuer, C.; Hugo, P.; Mann, G.; Seidel-Morgenstern, A. Scale up in preparative chromatography. J. Chromatogr. A 1996, 752, 19–29. [Google Scholar] [CrossRef]

- Gaggeri, R.; Rossi, D.; Collina, S.; Mannucci, B.; Baierl, M.; Juza, M. Quick development of an analytical enantioselective high performance liquid chromatography separation and preparative scale-up for the flavonoid Naringenin. J. Chromatogr. A 2011, 1218, 5414–5422. [Google Scholar] [CrossRef]

- Sutherland, I.A.; Audo, G.; Bourton, E.; Couillard, F.; Fisher, D.; Garrad, I.; Hewitson, P.; Intes, O. Rapid linear scale-up of protein separation by centrifugal partition chromatography. J. Chromatogr. A 2008, 1190, 57–62. [Google Scholar] [CrossRef] [PubMed]

- Bouju, E.; Berthod, A.; Faure, K. Carnosol purification. Scaling-up centrifugal partition chromatography separations. J. Chromatogr. A 2016, 1466, 59–66. [Google Scholar]

- Bouju, E.; Berthod, A.; Faure, K. Scale-up in centrifugal partition chromatography: The “free-space between peaks” method. J. Chromatogr. A 2015, 1409, 70–78. [Google Scholar] [CrossRef]

- Yoichiro, I. Golden rules and pitfalls in selecting optimum conditions for high-speed counter-current chromatography. J. Chromatogr. A 2005, 1065, 154–168. [Google Scholar]

- DeAmicis, C.; Edwards, N.A.; Giles, M.B. Comparison of preparative reversed-phase liquid chromatography and countercurrent chromatography for the kilogram scale purification of crude spinetoram insecticide. J. Chromatogr. A 2011, 1218, 6122–6127. [Google Scholar] [CrossRef] [PubMed]

- Szekeres, A.; Lorántfy, L.; Bencsik, O. Rapid purification method for fumonisin B1 using centrifugal partition chromatography. Food Addit. Contam. Part A 2013, 30, 147–155. [Google Scholar] [CrossRef]

- Hübner, F.; Harrer, H.; Fraske, A. Large scale purification of B-type fumonisins using centrifugal partition chromatography (CPC). Mycotoxin Res. 2012, 28, 37–43. [Google Scholar] [CrossRef] [PubMed]

- Onji, Y.; Aoki, Y.; Yamazoe, Y. Isolation of nivalenol and fusarenon-x from pressed barley culture by centrifugal partition chromatography. J. Liq. Chromatogr. 1988, 12, 2537–2546. [Google Scholar] [CrossRef]

- He, J.; Yang, R.; Zhou, T. Purification of deoxynivalenol from Fusarium graminearum rice culture and mouldy corn by high-speed countercurrent chromatography. J. Chromatogr. A 2007, 1151, 187–192. [Google Scholar] [CrossRef]

- He, J.; Tsao, R.; Yang, R. Purification of patulin from Penicillium expansum culture/ High-speed counter-current chromatography (HSCCC) versus preparative high-performance liquid chromatography (prep-HPLC). Food Addit. Contam. Part A 2009, 29, 101–107. [Google Scholar] [CrossRef]

- Frisvad, J.C.; Hubka, V.; Ezekiel, C.N. Taxonomy of Aspergillus section Flavi and their production of aflatoxins, ochratoxins and other mycotoxins. Stud. Mycol. 2019, 93, 1–63. [Google Scholar] [CrossRef] [PubMed]

| Column (mL) | Injected Amount | AFB1 (mg) | AFB2 (mg) | AFG1 (mg) | AFG2 (mg) | Total AFs (mg) | Recovery (%)b | Solvent Consumption (L) | |

|---|---|---|---|---|---|---|---|---|---|

| 250 | 90 mg (loop) | Yield (mg) Puritya (%) | 24 98.2 | 2 96.3 | 49 98.1 | 6 97.0 | 81 97.3 | 90.0 | 1.7 |

| 180 mg (loop) | Yield (mg) Puritya (%) | 50 97.8 | 6 96.0 | 93 98.5 | 10 98.0 | 159 97.6 | 88.3 | 1.7 | |

| 210 mg (loop) | Yield (mg) Puritya (%) | 61 97.8 | 6 97.0 | 112 99.3 | 13 98.0 | 192 98.0 | 91.4 | 1.7 | |

| 240 mg (loop) | Yield (mg) Puritya (%) | 67 98.0 | 7 97.9 | 127 98.6 | 15 97.8 | 216 98.0 | 90.0 | 1.7 | |

| 250 mg (loop) | Yield (mg) Puritya (%) | 70 98.8 | 7 98.1 | 131 99.3 | 16 98.0 | 224 98.5 | 89.6 | 1.7 | |

| 250 mg (pump) | Yield (mg) Puritya (%) | 60 98.1 | 4 97.0 | 110 99.0 | 5 98.0 | 179 98.0 | 71.6 | 1.7 | |

| 375 mg (pump) | Yield (mg) Puritya (%) | 66 98.5 | 3 96.5 | 125 99.0 | 5 97.0 | 199 97.8 | 53.0 | 1.725 | |

| 500 mg (pump) | Yield (mg) Puritya (%) | 107 98.7 | 16 97.0 | 145 99.5 | 22 99.0 | 290 98.5 | 58.0 | 1.725 | |

| 625 mg (pump) | Yield (mg) Puritya (%) | 169 99.0 | 28 97.8 | 213 98.9 | 53 96.5 | 463 98.1 | 74.1 | 1.725 | |

| 1000 | 1 g (pump) | Yield (mg) Puritya (%) | 320 98.3 | 29 96.9 | 434 99.0 | 70 99.0 | 853 98.3 | 85.3 | 6.9 |

| 1.5 g (pump) | Yield (mg) Puritya (%) | 420 98.9 | 45 98.0 | 502 98.9 | 100 97.3 | 1067 98.2 | 71.3 | 6.9 | |

| 2 g (pump) | Yield (mg) Puritya (%) | 513 97.9 | 72 98.7 | 625 98.9 | 194 99.0 | 1404 98,6 | 70.2 | 6.9 | |

| 2.5 g (pump) | Yield (mg) Puritya (%) | 602 99.0 | 101 99.0 | 840 98.5 | 199 98.7 | 1742 98.8 | 69.7 | 6.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Endre, G.; Nagy, B.E.; Hercegfalvi, D.; Kasuba, C.; Vágvölgyi, C.; Szekeres, A. Scale-up of Aflatoxin Purification by Centrifugal Partition Chromatography. Toxins 2023, 15, 178. https://doi.org/10.3390/toxins15030178

Endre G, Nagy BE, Hercegfalvi D, Kasuba C, Vágvölgyi C, Szekeres A. Scale-up of Aflatoxin Purification by Centrifugal Partition Chromatography. Toxins. 2023; 15(3):178. https://doi.org/10.3390/toxins15030178

Chicago/Turabian StyleEndre, Gábor, Babett Edit Nagy, Dániel Hercegfalvi, Csenge Kasuba, Csaba Vágvölgyi, and András Szekeres. 2023. "Scale-up of Aflatoxin Purification by Centrifugal Partition Chromatography" Toxins 15, no. 3: 178. https://doi.org/10.3390/toxins15030178

APA StyleEndre, G., Nagy, B. E., Hercegfalvi, D., Kasuba, C., Vágvölgyi, C., & Szekeres, A. (2023). Scale-up of Aflatoxin Purification by Centrifugal Partition Chromatography. Toxins, 15(3), 178. https://doi.org/10.3390/toxins15030178