Focused Ion Beam Processing for 3D Chiral Photonics Nanostructures

Abstract

:1. Introduction

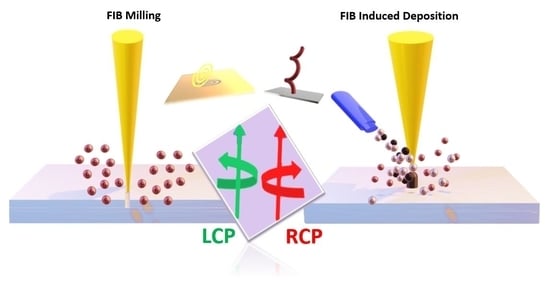

2. Focused Ion Beam Processing

- Emission of secondary electrons, usually employed for sample imaging;

- sputtering of the substrate atoms;

- deposition in the presence of gaseous precursors in the chamber; and

- re-deposition of some sputtered atoms and ion implantation from the beam, leading to amorphous/damaged/rough surfaces.

2.1. Basics of FIB Milling

2.2. Basics of FIBID Growth Dynamics

2.3. FIB under Cryogenic Conditions

3. Material Features of Nanostructure FIB Processing

Composition Assessment

4. 3D Chiral Nanostructures Realized by FIB Processing

4.1. 3D Chiral Nanostructures Realized by FIB Milling

4.1.1. One-Step Tilted-Angle Focused Ion Beam Milling

4.1.2. FIB Milling and Gray Scale Bitmap

4.1.3. Focused-Ion-Beam Stress-Induced Deformation Effects, Folding and Bending

4.1.4. Nano-Kirigami

4.1.5. Focused Ion Beam Milling for Stress-Induced 3D Chiral Fractal Metasurfaces

4.2. 3D Chiral Nanostructures Realized by FIB-Induced Deposition

4.2.1. 3D Chiral Nanohelix Growth

4.2.2. Optical Properties of Nano-Helices Arrays

4.2.3. Multiple Nanowire

4.2.4. Influence of the Helix Array Spatial Arrangement

5. Conclusions

5.1. Glancing Angle Deposition

5.2. Multi-Step Electron Beam Lithography

5.3. Self-Assembly

5.4. Nanoimprint Lithography

5.5. Direct Laser Writing

Author Contributions

Funding

Conflicts of Interest

References

- Liu, Y.; Zhang, X. Metamaterials: A new frontier of science and technology. Chem. Soc. Rev. 2011, 40, 2494–2507. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Guo, H.; Fu, L.; Kaiser, S.; Schweizer, H.; Giessen, H. Three-dimensional photonic metamaterials at optical frequencies. Nat. Mater. 2008, 7, 31–37. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi, R.; Leroux, X.; Degiron, A.; De Lustrac, A. 3D Optical Metamaterials; Springer: Berlin, Germany, 2012; ISBN 9781441911506. [Google Scholar]

- Di Fabrizio, E.; Schlücker, S.; Wenger, J.; Regmi, R.; Rigneault, H.; Calafiore, G.; West, M.; Cabrini, S.; Fleischer, M.; Van Hulst, N.F.; et al. Roadmap on biosensing and photonics with advanced nano-optical methods. J. Opt. 2016, 18. [Google Scholar] [CrossRef] [Green Version]

- Theories, C.; Problem, U. The Origin of Chirality in the Molecules of Life; Royal Society of Chemistry: Cambridge, UK, 2008; ISBN 9780854041565. [Google Scholar]

- Blaschke, G.; Kraft, H.P.; Fickentscher, K.; Köhler, F. Chromatographic separation of racemic thalidomide and teratogenic activity of its enantiomers (author’s transl). Arzneimittelforschung 1979, 29, 1640–1642. [Google Scholar]

- Schäferling, M.; Dregely, D.; Hentschel, M.; Giessen, H. Tailoring enhanced optical chirality: Design principles for chiral plasmonic nanostructures. Phys. Rev. X 2012, 2, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Collins, J.T.; Kuppe, C.; Hooper, D.C.; Sibilia, C.; Centini, M.; Valev, V.K. Chirality and Chiroptical Effects in Metal Nanostructures: Fundamentals and Current Trends. Adv. Opt. Mater. 2017, 5, 1–46. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Mutlu, M.; Ozbay, E. Chiral metamaterials: From optical activity and negative refractive index to asymmetric transmission. J. Opt. 2013, 15. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Cheng, F.; Winsor, T.; Liu, Y. Optical chiral metamaterials: A review of the fundamentals, fabrication methods and applications. Nanotechnology 2016, 27, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Hentschel, M.; Schäferling, M.; Duan, X.; Giessen, H.; Liu, N. Chiral plasmonics. Sci. Adv. 2017, 3, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Urban, M.J.; Shen, C.; Kong, X.-T.; Zhu, C.; Govorov, A.O.; Wang, Q.; Hentschel, M.; Liu, N. Chiral Plasmonic Nanostructures Enabled by Bottom-Up Approaches. Annu. Rev. Phys. Chem. 2019, 70, 275–299. [Google Scholar] [CrossRef] [Green Version]

- Schäferling, M.; Yin, X.; Engheta, N.; Giessen, H. Helical Plasmonic Nanostructures as Prototypical Chiral Near-Field Sources. ACS Photonics 2014, 1, 530–537. [Google Scholar] [CrossRef]

- Hendry, E.; Carpy, T.; Johnston, J.; Popland, M.; Mikhaylovskiy, R.V.; Lapthorn, A.J.; Kelly, S.M.; Barron, L.D.; Gadegaard, N.; Kadodwala, M. Ultrasensitive detection and characterization of biomolecules using superchiral fields. Nat. Nanotechnol. 2010, 5, 783–787. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Passaseo, A.; Esposito, M.; Cuscunà, M.; Tasco, V. Materials and 3D Designs of Helix Nanostructures for Chirality at Optical Frequencies. Adv. Opt. Mater. 2017, 5, 1–25. [Google Scholar] [CrossRef]

- Karst, J.; Cho, N.H.; Kim, H.; Lee, H.E.; Nam, K.T.; Giessen, H.; Hentschel, M. Chiral Scatterometry on Chemically Synthesized Single Plasmonic Nanoparticles. ACS Nano 2019, 13, 8659–8668. [Google Scholar] [CrossRef] [PubMed]

- Matsui, S. Focused-ion-beam deposition for 3-D nanostructure fabrication. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2007, 257, 758–764. [Google Scholar] [CrossRef]

- Reyntjens, S.; Puers, R. A review of focused ion beam applications in microsystem technology. J. Micromech. Microeng. 2001, 11, 287–300. [Google Scholar] [CrossRef]

- Reuss, R.H. Potential applications of focused ion beam technology for the semiconductor industry. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1985, 10–11, 515–521. [Google Scholar] [CrossRef]

- Nakamura, H.; Komano, H.; Ogasawara, M. Focused Ion Beam Assisted Etching of Quartz in XeF2without Transmittance Reduction for Phase Shifting Mask Repair. Jpn. J. Appl. Phys. 1992, 31, 4465–4467. [Google Scholar] [CrossRef]

- Stewart, D.K.; Doyle, A.F.; Casey, J.D., Jr. Focused ion beam deposition of new materials: Dielectric films for device modification and mask repair and tantalum films for x-ray mask repair. Int. Soc. Opt. Photonics 1995, 2437, 276–283. [Google Scholar]

- Harriott, L.R.; Wagner, A.; Fritz, F. Integrated circuit repair using focused ion beam milling. J. Vac. Sci. Technol. B Microelectron. Process. Phenom. 1986, 4, 181–184. [Google Scholar] [CrossRef]

- Ishitani, T.; Yaguchi, T. Cross-sectional sample preparation by focused ion beam: A review of ion-sample interaction. Microsc. Res. Tech. 1996, 35, 320–333. [Google Scholar] [CrossRef]

- Langford, R.M.; Reeves, C.M.; Goodall, J.G.; Findlay, J.; Jeffree, C.E. Cantilever technique for the preparation of cross sections for transmission electron microscopy using a focused ion beam workstation. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. Process. Meas. Phenom. 2000, 18, 100–103. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X. Focused ion beam technology and application in failure analysis. In Proceedings of the 2010 11th International Conference on Electronic Packaging Technology & High Density Packaging, Xi’an, China, 16–19 August 2010; pp. 957–960. [Google Scholar]

- Olbrich, A.; Ebersberger, B.; Boit, C.; Niedermann, P.; Hänni, W.; Vancea, J.; Hoffmann, H. High aspect ratio all diamond tips formed by focused ion beam for conducting atomic force microscopy. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. Process. Meas. Phenom. 1999, 17, 1570–1574. [Google Scholar] [CrossRef]

- Krogmeier, J.R.; Dunn, R.C. Focused ion beam modification of atomic force microscopy tips for near-field scanning optical microscopy. Appl. Phys. Lett. 2001, 79, 4494–4496. [Google Scholar] [CrossRef] [Green Version]

- De Ridder, R.M.; Hopman, W.C.L.; Ay, F. Focused-ion-beam processing for photonics. In Proceedings of the2007 9th International Conference on Transparent Optical Networks, Rome, Italy, 1–5 July 2007; Volume 2, pp. 212–215. [Google Scholar] [CrossRef] [Green Version]

- Kubena, R.L.; Ward, J.W.; Stratton, F.P.; Joyce, R.J.; Atkinson, G.M. A low magnification focused ion beam system with 8 nm spot size. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. Process. Meas. Phenom. 1991, 9, 3079–3083. [Google Scholar] [CrossRef]

- Editor, Z.M.W. Nanostructures; Springer: Berlin, Germany, 2013; ISBN 9783319028736. [Google Scholar]

- Niessen, F.; Nancarrow, M.J.B. Computer-aided manufacturing and focused ion beam technology enable machining of complex micro- And nano-structures. Nanotechnology 2019, 30. [Google Scholar] [CrossRef] [Green Version]

- Keskinbora, K.; Grévent, C.; Eigenthaler, U.; Weigand, M.; Schütz, G. Rapid Prototyping of Fresnel Zone Plates via Direct Ga+ Ion Beam Lithography for High-Resolution X-ray Imaging. ACS Nano 2013, 7, 9788–9797. [Google Scholar] [CrossRef]

- Cai, J.; Zhu, Z.; Alkemade, P.F.A.; van Veldhoven, E.; Wang, Q.; Ge, H.; Rodrigues, S.P.; Cai, W.; Li, W.-D. 3D Volumetric Energy Deposition of Focused Helium Ion Beam Lithography: Visualization, Modeling, and Applications in Nanofabrication. Adv. Mater. Interfaces 2018, 5, 1800203. [Google Scholar] [CrossRef]

- Tseng, A.A. Recent Developments in Nanofabrication Using Ion Projection Lithography. Small 2005, 1, 594–608. [Google Scholar] [CrossRef]

- Joshi-Imre, A.; Bauerdick, S. Direct-Write Ion Beam Lithography. J. Nanotechnol. 2014, 2014, 1–26. [Google Scholar] [CrossRef] [Green Version]

- Utke, I.; Hoffmann, P.; Melngailis, J. Gas-assisted focused electron beam and ion beam processing and fabrication. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2008, 26, 1197. [Google Scholar] [CrossRef] [Green Version]

- van Kouwen, L. Chapter Seven—Introduction to focused ion beams, ion sources, and the nano-aperture ion source. In Advances in Imaging and Electron Physics Including Proceedings CPO-10; Hawkes, P.W., Hÿtch, M.B.T.-A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 212, pp. 181–216. ISBN 1076-5670. [Google Scholar]

- Bischoff, L. Alloy liquid metal ion sources and their application in mass separated focused ion beams. Ultramicroscopy 2005, 103, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Bauerdick, S.; Bruchhaus, L.; Mazarov, P.; Nadzeyka, A.; Jede, R.; Fridmann, J.; Sanabia, J.E.; Gila, B.; Appleton, B.R. Multispecies focused ion beam lithography system and its applications. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2013, 31, 06F404. [Google Scholar] [CrossRef]

- Tseng, A.A. Recent Developments in Nanofabrication Using Focused Ion Beams. Small 2005, 1, 924–939. [Google Scholar] [CrossRef] [PubMed]

- Melngailis, J. Focused ion beam technology and applications. J. Vac. Sci. Technol. B Microelectron. Process. Phenom. 1987, 5, 469–495. [Google Scholar] [CrossRef]

- Mackenzie, R.A.D.; Smith, G.D.W. Focused ion beam technology: A bibliography. Nanotechnology 1990, 1, 163–201. [Google Scholar] [CrossRef]

- Allen, F.I.; Velez, N.R.; Thayer, R.C.; Patel, N.H.; Jones, M.A.; Meyers, G.F.; Minor, A.M. Gallium, neon and helium focused ion beam milling of thin films demonstrated for polymeric materials: Study of implantation artifacts. Nanoscale 2019, 11, 1403–1409. [Google Scholar] [CrossRef]

- Abbas, A.N.; Liu, G.; Liu, B.; Zhang, L.; Liu, H.; Ohlberg, D.; Wu, W.; Zhou, C. Patterning, Characterization, and Chemical Sensing Applications of Graphene Nanoribbon Arrays Down to 5 nm Using Helium Ion Beam Lithography. ACS Nano 2014, 8, 1538–1546. [Google Scholar] [CrossRef]

- Yang, J.; Ferranti, D.C.; Stern, L.A.; Sanford, C.A.; Huang, J.; Ren, Z.; Qin, L.-C.; Hall, A.R. Rapid and precise scanning helium ion microscope milling of solid-state nanopores for biomolecule detection. Nanotechnology 2011, 22, 285310. [Google Scholar] [CrossRef] [Green Version]

- Marshall, M.M.; Yang, J.; Hall, A.R. Direct and Transmission Milling of Suspended Silicon Nitride Membranes With a Focused Helium Ion Beam. Scanning 2012, 34, 101–106. [Google Scholar] [CrossRef]

- Scholder, O.; Jefimovs, K.; Shorubalko, I.; Hafner, C.; Sennhauser, U.; Bona, G.-L. Helium focused ion beam fabricated plasmonic antennas with sub-5 nm gaps. Nanotechnology 2013, 24, 395301. [Google Scholar] [CrossRef] [PubMed]

- Hahn, C.; Hajebifard, A.; Berini, P. Helium focused ion beam direct milling of plasmonic heptamer-arranged nanohole arrays. Nanophotonics 2020, 9, 393–399. [Google Scholar] [CrossRef]

- Burnett, T.L.; Kelley, R.; Winiarski, B.; Contreras, L.; Daly, M.; Gholinia, A.; Burke, M.G.; Withers, P.J. Large volume serial section tomography by Xe Plasma FIB dual beam microscopy. Ultramicroscopy 2016, 161, 119–129. [Google Scholar] [CrossRef] [PubMed]

- Dhawan, A.; Gerhold, M.; Madison, A.; Fowlkes, J.; Russell, P.E.; Vo-Dinh, T.; Leonard, D.N. Fabrication of nanodot plasmonic waveguide structures using FIB milling and electron beam-induced deposition. Scanning 2009, 31, 139–146. [Google Scholar] [CrossRef]

- Principe, M.; Consales, M.; Micco, A.; Crescitelli, A.; Castaldi, G.; Esposito, E.; La Ferrara, V.; Cutolo, A.; Galdi, V.; Cusano, A. Optical fiber meta-tips. Light Sci. Appl. 2017, 6, 16226. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Utke, I.; Michler, J.; Winkler, R.; Plank, H. Mechanical Properties of 3D Nanostructures Obtained by Focused Electron/Ion Beam-Induced Deposition: A Review. Micromachines. 2020, 11, 397. [Google Scholar] [CrossRef] [Green Version]

- Matsui, S.; Kaito, T.; Fujita, J.; Komuro, M.; Kanda, K.; Haruyama, Y. Three-dimensional nanostructure fabrication by focused-ion-beam chemical vapor deposition. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2000, 18, 3181. [Google Scholar] [CrossRef]

- Esposito, M.; Tasco, V.; Todisco, F.; Benedetti, A.; Sanvitto, D.; Passaseo, A. Three dimensional chiral metamaterial nanospirals in the visible range by vertically compensated focused ion beam induced-deposition. Adv. Opt. Mater. 2014, 2, 154–161. [Google Scholar] [CrossRef]

- Gazzadi, G.C.; Mulders, J.J.L.; Trompenaars, P.; Ghirri, A.; Rota, A.; Affronte, M.; Frabboni, S. Characterization of a new cobalt precursor for focused beam deposition of magnetic nanostructures. Microelectron. Eng. 2011, 88, 1955–1958. [Google Scholar] [CrossRef]

- Sadki, E.S.; Ooi, S.; Hirata, K. Focused-ion-beam-induced deposition of superconducting nanowires. Appl. Phys. Lett. 2004, 85, 6206–6208. [Google Scholar] [CrossRef] [Green Version]

- Fujita, J.; Ishida, M.; Sakamoto, T.; Ochiai, Y.; Kaito, T.; Matsui, S. Observation and characteristics of mechanical vibration in three-dimensional nanostructures and pillars grown by focused ion beam chemical vapor deposition. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. Process. Meas. Phenom. 2001, 19, 2834–2837. [Google Scholar] [CrossRef]

- Chen, P.; Salemink, H.W.M.; Alkemade, P.F.A. Proximity effect in ion-beam-induced deposition of nanopillars. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. Process. Meas. Phenom. 2009, 27, 1838–1843. [Google Scholar] [CrossRef] [Green Version]

- Kosters, D.; De Hoogh, A.; Zeijlemaker, H.; Acar, H.; Rotenberg, N.; Kuipers, L. Core-Shell Plasmonic Nanohelices. ACS Photonics 2017, 4, 1858–1863. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Plank, H.; Winkler, R.; Schwalb, C.H.; Hütner, J.; Fowlkes, J.D.; Rack, P.D.; Utke, I.; Huth, M. Focused electron beam-based 3D nanoprinting for scanning probe microscopy: A review. Micromachines 2020, 11, 48. [Google Scholar] [CrossRef] [Green Version]

- Utke, I.; Gabureac, M.; Friedli, V.; Bernau, L.; Michler, J. In-situ monitoring of gas-assisted focused ion beam and focused electron beam induced processing. J. Phys. Conf. Ser. 2010, 241, 012072. [Google Scholar] [CrossRef] [Green Version]

- Córdoba, R.; Orús, P.; Strohauer, S.; Torres, T.E.; De Teresa, J.M. Ultra-fast direct growth of metallic micro- and nano-structures by focused ion beam irradiation. Sci. Rep. 2019, 9, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Salvador-Porroche, A.; Sangiao, S.; Philipp, P.; Cea, P.; De Teresa, J.M. Optimization of pt-c deposits by cryo-fibid: Substantial growth rate increase and quasi-metallic behaviour. Nanomaterials 2020, 10, 1906. [Google Scholar] [CrossRef]

- Parmenter, C.D.J.; Fay, M.W.; Hartfield, C.; Eltaher, H.M. Making the practically impossible “Merely difficult”—Cryogenic FIB lift-out for “Damage free” soft matter imaging. Microsc. Res. Tech. 2016, 79, 298–303. [Google Scholar] [CrossRef]

- De Teresa, J.M.; Orús, P.; Córdoba, R.; Philipp, P. Comparison between focused electron/ion beam-induced deposition at room temperature and under cryogenic conditions. Micromachines 2019, 10. [Google Scholar] [CrossRef] [Green Version]

- Langford, R.M.; Wang, T.-X.; Ozkaya, D. Reducing the resistivity of electron and ion beam assisted deposited Pt. Microelectron. Eng. 2007, 84, 784–788. [Google Scholar] [CrossRef]

- Wanzenboeck, H.D.; Harasek, S.; Langfischer, H.; Bertagnolli, E. Deposition mechanism of oxide thin films manufactured by a focused energetic beam process. Mater. Res. Soc. Symp. Proc. 2002, 749, 305–310. [Google Scholar] [CrossRef]

- Rogov, O.Y.; Artemov, V.V.; Gorkunov, M.V.; Ezhov, A.A.; Khmelenin, D.N. FIB-fabricated complex-shaped 3D chiral photonic silicon nanostructures. J. Microsc. 2017, 268, 254–258. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Esposito, M.; Tasco, V.; Cuscunà, M.; Todisco, F.; Benedetti, A.; Tarantini, I.; De Giorgi, M.; Sanvitto, D.; Passaseo, A. Nanoscale 3D chiral plasmonic helices with circular dichroism at visible frequencies. ACS Photonics 2015, 2, 105–114. [Google Scholar] [CrossRef]

- Fujita, J.I.; Ishida, M.; Ichihashi, T.; Sakamoto, T.; Ochiai, Y.; Kaito, T.; Matsui, S. Structure and resonant characteristics of amorphous carbon pillars grown by focused-ion-beam-induced chemical vapor deposition. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 2002, 41, 4423–4426. [Google Scholar] [CrossRef]

- Kanda, K.; Yamada, N.; Okada, M.; Igaki, J.Y.; Kometani, R.; Matsui, S. Graphitization of thin films formed by focused-ion-beam chemical-vapor-deposition. Diam. Relat. Mater. 2009, 18, 490–492. [Google Scholar] [CrossRef]

- Lipp, S. Tetramethoxysilane as a precursor for focused ion beam and electron beam assisted insulator (SiOx) deposition. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 1996, 14, 3920. [Google Scholar] [CrossRef]

- Tao, T. Focused ion beam induced deposition of platinum. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 1990, 8, 1826. [Google Scholar] [CrossRef]

- Della Ratta, A.D.; Melngailis, J.; Thompson, C.V. Focused-ion beam induced deposition of copper. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. Process. Meas. Phenom. 1993, 11, 2195–2199. [Google Scholar] [CrossRef] [Green Version]

- Ro, J.S.; Thompson, C.V.; Melngailis, J. Microstructure of gold grown by ion-induced deposition. Thin Solid Films 1995, 258, 333–335. [Google Scholar] [CrossRef]

- De Teresa, J.M.; Córdoba, R.; Fernández-Pacheco, A.; Montero, O.; Strichovanec, P.; Ibarra, M.R. Origin of the Difference in the Resistivity of As-Grown Focused-Ion- and Focused-Electron-Beam-Induced Pt Nanodeposits. J. Nanomater. 2009, 2009, 936863. [Google Scholar] [CrossRef] [Green Version]

- Fernández-Pacheco, A.; De Teresa, J.M.; Córdoba, R.; Ibarra, M.R. Metal-insulator transition in Pt-C nanowires grown by focused-ion-beam- induced deposition. Phys. Rev. B Condens. Matter Mater. Phys. 2009, 79, 1–12. [Google Scholar] [CrossRef]

- Kometani, R.; Ishihara, S. Nanoelectromechanical device fabrications by 3-D nanotechnology using focused-ion beams. Sci. Technol. Adv. Mater. 2009, 10. [Google Scholar] [CrossRef] [PubMed]

- Kometani, R.; Ichihashi, T.; Kanda, K.; Suzuki, T.; Niihara, K.; Ishihara, S.; Kaito, T.; Matsui, S. Resistivity change of the diamondlike carbon, deposited by focused-ion-beam chemical vapor deposition, induced by the annealing treatment. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. Process. Meas. Phenom. 2008, 26, 2628–2631. [Google Scholar] [CrossRef]

- Matsui, S. Focused-Ion-Beam Chemical-Vapor-Deposition (FIB-CVD) BT—Encyclopedia of Nanotechnology; Bhushan, B., Ed.; Springer: Dordrecht, The Netherlands, 2012; pp. 866–876. ISBN 978-90-481-9751-4. [Google Scholar]

- Esposito, M.; Tasco, V.; Todisco, F.; Cuscunà, M.; Benedetti, A.; Scuderi, M.; Nicotra, G.; Passaseo, A. Programmable Extreme Chirality in the Visible by Helix-Shaped Metamaterial Platform. Nano Lett. 2016, 16, 5823–5828. [Google Scholar] [CrossRef]

- Cuscuna, M.; Manoccio, M.; Esposito, M.; Scuderi, M. Materials Horizons polarization handling. Mater. Horiz. 2020. [CrossRef]

- Gnaser, H.; Brodyanski, A.; Reuscher, B. Focused ion beam implantation of Ga in Si and Ge: Fluence-dependent retention and surface morphology. Surf. Interface Anal. 2008, 40, 1415–1422. [Google Scholar] [CrossRef]

- Elbadawi, C.; Toth, M.; Lobo, C.J. Pure Platinum Nanostructures Grown by Electron Beam Induced Deposition. ACS Appl. Mater. Interfaces 2013, 5, 9372–9376. [Google Scholar] [CrossRef] [Green Version]

- Stanford, M.G.; Lewis, B.B.; Noh, J.H.; Fowlkes, J.D.; Rack, P.D. Inert Gas Enhanced Laser-Assisted Purification of Platinum Electron-Beam-Induced Deposits. ACS Appl. Mater. Interfaces 2015, 7, 19579–19588. [Google Scholar] [CrossRef]

- Haverkamp, C.; Höflich, K.; Jäckle, S.; Manzoni, A.; Christiansen, S. Plasmonic gold helices for the visible range fabricated by oxygen plasma purification of electron beam induced deposits. Nanotechnology 2017, 28. [Google Scholar] [CrossRef] [Green Version]

- Höflich, K.; Yang, R.B.; Berger, A.; Leuchs, G.; Christiansen, S. The direct writing of plasmonic gold nanostructures by electron-beam- induced deposition. Adv. Mater. 2011, 23, 2657–2661. [Google Scholar] [CrossRef]

- Wang, M.; Salut, R.; Lu, H.; Suarez, M.A.; Martin, N.; Grosjean, T. Subwavelength polarization optics via individual and coupled helical traveling-wave nanoantennas. Light Sci. Appl. 2019, 8. [Google Scholar] [CrossRef] [PubMed]

- Wozniak, P.; De Leon, I.; Hoich, K.; Haverkamp, C.; Christiansen, S.; Leuchs, G.; Banzer, P. Chiroptical response of a single plasmonic nanohelix. Opt. Express 2018, 26, 1513–1515. [Google Scholar] [CrossRef] [PubMed]

- Höflich, K.; Feichtner, T.; Hansjürgen, E.; Haverkamp, C.; Kollmann, H.; Lienau, C.; Silies, M. Resonant behavior of a single plasmonic helix. Optica 2019, 6, 1098. [Google Scholar] [CrossRef]

- Perez-Roldan, M.J.; Mulders, J.J.L.; Trompenaars, P.H.F. Oxygen-assisted purification of platinum structures deposited by ion and electron beam induced processes. J. Phys. D. Appl. Phys. 2017, 50. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, J.; Yang, X. Chiral Metamaterials of Plasmonic Slanted Nanoapertures with Symmetry Breaking. Nano Lett. 2018, 18, 520–527. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, Y.; Brown, A.S.; Moreno, F.; Losurdo, M. Plasmonics beyond noble metals: Exploiting phase and compositional changes for manipulating plasmonic performance. J. Appl. Phys. 2020, 128, 80901. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, X.; Gao, J. 3D Janus plasmonic helical nanoapertures for polarization-encrypted data storage. Light Sci. Appl. 2019, 8. [Google Scholar] [CrossRef]

- Barron, L.D. An Introduction to Chirality at the Nanoscale. Chirality Nanoscale 2009, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Rajaei, M.; Zeng, J.; Albooyeh, M.; Kamandi, M.; Hanifeh, M.; Capolino, F.; Wickramasinghe, H.K. Giant Circular Dichroism at Visible Frequencies Enabled by Plasmonic Ramp-Shaped Nanostructures. ACS Photonics 2019, 6, 924–931. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, J.; Yang, X. Chiral Grayscale Imaging with Plasmonic Metasurfaces of Stepped Nanoapertures. Adv. Opt. Mater. 2019, 7, 1–8. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Chen, W.T.; Zhu, A.Y.; Oh, J.; Devlin, R.C.; Rousso, D.; Capasso, F. Multispectral Chiral Imaging with a Metalens. Nano Lett. 2016, 16, 4595–4600. [Google Scholar] [CrossRef] [PubMed]

- Zang, X.; Dong, F.; Yue, F.; Zhang, C.; Xu, L.; Song, Z.; Chen, M.; Chen, P.Y.; Buller, G.S.; Zhu, Y.; et al. Polarization Encoded Color Image Embedded in a Dielectric Metasurface. Adv. Mater. 2018, 30, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Yue, F.; Zhang, C.; Zang, X.F.; Wen, D.; Gerardot, B.D.; Zhang, S.; Chen, X. High-resolution grayscale image hidden in a laser beam. Light Sci. Appl. 2018, 7, 17129. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.Q.; Bryan, N.K.A.; Shing, O.N.; Hung, N.P. Influence of the redeposition effect for focused ion beam 3D micromachining in silicon. Int. J. Adv. Manuf. Technol. 2000, 16, 877–880. [Google Scholar] [CrossRef]

- Chen, X.; Xia, Y.; Mao, Y.; Huang, Y.; Zhu, J.; Xu, J.; Zhu, R.; Shi, L.; Wu, W. A programmable nanofabrication method for complex 3D meta-atom array based on focused-ion-beam stress-induced deformation effect. Micromachines 2020, 11. [Google Scholar] [CrossRef] [Green Version]

- Mao, Y.; Zheng, Y.; Li, C.; Guo, L.; Pan, Y.; Zhu, R.; Xu, J.; Zhang, W.; Wu, W. Programmable bidirectional folding of metallic thin films for 3D chiral optical antennas. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Jin, S.; Chen, Z.; Chen, X.; Zhu, R.; Zhu, J.; Huang, Y.; Xu, J.; Wu, W. 3D Nanoscale Chiral Helixes Fabricated by Focused Helium Ion Beam Manufacturing Process. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020; pp. 897–900. [Google Scholar] [CrossRef]

- Li, J.; Liu, Z. Focused-ion-beam-based nano-kirigami: From art to photonics. Nanophotonics 2018, 7, 1637–1650. [Google Scholar] [CrossRef]

- Chen, S.; Chen, J.; Zhang, X.; Li, Z.-Y.; Li, J. Kirigami/origami: Unfolding the new regime of advanced 3D microfabrication/nanofabrication with “folding”. Light Sci. Appl. 2020, 9, 75. [Google Scholar] [CrossRef]

- Pan, R.; Li, Z.; Liu, Z.; Zhu, W.; Zhu, L.; Li, Y.; Chen, S.; Gu, C.; Li, J. Rapid Bending Origami in Micro/Nanoscale toward a Versatile 3D Metasurface. Laser Photon. Rev. 2020, 14, 1900179. [Google Scholar] [CrossRef]

- Cui, A.; Liu, Z.; Li, J.; Shen, T.H.; Xia, X.; Li, Z.; Gong, Z.; Li, H.; Wang, B.; Li, J.; et al. Directly patterned substrate-free plasmonic “nanograter” structures with unusual Fano resonances. Light Sci. Appl. 2015, 4. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Liu, Z.; Li, J.; Li, W.; Li, J.; Gu, C.; Li, Z.-Y. 3D conductive coupling for efficient generation of prominent Fano resonances in metamaterials. Sci. Rep. 2016, 6, 27817. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.; Li, J.; Liu, Z.; Li, W.; Li, J.; Gu, C.; Li, Z.-Y. Fano resonance Rabi splitting of surface plasmons. Sci. Rep. 2017, 7, 8010. [Google Scholar] [CrossRef]

- Liu, Z.; Du, H.; Li, J.; Lu, L.; Li, Z.Y.; Fang, N.X. Nano-kirigami with giant optical chirality. Sci. Adv. 2018, 4, 1–9. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tseng, M.L.; Lin, Z.H.; Kuo, H.Y.; Huang, T.T.; Huang, Y.T.; Chung, T.L.; Chu, C.H.; Huang, J.S.; Tsai, D.P. Stress-Induced 3D Chiral Fractal Metasurface for Enhanced and Stabilized Broadband Near-Field Optical Chirality. Adv. Opt. Mater. 2019, 7, 1–7. [Google Scholar] [CrossRef]

- Balanis, C. A Antenna Theory Analysis and Design, 2nd ed.; Wiley Sons Inc.: New York, NY, USA, 1997. [Google Scholar]

- Tinoco, I.; Freeman, M.P. The optical activity of oriented copper helices. I. Experimental. J. Phys. Chem. 1957, 61, 1196–1200. [Google Scholar] [CrossRef]

- Gansel, J.K.; Wegener, M.; Burger, S.; Linden, S. Gold helix photonic metamaterials: A numerical parameter study. Opt. Express 2010, 18, 1059. [Google Scholar] [CrossRef] [Green Version]

- Thiel, M.; Decker, M.; Deubel, M.; Wegener, M.; Linden, S.; Von Freymann, G. Polarization stop bands in chiral polymeric three-dimensional photonic crystals. Adv. Mater. 2007, 19, 207–210. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.-Y.; Zhao, Y.-P. The visible extinction peaks of Ag nanohelixes: A periodic effective dipole model. Appl. Phys. Lett. 2011, 98, 83102. [Google Scholar] [CrossRef]

- Li, Y.R.; Ho, R.M.; Hung, Y.C. Plasmon hybridization and dipolar interaction on the resonances of helix metamaterials. IEEE Photonics J. 2013, 5, 2700510. [Google Scholar] [CrossRef]

- Tasco, V.; Esposito, M.; Todisco, F.; Benedetti, A.; Cuscunà, M.; Sanvitto, D.; Passaseo, A. Three-dimensional nanohelices for chiral photonics. Appl. Phys. A Mater. Sci. Process. 2016, 122, 2–7. [Google Scholar] [CrossRef]

- Manoccio, M.; Esposito, M.; Tasco, V.; Cuscun, M.; Passaseo, A. Engineering structural and optical properties of 3D chiral dielectric nanostructures. In Proceedings of the 2019 13th International Congress on Artificial Materials for Novel Wave Phenomena, Metamaterials, Rome, Italy, 16–21 September 2019. [Google Scholar]

- Córdoba, R.; Mailly, D.; Rezaev, R.O.; Smirnova, E.I.; Schmidt, O.G.; Fomin, V.M.; Zeitler, U.; Guillamón, I.; Suderow, H.; De Teresa, J.M. Three-Dimensional Superconducting Nanohelices Grown by He+-Focused-Ion-Beam Direct Writing. Nano Lett. 2019, 19, 8597–8604. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, M.; Salut, R.; Suarez, M.A.; Martin, N.; Grosjean, T. Chiroptical transmission through a plasmonic helical traveling-wave nanoantenna, towards on-tip chiroptical probes. Opt. Lett. 2019, 44, 4861–4864. [Google Scholar] [CrossRef] [PubMed]

- Tasco, V.; Passaseo, A.; Leahu, G.; Alam, B.; Esposito, M.; Belardini, A.; Li Voti, R.; Sibilia, C.; Benedetti, A. Precise detection of circular dichroism in a cluster of nano-helices by photoacoustic measurements. Sci. Rep. 2017, 7, 1–7. [Google Scholar] [CrossRef]

- Kaschke, J.; Gansel, J.K.; Wegener, M. On metamaterial circular polarizers based on metal N-helices. Opt. Express 2012, 20, 26012–26020. [Google Scholar] [CrossRef]

- Esposito, M.; Tasco, V.; Todisco, F.; Cuscunà, M.; Benedetti, A.; Sanvitto, D.; Passaseo, A. Triple-helical nanowires by tomographic rotatory growth for chiral photonics. Nat. Commun. 2015, 6, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Esposito, M.; Tasco, V.; Todisco, F.; Benedetti, A.; Tarantini, I.; Cuscunà, M.; Dominici, L.; De Giorgi, M.; Passaseo, A. Tailoring chiro-optical effects by helical nanowire arrangement. Nanoscale 2015, 7, 18081–18088. [Google Scholar] [CrossRef]

- Venkataramanababu, S.; Nair, G.; Deshpande, P.; Jithin, M.A.; Mohan, S.; Ghosh, A. Chiro-Plasmonic Refractory Metamaterial with Titanium Nitride (TiN) Core-Shell Nanohelices. Nanotechnology 2018. [Google Scholar] [CrossRef]

- Singh, H.J.; Ghosh, A. Large and Tunable Chiro-Optical Response with All Dielectric Helical Nanomaterials. ACS Photonics 2018, 5, 1977–1985. [Google Scholar] [CrossRef]

- Singh, J.H.; Nair, G.; Ghosh, A.; Ghosh, A. Wafer scale fabrication of porous three-dimensional plasmonic metamaterials for the visible region: Chiral and beyond. Nanoscale 2013, 5, 7224–7228. [Google Scholar] [CrossRef]

- Larsen, G.K.; He, Y.; Wang, J.; Zhao, Y. Scalable Fabrication of Composite Ti/Ag Plasmonic Helices: Controlling Morphology and Optical Activity by Tailoring Material Properties. Adv. Opt. Mater. 2014, 2, 245–249. [Google Scholar] [CrossRef]

- Gibbs, J.G.; Mark, A.G.; Eslami, S.; Fischer, P. Plasmonic nanohelix metamaterials with tailorable giant circular dichroism. Appl. Phys. Lett. 2013, 103, 10–14. [Google Scholar] [CrossRef]

- Mark, A.G.; Gibbs, J.G.; Lee, T.C.; Fischer, P. Hybrid nanocolloids with programmed three-dimensional shape and material composition. Nat. Mater. 2013, 12, 802–807. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.H.; Mark, A.G.; Alarcón-Correa, M.; Kim, I.; Oswald, P.; Lee, T.C.; Fischer, P. Dispersion and shape engineered plasmonic nanosensors. Nat. Commun. 2016, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sarkar, S.; Behunin, R.O.; Gibbs, J.G. Shape-Dependent, Chiro-optical Response of UV-Active, Nanohelix Metamaterials. Nano Lett. 2019, 19, 8089–8096. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.H.; Mark, A.G.; Fischer, P. Magnesium plasmonics for UV applications and chiral sensing. Chem. Commun. 2016, 52, 12179–12182. [Google Scholar] [CrossRef] [Green Version]

- Yin, X.; Schäferling, M.; Metzger, B.; Giessen, H. Interpreting Chiral Nanophotonic Spectra: The Plasmonic Born–Kuhn Model. Nano Lett. 2013, 13, 6238–6243. [Google Scholar] [CrossRef]

- Zhao, Y.; Askarpour, A.N.; Sun, L.; Shi, J.; Li, X.; Alù, A. Chirality detection of enantiomers using twisted optical metamaterials. Nat. Commun. 2017, 8, 6–13. [Google Scholar] [CrossRef]

- Decker, M.; Zhao, R.; Soukoulis, C.M.; Linden, S.; Wegener, M. Twisted split-ring-resonator photonic metamaterial with huge optical activity. Opt. Lett. 2010, 35, 1593–1595. [Google Scholar] [CrossRef] [Green Version]

- Decker, M.; Ruther, M.; Kriegler, C.E.; Zhou, J.; Soukoulis, C.M.; Linden, S.; Wegener, M. Strong optical activity from twisted-cross photonic metamaterials. Opt. Lett. 2009, 34, 2501–2503. [Google Scholar] [CrossRef]

- Dietrich, K.; Lehr, D.; Helgert, C.; Tünnermann, A.; Kley, E.-B. Circular Dichroism from Chiral Nanomaterial Fabricated by On-Edge Lithography. Adv. Mater. 2012, 24, OP321–OP325. [Google Scholar] [CrossRef]

- Dietrich, K.; Menzel, C.; Lehr, D.; Puffky, O.; Hübner, U.; Pertsch, T.; Tünnermann, A.; Kley, E.-B. Elevating optical activity: Efficient on-edge lithography of three-dimensional starfish metamaterial. Appl. Phys. Lett. 2014, 104, 193107. [Google Scholar] [CrossRef]

- Kuzyk, A.; Schreiber, R.; Fan, Z.; Pardatscher, G.; Roller, E.M.; Högele, A.; Simmel, F.C.; Govorov, A.O.; Liedl, T. DNA-based self-assembly of chiral plasmonic nanostructures with tailored optical response. Nature 2012, 483, 311–314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shen, X.; Song, C.; Wang, J.; Shi, D.; Wang, Z.; Liu, N.; Ding, B. Rolling Up Gold Nanoparticle-Dressed DNA Origami into Three-Dimensional Plasmonic Chiral Nanostructures. J. Am. Chem. Soc. 2012, 134, 146–149. [Google Scholar] [CrossRef] [PubMed]

- Lan, X.; Lu, X.; Shen, C.; Ke, Y.; Ni, W.; Wang, Q. Au Nanorod Helical Superstructures with Designed Chirality. J. Am. Chem. Soc. 2015, 137, 457–462. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.; Xu, L.; Xu, C.; Ma, W.; Kuang, H.; Wang, L.; Kotov, N.A. Self-Assembly of Chiral Nanoparticle Pyramids with Strong R/S Optical Activity. J. Am. Chem. Soc. 2012, 134, 15114–15121. [Google Scholar] [CrossRef]

- Shen, X.; Asenjo-Garcia, A.; Liu, Q.; Jiang, Q.; García de Abajo, F.J.; Liu, N.; Ding, B. Three-Dimensional Plasmonic Chiral Tetramers Assembled by DNA Origami. Nano Lett. 2013, 13, 2128–2133. [Google Scholar] [CrossRef]

- Golod, S.V.; Gayduk, A.E.; Kurus, N.N.; Kubarev, V.V.; Prinz, V.Y. 3D micro/nanoshaping of metal strip arrays by direct imprinting for chiral metasurfaces. Nanotechnology 2020, 31, 435302. [Google Scholar] [CrossRef]

- Zhang, M.; Pacheco-Peña, V.; Yu, Y.; Chen, W.; Greybush, N.J.; Stein, A.; Engheta, N.; Murray, C.B.; Kagan, C.R. Nanoimprinted Chiral Plasmonic Substrates with Three-Dimensional Nanostructures. Nano Lett. 2018, 18, 7389–7394. [Google Scholar] [CrossRef] [PubMed]

- Gansel, J.K.; Thiel, M.; Rill, M.S.; Decker, M.; Bade, K.; Saile, V.; von Freymann, G.; Linden, S.; Wegener, M. Gold Helix Photonic Metamaterial as Broadband Circular Polarizer. Science 2009, 325, 1513–1515. [Google Scholar] [CrossRef]

- Gansel, J.K.; Latzel, M.; Frölich, A.; Kaschke, J.; Thiel, M.; Wegener, M. Tapered gold-helix metamaterials as improved circular polarizers. Appl. Phys. Lett. 2012, 100, 23–26. [Google Scholar] [CrossRef]

- Kaschke, J.; Blume, L.; Wu, L.; Thiel, M.; Bade, K.; Yang, Z.; Wegener, M. A Helical Metamaterial for Broadband Circular Polarization Conversion. Adv. Opt. Mater. 2015, 3, 1411–1417. [Google Scholar] [CrossRef]

- Kaschke, J.; Wegener, M. Gold triple-helix mid-infrared metamaterial by STED-inspired laser lithography. Opt. Lett. 2015, 40, 3986–3989. [Google Scholar] [CrossRef] [PubMed]

- Thiel, M.; Rill, M.S.; Von Freymann, G.; Wegener, M. Three-dimensional bi-chiral photonic crystals. Adv. Mater. 2009, 21, 4680–4682. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Ho, J.; Ng, R.C.; Ng, R.J.H.; Hall-Chen, V.H.; Koay, E.H.H.; Dong, Z.; Liu, H.; Qiu, C.W.; et al. Structural color three-dimensional printing by shrinking photonic crystals. Nat. Commun. 2019, 10. [Google Scholar] [CrossRef] [Green Version]

- Bischoff, L.; Klingner, N.; Mazarov, P.; Pilz, W.; Meyer, F. Boron liquid metal alloy ion sources for special FIB applications. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2020, 042801. [Google Scholar] [CrossRef]

- Hentschel, M.; Karst, J.; Giessen, H. Tailored Optical Functionality by Combining Electron-Beam and Focused Gold-Ion Beam Lithography for Solid and Inverse Coupled Plasmonic Nanostructures. Adv. Opt. Mater. 2020, 8, 2000879. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manoccio, M.; Esposito, M.; Passaseo, A.; Cuscunà, M.; Tasco, V. Focused Ion Beam Processing for 3D Chiral Photonics Nanostructures. Micromachines 2021, 12, 6. https://doi.org/10.3390/mi12010006

Manoccio M, Esposito M, Passaseo A, Cuscunà M, Tasco V. Focused Ion Beam Processing for 3D Chiral Photonics Nanostructures. Micromachines. 2021; 12(1):6. https://doi.org/10.3390/mi12010006

Chicago/Turabian StyleManoccio, Mariachiara, Marco Esposito, Adriana Passaseo, Massimo Cuscunà, and Vittorianna Tasco. 2021. "Focused Ion Beam Processing for 3D Chiral Photonics Nanostructures" Micromachines 12, no. 1: 6. https://doi.org/10.3390/mi12010006

APA StyleManoccio, M., Esposito, M., Passaseo, A., Cuscunà, M., & Tasco, V. (2021). Focused Ion Beam Processing for 3D Chiral Photonics Nanostructures. Micromachines, 12(1), 6. https://doi.org/10.3390/mi12010006