Progress on Optical Fiber Biochemical Sensors Based on Graphene

Abstract

:1. Introduction

2. Graphene Synthesis Methods

2.1. Mechanical Exfoliation Method

2.2. Oxidation-Reduction (Redox) Method

2.3. Chemical Vapor Deposition (CVD) Method

2.4. Epitaxial Growth Method

3. The Sensing Properties and Mechanism of Graphene-Based Optical Fiber

3.1. Sensing Properties of Graphene

3.1.1. Optical Absorption Characteristics

3.1.2. Photoluminescence Characteristics

3.1.3. Optical Conductivity

3.1.4. Surface Plasmon Properties

3.2. The Sensing Mechanism of Graphene-Based Optical Fiber

3.2.1. Kubo Model of Graphene

3.2.2. Sensing Mechanism-SPR and Evanescent Field

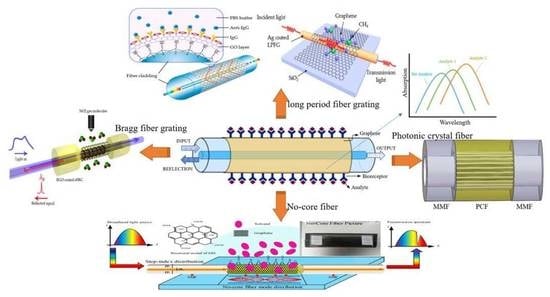

4. Progress of Graphene Optical Fiber Biochemical Sensor

4.1. Graphene Fiber-Grating Sensor

4.1.1. Graphene Long-Period Fiber-Grating Sensor

4.1.2. Graphene Bragg Fiber-Grating Sensor

4.2. Graphene No-Core Fiber Sensor

4.3. Graphene Photonic Crystal Fiber Sensor

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [Green Version]

- Choi, W.; Lahiri, I.; Seelaboyina, R.; Kang, Y.S. Synthesis of Graphene and Its Applications: A Review. Crit. Rev. Solid State Mater. Sci. 2010, 35, 52–71. [Google Scholar] [CrossRef]

- Chen, K.; Lu, G.; Chang, J.; Mao, S.; Yu, K.; Cui, S.; Chen, J. Hg(II) Ion Detection Using Thermally Reduced Graphene Oxide Decorated with Functionalized Gold Nanoparticles. Anal. Chem. 2012, 84, 4057–4062. [Google Scholar] [CrossRef] [PubMed]

- Novodchuk, I.; Bajcsy, M.; Yavuz, M. Graphene-based field effect transistor biosensors for breast cancer detection: A review on biosensing strategies. Carbon 2021, 172, 431–453. [Google Scholar] [CrossRef]

- Geim, A.K. Graphene: Status and Prospects. Science 2009, 324, 1530–1534. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wassei, J.K.; Kaner, R.B. Graphene, a promising transparent conductor. Mater. Today 2010, 13, 52–59. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, B.-T. Surface plasmon resonance biosensor based on graphene oxide/silver coated polymer cladding silica fiber. Sens. Actuators B Chem. 2018, 275, 332–338. [Google Scholar] [CrossRef]

- Rahman, M.S.; Anower, M.S.; Abdulrazak, L.F. Utilization of a phosphorene-graphene/TMDC heterostructure in a surface plasmon resonance-based fiber optic biosensor. Photonics Nanostruct. Fundam. Appl. 2019, 35, 100711. [Google Scholar] [CrossRef]

- Rahman, M.S.; Noor, S.S.; Anower, M.S.; Abdulrazak, L.F.; Rahman, M.M.; Rikta, K.A. Design and numerical analysis of a graphene-coated fiber-optic SPR biosensor using tungsten disulfide. Photonics Nanostruct. Fundam. Appl. 2019, 33, 29–35. [Google Scholar] [CrossRef]

- Hong, X.D.; Zheng, H.R.; Liang, D. Stable electron field emission from graphene/hexagonal boron nitride hybrid structure. Mater. Lett. 2020, 277, 128356. [Google Scholar] [CrossRef]

- Hossain, M.B.; Islam, M.M.; Abdulrazak, L.F.; Rana, M.M.; Akib, T.B.A.; Hassan, M. Graphene-Coated Optical Fiber SPR Biosensor for BRCA1 and BRCA2 Breast Cancer Biomarker Detection: A Numerical Design-Based Analysis. Photonic Sens. 2020, 10, 67–79. [Google Scholar] [CrossRef] [Green Version]

- Song, G.; Luo, S.; Zhang, J.; Zhang, M.; Qiu, G.; Meng, A.; Lin, Y.; Li, Z. Template-free one-step synthesis of the multi-layer carbon or stacked graphene sheets coessentially coating N-doped graphene tubes and their field emission and photoluminescence properties. J. Alloys Compd. 2020, 829, 154411. [Google Scholar] [CrossRef]

- Dusane, P.R.; Gavhane, D.S.; Kolhe, P.S.; Bankar, P.K.; Thombare, B.R.; Lole, G.S.; Kale, B.B.; More, M.A.; Patil, S.I. Controlled decoration of palladium (Pd) nanoparticles on graphene nanosheets and its superior field emission behavior. Mater. Res. Bull. 2021, 140, 111335. [Google Scholar] [CrossRef]

- Feng, D.; Niu, Z.; Yang, J.; Xu, W.; Liu, S.; Mao, X.; Li, X. Flexible artificial synapse with relearning function based on ion gel-graphene FET. Nano Energy 2021, 90, 106526. [Google Scholar] [CrossRef]

- Xia, Y.; Sun, Y.; Li, H.; Chen, S.; Zhu, T.; Wang, G.; Man, B.; Pan, J.; Yang, C. Plasma treated graphene FET sensor for the DNA hybridization detection. Talanta 2021, 223, 121766. [Google Scholar] [CrossRef]

- Singh, P.; Sohi, P.A.; Kahrizi, M. In silico design and analysis of Pt functionalized graphene-based FET sensor for COVID-19 biomarkers: A DFT coupled FEM study. Phys. E Low Dimens. Syst. Nanostruct. 2022, 135, 114972. [Google Scholar] [CrossRef]

- Xu, Y.; Xiong, M.; Yan, H. A portable optical fiber biosensor for the detection of zearalenone based on the localized surface plasmon resonance. Sens. Actuators B Chem. 2021, 336, 129752. [Google Scholar] [CrossRef]

- Yin, M.-J.; Gu, B.; An, Q.-F.; Yang, C.; Guan, Y.L.; Yong, K.-T. Recent development of fiber-optic chemical sensors and biosensors: Mechanisms, materials, micro/nano-fabrications and applications. Coord. Chem. Rev. 2018, 376, 348–392. [Google Scholar] [CrossRef]

- Molardi, C.; Beisenova, A.; Issatayeva, A.; Korganbayev, S.; Blanc, W.; Tosi, D. Parallel multiplexing in Optical Backscatter Reflectometry by the use of nano-particles doped optical fiber. Opt. Fibers Sens. Med. Diagn. Treat. Appl. XIX 2019, 28, 10872. [Google Scholar]

- Sypabekova, M.; Korganbayev, S.; Gonzalez-Vila, A.; Caucheteur, C.; Shaimerdenova, M.; Ayupova, T.; Bekmurzayeva, A.; Vangelista, L.; Tosi, D. Functionalized etched tilted fiber Bragg grating aptasensor for label-free protein detection. Biosens. Bioelectron. 2019, 146, 111765. [Google Scholar] [CrossRef]

- Ribaut, C.; Loyez, M.; Larrieu, J.-C.; Chevineau, S.; Lambert, P.; Remmelink, M.; Wattiez, R.; Caucheteur, C. Cancer biomarker sensing using packaged plasmonic optical fiber gratings: Towards in vivo diagnosis. Biosens. Bioelectron. 2017, 92, 449–456. [Google Scholar] [CrossRef]

- Krishnan, Y.; Simmel, F.C. Nucleic Acid Based Molecular Devices. Angew. Chem. Int. Ed. 2011, 50, 3124–3156. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, R.C.; Ortiz, C.; Berenguer-Murcia, A.; Torres, R.; Fernandez-Lafuente, R. Modifying enzyme activity and selectivity by immobilization. Chem. Soc. Rev. 2013, 42, 6290–6307. [Google Scholar] [CrossRef] [PubMed]

- Carter, P.J.; Lazar, G.A. Next generation antibody drugs: Pursuit of the ‘high-hanging fruit’. Nat. Rev. Drug Discov. 2018, 17, 197–223. [Google Scholar] [CrossRef] [PubMed]

- Jhunjhunwala, S.; Hammer, C.; Delamarre, L. Antigen presentation in cancer: Insights into tumour immunogenicity and immune evasion. Nat. Rev. Cancer 2021, 21, 298–312. [Google Scholar] [CrossRef] [PubMed]

- Sypabekova, M.; Aitkulov, A.; Blanc, W.; Tosi, D. Reflector-less nanoparticles doped optical fiber biosensor for the detection of Case thrombin. Biosens. Bioelectron. 2020, 165, 112365. [Google Scholar] [CrossRef]

- Wu, L.; Chu, H.S.; Koh, W.S.; Li, E.P. Highly sensitive graphene biosensors based on surface plasmon resonance. Opt. Express 2010, 18, 14395–14400. [Google Scholar] [CrossRef]

- Xia, F.; Wang, H.; Xiao, D.; Dubey, M.; Ramasubramaniam, A. Two-dimensional material nanophotonics. Nat. Photonics 2014, 8, 899–907. [Google Scholar] [CrossRef]

- Llatser, I.; Kremers, C.; Cabellos-Aparicio, A.; Jornet, J.M.; Alarcon, E.; Chigrin, D.N. Graphene-based nano-patch antenna for terahertz radiation. Photonics Nanostruct. Fundam. Appl. 2012, 10, 353–358. [Google Scholar] [CrossRef] [Green Version]

- Suvarnaphaet, P.; Pechprasarn, S. Graphene-Based Materials for Biosensors: A Review. Sensors 2017, 17, 2161. [Google Scholar] [CrossRef] [Green Version]

- Andronescu, C.; Schuhmann, W. Graphene-based field effect transistors as biosensors. Curr. Opin. Electrochem. 2017, 3, 11–17. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; Xing, F. Graphene Optical Biosensors. Int. J. Mol. Sci. 2019, 20, 2461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hernaez, M.; Zamarreno, C.R.; Melendi-Espina, S.; Bird, L.R.; Mayes, A.G.; Arregui, F.J. Optical Fibre Sensors Using Graphene-Based Materials: A Review. Sensors 2017, 17, 155. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- An, N.; Qin, C.; Li, Y.; Tan, T.; Yuan, Z.; Zhang, H.; Wu, Y.; Yao, B.; Rao, Y. Graphene-Fiber Biochemical Sensors: Principles, Implementations, and Advances. Photonic Sens. 2021, 11, 123–139. [Google Scholar] [CrossRef]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically Thin MoS2: A New Direct-Gap Semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef] [Green Version]

- Tang, Q.; Zhou, Z. Graphene-analogous low-dimensional materials. Prog. Mater. Sci. 2013, 58, 1244–1315. [Google Scholar] [CrossRef]

- Kime, G.; Leontiadou, M.A.; Brent, J.R.; Savjani, N.; O’Brien, P.; Binks, D. Ultrafast Charge Dynamics in Dispersions of Monolayer MoS2 Nanosheets. J. Phys. Chem. C 2017, 121, 22415–22421. [Google Scholar] [CrossRef]

- Mannix, A.J.; Kiraly, B.; Hersam, M.C.; Guisinger, N.P. Synthesis and chemistry of elemental 2D materials. Nat. Rev. Chem. 2017, 1, 13751894. [Google Scholar] [CrossRef]

- Geng, D.; Yang, H.Y. Recent Advances in Growth of Novel 2D Materials: Beyond Graphene and Transition Metal Dichalcogenides. Adv. Mater. 2018, 30, 1800865. [Google Scholar] [CrossRef]

- Guo, B.; Xiao, Q.-l.; Wang, S.-h.; Zhang, H. 2D Layered Materials: Synthesis, Nonlinear Optical Properties, and Device Applications. Laser Photonics Rev. 2019, 13, 1800327. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Liu, H.; Zhou, S.; Li, J.; Pan, C.; Liu, Y. Preparation of graphene via modified redox method and its electronic performance. Ferroelectrics 2019, 551, 251–258. [Google Scholar] [CrossRef]

- Staudenmaier, L. Verfahren zur Darstellung der Graphitsäure. Ber. Dtsch. Chem. Ges. 1899, 32, 1394–1399. [Google Scholar] [CrossRef] [Green Version]

- Brodie, B.C. XIII. On the atomic weight of graphite. Philos. Trans. R. Soc. Lond. 1859, 149, 249–259. [Google Scholar] [CrossRef] [Green Version]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of Graphitic Oxide. ACS Publ. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Song, J.; Kang, S.W.; Lee, Y.W.; Park, Y.; Kim, J.-H.; Han, S.W. Regulating the Catalytic Function of Reduced Graphene Oxides Using Capping Agents for Metal-Free Catalysis. ACS Appl. Mater. Interfaces 2017, 9, 1692–1701. [Google Scholar] [CrossRef]

- Lin, L.; Deng, B.; Sun, J.; Peng, H.; Liu, Z. Bridging the Gap between Reality and Ideal in Chemical Vapor Deposition Growth of Graphene. Chem. Rev. 2018, 118, 9281–9343. [Google Scholar] [CrossRef]

- Yu, Q.; Lian, J.; Siriponglert, S.; Li, H.; Chen, Y.P.; Pei, S.-S. Graphene segregated on Ni surfaces and transferred to insulators. Appl. Phys. Lett. 2008, 93, 113103. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhang, L.; Zhou, C. Review of chemical vapor deposition of graphene and related applications. Acc. Chem. Res. 2013, 46, 2329–2339. [Google Scholar] [CrossRef]

- Reina, A.; Jia, X.; Ho, J.; Nezich, D.; Son, H.; Bulovic, V.; Dresselhaus, M.S.; Kong, J. Large Area, Few-Layer Graphene Films on Arbitrary Substrates by Chemical Vapor Deposition. Nano Lett. 2009, 9, 30–35. [Google Scholar] [CrossRef]

- Kalbac, M.; Frank, O.; Kavan, L. The control of graphene double-layer formation in copper-catalyzed chemical vapor deposition. Carbon 2012, 50, 3682–3687. [Google Scholar] [CrossRef] [Green Version]

- Addou, R.; Dahal, A.; Sutter, P.; Batzill, M. Monolayer graphene growth on Ni(111) by low temperature chemical vapor deposition. Appl. Phys. Lett. 2012, 100, 021601. [Google Scholar] [CrossRef]

- Berger, C.; Song, Z.; Li, X.; Wu, X.; Brown, N.; Naud, C.; Mayou, D.; Li, T.; Hass, J.; Marchenkov, A.N.; et al. Electronic confinement and coherence in patterned epitaxial graphene. Science 2006, 312, 1191–1196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- First, P.N.; de Heer, W.A.; Seyller, T.; Berger, C.; Stroscio, J.A.; Moon, J.-S. Epitaxial Graphenes on Silicon Carbide. MRS Bull. 2010, 35, 296–305. [Google Scholar] [CrossRef] [Green Version]

- Zangwill, A.; Vvedensky, D.D. Novel Growth Mechanism of Epitaxial Graphene on Metals. Nano Lett. 2011, 11, 2092–2095. [Google Scholar] [CrossRef] [Green Version]

- Berger, C.; Song, Z.; Li, T.; Li, X.; Ogbazghi, A.Y.; Feng, R.; Dai, Z.; Marchenkov, A.N.; Conrad, E.H.; First, P.N.; et al. Ultrathin Epitaxial Graphite: 2D Electron Gas Properties and a Route toward Graphene-based Nanoelectronics. J. Phys. Chem. B 2004, 108, 19912–19916. [Google Scholar] [CrossRef] [Green Version]

- Chauhan, N.; Maekawa, T.; Kumar, D.N.S. Graphene based biosensors—Accelerating medical diagnostics to new-dimensions. J. Mater. Res. 2017, 32, 2860–2882. [Google Scholar] [CrossRef] [Green Version]

- Deng, X.; Tang, H.; Jiang, J. Recent progress in graphene-material-based optical sensors. Anal. Bioanal. Chem. 2014, 406, 6903–6916. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Bonaccorso, F.; Fal’ko, V.; Novoselov, K.S.; Roche, S.; Boggild, P.; Borini, S.; Koppens, F.H.L.; Palermo, V.; Pugno, N.; et al. Science and technology roadmap for graphene, related two-dimensional crystals, and hybrid systems. Nanoscale 2015, 7, 4598–4810. [Google Scholar]

- Feng, L.; Wu, L.; Qu, X. New Horizons for Diagnostics and Therapeutic Applications of Graphene and Graphene Oxide. Adv. Mater. 2013, 25, 168–186. [Google Scholar] [CrossRef]

- Morales-Narvaez, E.; Merkoci, A. Graphene Oxide as an Optical Biosensing Platform. Adv. Mater. 2012, 24, 3298–3308. [Google Scholar] [CrossRef] [PubMed]

- Xing, F.; Meng, G.-X.; Zhang, Q.; Pan, L.-T.; Wang, P.; Liu, Z.-B.; Jiang, W.-S.; Chen, Y.; Tian, J.-G. Ultrasensitive Flow Sensing of a Single Cell Using Graphene-Based Optical Sensors. Nano Lett. 2014, 14, 3563–3569. [Google Scholar] [CrossRef]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine structure constant defines visual transparency of graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ye, Q.; Wang, J.; Liu, Z.; Deng, Z.-C.; Kong, X.-T.; Xing, F.; Chen, X.-D.; Zhou, W.-Y.; Zhang, C.-P.; Tian, J.-G. Polarization-dependent optical absorption of graphene under total internal reflection. Appl. Phys. Lett. 2013, 102, 021912. [Google Scholar] [CrossRef]

- Xing, F.; Liu, Z.-B.; Deng, Z.-C.; Kong, X.-T.; Yan, X.-Q.; Chen, X.-D.; Ye, Q.; Zhang, C.-P.; Chen, Y.-S.; Tian, J.-G. Sensitive Real-Time Monitoring of Refractive Indexes Using a Novel Graphene-Based Optical Sensor. Sci. Rep. 2012, 2, 908. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huynh Vinh, P.; Nguyen Ngoc, H. Nonlinear optical absorption in graphene via two-photon absorption process. Opt. Commun. 2015, 344, 12–16. [Google Scholar]

- Ding, L.Y.; Xu, C.; Xia, Z.L.; Xu, B.; Huang, J. Controlling polarization-dependent optical absorption of graphene through its thickness. Optik 2017, 137, 59–64. [Google Scholar] [CrossRef]

- Pirruccio, G.; Martin Moreno, L.; Lozano, G.; Rivas, J.G. Coherent and Broadband Enhanced Optical Absorption in Graphene. ACS Nano 2013, 7, 4810–4817. [Google Scholar] [CrossRef]

- Cai, Y.; Zhu, J.; Liu, Q.H. Tunable enhanced optical absorption of graphene using plasmonic perfect absorbers. Appl. Phys. Lett. 2015, 106, 043105. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Cheng, Z.; Shu, C.; Tsang, H.K. Optical Absorption in Graphene-on-Silicon Nitride Microring Resonators. IEEE Photonics Technol. Lett. 2015, 27, 1765–1767. [Google Scholar] [CrossRef]

- Selvakumar, N.; Biswas, A.; Krupanidhi, S.B.; Barshilia, H.C. Enhanced optical absorption of graphene-based heat mirror with tunable spectral selectivity. Sol. Energy Mater. Sol. Cells 2018, 186, 149–153. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, C.; Xiao, S. Gain-assisted critical coupling for enhanced optical absorption in graphene. Nanotechnology 2021, 32, 205202. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Liu, X.-K.; Gao, F. Chapter 1—Fundamentals of Solar Cells and Light-Emitting Diodes. In Advanced Nanomaterials for Solar Cells and Light Emitting Diodes; Gao, F., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–35. [Google Scholar]

- Nemade, K.R.; Waghuley, S.A. in situ synthesis of graphene/SnO2 quantum dots composites for chemiresistive gas sensing. Mater. Sci. Semicond. Processing 2014, 24, 126–131. [Google Scholar] [CrossRef]

- Sk, M.A.; Ananthanarayanan, A.; Huang, L.; Lim, K.H.; Chen, P. Revealing the tunable photoluminescence properties of graphene quantum dots. J. Mater. Chem. C 2014, 2, 6954–6960. [Google Scholar] [CrossRef]

- Chung, S.; Revia, R.A.; Zhang, M. Graphene Quantum Dots and Their Applications in Bioimaging, Biosensing, and Therapy. Adv. Mater. 2021, 33, e1904362. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Li, X.-g.; Zhou, X.; Zhang, Y.-n. Review on the graphene based optical fiber chemical and biological sensors. Sens. Actuators B Chem. 2016, 231, 324–340. [Google Scholar] [CrossRef]

- Houmad, M.; Zaari, H.; Benyoussef, A.; El Kenz, A.; Ez-Zahraouy, H. Optical conductivity enhancement and band gap opening with silicon doped graphene. Carbon 2015, 94, 1021–1027. [Google Scholar] [CrossRef]

- Nirmalraj, P.N.; Lutz, T.; Kumar, S.; Duesberg, G.S.; Boland, J.J. Nanoscale Mapping of Electrical Resistivity and Connectivity in Graphene Strips and Networks. Nano Lett. 2011, 11, 16–22. [Google Scholar] [CrossRef]

- Dash, J.N.; Jha, R. Graphene-Based Birefringent Photonic Crystal Fiber Sensor Using Surface Plasmon Resonance. IEEE Photonics Technol. Lett. 2014, 26, 1092–1095. [Google Scholar] [CrossRef]

- Yang, H.; Liu, M.; Chen, Y.; Guo, L.; Xiao, G.; Liu, H.; Li, J.; Yuan, L. Highly Sensitive Graphene-Au Coated Plasmon Resonance PCF Sensor. Sensors 2021, 21, 818. [Google Scholar] [CrossRef]

- Jiang, X.Q.; Liu, Z.B.; Tian, J.G. Progress in Optical Properties and Applications of Graphene. Prog. Phys. 2017, 37, 22–36. [Google Scholar]

- Li, Z.Q.; Henriksen, E.A.; Jiang, Z.; Hao, Z.; Martin, M.C.; Kim, P.; Stormer, H.L.; Basov, D.N. Dirac charge dynamics in graphene by infrared spectroscopy. Nat. Phys. 2008, 4, 532–535. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Zhang, Y.; Tian, C.; Girit, C.; Zettl, A.; Crommie, M.; Shen, Y.R. Gate-variable optical transitions in graphene. Science 2008, 320, 206–209. [Google Scholar] [CrossRef] [PubMed]

- Bao, Q.; Loh, K.P. Graphene Photonics, Plasmonics, and Broadband Optoelectronic Devices. ACS Nano 2012, 6, 3677–3694. [Google Scholar] [CrossRef] [PubMed]

- Jiao, S.; Gu, S.; Yang, H.; Fang, H.; Xu, S. High y sensitive dual-core photonic crystal fiber based on a surface plasmon resonance sensor with a silver nano-continuous grating. Appl. Opt. 2018, 57, 8350–8358. [Google Scholar] [CrossRef]

- Gusynin, V.P.; Sharapov, S.G. Transport of Dirac quasiparticles in graphene: Hall and optical conductivities. Phys. Rev. 2006, 73, 245411. [Google Scholar] [CrossRef] [Green Version]

- Falkovsky, L.A.; Pershoguba, S.S. Optical far-infrared properties of a graphene monolayer and multilayer. Phys. Rev. B 2007, 76, 153410. [Google Scholar] [CrossRef] [Green Version]

- Xiao, G.; Xiuhua, H.; Yang, H.; Dou, W.; Xu, J.; Wei, Q.; Li, H.; Zhang, F.; Li, Q.; Chen, Y.; et al. Plasma Refractive Index Sensor with Tunable Cross Tie-Shaped Graphene Array Structure. Acta Opt. Sin. 2019, 39, 431–439. [Google Scholar]

- Xu, Y.; Cottenden, A.; Jones, N.B. A theoretical evaluation of fibre-optic evanescent wave absorption in spectroscopy and sensors. Opt. Lasers Eng. 2006, 44, 93–101. [Google Scholar] [CrossRef]

- Sharma, A.K.; Gupta, J. Graphene based chalcogenide fiber-optic evanescent wave sensor for detection of hemoglobin in human blood. Opt. Fiber Technol. 2018, 41, 125–130. [Google Scholar] [CrossRef]

- HaiKun, Q.; Min, Z.; YuLiang, L.; YanBiao, T. Summary of research progress of fiber optic grating biosensors. Laser Mag. 2008, 5, 1–3. [Google Scholar]

- Liu, C.; Cai, Q.; Xu, B.; Zhu, W.; Zhang, L.; Zhao, J.; Chen, X. Graphene oxide functionalized long period grating for ultrasensitive label-free immunosensing. Biosens. Bioelectron. 2017, 94, 200–206. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, W.; Nong, J.; Zhang, G.; Tang, L.; Jiang, X.; Chen, N.; Luo, S.; Lan, G.; Zhu, Y. Graphene-Based Long-Period Fiber Grating Surface Plasmon Resonance Sensor for High-Sensitivity Gas Sensing. Sensors 2017, 17, 2. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Ren, Z.; Kong, D.; Hu, B.; He, Z. Highly sensitive label-free biosensor based on graphene-oxide functionalized micro-tapered long period fiber grating. Opt. Mater. 2020, 109, 110253. [Google Scholar] [CrossRef]

- Esposito, F.; Sansone, L.; Srivastava, A.; Baldini, F.; Campopiano, S.; Chiavaioli, F.; Giordano, M.; Giannetti, A.; Iadicicco, A. Long period grating in double cladding fiber coated with graphene oxide as high-performance optical platform for biosensing. Biosens. Bioelectron. 2021, 172, 112747. [Google Scholar] [CrossRef] [PubMed]

- Sridevi, S.; Vasu, K.S.; Jayaraman, N.; Asokan, S.; Sood, A.K. Optical bio-sensing devices based on etched fiber Bragg gratings coated with carbon nanotubes and graphene oxide along with a specific dendrimer. Sens. Actuators B Chem. 2014, 195, 150–155. [Google Scholar]

- Yao, B.C.; Wu, Y.; Webb, D.J.; Zhou, J.H.; Rao, Y.J.; Pospori, A.; Yu, C.B.; Gong, Y.; Chen, Y.F.; Wang, Z.G. Graphene-Based D-Shaped Polymer FBG for Highly Sensitive Erythrocyte Detection. IEEE Photonics Technol. Lett. 2015, 27, 2399–2402. [Google Scholar] [CrossRef]

- Sridevi, S.; Vasu, K.S.; Bhat, N.; Asokan, S.; Sood, A.K. Ultra sensitive NO2 gas detection using the reduced graphene oxide coated etched fiber Bragg gratings. Sens. Actuators B Chem. 2016, 223, 481–486. [Google Scholar] [CrossRef]

- Wu, Q.; Semenova, Y.; Wang, P.; Farrell, G. High sensitivity SMS fiber structure based refractometer—Analysis and experiment. Opt. Express 2011, 19, 7937–7944. [Google Scholar] [CrossRef]

- Xiao, G.; Zhang, K.; Yang, Y.; Yang, H.; Guo, L.; Li, J.; Yuan, L. Graphene Oxide Sensitized No-Core Fiber Step-Index Distribution Sucrose Sensor. Photonics 2020, 7, 101. [Google Scholar] [CrossRef]

- Ortigosa-Blanch, A.; Knight, J.C.; Wadsworth, W.J.; Arriaga, J.; Mangan, B.J.; Birks, T.A.; Russell, P.S. Highly birefringent photonic crystal fibers. Opt. Lett. 2000, 25, 1325–1327. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Lu, Y.; Liu, B.; Yao, J. Analysis of Graphene-Based Photonic Crystal Fiber Sensor Using Birefringence and Surface Plasmon Resonance. Plasmonics 2017, 12, 489–496. [Google Scholar] [CrossRef]

- Wang, F.; Sun, Z.; Liu, C.; Sun, T.; Chu, P.K. A Highly Sensitive Dual-Core Photonic Crystal Fiber Based on a Surface Plasmon Resonance Biosensor with Silver-Graphene Layer. Plasmonics 2017, 12, 1847–1853. [Google Scholar] [CrossRef]

- Rifat, A.A.; Mahdiraji, G.A.; Ahmed, R.; Chow, D.M.; Sua, Y.M.; Shee, Y.G.; Adikan, F.R.M. Copper-Graphene-Based Photonic Crystal Fiber Plasmonic Biosensor. IEEE Photonics J. 2016, 8, 1–8. [Google Scholar] [CrossRef]

- Lou, J.; Cheng, T.; Li, S.; Zhang, X. Surface plasmon resonance photonic crystal fiber biosensor based on gold-graphene layers. Opt. Fiber Technol. 2019, 50, 206–211. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, B. Sensitivity enhanced SPR immunosensor based on graphene oxide and SPA co-modified photonic crystal fiber. Opt. Laser Technol. 2018, 107, 210–215. [Google Scholar] [CrossRef]

- Guo, C.-Y.; Wang, D.; Mu, C.-L. Progress on Optical Fiber Sensors Based on Graphene/Graphene Oxide. Laser Optoelectron. Prog. 2020, 57, 31–43. [Google Scholar]

- Tong, K.; Wang, F.; Wang, M.; Dang, P.; Wang, Y.; Sun, J. D-Shaped photonic crystal fiber biosensor based on silver-graphene. Optik 2018, 168, 467–474. [Google Scholar] [CrossRef]

- Esfahani Monfared, Y.; Qasymeh, M. Plasmonic Biosensor for Low-Index Liquid Analyte Detection Using Graphene-Assisted Photonic Crystal Fiber. Plasmonics 2021, 16, 881–889. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhou, L.; Qiao, D.; Liu, M.; Yang, H.; Meng, C.; Miao, T.; Xue, J.; Yao, Y. Progress on Optical Fiber Biochemical Sensors Based on Graphene. Micromachines 2022, 13, 348. https://doi.org/10.3390/mi13030348

Zhang Y, Zhou L, Qiao D, Liu M, Yang H, Meng C, Miao T, Xue J, Yao Y. Progress on Optical Fiber Biochemical Sensors Based on Graphene. Micromachines. 2022; 13(3):348. https://doi.org/10.3390/mi13030348

Chicago/Turabian StyleZhang, Yani, Lei Zhou, Dun Qiao, Mengyin Liu, Hongyan Yang, Cheng Meng, Ting Miao, Jia Xue, and Yiming Yao. 2022. "Progress on Optical Fiber Biochemical Sensors Based on Graphene" Micromachines 13, no. 3: 348. https://doi.org/10.3390/mi13030348

APA StyleZhang, Y., Zhou, L., Qiao, D., Liu, M., Yang, H., Meng, C., Miao, T., Xue, J., & Yao, Y. (2022). Progress on Optical Fiber Biochemical Sensors Based on Graphene. Micromachines, 13(3), 348. https://doi.org/10.3390/mi13030348