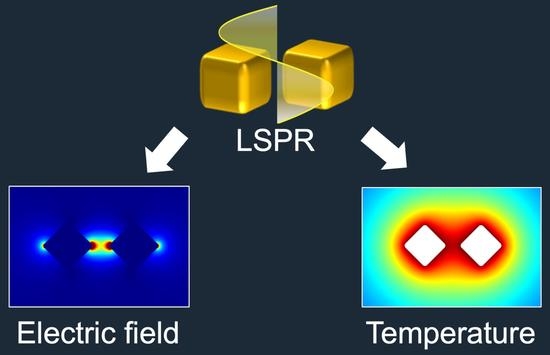

Gap Effect on Electric Field Enhancement and Photothermal Conversion in Gold Nanostructures

Abstract

:1. Introduction

2. Numerical Simulation

2.1. Computational Model

2.2. Electric and Temperature Fields Calculation

2.3. Boundary Conditions

3. Results and Discussion

3.1. Electric Field Enhancement

3.2. Temperature Field

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Yoo, H.; Shin, J.; Sim, J.; Cho, H.; Hong, S. Reusable surface plasmon resonance biosensor chip for the detection of H1N1 influenza virus. Biosens. Bioelectron. 2020, 168, 112561. [Google Scholar] [CrossRef] [PubMed]

- Heller, M.J. DNA microarray technology: Devices, systems, and applications. Annu. Rev. Biomed. Eng. 2002, 4, 129–153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peng, T.; Li, X.; Li, K.; Nie, Z.; Tan, W. DNA-modulated plasmon resonance: Methods and optical applications. ACS Appl. Mater. Interfaces 2020, 12, 14741–14760. [Google Scholar] [CrossRef] [PubMed]

- Bussy, C.; Ali-Boucetta, H.; Kostarelos, K. Safety considerations for graphene: Lessons learnt from carbon nanotubes. Acc. Chem. Res. 2013, 46, 692–701. [Google Scholar] [CrossRef]

- Saikia, J.; Narzary, B.; Roy, S.; Bordoloi, M.; Saikia, B.K. Nanominerals, fullerene aggregates, and hazardous elements in coal and coal combustion-generated aerosols: An environmental and toxicological assessment. Chemosphere 2016, 164, 84–91. [Google Scholar] [CrossRef]

- Li, Y.C.; Xin, H.B.; Lei, H.X.; Liu, L.L.; Li, Y.Z.; Li, B.J. Manipulation and detection of single nanoparticles and biomolecules by a photonic nanojet. Light Sci. Appl. 2016, 5, e16176. [Google Scholar] [CrossRef]

- Liu, L.; Chen, K.; Xiang, N.; Ni, Z. Dielectrophoretic manipulation of nanomaterials: A review. Electrophoresis 2019, 40, 873–889. [Google Scholar] [CrossRef]

- Okada, K.; Kodama, K.; Yamamoto, K.; Motosuke, M. Accumulation mechanism of nanoparticles around photothermally generated surface bubbles. J. Nanopart. Res. 2021, 23, 188. [Google Scholar] [CrossRef]

- Tian, Z.; Yang, S.; Huang, P.-H.; Wang, Z.; Zhang, P.; Gu, Y.; Bachman, H.; Chen, C.; Wu, M.; Xie, Y.; et al. Wave number-spiral acoustic tweezers for dynamic and reconfigurable manipulation of particles and cells. Sci. Adv. 2019, 5, 6062. [Google Scholar] [CrossRef] [Green Version]

- Marzo, A.; Drinkwater, B.W. Holographic acoustic tweezers. Proc. Natl. Acad. Sci. USA 2019, 116, 84–89. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Ho, C.; Tsatskis, Y.; Law, J.; Zhang, Z.; Zhu, M.; Dai, C.; Wang, F.; Tan, M.; Hopyan, S.; et al. Intracellular manipulation and measurement with multipole magnetic tweezers. Sci. Robot. 2019, 4, 6180. [Google Scholar] [CrossRef] [PubMed]

- Liang, L.; Xuan, X. Diamagnetic particle focusing using ferromicrofluidics with a single magnet. Microfluid. Nanofluid. 2012, 13, 637. [Google Scholar] [CrossRef]

- Shoji, T.; Tsuboi, Y. Plasmonic optical tweezers toward molecular manipulation: Tailoring plasmonic nanostructure, light source, and resonant trapping. J. Phys. Chem. Lett. 2014, 5, 2957–2967. [Google Scholar] [CrossRef] [PubMed]

- Vigolo, D.; Rusconi, R.; Stone, H.A.; Piazza, R. Thermophoresis: Microfluidics characterization and separation. Soft Matter 2010, 6, 3489–3493. [Google Scholar] [CrossRef]

- Huft, P.R.; Kolbow, J.D.; Thweatt, J.T.; Lindquist, N.C. Holographic Plasmonic nanotweezers for dynamic trapping and manipulation. Nano Lett. 2017, 17, 7920–7925. [Google Scholar] [CrossRef]

- Tsuji, T.; Saita, S.; Kawano, S. Dynamic pattern formation of microparticles in a uniform flow by an on-chip thermophoretic separation device. Phys. Rev. Appl. 2018, 9, 024035. [Google Scholar] [CrossRef]

- Braun, M.; Cichos, F. Optically controlled thermophoretic trapping of single nano-bjects. ACS Nano 2013, 7, 11200–11208. [Google Scholar] [CrossRef]

- Zhang, Y.; Min, C.; Dou, X.; Wang, X.; Urbach, H.P.; Somekh, M.G.; Yuan, X. Plasmonic tweezers: For nanoscale optical trapping and beyond. Light Sci. Appl. 2021, 10, 59. [Google Scholar] [CrossRef]

- Grabar, K.C.; Allison, K.J.; Baker, B.E.; Bright, R.M.; Brown, K.R.; Freeman, R.G.; Fox, A.P.; Keating, C.D.; Musick, M.D.; Natan, M.J. Two-dimensional arrays of colloidal gold particles: A flexible approach to macroscopic metal surfaces. Langmuir 1996, 12, 2353–2361. [Google Scholar] [CrossRef]

- Ueno, K.; Misawa, H. Spectral properties and electromagnetic field enhancement effects on nano-engineered metallic nanoparticles. Phys. Chem. Chem. Phys. 2013, 15, 4093–4099. [Google Scholar] [CrossRef]

- Su, M.N.; Sun, Q.; Ueno, K.; Chang, W.S.; Misawa, H.; Link, S. Optical characterization of gold nanoblock dimers: From capacitive coupling to charge transfer plasmons and rod modes. J. Phys. Chem. C 2018, 122, 18005–18011. [Google Scholar] [CrossRef]

- Yaraki, M.T.; Rezaei, S.D.; Tan, Y.N. Simulation guided design of silver nanostructures for plasmon-enhanced fluorescence, singlet oxygen generation and SERS applications. Phys. Chem. Chem. Phys. 2020, 22, 5673–5687. [Google Scholar] [CrossRef] [PubMed]

- Baffou, G.; Quidant, R.; Abajo, F.J.G.d. Nanoscale control of optical heating in complex plasmonic systems. ACS Nano 2010, 4, 709–716. [Google Scholar] [CrossRef] [PubMed]

- Pathak, N.K.; Sarathi, P. Study of thermoplasmonic properties of gold nanodimer in visible -infrared region of electromagnetic spectrum. Nano Exp. 2021, 2, 040007. [Google Scholar] [CrossRef]

- Rakić, D.A.; Djurišić, B.A.; Elazar, M.J.; Majewski, L.M. Optical properties of metallic films for vertical-cavity optoelectronic devices. Appl. Opt. 1998, 37, 5271–5283. [Google Scholar] [CrossRef]

- Dhawan, A.; Norton, S.J.; Gerhold, M.D.; Vo-Dinh, T. Comparison of FDTD numerical computations and analytical multipole expansion method for plasmonics-active nanosphere dimers. Opt. Express 2009, 17, 9688–9703. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiba, H.; Kodama, K.; Okada, K.; Ichikawa, Y.; Motosuke, M. Gap Effect on Electric Field Enhancement and Photothermal Conversion in Gold Nanostructures. Micromachines 2022, 13, 801. https://doi.org/10.3390/mi13050801

Chiba H, Kodama K, Okada K, Ichikawa Y, Motosuke M. Gap Effect on Electric Field Enhancement and Photothermal Conversion in Gold Nanostructures. Micromachines. 2022; 13(5):801. https://doi.org/10.3390/mi13050801

Chicago/Turabian StyleChiba, Hirotomo, Kento Kodama, Koki Okada, Yoshiyasu Ichikawa, and Masahiro Motosuke. 2022. "Gap Effect on Electric Field Enhancement and Photothermal Conversion in Gold Nanostructures" Micromachines 13, no. 5: 801. https://doi.org/10.3390/mi13050801

APA StyleChiba, H., Kodama, K., Okada, K., Ichikawa, Y., & Motosuke, M. (2022). Gap Effect on Electric Field Enhancement and Photothermal Conversion in Gold Nanostructures. Micromachines, 13(5), 801. https://doi.org/10.3390/mi13050801