1. Introduction

Magnetic field sensors can be realized by different methods such as Hall-effect sensor, magnetodiode, anisotropic magnetoresistance (AMR), giant magnetoresistance (GMR), MEMS Lorentz force, fluxgate, search coil, and superconducting quantum interference device (SQUID) magnetometers [

1]. These magnetic field sensors have a wide range of applications. They can measure a wide range of magnetic fields, ranging from certain femto-tesla (using precise SQUID magnetometers) to kilo-tesla (using search coil magnetometers) [

2,

3]. Depending on the sensor’s type and its requirements, magnetometers can be realized by conventional macro machining (search coil and fluxgate magnetometers), semiconductor process (Hall sensors in silicon and III–V semiconductor), MEMS fabrication processes (MEMS Lorentz force magnetic field sensors), etc. Among these magnetometers, search coil magnetometers (SCMs) have some inherent advantages. An SCM is a passive sensor, where typical power consumption results from the signal conditioning circuit and the amplifier circuit. Therefore, with a proper readout circuit design, they can be considered ultra-low-power sensors, which can operate for several years with small batteries [

4]. In addition, SCMs can be used in harsh environments due to their low sensitivity to the ambient temperature compared to other types of semiconductor magnetometers in a wide temperature range [

5]. Furthermore, they have the widest dynamic range and good linearity, especially an air-core SCM [

3]. Finally, the output voltage of an SCM is proportional both to the input magnetic field amplitude and its frequency. This unique feature of the SCM can be utilized to detect high-frequency magnetic fields.

Zeidi et al. [

6] utilized a planar spiral inductor to detect the partial discharge between a sharp needle and a conductive plate. The induced voltage frequency spectrum showed a detectable magnitude in the mega Hz range even 10 cm away from the discharge platform. This indicates that even a very small high-frequency magnetic field can be detected by an SCM due to its unique working principles. Vejella and Chowdhury [

7] designed and simulated an ultra-wide-band µSCM with a ferromagnetic core for the GHz frequency range. The induced voltage on the inductor was utilized to change the capacitance on a diaphragm. Although the presented sensor system was not fabricated, a sensitivity of 4.5 aF/0.8 µA/m was achieved according to the reported calculation and FEM simulation results. Despite the lack of fabrication in this work, it is a good option for high-frequency power measurements, such as 5G and Wi-Fi.

Conventional SCMs have a simple fabrication process: wrapping a long thin wire around a magnetic core for several 10,000 turns. The core and wound wire are usually sandwiched between two magnetic field concentrators. Although this simple realization method can achieve a very low noise equivalent magnetic induction (

NEMI) to several femto-tesla/Hz

0.5, conventional SCMs are bulky and not CMOS compatible [

8,

9,

10,

11,

12].

NEMI is defined by the ratio of the total noise power spectral density to the sensitivity of an SCM [

8]. The sensitivity of an SCM is the ratio of the output voltage to the input magnetic field. Therefore,

NEMI is inversely proportional to the

SNR of an SCM [

13]. Several works have been reported concerning the optimization and improvement of the performance of SCMs. Grosz and Paperno [

14] presented an analytical calculation for the

NEMI of a conventional SCM. They ignored the stray capacitance of the coil since the frequency of interest was an order of magnitude smaller than the resonance frequency of the inductor. The optimum core and wire diameters were calculated considering the noise sources of the amplifier. The size of their sensor was 60 mm in length and 30 mm in diameter, and they achieved a

NEMI of 11 pT/Hz

0.5. Grosz et al. [

10] presented a compact, three-axis SCM whose power consumption was 252 µW; therefore, the SCM could operate continuously for 7 years with four 1/2AA lithium batteries. This ultra-low-power feature of the SCM stems from the output signal of the SCM being the induced voltage on the coil without any bias voltage, unlike a Hall-effect sensor. The size of their sensor system was 72 × 69 × 69 mm

3, and the

NEMI was 12 pT/Hz

0.5 at 1 Hz. The power consumption of an SCM can be 2 orders of magnitudes lower than a fluxgate sensor with the same resolution [

12].

Few works were reported for the miniaturization of conventional SCMs. The previously reported works for µSCM can be classified into fixed and vibrating coils. The vibrating-type µSCMs [

15] can overcome the limitation of DC magnetic field detection in terms of the complicated fabrication process and extra circuitry for the actuation of the moveable part. Liu et al., reported a vibrating electromagnetic magnetometer [

16]. The magnetometer consisted of a vibrating seesaw plate, which was actuated electrostatically, plus a coil. The applied electrostatic force between electrodes on a glass substrate and the seesaw plate leads to vibration in the vertical direction. When the deposited coil on the moveable seesaw plate is exposed to an external magnetic field, a voltage will be induced on the coil due to Faraday’s induction law. The vibration angle will be maximized at the resonance frequency of the seesaw plate. Therefore, maximum sensitivity can be achieved at the resonance frequency. The maximum sensitivity at the resonance frequency is due to (1) the maximum tilt angle at the resonance frequency (42.404 kHz) and (2) the inner vector product of the normal vector to the coil and the input magnetic field being larger at the resonance frequency. The presented sensor can be used for both AC and DC magnetic field measurement. For the AC magnetic field measurement, electrostatic actuation is not required. Although the fabrication process is not as simple (silicon on glass technology) compared to a Hall sensor, the low power consumption (0.75 µW) of this sensor is a very suitable choice for IoT applications. In addition, sensitivity can be increased at low pressure, which can be achieved by vacuum packaging due to a lower damping coefficient. The vacuum packaging of the vibrating µSCM was reported in reference [

17]. The achieved quality factor in this design was 42,000, which is more than one order of magnitude larger than the atmospheric pressure resonator. Liang et al. [

18] presented a different actuation mechanism for the vibrating coil compared with reference [

17]. They utilized an interdigitated, staggered, comb-drive actuation method instead of a parallel plate type. Since the air damping effect was reduced significantly in this design compared to parallel plate actuation [

16], the quality factor of the resonating structure was increased noticeably. The achieved sensitivity and resolution were 468 mV/mT and 6 µT, respectively. The resonance frequency of the structure was 12.65 kHz, and the power consumption was 78 nW, which is much lower than other types of semiconductor magnetometers such as Hall sensors. In reference [

19], an out-of-plane resonance induction electromagnetic magnetometer was presented. The in-plane vibration of the S-shaped springs, which are actuated electrostatically by a comb-drive structure, leads to the closed area change of the deposited coils on the springs. Therefore, in the presence of an input DC magnetic field, the output voltage will be induced across the coils due to the enclosed area changes of the coil (this actuation method is not similar to references [

15,

17], where the angle between the coil and the applied magnetic field varies due to the electrostatic actuation). The sensitive axis is perpendicular to the vibrating structure, while in references [

15,

17], the external magnetic field must be parallel to the vibrating coil. Vibrating coil structures were also reported in references [

20,

21] with much higher resonance frequencies (4.361 MHz and 4.33 MHz, respectively) compared with other works. The main disadvantage of the vibrating coil for magnetic field detection is its complicated fabrication process (in some cases, it requires eight-times lithography and four-times DRIE processes [

18]) compared with other semiconductor magnetometers that do not have moving parts.

Fixed µSCMs have a simpler fabrication process compared with vibrating coil magnetometers. In addition, they are CMOS compatible and can be realized completely by a CMOS process without any need for post-processing in most cases. In reference [

5], two µSCMs with the dimensions of 1 mm × 3 mm were utilized for surface crack detection. The two planar inductors were used to detect the spatial derivative of the magnetic field on the top of the existing crack. The achieved sensitivity with track width = 7 µm, track thickness = 2 µm, and number of turns = 40 was 0.2 mV/mT at 2 kHz. Although the sensitivity of the µSCM was relatively lower than commercial products such as a magnetodiode (MD-130 by Sony) 20 mV/mT, the temperature independency of the µSCM is the inherent advantage of a µSCM over other semiconductor magnetometers. The output signal of the µSCM for crack detection remained unchanged for the temperature range of 30~75 °C, while the output voltage of the magnetodiode dropped by 80% in the mentioned temperature range. Eyre et al. [

22] presented a three-axis µSCM. Their work was realized by the post-CMOS process. The vertical coils were connected to the substrate by aluminum hinges, which were permanently deformed to the desired position. The sensor consisted of three spiral inductors, and the sensitivity was calculated by summing up the area of each turn of the coil. Although the thermal noise of DC resistance was calculated, no optimization was performed to achieve the maximum signal-to-noise ratio. The measured and calculated relative sensitivities were 1.3 × 10

−4 V/T.Hz and 1.6 × 10

−4 V/T.Hz, respectively. The dimensions of the two-layer stacked inductors were 0.45 mm × 1.5 mm. The measurement was performed in the range of 5 kHz~1.5 MHz, and an almost linear response was reported for this frequency range. Azmi et al. [

23] used a planar spiral inductor to perform an FEM simulation to present a µSCM. The size of their sensor was 3.16 mm × 3.16 mm. In the proposed fabrication process, two planar spiral inductors were fabricated separately and bonded by the flip-chip bonding technique. The sensitivity and the noise analyses of the µSCM were not studied in their work. In our previous work [

24], a four-layer printed circuit board (PCB) was utilized to realize an SCM with four stacked planar spiral inductors. The mutual inductance [

25,

26] between the bottom coil and the other three coils was utilized for on-chip calibration purposes, which is very useful for long-term applications.

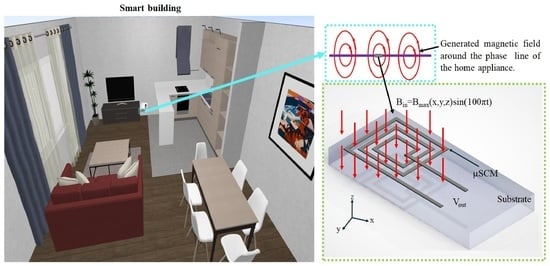

The summary of the reported works and their novel ideas are listed in

Table 1. To the authors’ best knowledge, few works comprehensively studied the optimization of a µSCM to achieve maximum

SNR for a low-frequency application such as power monitoring of home appliances in smart buildings. In this work,

SNR optimization was achieved by introducing three dimensionless parameters. An analytical method was presented to calculate the

SNR. The presented method included all layout parameters of the planar spiral inductor. To calculate the noise of the µSCM, the thermal noise of the coil and all noise sources of the utilized instrumentation amplifier were included in the

SNR calculation.

2. Materials and Methods

The working principle of the µSCM is based on Faraday’s law of induction [

3]. When a fixed inductor is exposed to an alternating magnetic field, an AC voltage is induced on the coil. The induced voltage is proportional to the derivative of the input magnetic field, as shown in

Figure 1a. The output voltage of the µSCM can be calculated by Equation (1):

where

Vo,

Bi, and

Ae are the inducted output voltage, input magnetic field, and the effective area of the inductor, respectively. If the input magnetic field

Bi is equal to

, then the output voltage for a fixed coil can be calculated by Equation (2):

where

f,

Bm, and

t are the frequency of the input magnetic field, the amplitude of the input magnetic field, and time, respectively. To miniaturize the SCM and realize it through the microfabrication process, a square planar spiral inductor was utilized in this work. This inductor can be defined by its layout parameters: track width (

W), track spacing (

S), track thickness (

h), outer diameter (

Do), and inner diameter (

Di). The planar spiral inductor can be approximated by closed-loop areas [

25,

26], as shown in

Figure 1b. The flowchart of the optimum design methodology is shown in

Figure 1c. The three dimensionless numbers were defined to achieve more general results. The effect of these parameters was summarized in a 4D nomogram. By combining the results from the nomogram and the effect of the noise sources from the amplifier circuit, optimum values for the mentioned dimensionless parameters could be calculated.

The number of turns (

N) of the planar inductor is a function of the aforesaid geometrical layout parameters and can be formulated by Equation (3):

In this work, a square planar inductor was used to enable the maximum enclosed area in a fixed die size. The effective area of the square planar inductor is calculated by Equation (4):

where

Ai is the area of

ith turn, which can be formulated by Equation (5) for the square-shape spiral planar inductor.

Therefore, the effective area of the square planar inductor can be calculated by Equation (6):

By substituting Equation (3) into Equation (6), the effective area can be calculated as a function of layout parameters by Equation (7):

The sensitivity (

Se) of the µSCM can be defined by dividing the maximum induced voltage by the maximum input magnetic field [

22], which is formulated by Equation (8):

where

Vm is the maximum induced voltage at the maximum input magnetic field. According to Equations (7) and (8), the sensitivity monotonically increases by increasing

Do and decreasing

w and

s. Increasing

Do will lead to an increase in the size of the µSCM, which is usually limited in microfabrication. However, in a fixed die size, decreasing the track width and spacing will increase the DC resistance of the coil. The DC resistance of the µSCM can generate thermal noise, of which the corresponding spectral density (

enR) can be determined as follows, i.e., Equation (9):

where

kB,

T, and

R are the Boltzmann constant, the temperature in Kelvin, and resistance, respectively.

The DC resistance of the inductor can be calculated by Equation (10) (notably, the skin effect is ignored in Equation (10) since the focus of this work was on low-frequency magnetic fields, such as the 50 Hz magnetic field around home appliances):

where

ρ and

L are the inductor material’s resistivity and total length of the inductor, respectively. The total length of the spiral coil can be approximated by Equation (11):

where

Li is the length of the

ith turn. For a square spiral inductor,

Li can be calculated by Equation (12):

Therefore, the total coil’s length can be formulated by Equation (13):

By substituting Equations (3) and (13) into Equation (10), the resistance of the square planar inductor can be expressed by Equation (14):

The

SNR of the µSCM is the ratio of the output voltage to the noise voltage, which is expressed by Equation (15):

where

Vo_rms and

BW are the root mean square (rms) value of the output voltage and the noise measurement bandwidth, respectively. The resolution (minimum detectable magnetic field, commonly called

NEMI) is the ratio of noise to sensitivity [

14,

22,

27]. Here, we assume normalized

SNR (

SNRn) for a µSCM, which is the inverse of

NEMI and can be defined by Equation (16):

Therefore,

SNRn is a function of geometrical layout parameters, coil material resistivity, and temperature.

SNRn can be expressed by Equation (17):

The resistivity and thickness of the metal layers are usually predetermined in the fabrication process (e.g., a CMOS foundry process). Therefore,

SNRn can be rewritten by Equation (18):

where

SNR* is defined by Equation (19). Thus, the goal of this work was to find optimal values for geometrical layout parameters to achieve maximum

SNR*.

According to the Buckingham π theorem, dimensional analysis can be used to identify critical normalized parameters [

28,

29] and the three dimensionless parameters are defined to have more generalized results. These parameters are defined in Equation (20):

As mentioned in Equation (3),

; so,

. By substituting Equation (20) into Equation (19),

SNR* can be rewritten by Equation (21):

By substituting Equations (7) and (20) into Equation (21) and dividing

SNR* by the die area, which is

Do2, Equation (22) can be derived. Equation (22) can be used to study the effect of the three dimensionless parameters, which can provide more general results compared to pure geometrical layout parameters.

Here, we try to obtain the optimized maximum SNR*/Do2 for an improved SNR. The effect of the three dimensionless parameters is studied in the following sections.

2.1. Effect of di, While w and s Are Fixed

The effect of

di for different fixed

w =

s is shown in

Figure 2a. Without a loss of generality, this figure is plotted for

Do = 1 mm and

Do2 = 1 mm

2, considered to be unity for simplicity. As shown in

Figure 2a, two regions were determined by increasing

di. In region 1,

SNR*/

Do2 did not change substantially. This is because, by increasing

di, which decreased the number of turns, both thermal noise and sensitivity decreased. Although sensitivity and noise decreased simultaneously, the ratio of sensitivity to noise was almost constant in region 1. Therefore, there was no significant change in the

SNR*/

Do2 value. In region 2 of

Figure 2a, sensitivity reduction was dominant compared to noise reduction. Thus,

SNR*/

Do2 started to drop sharply. An important result can be concluded from

Figure 2a: almost the same

SNR*/

Do2 can be achieved with a reduced number of turns, as shown in

Figure 2b. This result was beneficial in reducing the DC resistance of the µSCM. Furthermore, reducing the number of turns led to a reduction in the coupling capacitance of the spiral planar inductor [

30]. Therefore, the resonance frequency and the bandwidth of the µSCM increased without a noticeable change in the

SNR*/

Do2.

2.2. Effect of w = s, While di Is Fixed

If the normalized track width (

w) and the normalized spacing (

s) change simultaneously with a fixed normalized inner diameter (

di), there is a slight change in the value of

SNR*/

Do2. This issue is illustrated in

Figure 3, where

Do = 1 mm and

Do2 = 1 mm

2 is considered to be unity for simplicity. The intuitive explanation for this issue is that the ratio of sensitivity and noise of the µSCM is almost constant when

w and

s change simultaneously.

2.3. Effect of w, While di and s Are Fixed

The variation of

w, while

di and

s are fixed, has a substantial effect on

SNR*/

Do2, as shown in

Figure 4. Similar to the previous two figures,

Do = 1 mm and

Do2 is considered to be unity for simplicity without a loss of generality. Some results can be concluded from

Figure 4:

- -

Smaller

s leads to greater

SNR*/

Do2. In other words, the smaller track spacing is preferred to achieve higher

SNR for a µSCM. This statement is valid for the low-frequency range (at least one order of magnitude smaller than the resonance frequency of the inductor [

14]), where the coupling capacitance of the coil can be ignored.

- -

By increasing w in region 1, noise reduction has a dominant effect on SNR*/Do2 compared with sensitivity reduction. Therefore, greater SNR*/Do2 can be achieved in this region by increasing w. It is interesting to note that region 1 is the practical region because the output voltage in this region can be detected or amplified by available commercial readout circuits.

- -

By increasing

w in region 2, noise and sensitivity reduction are approximately the same. Therefore, there is no significant change in the value of

SNR*/

Do2. Thus,

SNR*/

Do2 tends to saturate in region 2. Although

SNR*/

Do2 offers a higher value in region 2, this region is not an efficient region for practical applications. The induced voltage in region 2 can be smaller than the input-referred noise of an amplifier in most cases. Therefore, it is advisable to choose a proper value for

w in region 1. This is further explained in

Section 2.5.

2.4. Novel 4D Nomogram for a General Guide Design of the µSCM

By combining the results of the previous sections, we proposed a novel 4D nomogram that describes

SNR*/

Do2 as a function of the normalized inner diameter (

di), normalized track width (

w), and normalized spacing (

s), as shown in

Figure 5a. In this nomogram,

Do = 1 mm and

Do2 = 1 mm

2 is considered to be unity for simplicity without a loss of generality. This 4D nomogram can be used as a general guideline for designers to design an optimized µSCM with a square planar inductor. After choosing the maximum available die size, the proper inner diameter can be chosen from this figure. This issue is illustrated more clearly in

Figure 5b, which is the 2D perspective of

Figure 5a. As shown in

Figure 5b,

SNR*/

Do2 is almost constant for a specific range of

di (almost

di < 0.5). As described previously,

s must be set to the minimum value according to the minimum track spacing in the fabrication process. Finally,

w should be set to the maximum value while considering the noise of the designed µSCM is greater than the input-referred noise of the readout circuit. Although the theoretically higher value of

SNR*/

Do2 can be achieved by increasing

w, as shown in

Figure 5a, in practical terms, the output-induced voltage at a large value of

w will be too small to be measured or amplified by available commercial electrical components or instruments. Therefore, the noise of the readout circuit must be considered when choosing a proper value for

w. Therefore, taking this into account, the noise sources of the utilized amplifier are complementary to the 4D nomogram, as shown in

Figure 1c. Further information about this issue can be found in

Section 2.5.

The exponents of important parameters were extracted and are listed in

Table 2. It is interesting to note that noise (

enR), sensitivity (

Se), and

SNRn increased by enlarging

Do, but with different exponents, as seen in

Table 2. Notably, fabrication of the µSCM using a metal with higher track thickness and lower resistivity can further improve the

SNRn (

SNRn ∝

). Therefore, it is better to use the maximum possible metal thickness and lowest resistivity in the fabrication of the µSCM (in the low-frequency range where the skin effect can be ignored). In this work, aluminum with a 2 µm thickness was utilized for the fabrication of the µSCM due to the practical limitations in the fabrication process. Furthermore, a metal with greater thickness and lower resistivity such as gold or copper can further improve the

SNRn.

2.5. Effect of Amplifier Noise Parameters on SNR

The noise model of the µSCM integrated with an instrumentation amplifier is illustrated in

Figure 6a. The noise sources of the instrumentation amplifiers should also be considered in the calculation of

SNRn. The total noise spectral density can be calculated by Equation (23) [

31]:

where

enT,

in-in,

en-in,

en-out, and

G are total input-referred noise spectral density, input current noise, input voltage noise, output noise, and the gain of the instrumentation amplifier, respectively. As shown in

Figure 6a, the noise sources can be classified into sensor noise (

enR) and amplifier noise (

en-amp). It is notable that the higher resistance value of the µSCM not only increased the thermal noise of the sensor, but it also increased the amplifier noise because of its input current noise. This statement can be verified by Equation (23).

The effect of the normalized track width (

w) on

SNR*/

Do2 without considering the amplifier noise was presented in previous sections. It was shown that increasing

w leads to a higher

SNR, without considering the noise of the amplifier circuit. The comparison between the noise of the µSCM and the utilized instrumentation amplifier is illustrated in

Figure 6b. As illustrated in this figure, at small values of

w, the amplifier noise (

en-amp) is greater than the µSCM noise (

enR). In this region, the current noise of the amplifier is the dominant noise source. By increasing

w, current noise becomes less significant and the sensor noise becomes the dominant noise source. By further increasing

w, current noise and sensor noise gradually become negligible compared to the voltage noise of the amplifier. In this region, the voltage noise is the dominant noise source, and increasing the

w does not help to enhance the

SNR. Therefore, there is a critical

w that leads to maximum

SNR. This issue is proven analytically and experimentally in

Section 3.2.

4. Conclusions

We conducted dimensional and scaling analyses for a µSCM and proposed a novel 4D nomogram for the design optimization of a µSCM’s SNR for low-frequency applications, such as power measurement of home appliances. The three dimensionless parameters (track width, spacing, and inner diameter divided by the outer diameter) were defined and utilized to perform the theoretical analysis for the sensor’s key performance indices. The effect of these parameters was studied in detail. It was concluded that the sensitivity, the noise, and the SNR of a µSCM without an amplifier circuit are proportional to Do3, Do1, and Do2, respectively. Furthermore, the noise sources of an instrumentation amplifier were included in the analysis. It was proven that either noise or sensitivity could be the dominant factor in determining the SNR of the sensor for a different range of dimensionless parameters.

Moreover, the dominant noise source varied from sensor to amplifier by changing

w (the ratio between track width to outer diameter). The critical values for dimensionless parameters to achieve maximum

SNR were calculated. It was shown that the noise of the amplifier equaled that of the sensor at two values of

w. The second intersection of the abovementioned noises was the critical value for

w to achieve maximum

SNR. Seven different samples were fabricated by a single-mask lithography process. The noise (with an 800 Hz measurement bandwidth) and sensitivity of the fabricated samples were measured at zero input and a 50 Hz magnetic field, respectively. The measurement results for sensitivity, noise, and

SNR (at 1 mT a 50 Hz magnetic field) were compared with the theoretical analysis. The discrepancy between

SNR calculation and measurement was 12.8% and 1.5% for

Do = 1 mm and

Do = 5 mm, respectively. It was observed that

SNR increased by increasing the outer diameter of the µSCM. The sensitivity of 1612 mV/mT and

SNR (at 1 mT and noise bandwidth of 800 Hz) of 63.5 dB with

Do = 5 mm was better than the previously reported µSCM (

S = 6.5 mV/mT) by more than 2 orders of magnitude [

22] at a 50 Hz magnetic field. In addition, one of the fabricated µSCMs with excellent sensitivity was used to measure the power consumption of a PC, while different computer programs performed an operation or FEM simulation. In summary, µSCM will be useful for real-time monitoring of smart buildings to achieve a significant reduction of carbon emission and much high-energy efficiency in the era of the Internet of Things.