1. Introduction

The field of Microtechnology and Micro-Electro-Mechanical Systems (MEMS) has grown rapidly in the last few years [

1]. The beginning of microtechnology relies, mainly, in micromachining from glass or silicon. Although these technologies offer high precision, their fabrication methods are often complex, time consuming, and sometimes costly, which boosted research into alternative materials [

2]. Nowadays, polymers have emerged as preferential material for microstructures fabrication due to their low‑cost and easy processing [

1,

2,

3]. In particular, epoxy-based negative photoresist (SU-8) is used as a structural and mold material. Its photosensitivity allows its patterning by Ultraviolet Rays (UV) photolithography and its transparency to visible light makes it compatible with optical detection systems. Moreover, it is biocompatible and mechanically and chemically stable [

4,

5].

SU-8 was originally developed by IBM in Yorktown in the late 1980s and was designed for the fabrication of microstructures of high aspect ratios [

3]. Currently, it is commercially available from Microchem Corporation (Westborough, MA, USA) [

6] and Gersteltec Sàrl (Pully, Switzerland) [

7] in various formulations that cover thicknesses from 1 to 600 μm. Despite that its use for the fabrication of microstructures is specified by a protocol available at the suppliers, in practice, SU-8 is very sensitive to the processing parameters, therefore, those protocols involve optimizations when the environmental and tools’ conditions are changed, as well as according to the structural dimensions and the design of the microstructure. In this paper, it is reported processing values that are crucial for achieved SU-8 microstructures with a low-cost process (masks and equipment) and without the use of a cleanroom. The fabrication of 3D SU-8 microstructures, using gray-scale masks, is also addressed. Furthermore, the applications of SU-8 for microfluidic and MEMS are also demonstrated.

2. SU-8 Processing Using Low-Cost Facilities

The processing of SU-8 is a challenging task that involves several lithographic methods being the most common the UV radiation, although it can be used X-ray, electron and protons beams [

3]. Each step of the process strongly influences the results and must be individually tailored to the desired application. The patterning of the SU-8 by lithography allows microstructures of almost any shape and size; not only planar microstructures, but also multilayer and 3D microstructures [

8]. For that, several lithographic techniques can be used, such as, layer-by-layer multi exposure lithography [

8,

9], inclined/rotated lithography [

8,

10], holographic lithography, and gray-scale lithography [

8,

11].

Figure 1 shows the SU-8 processing steps and the respective equipment used that allows the fabrication of microstructures with aspect ratios of more than 20, with low-cost and without cleanroom facility. Details of each step will be discussed in

Section 2.1. The remove and hardbake steps are optional steps. The hardbake is used to further harden the SU-8 structure when it is used in a final device. The remove step is used to obtain free SU-8 microstructures,

i.e., without the substrate. In this case it is necessary to deposit a layer of Omnicoater after the substrate preparation and before the SU-8 deposition [

12]. All the microstructures reported throughout this paper were fabricated using that equipment.

Despite the processing of SU-8 is described in the datasheets of suppliers, experimentally, the equipment and the environmental conditions differ from those presented in the protocols. Therefore, it is necessary to find optimal processing conditions at each microfabrication laboratory, especially when no cleanroom is available. Thus, this work involved the study and optimization of the SU-8 processing using four types of SU-8: SU-8 2, SU-8 25, SU-8 100, and SU-8 2150, at different room temperatures (ranging from 19 to 27 °C) and for different aspect ratio of the microstructures. All experimental details are presented. It is necessary to mention that, throughout the process, the SU-8 should be less exposed to room light.

Figure 1.

Basic steps of the epoxy-based negative photoresist (SU-8) processing with low-cost and without cleanroom facility.

Figure 1.

Basic steps of the epoxy-based negative photoresist (SU-8) processing with low-cost and without cleanroom facility.

2.1. Preparation of the Substrate

The substrates used for the fabrication of SU-8 microstructures are standard microscope glass slides (76 × 26 mm) once they are low-cost and exhibit high transparency, which enables their use directly in optical devices. Before use, the glass slides are cleaned with solvents (such as isopropyl alcohol—IPA) followed by drying with a nitrogen stream. In order to dehydrate the surface, the substrates are thermally treated at 200 °C for 5 min by using a hot plate.

2.2. SU-8 Deposition

The SU-8 is deposited using a spin-coater (Polos 200, ATP GmbH, Bienenbüttel, Germany). The influence of the spin-coater rotational speed on the thickness value of the final structure was determined for the four types of SU-8 and for two ranges of room temperature.

The SU-8 2 and SU-8 25 are placed on the center of the glass slides with a Pasteur pipette in an amount of 1 mL. In turn, and due to their high viscosities, the SU-8 100 and SU-8 2150 are weighed and placed on the glass slide. After several experiments, it was found that 1 g is the appropriate amount of SU-8 in order to obtain a smooth and flat layer across the substrate. The spin-coating deposition is performed in two cycles. The first cycle is set at 500 rpm with a duration time of 7 s and with an acceleration of 300 rpm/s. The second cycle allows defining the final thickness of the microstructure by adjusting the rotational speed. The thicknesses obtained with rotational speeds of 1000, 2000, and 3000 rpm at acceleration of 300 rpm/s and during a time of 30 s are given in

Figure 2, for two ranges of room temperature (19–23 °C and 24–27 °C). It was considered two temperatures ranges once within them the thickness variation is insignificant. The thickness of the fabricated microstructures was characterized using a Veeco Dektak 150 Surface profilometer (Plainview, NY, USA).

The thicknesses obtained with SU-8 2 and SU-8 25 are not influenced by the room temperature, since these types of SU-8 features a very low viscosity. Regarding the SU-8 2150, a thickness of 550 μm is obtained with a rotational speed of 1000 rpm and at an ambient temperature between 19 and 23 °C. At higher temperatures (24–27 °C) and for the same rotational speed, microstructures with 370 μm thick are obtained. The decrease of the thickness with the temperatures for both SU-8 2150 and SU-8 100 is explained by the decrease of viscosity of the SU-8 with temperature.

Despite that the SU-8 supplier protocol indicates that each type of SU-8 comprises a specific range of thickness [

6], with different environmental and laboratory conditions it is possible to obtain a wider range of thickness than the one referred by the supplier (

Table 1).

Figure 2.

Thicknesses vs. rotational speeds for (a) SU-8 2 and SU-8 25; (b) SU-8 100 and SU-8 2150, for two ranges of room temperatures.

Figure 2.

Thicknesses vs. rotational speeds for (a) SU-8 2 and SU-8 25; (b) SU-8 100 and SU-8 2150, for two ranges of room temperatures.

Table 1.

Thicknesses ranges given by supplier and obtained for various types of SU-8.

Table 1.

Thicknesses ranges given by supplier and obtained for various types of SU-8.

| SU-8 type | Thickness range given by supplier (µm) [6] | Thickness obtained (µm) |

|---|

| SU-8 2 | 1.5–5 | 1–5 |

| SU-8 25 | 15–40 | 10–47 |

| SU-8 100 | 100–250 | 80–480 |

| SU-8 2150 | 180–550 | 110–580 |

2.3. Prebake

The prebake step, responsible for the evaporation of the SU-8 solvent, is performed using a ramping hot plate (

Präzitherm type PZ28-2, 1100 W, Harry Gestigkeit GmbH, Düsseldorf, Deutschland). This step involves two cycles. In the first one prebake is done at 65 °C in order to create a slow evaporation of the solvent resulting in a better coating and a better adhesion to the substrate. The second cycle consists in heating the substrate with the SU-8 layer up to 95 °C, in order to densify the SU-8. The temperature is gradually applied at a rate of 2.5 °C/min to decrease the tension induced into the film, to ensure the total evaporation of the solvent and to avoid the occurrence of SU-8 shrinkage after the exposure and cracking formation. Indeed, a quick heating can lead to the incomplete evaporation of the solvent due to the formation of a film on the surface of the SU-8 layer, resulting on tension and shrinkage after UV exposure [

3].

Short prebake times cause, as well, an incomplete evaporation of the SU-8 solvent, making small microstructures to move after development, due to the existence of non-polymerized SU-8 at the bottom. The prebake time of each cycle depends on the thickness and type of the SU-8 deposited.

Table 2 shows the optimal times of prebake for each type of SU-8 at different room temperatures. After the prebake, the glass slides with SU-8 are cooled to the room temperature (RT) covered with a dark container. Following

Table 2 data carefully, no cracking formation appeared.

Table 2.

Optimal times of prebake for several types of SU-8.

Table 2.

Optimal times of prebake for several types of SU-8.

| SU-8 type | Final thickness (µm) | Prebake time (min) |

|---|

| 65 °C | 95 °C |

|---|

| SU-8 2 | 1 ± 0.2 | 1 | 3 |

| 2 ± 0.2 | 1 | 5 |

| 4.5 ± 0.2 | 1 | 8 |

| SU-8 25 | 10 ± 3 | 5 | 7 |

| 22 ± 3 | 5 | 10 |

| 47 ± 3 | 5 | 20 |

| SU-8 100 (RT 19–23 °C) | 130 ± 10 | 25 | 45 |

| 260 ± 15 | 35 | 80 |

| 480 ± 20 | 50 | 180 |

| SU-8 100 (RT 24–27 °C) | 80 ± 10 | 15 | 35 |

| 170 ± 15 | 30 | 60 |

| 320 ± 20 | 40 | 120 |

| SU-8 2150 (RT 19–23 °C) | 210 ± 15 | 15 | 75 |

| 350 ± 20 | 20 | 120 |

| 550 ± 30 | 35 | 180 |

| SU-8 2150 (RT 24–27 °C) | 110 ± 10 | 10 | 45 |

| 190 ± 15 | 15 | 75 |

| 370 ± 20 | 20 | 120 |

The time of the SU-8 100 prebake is longer compared to the time of the SU-8 2150 prebake even if the amount of solvent is smaller. This is due to the fact that the solvent SU-8 2150 (cyclopentanone), evaporates more rapidly than the SU-8 100 solvent (gamma-butyrolactone).

2.4. UV Exposure

The UV exposure is responsible for the generation of a photoacid which cause the polymerization of the SU-8 during the postbake step. In fact, the photoacid opens the epoxide rings of the photoresist and acts as a catalyst in cross-linking reaction [

3]. Thus, the UV exposure allows transferring the masks pattern to the SU-8. Chromium masks are the most employed because they present an excellent resolution, <1 µm feature sizes. These masks consist in chromium opaque pattern areas deposited in high quality quartz plate with a very high transparency to UV radiation [

13]. However, they have high-cost fabrication [

14]. Several authors have conducted studies where inexpensive photomasks are used in order to reduce the overall costs of the photomasks fabrication (including facilities) and, consequently, of the photolithographic processes [

15,

16]. Despite portraying the need for low-cost technologies these approaches use specific equipment and relatively complex processes. To overcome this limitation a cheaper solution (€10 per A4 sheet) based in photomasks (high photographic transparent sheets, despite lower than the chromium masks) can be used. This method starts with the design of the desired pattern in a Computer Aided Design (CAD) software and their printing using a laser printer with high resolution (

Figure 3). For example, a 2400 dpi printer (Avantra 44s, Agfa, Mortsel, Belgium), which is the most commonly used, allows the fabrication of microstructures with minimum dimensions of 10 μm (

Figure 4).

Figure 3.

(a) Mask design in the CAD software and (b) photo of a photomask.

Figure 3.

(a) Mask design in the CAD software and (b) photo of a photomask.

Figure 4.

Photo of a photomask with minimum dimensions of 10 μm (the line splitting the squares in the zoom).

Figure 4.

Photo of a photomask with minimum dimensions of 10 μm (the line splitting the squares in the zoom).

Usually, the equipment used to perform the SU-8 UV exposure is a Mask Aligner. This equipment is expensive, as well as less available, in most laboratories. To overcome this limitation, 10 UV 20 W bulbs (

Photomeca- type IPP 45, Maxville, France,

Figure 5), commonly employed in the Printed Circuit Board (PCB) industry and with an emission range between 347 and 377 nm (FWHM, Full Width Half Maximum = 30 nm) is used, which is within the emission range suitable for SU-8 exposure [

6]. Moreover, below 331 nm, and after 397 nm, their intensity is zero. Due to their emission range and FWHM values, there is no need for using UV bandpass optical filters, so getting the equipment as used in the PCB industry. Moreover, the obtained structures are well defined, as shown along the paper. That equipment has an air suction system that allows creating a vacuum zone and, therefore, a conformal contact between the mask and the SU-8 without the presence of voids.

The exposure time of SU-8 using that machine is based on Equation (1) [

17]. This exposure time served as a reference value and it was optimized according to the results obtained after the development of the final structure in SU-8.

The light intensity of that equipment is 1.2 mW/cm

2. The exposure energy used to determine the exposure time was obtained through the MicroChem datasheets. If the exposure time is inferior to the optimized ones, the microstructures obtained are imperfect. An example is shown in

Figure 6. A perfect cross between the vertical and horizontal lines should have been obtained, as shown in the photomask (

Figure 6a), contrary to the SU-8 microstructure obtained (

Figure 6b).

On the other hand, excessive UV exposure can lead to the hardening of the SU-8 parts that are not exposed since photoacid diffusion can occur. Moreover, it can also cause light diffraction/dispersion effect resulting in severe sidewall distortions [

18]. The optimal exposure times using the equipment and tools presented above are shown in

Table 3.

Figure 5.

Photography of the UV exposure equipment.

Figure 5.

Photography of the UV exposure equipment.

Figure 6.

(a) Photomask with the desired pattern; (b) Photography of the SU-8 microstructure obtained with a short exposure time and zoom of the cross lines.

Figure 6.

(a) Photomask with the desired pattern; (b) Photography of the SU-8 microstructure obtained with a short exposure time and zoom of the cross lines.

Table 3.

Optimal times of UV exposure for several types of SU-8.

Table 3.

Optimal times of UV exposure for several types of SU-8.

| SU-8 type | Final thickness (µm) | Exposure time (min) |

|---|

| SU-8 2 | 1 ± 0.2 | 1 |

| 2 ± 0.2 | 1 |

| 4.5 ± 0.2 | 1.5 |

| SU-8 25 | 10 ± 3 | 2 |

| 22 ± 3 | 2 |

| 47 ± 3 | 3 |

| SU-8 100 (RT 19–23 °C) | 130 ± 10 | 7 |

| 260 ± 15 | 10 |

| 480 ± 20 | 13 |

| SU-8 100 (RT 24–27 °C) | 80 ± 10 | 5 |

| 170 ± 15 | 8 |

| 320 ± 20 | 11 |

| SU-8 2150 (RT 19–23 °C) | 210 ± 15 | 7 |

| 350 ± 20 | 9 |

| 550 ± 30 | 12 |

| SU-8 2150 (RT 24–27 °C) | 110 ± 10 | 4 |

| 190 ± 15 | 6 |

| 370 ± 20 | 10 |

2.5. Postbake

Postbake is responsible for increasing the degree of cross-linking in the SU-8 irradiated areas (due to the photoacid generated in the UV exposure step) making it resistant to the action of solvents in the developing step.

Similarly to the preback step, the temperature is applied gradually to reach two specific temperatures: 65 °C followed by 95 °C. The optimal postbake times according to the thickness of the SU-8 microstructure are shown in

Table 4. After postbake, the substrate must be cooled slowly to prevent thermal shock.

Table 4.

Optimal times of postbake for various types of SU-8.

Table 4.

Optimal times of postbake for various types of SU-8.

| SU-8 type | Final thickness (µm) | Postbake time (min) |

|---|

| 65 °C | 95 °C |

|---|

| SU-8 2 | 1 ± 0.2 | 1 | 2 |

| 2 ± 0.2 | 1 | 2 |

| 4.5 ± 0.2 | 1 | 3 |

| SU-8 25 | 10 ± 3 | 2 | 4 |

| 22 ± 3 | 2 | 5 |

| 47 ± 3 | 3 | 6 |

| SU-8 100 (RT 19–23 °C) | 130 ± 10 | 5 | 10 |

| 260 ± 15 | 10 | 15 |

| 480 ± 20 | 20 | 25 |

| SU-8 100 (RT 24–27 °C) | 80 ± 10 | 5 | 10 |

| 170 ± 15 | 10 | 12 |

| 320 ± 20 | 15 | 20 |

| SU-8 2150 (RT 19–23 °C) | 210 ± 15 | 5 | 15 |

| 350 ± 20 | 10 | 20 |

| 550 ± 30 | 15 | 30 |

| SU-8 2150 (RT 24–27 °C) | 110 ± 10 | 5 | 10 |

| 190 ± 15 | 5 | 15 |

| 370 ± 20 | 10 | 25 |

2.6. Development

To complete the process and obtained the final SU-8 microstructure, it is necessary to remove the non-polymerized SU-8. For that, the microstructures are immersed in a container with SU-8 Developer from Microchem. Magnetic agitation was used to enhance the removal efficiency of the non-exposed SU-8.

The development times are crucial in order to obtain well-defined SU-8 microstructures. While short development times imply that the non-polymerized SU-8 remains in the structure, longer development times can damage the structure and cause its release from the substrate. The development times are presented in

Table 5. However, this step requires a final confirmation of the development using IPA, followed by a nitrogen beam. Evidence of a white color, after this confirmation step, means that the structure has not been fully developed and, therefore, the microstructure must be immersed again into the developer solution. This wash process is repeated until there is no white color. The IPA allows the confirmation of the development degree and also confirms the end of the development. A final confirmation step can be performed using optical microscopy.

Table 5.

Optimal times for the development step for various types of SU-8.

Table 5.

Optimal times for the development step for various types of SU-8.

| SU-8 type | Final thickness (µm) | Development time (min) |

|---|

| SU-8 2 | 1 ± 0.2 | 1 |

| 2 ± 0.2 | 1 |

| 4.5 ± 0.2 | 1 |

| SU-8 25 | 10 ± 3 | 2 |

| 22 ± 3 | 3 |

| 47 ± 3 | 5 |

| SU-8 100 (RT 19–23 °C) | 130 ± 10 | 10 |

| 260 ± 15 | 20 |

| 480 ± 20 | 35 |

| SU-8 100 (RT 24–27 °C) | 80 ± 10 | 7 |

| 170 ± 15 | 12 |

| 320 ± 20 | 25 |

| SU-8 2150 (RT 19–23 °C) | 210 ± 15 | 20 |

| 350 ± 20 | 25 |

| 550 ± 30 | 40 |

| SU-8 2150 (RT 24–27 °C) | 110 ± 10 | 10 |

| 190 ± 15 | 20 |

| 370 ± 20 | 30 |

For applications where the SU-8 structure is part of the final device, a hardbake step should be done. For that, the SU-8 microstructure must be heated at a temperature in the range of 150 °C to 200 °C and for a time between 5 to 30 min using a hot plate. The times of hardbake depends on the thickness of SU-8 microstructure.

After all these processing steps, the final SU-8 microstructure is obtained.

Figure 7 presents photographs and scanning electron microscope (SEM) images of some SU-8 microstructures fabricated following all the process and the optimizations described. The SEM images were obtained using a Scanning Electron Microscope (Model S360, Cambridge instruments, Cambridge, UK).

The process was optimized for various thicknesses and various types of SU-8, as well as for several structures. The results show high repeatability and reproducibility for the same environmental conditions and the same type of SU-8. Similar microstructures were processed on different days and proved this fact.

Figure 7.

(a) Photography of SU-8 microstructures in glass substrate with lines of 25 µm width and 110 µm thickness. Scanning electron microscope (SEM) images of SU-8 microstructures with (b) crossed vertical and horizontal lines with a width of 200 µm and a thickness of 20 µm, (c) micropillar arrays with a diameter of 400 µm and a thickness of 140 µm, and (d) microwells with a diameter of 10 µm and a depth of 4.7 µm.

Figure 7.

(a) Photography of SU-8 microstructures in glass substrate with lines of 25 µm width and 110 µm thickness. Scanning electron microscope (SEM) images of SU-8 microstructures with (b) crossed vertical and horizontal lines with a width of 200 µm and a thickness of 20 µm, (c) micropillar arrays with a diameter of 400 µm and a thickness of 140 µm, and (d) microwells with a diameter of 10 µm and a depth of 4.7 µm.

2.7. Free Microstructures in SU-8

For applications requiring the removal of the SU-8 structure from the substrate, a thin layer of Microchem Omnicoat is deposited by spin-coating after cleaning the substrate and prior to the deposition step of the SU-8. For that, 1 mL of Omnicoat is placed on the glass slide and a rotational speed of 500 rpm at an acceleration of 300 rpm/s during 40 s is applied. Then, the glass slide is placed on the hot plate at 200 °C for 5 min. This deposition is repeated 4 times to obtain a thicker layer of Omnicoat in order to facilitate the later removal of the structure. At the end of the fourth layer the glass slide is subjected at a temperature of 200 °C for 30 min. The subsequent steps are the same as the normal processing of SU-8 (

Section 2.2,

Section 2.3,

Section 2.4,

Section 2.5 and

Section 2.6 ), adding only a final step to remove the Omnicoat after the development step. This removal involves that the structure be immersed in the RemoverPG Microchem until the structure be detached from the glass substrate. Some examples of SU-8 free microstructures fabricated with this process are shown in

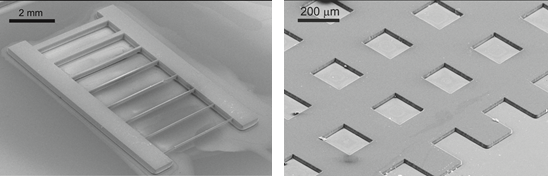

Figure 8.

Figure 8.

Free microstructures in SU-8.

Figure 8.

Free microstructures in SU-8.

2.8. Gray-Scale Lithography

Several methods have been developed to generate 3D microstructures using a coating single layer of SU-8 and with a single UV exposure step. One of these methods is called gray-scale lithography [

8]. The gray-scale lithography is typically implemented using gray shades mask allowing the modulation of the exposure dose that reaches the photoresist. With this modulation, different penetration depths of the radiation are obtained resulting in a 3D structure after development [

8,

11]. This type of photolithography uses similar steps of the traditional photolithography differing only in the mask used in the UV exposure step. They are gray-scale masks that are fabricated using the dots per inch (dpi) variation across the mask [

11]. The gray levels are obtained from pseudo gray-scale, which are generated by dots with different sizes and densities. When the photomask presents low density and small dots (greater transparency), higher exposure doses penetrate the SU-8, which results in a greater final thickness. This density and size of dots is dependent on the resolution of commercial printing equipment. Images of a gray-scale photomask are presented in

Figure 9.

Two examples of 3D SU-8 microstructures fabricated by gray-scale lithography are shown in

Figure 10a,b, which correspond to the photomasks shown in

Figure 9a,b, respectively. To perform the lens-shaped structures of

Figure 10b, the mask has few points in the central area, increasing towards the periphery (red square of

Figure 9b), which led in higher thickness of the SU-8 in the central area. To demonstrate the curvature degree of the fabricated microstructures a Veeco Dektak 150 Surface profilometer that allows profiles studying was used and the profile is presented in

Figure 11. This profile represents a scan over the total surface of one of the lens showed in

Figure 10b, the one that has the red dashed arrow, despite

Figure 10b show only half lens for better visualization of the curvature.

Figure 9.

Photos of two photomasks with several gray levels.

Figure 9.

Photos of two photomasks with several gray levels.

Figure 10.

(

a) Inclined and (

b) curved SU-8 structure obtained with gray-scale lithography. The red dashed arrow in

Figure 10b indicates the lens that was used for the profilometer scan and it corresponds to a distance covered of 535 µm to 2700 µm in the lens surface,

x-axis of figure.

Figure 10.

(

a) Inclined and (

b) curved SU-8 structure obtained with gray-scale lithography. The red dashed arrow in

Figure 10b indicates the lens that was used for the profilometer scan and it corresponds to a distance covered of 535 µm to 2700 µm in the lens surface,

x-axis of figure.

Figure 11.

Profile of the SU-8 microstructure presented in

Figure 10b. The red dashed rectangle is the distance covered correspondent to the red dashed arrow of

Figure 10b, which means the curvature degree of the lens surface.

Figure 11.

Profile of the SU-8 microstructure presented in

Figure 10b. The red dashed rectangle is the distance covered correspondent to the red dashed arrow of

Figure 10b, which means the curvature degree of the lens surface.

2.9. Limits of the SU-8 Processing

The SU-8 resolution limits were also tested using the facilities previously described. For this purpose, photomasks with lines of 100, 50, 25, and 10 μm widths and with different geometries were fabricated. The minimum lateral feature size of 10 µm is imposed by the resolution of the commercial print equipment of the photomask. With this study, it was found that SU-8 microstructures with aspect ratios more than 20 are successfully obtained using the processing conditions described above. Photographs and SEM images are shown in

Figure 12.

Figure 12.

SU-8 microstructures with lines of (a) 300, 200, 100, 50, 40, 30, 20, and 10 μm width and of 340 µm thick, (b) 300, 200, 100, 50, and 25 μm width and of 23 µm thick and (c) 10 μm width and 5 μm thick.

Figure 12.

SU-8 microstructures with lines of (a) 300, 200, 100, 50, 40, 30, 20, and 10 μm width and of 340 µm thick, (b) 300, 200, 100, 50, and 25 μm width and of 23 µm thick and (c) 10 μm width and 5 μm thick.

4. Conclusions

This paper presents the fabrication of SU-8 microstructures through a low-cost process and without the need for a cleanroom facility. Simple and low-cost solutions for photolithographic processes are always interesting, especially in microfluidic and MEMS areas, since the main disadvantage of this technique lies in the high cost of processing and equipments. The solutions presented demonstrate the possibility of using alternative photomask printed in transparent photographic sheet, as well as equipment and tools commonly employed in the PCB industry (UV light equipment) for SU-8 microstructures fabrication. The fabrication of well-defined SU-8 microstructures, with a minimum resolution of 10 µm and an aspect ratio more than 20, was successfully achieved using this process. The resolution of this process is suitable for most microfluidic applications. Moreover, the gray-scale technology for the fabrication of 3D microstructures has also been demonstrated. All the parameters used in the SU-8 microstructures processing are described, as well as their optimization. Some possible applications of the SU-8 in microfluidic systems and MEMS prove the feasibility of the fabrication process. In microfluidic systems, SU-8 microstructures have been widely used as molds to fabricate PDMS microchannels for several applications including purification and biomolecules analysis, and to integrate fuel cell. In MEMS, the main application consisted in the fabrication of diaphragms for piezoresistive pressure sensors, among others. Therefore, the scientific and academic community that does not have access to clean room facilities could, following some guidelines presented here, implement and optimize the SU-8 processing, according their environmental and tools conditions.