Fabrication of SiNx Thin Film of Micro Dielectric Barrier Discharge Reactor for Maskless Nanoscale Etching

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Procedure

2.2. Numerical Model

3. Results and Discussion

3.1. Simulation Results

3.2. Influence of the Key Process Parameters on the Intrinsic Stress Level and Deposition Rate

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Park, S.J.; Chen, K.F.; Ostrom, N.P.; Eden, J.G. 40000 pixel arrays of AC-excited silicon microcavity plasma devices. Appl. Phys. Lett. 2005, 86, 111501. [Google Scholar] [CrossRef]

- Priest, C.; Gruner, P.J.; Szili, E.J.; Al-Bataineh, S.A.; Bradley, J.W.; Ralston, J.; Steele, D.A.; Short, R.D. Microplasma patterning of bonded microchannels using high-precision “injected” electrodes. Lab Chip 2011, 11, 541–544. [Google Scholar] [CrossRef] [PubMed]

- Desmet, G.; Michelmore, A.; Szili, E.J.; Park, S.-J.; Eden, J.G.; Short, R.D.; Al-Bataineh, S.A. On the effects of atmospheric-pressure microplasma array treatment on polymer and biological materials. RSC Adv. 2013, 3, 13437. [Google Scholar] [CrossRef]

- Tatarova, E.; Bundaleska, N.; Sarrette, J.P.; Ferreira, C.M. Plasmas for environmental issues: From hydrogen production to 2D materials assembly. Plasma Sources Sci. Technol. 2014, 23, 063002. [Google Scholar] [CrossRef]

- Paetzelt, H.; Böhm, G.; Arnold, T. Etching of silicon surfaces using atmospheric plasma jets. Plasma Sources Sci. Technol. 2015, 24, 025002. [Google Scholar] [CrossRef]

- Mariotti, D.; Belmonte, T.; Benedikt, J.; Velusamy, T.; Jain, G.; Švrček, V. Low-temperature atmospheric pressure plasma processes for “green” third generation photovoltaics. Plasma Process. Polym. 2016, 13, 70–90. [Google Scholar] [CrossRef]

- Lee, O.J.; Ju, H.W.; Khang, G.; Sun, P.P.; Rivera, J.; Cho, J.H.; Park, S.J.; Eden, J.G.; Park, C.H. An experimental burn wound-healing study of non-thermal atmospheric pressure microplasma jet arrays. J. Tissue Eng. Regen. Med. 2016, 10, 348–357. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.; Chappanda, K.N.; Tabib-Azar, M. Fabrication of plasma probe for chemical vapor deposition. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 1622–1625.

- Xie, Y.; Yuan, W.; Tabib-Azar, M.; Mastrangelo, C.H. Microfabrication of plasma nanotorch tips for localized etching and deposition. In Proceedings of the 2010 IEEE Sensors, Waikoloa, HI, USA, 1–4 November 2010; pp. 2243–2246.

- Tabib-Azar, M.; Yuan, W. Tip based chemical vapor deposition of silicon. In Proceedings of the 2010 IEEE Sensors, Waikoloa, HI, USA, 1–4 November 2010; pp. 2235–2238.

- Tabib-Azar, M. Microplasma chemical vapor deposition with atomic force microscope. Proc. SPIE 2013. [Google Scholar] [CrossRef]

- Xie, Y.; Surapaneni, R.; Chowdhury, F.K.; Tabib-Azar, M.; Mastrangelo, C.H. Fabrication of localized plasma gold-tip nanoprobes with integrated microchannels for direct-write nanomanufacturing. In Proceedings of the 2012 IEEE Sensors, Taipei, Taiwan, 28–31 October 2012; pp. 1–4.

- Guo, H.; Liu, J.; Yang, B.; Chen, X.; Yang, C. Localized etching of polymer films using an atmospheric pressure air microplasma jet. J. Micromech. Microeng. 2014, 25, 015010. [Google Scholar] [CrossRef]

- Yang, Y.J.; Tsai, M.Y.; Liang, W.C.; Chen, H.Y.; Hsu, C.C. Ultra-low-cost and flexible paper-based microplasma generation devices for maskless patterning of poly(ethylene oxide)-like films. ACS Appl. Mater. Interfaces 2014, 6, 12550–12555. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Xu, L.; Chen, X.; Wang, X.; Sheng, M.; Stubhan, F.; Merkel, K.-H.; Wilde, J. Moisture-resistant properties of SiNx films prepared by PECVD. Thin Solid Films 1998, 333, 71–76. [Google Scholar] [CrossRef]

- Han, G.; Luo, P.; Li, K.; Liu, Z.; Wu, Y. Growth and characterization of silicon nitride films on various underlying materials. Appl. Phys. A 2002, 74, 243–247. [Google Scholar] [CrossRef]

- Kim, J.H.; Chung, K.W. Microstructure and properties of silicon nitride thin films deposited by reactive bias magnetron sputtering. J. Appl. Phys. 1998, 83, 5831–5839. [Google Scholar] [CrossRef]

- Moslehi, M.M.; Fu, C.Y.; Saraswat, K. Low-Temperature Direct Nitridation of Silicon in Nitrogen Plasma Generated by Microwave Discharge. U.S. Patent 4,715,937, 29 December 1987. [Google Scholar]

- Droopad, R.; Abrokwah, J.K.; Passlack, M.; Yu, Z.J. Method of Forming a Silicon Nitride Layer. U.S. Patent 5,907,792, 25 May 1999. [Google Scholar]

- Piccirillo, A.; Gobbi, A. Physical-electrical properties of silicon nitride deposited by PECVD on III–V semiconductors. J. Electrochem. Soc. 1990, 137, 3910–3917. [Google Scholar] [CrossRef]

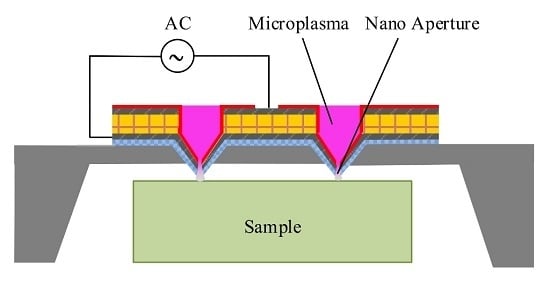

- Liu, J.; Wen, L.; Li, H.; Wang, H.; Peng, J. Fabrication of Thin-Wall Inverted Pyramid Hollow Tips Array and Nano-Aperture for Maskless Nanoscaled Plasma Patterning. In Proceedings of the 2015 IEEE 10th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xi’an, China, 7–11 April 2015; pp. 498–501.

- Xie, H.; Wen, L.; Wang, H.; Chu, J. Fabrication and operation of microplasma reactor array for maskless nanoscale material etching. In Proceedings of the 2013 13th IEEE Conference on Nanotechnology (NANO), Beijing, China, 5–8 August 2013; pp. 1180–1183.

- Tarraf, A.; Daleiden, J.; Irmer, S.; Prasai, D.; Hillmer, H. Stress investigation of PECVD dielectric layers for advanced optical MEMS. J. Micromech. Microeng. 2003, 14, 317. [Google Scholar] [CrossRef]

- Cazzanelli, M.; Bianco, F.; Borga, E.; Pucker, G.; Ghulinyan, M.; Degoli, E.; Luppi, E.; Veniard, V.; Ossicini, S.; Modotto, D.; et al. Second-harmonic generation in silicon waveguides strained by silicon nitride. Nat. Mater. 2012, 11, 148–154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Franssila, S. Introduction to Microfabrication; John Wiley & Sons: Chichester, West Sussex, UK, 2010. [Google Scholar]

- Xu, S.; Ren, Z.; Shen, K. Measurement of plasma parameters in RF-biased ECR-PECVD. Nucl. Fusion Plasma Phys. 2004, 24, 63–66. [Google Scholar]

- Cotler, T.J.; Chapple-Sokol, J. High quality plasma-enhanced chemical vapor deposited silicon nitride films. J. Electrochem. Soc. 1993, 140, 2071–2075. [Google Scholar] [CrossRef]

- Ong, P.L.; Wei, J.; Tay, F.E.H.; Iliescu, C. A new fabrication method for low stress PECVD-SiNx layers. J. Phys. 2006, 34, 764–769. [Google Scholar] [CrossRef]

| Film | Si | SiO2 | Ni | PI | SiNx |

|---|---|---|---|---|---|

| Density (kg/m3) | 2329 | 2200 | 8900 | 1300 | 3100 |

| Poisson’s ratio | 0.28 | 0.17 | 0.31 | 0.42 | 0.23 |

| Young’s modulus (GPa) | 170 | 70 | 219 | 3.1 | 250 |

| CTE (1/K) | 2.6 × 10−6 | 5 × 10−7 | 1.3 × 10−5 | 3.5 × 10−5 | 2.3 × 10−6 |

| Residual stress (MPa) | 0 | −480 | 200 | 30 | (−800, 100, 800) |

| RF Power (W) | Deposition Rate (nm·min−1) | Intrinsic Stress (MPa) |

|---|---|---|

| 35 | 16 | −440.6 |

| 60 | 19 | −507.8 |

| 100 | 26 | −522.3 |

| 200 | 26 | −622.5 |

| SiH4/NH3 | Deposition Rate (nm·min−1) | Si/N | Intrinsic Stress (MPa) |

|---|---|---|---|

| 100/80 | 11 | 0.70 | −344.0 |

| 100/40 | 12 | 0.83 | −386.9 |

| 100/20 | 13 | 0.94 | −434.1 |

| 100/10 | 16 | 1.11 | −440.6 |

| Chamber Pressure (Pa) | Deposition Rate (nm·min−1) | Intrinsic Stress (MPa) |

|---|---|---|

| 80 | 9 | −424.4 |

| 90 | 10 | −407.5 |

| 95 | 11 | −182.4 |

| 100 | 11 | −308.0 |

| 110 | 13 | −519.6 |

| Temperature (°C) | Deposition Rate (nm·min−1) | Intrinsic Stress (MPa) |

|---|---|---|

| 240 | 9 | −296.9 |

| 280 | 11 | −255.3 |

| 300 | 11 | −182.4 |

| 350 | 10 | −563.7 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Liu, J.; Dai, Y.; Xiang, W.; Zhang, M.; Wang, H.; Wen, L. Fabrication of SiNx Thin Film of Micro Dielectric Barrier Discharge Reactor for Maskless Nanoscale Etching. Micromachines 2016, 7, 232. https://doi.org/10.3390/mi7120232

Li Q, Liu J, Dai Y, Xiang W, Zhang M, Wang H, Wen L. Fabrication of SiNx Thin Film of Micro Dielectric Barrier Discharge Reactor for Maskless Nanoscale Etching. Micromachines. 2016; 7(12):232. https://doi.org/10.3390/mi7120232

Chicago/Turabian StyleLi, Qiang, Jie Liu, Yichuan Dai, Wushu Xiang, Man Zhang, Hai Wang, and Li Wen. 2016. "Fabrication of SiNx Thin Film of Micro Dielectric Barrier Discharge Reactor for Maskless Nanoscale Etching" Micromachines 7, no. 12: 232. https://doi.org/10.3390/mi7120232

APA StyleLi, Q., Liu, J., Dai, Y., Xiang, W., Zhang, M., Wang, H., & Wen, L. (2016). Fabrication of SiNx Thin Film of Micro Dielectric Barrier Discharge Reactor for Maskless Nanoscale Etching. Micromachines, 7(12), 232. https://doi.org/10.3390/mi7120232