Wrinkled Graphene–AgNWs Hybrid Electrodes for Smart Window

Abstract

:1. Introduction

2. Preparation and Experiment

2.1. Materials

2.2. Fabrication

2.3. Experiment Method

3. Results and Discussions

3.1. Uni- and Bi-axially Wrinkled Electrode

3.2. Morphology Variation with Tensile Strength

3.3. Electrical Measurement

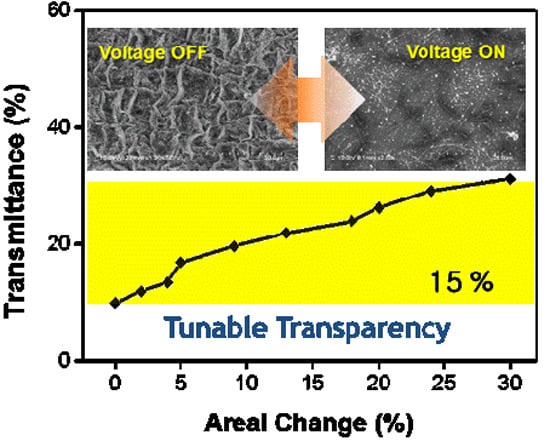

3.4. Electromechanical Transducer with Elastomer Films

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Beaujuge, P.M.; Reynolds, J.R. Color control in π-conjugated organic polymers for use in electrochromic devices. Chem. Rev. 2010, 110, 268–320. [Google Scholar] [CrossRef] [PubMed]

- Bechinger, C.; Ferrer, S.; Zaban, A.; Sprague, J.; Gregg, B.A. Photoelectrochromic windows and displays. Nature 1996, 383, 608–610. [Google Scholar] [CrossRef]

- Granqvist, C.G. Electrochromic tungsten oxide films: Review of progress 1993–1998. Sol. Energy Mater. Sol. Cells 2000, 60, 201–262. [Google Scholar] [CrossRef]

- Lampert, C.M. Chromogenic smart materials. Mater. Today 2004, 7, 28–35. [Google Scholar] [CrossRef]

- An, B.W.; Gwak, E.-J.; Kim, K.; Kim, Y.-C.; Jang, J.; Kim, J.-Y.; Park, J.-U. Stretchable, transparent electrodes as wearable heaters using nanotrough networks of metallic glasses with superior mechanical properties and thermal stability. Nano Lett. 2016, 16, 471–478. [Google Scholar] [CrossRef] [PubMed]

- An, B.W.; Hyun, B.G.; Kim, S.-Y.; Kim, M.; Lee, M.-S.; Lee, K.; Koo, J.B.; Chu, H.Y.; Bae, B.-S.; Park, J.-U. Stretchable and transparent electrodes using hybrid structures of graphene–metal nanotrough networks with high performances and ultimate uniformity. Nano Lett. 2014, 14, 6322–6328. [Google Scholar] [CrossRef] [PubMed]

- He, T.; Xie, A.; Reneker, D.H.; Zhu, Y. A tough and high-performance transparent electrode from a scalable and transfer-free method. ACS Nano 2014, 8, 4782–4789. [Google Scholar] [CrossRef] [PubMed]

- Hsu, P.-C.; Wang, S.; Wu, H.; Narasimhan, V.K.; Kong, D.; Ryoung Lee, H.; Cui, Y. Performance enhancement of metal nanowire transparent conducting electrodes by mesoscale metal wires. Nat. Commun. 2013, 4, 2522. [Google Scholar] [CrossRef] [PubMed]

- Hsu, P.-C.; Wu, H.; Carney, T.J.; McDowell, M.T.; Yang, Y.; Garnett, E.C.; Li, M.; Hu, L.; Cui, Y. Passivation coating on electrospun copper nanofibers for stable transparent electrodes. ACS Nano 2012, 6, 5150–5156. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Lee, M.-S.; Jeon, S.; Kim, M.; Kim, S.; Kim, K.; Bien, F.; Hong, S.Y.; Park, J.-U. Highly transparent and stretchable field-effect transistor sensors using graphene–nanowire hybrid nanostructures. Adv. Mater. 2015, 27, 3292–3297. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Kim, J.; Hyun, B.G.; Ji, S.; Kim, S.-Y.; Kim, S.; An, B.W.; Park, J.-U. Stretchable and transparent electrodes based on in-plane structures. Nanoscale 2015, 7, 14577–14594. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Kong, D.; Ruan, Z.; Hsu, P.-C.; Wang, S.; Yu, Z.; Carney, T.J.; Hu, L.; Fan, S.; Cui, Y. A transparent electrode based on a metal nanotrough network. Nat. Nanotechnol. 2013, 8, 421–425. [Google Scholar] [CrossRef] [PubMed]

- Chan, E.P.; Crosby, A.J. Fabricating microlens arrays by surface wrinkling. Adv. Mater. 2006, 18, 3238–3242. [Google Scholar] [CrossRef]

- Chandra, D.; Yang, S.; Lin, P.-C. Strain responsive concave and convex microlens arrays. Appl. Phys. Lett. 2007, 91, 251912. [Google Scholar] [CrossRef]

- Khang, D.-Y.; Jiang, H.; Huang, Y.; Rogers, J.A. A stretchable form of single-crystal silicon for high-performance electronics on rubber substrates. Science 2006, 311, 208–212. [Google Scholar] [CrossRef] [PubMed]

- Scalisi, R.G.; Paleari, M.; Favetto, A.; Stoppa, M.; Ariano, P.; Pandolfi, P.; Chiolerio, A. Inkjet printed flexible electrodes for surface electromyography. Org. Electron. 2015, 18, 89–94. [Google Scholar] [CrossRef]

- Harrison, C.; Stafford, C.M.; Zhang, W.; Karim, A. Sinusoidal phase grating created by a tunably buckled surface. Appl. Phys. Lett. 2004, 85, 4016–4018. [Google Scholar] [CrossRef]

- Opris, D.M.; Molberg, M.; Walder, C.; Ko, Y.S.; Fischer, B.; Nüesch, F.A. New silicone composites for dielectric elastomer actuator applications in competition with acrylic foil. Adv. Funct. Mater. 2011, 21, 3531–3539. [Google Scholar] [CrossRef]

- Jun, K.W.; Lee, J.M.; Lee, J.Y.; Oh, I.K. Bio-inspired dielectric elastomer actuator with agnws coated on carbon black electrode. J. Nanosci. Nanotechnol. 2014, 14, 7483–7487. [Google Scholar] [CrossRef] [PubMed]

- Tien, H.-W.; Hsiao, S.-T.; Liao, W.-H.; Yu, Y.-H.; Lin, F.-C.; Wang, Y.-S.; Li, S.-M.; Ma, C.-C.M. Using self-assembly to prepare a graphene-silver nanowire hybrid film that is transparent and electrically conductive. Carbon 2013, 58, 198–207. [Google Scholar] [CrossRef]

- Jin, J.; Lee, J.; Jeong, S.; Yang, S.; Ko, J.-H.; Im, H.-G.; Baek, S.-W.; Lee, J.-Y.; Bae, B.-S. High-performance hybrid plastic films: A robust electrode platform for thin-film optoelectronics. Energy Environ. Sci. 2013, 6, 1811–1817. [Google Scholar] [CrossRef]

- Lee, J.; Lee, I.; Kim, T.-S.; Lee, J.-Y. Efficient welding of silver nanowire networks without post-processing. Small 2013, 9, 2887–2894. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Gu, H.; Lin, W.; Yuen, M.M.; Wong, C.P.; Xiong, M.; Gao, B. Silver nanowires: From scalable synthesis to recyclable foldable electronics. Adv. Mater. 2011, 23, 3052–3056. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jun, K.-W.; Kim, J.-N.; Jung, J.-Y.; Oh, I.-K. Wrinkled Graphene–AgNWs Hybrid Electrodes for Smart Window. Micromachines 2017, 8, 43. https://doi.org/10.3390/mi8020043

Jun K-W, Kim J-N, Jung J-Y, Oh I-K. Wrinkled Graphene–AgNWs Hybrid Electrodes for Smart Window. Micromachines. 2017; 8(2):43. https://doi.org/10.3390/mi8020043

Chicago/Turabian StyleJun, Ki-Woo, Jong-Nam Kim, Jin-Young Jung, and Il-Kwon Oh. 2017. "Wrinkled Graphene–AgNWs Hybrid Electrodes for Smart Window" Micromachines 8, no. 2: 43. https://doi.org/10.3390/mi8020043

APA StyleJun, K. -W., Kim, J. -N., Jung, J. -Y., & Oh, I. -K. (2017). Wrinkled Graphene–AgNWs Hybrid Electrodes for Smart Window. Micromachines, 8(2), 43. https://doi.org/10.3390/mi8020043