3D Shape Reconstruction of 3D Printed Transparent Microscopic Objects from Multiple Photographic Images Using Ultraviolet Illumination

Abstract

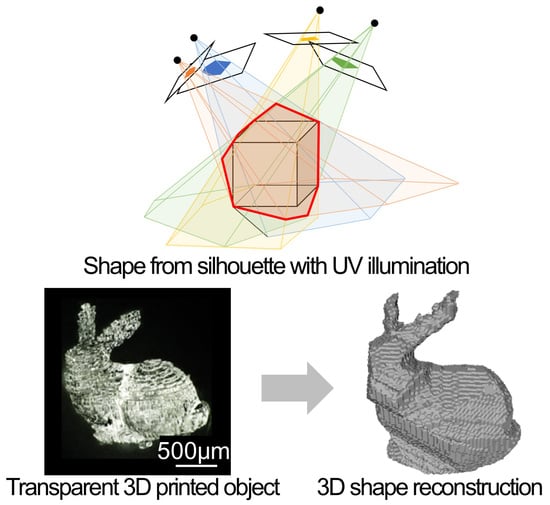

:1. Introduction

2. Materials and Methods

2.1. 3D Shape Acquisition Based on the Shape from Silhouette (SFS) Method

2.2. 3D Shape Acquisition System Based on SFS with Ultraviolet Light

2.3. Micro-Stereolithography Systems and Photocurable Resins

3. Results and Discussion

3.1. Transmission Spectrum of Photopolymer

3.2. 3D Shape Acquisition of Transparent 3D Printed Objects

3.3. Evaluating the Accuracy of 3D Shape Acquisition Using the Pillar Array Model

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- William, E.F. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Deckers, J.; Vleugels, J.; Kruth, J.P. Additive manufacturing of ceramics: A review. J. Ceram. Sci. Technol. 2014, 5, 245–260. [Google Scholar] [CrossRef]

- Thompson, A.; Maskery, I.; Leach, R.K. X-ray computed tomography for additive manufacturing: A review. Meas. Sci. Technol. 2016, 27, 1–17. [Google Scholar] [CrossRef]

- Saha, S.K.; Oakdale, J.S.; Cuadra, J.A.; Divin, C.; Ye, J.; Forien, J.B.; Aji, L.B.; Biener, J.; Smith, W.L. Radiopaque resists for two-photon lithography to enable submicron 3D imaging of polymer parts via X-ray computed tomography. ACS Appl. Mater. Interfaces 2018, 10, 1164–1172. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Brown, G.M.; Song, M. Overview of three-dimensional shape measurement using optical methods. Opt. Eng. 2000, 39, 10–22. [Google Scholar] [CrossRef]

- Moons, T.; Gool, L.V.; Vergauwen, M. 3D Reconstruction from multiple images part 1: Principles. Comput. Graph. Vis. 2008, 4, 287–398. [Google Scholar] [CrossRef]

- Zhang, R.; Tsai, P.S.; Cryer, J.E.; Shah, M. Shape-from-shading: A survey. IEEE Trans. Pattern Anal. Mach. Intell. 1999, 21, 690–706. [Google Scholar] [CrossRef]

- Cheung, G.; Baker, S.; Kanade, T. Shape-from-silhouette across time part I: Theory and algorithms. Int. J. Comput. Vis. 2005, 62, 221–247. [Google Scholar] [CrossRef]

- Atsushi, K.; Sueyasu, H.; Funayama, Y.; Maekawa, T. System for reconstruction of three-dimensional micro objects from multiple photographic images. Comput. Aided Des. 2011, 43, 1045–1055. [Google Scholar] [CrossRef]

- Monri, K.; Maruo, S. Three-dimensional ceramic molding based on microstereolithography for the production of piezoelectric energy harvesters. Sens. Actuators A 2013, 200, 31–36. [Google Scholar] [CrossRef]

- Maruo, S.; Fourkas, J.T. Recent progress in multiphoton microfabrication. Laser Photon. Rev. 2008, 2, 100–111. [Google Scholar] [CrossRef]

- Gonen, E.; Olivier, A.; Fabrice, M.; Sanchez, L.A.; David, F.; Teoman, N.A.; Frederic, T.; Aytul, E. Scanning from heating: 3D shape estimation of transparent objects from local surface heating. Opt. Express 2009, 17, 57–68. [Google Scholar] [CrossRef]

- Miyazaki, D.; Saito, M.; Sato, Y.; Ikeuchi, K. Determining surface orientations of transparent objects based on polarization degrees in visible and infrared wavelengths. J. Opt. Soc. Am. 2002, 19, 687–705. [Google Scholar] [CrossRef]

- William, E.L.; Cline, H.E. Marching cubes: A high resolution 3D surface construction algorithm. ACM Siggraph Comput. Graph. 1987, 21, 163–169. [Google Scholar] [CrossRef]

- Lavest, J.M.; Rives, G.; Dhome, M. Three-dimensional Reconstruction by Zooming. IEEE J. Robot. Autom. 1993, 9, 196–207. [Google Scholar] [CrossRef]

- Inada, M.; Hiratsuka, D.; Tatami, J.; Maruo, S. Fabrication of three-dimensional transparent SiO2 microstructures by microstereolithographic molding. Jpn. J. Appl. Phys. 2009, 48, 06FK01. [Google Scholar] [CrossRef]

- Torii, T.; Inada, M.; Maruo, S. Three-dimensional molding based on microstereolithography using beta-tricalcium phosphate slurry for the production of bio ceramic scaffolds. Jpn. J. Appl. Phys. 2011, 50, 06GL15. [Google Scholar] [CrossRef]

- Gallo, A.; Muzzupappa, M.; Bruno, F. 3D reconstruction of small sized objects from a sequence of multi-focused images. J. Cult. Herit. 2014, 15, 173–182. [Google Scholar] [CrossRef]

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-dimensional printing of transparent fused silica glass. Nature 2017, 544, 337–339. [Google Scholar] [CrossRef] [PubMed]

- Klein, J.; Stern, M.; Franchin, G.; Kayser, M.; Inamura, C.; Dave, S.; Weaver, J.C.; Houk, P.; Colombo, P.; Yang, M.; et al. Additive manufacturing of optically transparent glass. 3D Print. Addit. Manuf. 2015, 2, 92–105. [Google Scholar] [CrossRef]

| Pillar Number | Actual Pillar Diameter Measured by an Optical Microscope | Averaged Pillar Diameter Estimated by SFS Method |

|---|---|---|

| 1 | 106 μm | 94 μm |

| 2 | 152 μm | 151 μm |

| 3 | 248 μm | 268 μm |

| 4 | 347 μm | 333 μm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koyama, K.; Takakura, M.; Furukawa, T.; Maruo, S. 3D Shape Reconstruction of 3D Printed Transparent Microscopic Objects from Multiple Photographic Images Using Ultraviolet Illumination. Micromachines 2018, 9, 261. https://doi.org/10.3390/mi9060261

Koyama K, Takakura M, Furukawa T, Maruo S. 3D Shape Reconstruction of 3D Printed Transparent Microscopic Objects from Multiple Photographic Images Using Ultraviolet Illumination. Micromachines. 2018; 9(6):261. https://doi.org/10.3390/mi9060261

Chicago/Turabian StyleKoyama, Keishi, Masayuki Takakura, Taichi Furukawa, and Shoji Maruo. 2018. "3D Shape Reconstruction of 3D Printed Transparent Microscopic Objects from Multiple Photographic Images Using Ultraviolet Illumination" Micromachines 9, no. 6: 261. https://doi.org/10.3390/mi9060261

APA StyleKoyama, K., Takakura, M., Furukawa, T., & Maruo, S. (2018). 3D Shape Reconstruction of 3D Printed Transparent Microscopic Objects from Multiple Photographic Images Using Ultraviolet Illumination. Micromachines, 9(6), 261. https://doi.org/10.3390/mi9060261