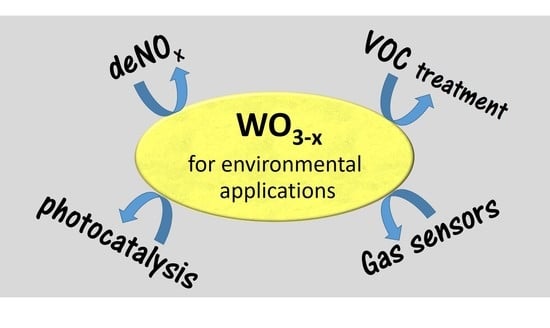

Tungsten-Based Catalysts for Environmental Applications

Abstract

:1. Introduction

2. Structure of Tungsten-Based Catalysts

2.1. Structure of Unsupported Tungsten Oxides

2.1.1. Tungsten Trioxide

2.1.2. Tungsten Trioxide WO2.9 Blue Oxide (β-Tungsten Oxide W20O58) and Other Suboxides WO3−δ (δ < 0.13)

2.1.3. WO2.72 Violet Oxide (γ-Tungsten Oxide W18O49) and Other Suboxides WO3−δ (δ > 0.2)

2.1.4. Tungsten Dioxide (WO2)

2.2. Structure of Supported Tungsten Oxides

3. Acidity of Supported Tungsten Oxide Catalysts

3.1. General Overview

3.2. Silica-Supported Tungsten Oxides

3.3. Alumina-Supported Tungsten Oxides

3.4. Zirconia-Supported Tungsten Oxides

3.5. Titania-Supported Tungsten Oxides

3.6. Conclusions

4. WO3 Catalysts for DeNOx Applications: WO3-V2O5/TiO2 and Other Tungsten-Based Materials

4.1. Mechanisms and Surface Intermediates

4.2. Influence of the Preparation Method: Powder and Monolithic Catalysts

4.3. Poisoning of V2O5-WO3/TiO2 Catalysts

4.3.1. Potassium and Calcium Poisoning

4.3.2. Sulfur Poisoning

4.3.3. Arsenic Poisoning

4.3.4. Metal Release and Reuse of V-W-TiO2 Catalysts

4.4. Cerium-Promoted WO3 Catalysts for NH3-SCR

4.4.1. Ceria Added to V2O5-WO3/TiO2

4.4.2. Ceria Added to WO3/TiO2 (Without Vanadium)

4.4.3. Ceria Added to WO3 (Without Vanadia or Titania)

4.5. Iron-Promoted WO3 Catalysts for NH3-SCR

4.6. Manganese-Promoted WO3 Catalysts for NH3-SCR

5. Other DeNOx Applications of WO3-Doped Catalysts

5.1. Tungsten Catalysts for the NOx Trap–SCR Coupled System

5.2. Tungsten Catalysts for NOx Reduction by Other Reductants

5.2.1. Reduction by Hydrogen (H2-SCR)

5.2.2. Reduction by Ethanol (C2H5OH-SCR)

5.3. Conclusions

6. Total Oxidation of Volatile Organic Compounds in Gas Phase and Gas Sensors

6.1. VOC Oxidation in Gas Phase on Tungsten Catalysts

6.1.1. VOC Oxidation on Tungsten Catalysts (Non-Photocatalyzed Reactions)

6.1.2. WO3-Based Photocatalysts for VOC Oxidation

6.2. Gas Sensors Using Tungsten-Based Catalytic Materials

6.2.1. WO3-Based Sensor for NO2 Detection

6.2.2. WO3-Based Sensors for Detection of Gasses Other Than NO2

6.3. Conclusions

7. Pollutant Remediation in Liquid Phase (Photocatalysis)

7.1. Undoped WO3 Photocatalysts

7.2. WO3–Carbon Photocatalysts

7.3. WO3 Photocatalysts Doped by Precious Metals or Silver

7.3.1. WO3 Photocatalysts Doped by Precious Metals

7.3.2. WO3 Photocatalysts Doped by Silver

7.4. WO3–TiO2-Based Photocatalysts

7.4.1. WO3–TiO2-Based Systems as Supported and Composite Photocatalysts

7.4.2. Metal-Doped WO3–TiO2-Doped Systems

7.5. WO3 Associated with Transition Metal Oxides Other Than TiO2 (Zn, Fe, Sn, Mn, Ni, Mo, Co, Nb)

7.5.1. ZnO–WO3

7.5.2. MO–WO3 (MO: Metal Oxides = Fe, Sn, Mn, Ni, Mo, Co)

7.6. WO3 Associated with Other Systems (Post-Transition Metal Oxides and Metalloids, Rare Earths, Nitrides)

7.6.1. Post-Transition Metal or Metalloid–WO3 Systems

7.6.2. Rare Earth–WO3 Systems

7.6.3. Nitride–WO3 Systems

7.6.4. Photoreduction over WO3 Based Systems

7.7. Conclusions

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lassner, E.; Schubert, W.D. Tungsten, Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds; Kluwer Academic Plenum Publishers: Vienna, Austria, 1999. [Google Scholar]

- Morcom, W.W.R.; Worrell, W.L.; Sell, H.G.; Kaplan, H.I. The preparation and characterization of beta-tungsten, a metastable tungsten phase. Metallurg. Trans. 1974, 5, 155–161. [Google Scholar]

- Christian, J.; Singh Gaur, R.P.; Wolfe, T.; Trasorras, J.R.L. Tungsten Chemicals and their Applications. In Tungsten; Newsletter of the International Tungsten Industry Association: London, UK, 2011. [Google Scholar]

- Chianelli, R.R.; Berhault, G.; Torres, B. Unsupported transition metal sulfide catalysts: 100 years of science and application. Catal. Today 2009, 147, 275–286. [Google Scholar] [CrossRef]

- Shan, S.; Yuan, P.; Han, W.; Shi, G.; Bao, X. Supported NiW catalysts with tunable size and morphology of active phases for highly selective hydrodesulfurization of fluid catalytic cracking naphtha. J. Catal. 2015, 330, 288–301. [Google Scholar] [CrossRef]

- Zou, X.; Zhang, Y. Noble metal-free hydrogen evolution catalysts for water splitting. Chem. Soc. Rev. 2015, 44, 5148–5180. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.K.; Hai, X.; Ye, J. Transition Metal Disulfides as Noble-Metal-Alternative Co-Catalysts for Solar Hydrogen Production. Adv. Energy Mater. 2016, 6, 1502555. [Google Scholar] [CrossRef]

- Xiang, Q.J.; Cheng, F.Y.; Lang, D. Hierarchical Layered WS2/Graphene-Modified CdS Nanorods for Efficient Photocatalytic Hydrogen Evolution. ChemSusChem 2016, 9, 996–1002. [Google Scholar] [CrossRef]

- Ledendecker, M.; Mondschein, J.S.; Kasian, O.; Geiger, S.; Göhl, D.; Schalenbach, M.; Zeradjanin, A.; Cherevko, S.; Schaak, R.E.; Mayrhofer, K. Stability and Activity of Non-Noble-Metal-Based Catalysts Toward the Hydrogen Evolution Reaction. Angew. Chem. Int. Ed. 2017, 56, 9767–9771. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tackett, B.M.; Sheng, W.; Chen, J.G. Opportunities and Challenges in Utilizing Metal-Modified Transition Metal Carbides as Low-Cost Electrocatalysts. Perspective paper. Joule 2017, 1, 253–263. [Google Scholar] [CrossRef] [Green Version]

- Omwoma, S.; Chen, W.; Tsunashima, R.; Song, Y.F. Recent advances on polyoxometalates intercalated layered double hydroxides: From synthetic approaches to functional material applications. Coord. Chem. Rev. 2014, 258–259, 58–71. [Google Scholar] [CrossRef]

- Enferadi-Kerenkan, A.; Do, T.O.; Kaliaguine, S. Heterogeneous catalysis by tungsten-based heteropoly compounds. Catal. Sci. Technol. 2018, 8, 2257–2284. [Google Scholar] [CrossRef]

- Farsani, M.R.; Jalilian, F.; Yadollahi, B.; Rudbari, H.A. A comparative study on Keggin and Wells–Dawson sandwich type polyoxometallates in the oxidation of alcohols with 30% hydrogen peroxide. Polyhedron 2014, 76, 102–107. [Google Scholar] [CrossRef]

- Vickers, J.W.; Ly, H.; Sumliner, J.M.; Zhu, G.; Luo, Z.; Musaev, D.G.; Geletii, Y.V.; Hill, C.L. Differentiating homogeneous and heterogeneous water oxidation catalysis: Confirmation that [Co4(H2O)2(α-PW9O34)2]10− is a molecular water oxidation catalyst. J. Am. Chem. Soc. 2013, 135, 14110–14118. [Google Scholar] [CrossRef] [PubMed]

- Dai, W.L.; Ding, J.; Zhu, Q.; Gao, R.; Yang, X. Tungsten containing materials as heterogeneous catalysts for green catalytic oxidation process. In Catalysis; The Royal Society of Chemistry: London, UK, 2016; Volume 28, pp. 1–27. [Google Scholar]

- Rieck, G.D. Tungsten and Its Compounds; Elsevier: Amsterdam, The Netherlands, 1967. [Google Scholar]

- Diehl, R.; Brandt, G.; Salje, E. The crystal structure of triclinic WO3. Acta Cryst. 1978, B34, 1105–1111. [Google Scholar] [CrossRef]

- Corà, F.; Patel, A.; Harrison, N.M.; Dovesi, R.; Catlow, C.R.A. An ab Initio Hartree-Fock Study of the cubic and tetragonal phases of bulk tungsten trioxide. J. Am. Chem. Soc. 1996, 118, 12174–12182. [Google Scholar] [CrossRef]

- Sun, W.; Yeung, M.T.; Lech, A.T.; Lin, C.W.; Lee, C.; Li, T.; Duan, X.; Zhou, J.; Kaner, R.B. High surface area tunnels in hexagonal WO3. Nano Lett. 2015, 15, 4834–4838. [Google Scholar] [CrossRef]

- Szilágyi, I.M.; Fórizs, B.; Rosseler, O.; Szegedi, Á.; Németh, P.; Király, P.; Tárkány, G.; Vajna, B.; Varga-Josepovits, K.; László, K.; et al. WO3 photocatalysts: Influence of structure and composition. J. Catal. 2012, 294, 119–127. [Google Scholar] [CrossRef] [Green Version]

- Szilágyi, I.M.; Madarász, J.; Pokol, G.; Király, P.; Tárkány, G.; Saukko, S.; Mizsei, J.; Tóth, A.L.; Szabó, A.; Varga-Josepovits, K. Stability and controlled composition of hexagonal WO3. Chem. Mater. 2008, 20, 4116–4125. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, S.; Xie, S.; Li, H. Hexagonal single crystal growth of WO3 nanorods along a [110] axis with enhanced adsorption capacity. Chem. Commun. 2011, 47, 4403–4405. [Google Scholar] [CrossRef]

- Gu, Z.; Li, H.; Zhai, T.; Yang, W.; Xia, Y.; Ma, Y.; Yao, J. Large-scale synthesis of single-crystal hexagonal tungsten trioxide nanowires and electrochemical lithium intercalation into the nanocrystals. J. Solid State Chem. 2007, 180, 98–105. [Google Scholar] [CrossRef]

- Zheng, H.; Zhen Ou, J.; Strano, M.S.; Kaner, R.B.; Mitchell, A.; Kalantar-zadeh, K. Nanostructured tungsten oxide—Properties, synthesis, and applications. Adv. Struct. Mater. 2011, 21, 2175–2196. [Google Scholar] [CrossRef]

- Zhang, H.; Duan, G.; Li, Y.; Xu, X.; Dai, Z.; Cai, W. Leaf-like tungsten oxide nanoplatelets induced by laser ablation in liquid and subsequent aging. Cryst. Growth Des. 2012, 12, 2646–2652. [Google Scholar] [CrossRef]

- Magnéli, A. Crystal structure studies on beta-tungsten oxide. Ark Kemie 1950, 1, 513. [Google Scholar]

- Magnéli, A. Structure of β-tungsten oxide. Nature 1950, 165, 356–357. [Google Scholar] [CrossRef]

- Tilley, R.J.D. The crystal chemistry of the higher tungsten oxides. Int. J. Refract. Met. Hard Mater. 1995, 13, 93–109. [Google Scholar] [CrossRef]

- Slobodchikov, A.A.; Nekrasov, I.A.; Pavlov, N.S.; Korshunov, M.M. Simplicity Out of Complexity: Band Structure for W20O58 Superconductor. Nanomaterials 2021, 11, 97. [Google Scholar] [CrossRef]

- Chen, S.; Xiao, Y.; Xie, W.; Wang, Y.; Hu, Z.; Zhang, W.; Zhao, H. Facile Strategy for Synthesizing Non-stoichiometric monoclinic structured tungsten trioxide (WO3−x) with plasma resonance absorption and enhanced photocatalytic activity. Nanomaterials 2018, 8, 553. [Google Scholar] [CrossRef] [Green Version]

- Walter, J.L.; Lou, K.A. Structures and chemistry of tungsten powder from doped and undoped tungsten blue oxide. J. Mater. Sci. 1989, 24, 3577–3587. [Google Scholar] [CrossRef]

- Kurumada, M.; Kido, O.; Sato, T.; Suzuki, H.; Kimura, Y.; Kamitsuji, K.; Saito, Y.; Kaito, C. Structure of WO3 ultrafine particles and their characteristic solid states. J. Cryst. Growth 2005, 275, e1673–e1678. [Google Scholar] [CrossRef]

- Fang, Z.; Jiao, S.; Wang, B.; Yin, W.; Liu, S.; Gao, R.; Liu, Z.; Pang, G.; Feng, S. Synthesis of reduced cubic phase WO3−x nanosheet by direct reduction of H2WO4·H2O. Mater. Today Energy 2017, 6, 146–153. [Google Scholar] [CrossRef]

- Solonin, Y.M.; Khyzhun, O.Y.; Graivoronskaya, E.A. Nonstoichiometric tungsten oxide based on hexagonal WO3. Cryst. Growth Des. 2001, 1, 473–477. [Google Scholar] [CrossRef]

- Cheng, H.; Klapproth, M.; Sagaltchik, A.; Li, S.; Thomas, A. Ordered mesoporous WO2.83: Selective reduction synthesis, exceptional localized surface Plasmon resonance and enhanced hydrogen evolution reaction activity. J. Mater. Chem. A 2018, 6, 2249–2256. [Google Scholar] [CrossRef]

- Sarin, V.K. Morphological changes occurring during reduction of WO3. J. Mater. Sci. 1975, 10, 593–598. [Google Scholar] [CrossRef]

- Pfeifer, J.; Badaljan, E.; Tekula-Buxbaum, P.; Kovacs, T.; Geszti, O.; Toth, A.L.; Lunk, H.J. Growth and morphology of W18049 crystals produced by microwave decomposition of ammonium paratungstate. J. Cryst. Growth 1996, 169, 727–733. [Google Scholar] [CrossRef]

- Wu, C. Preparation of ultrafine tungsten powders by in-situ hydrogen reduction of nano-needle violet tungsten oxide. Int. J. Refract. Met. Hard Mater. 2011, 29, 686–691. [Google Scholar] [CrossRef]

- Soultanidis, N.; Zhou, W.; Kiely, C.J.; Wong, M.S. Solvothermal Synthesis of Ultrasmall Tungsten Oxide Nanoparticles. Langmuir 2012, 28, 17771–17777. [Google Scholar] [CrossRef] [PubMed]

- Shpak, A.P.; Korduban, A.M.; Medvedskij, M.M.; Kandyba, V.O. XPS studies of active elements surface of gas sensors based on WO3−x nanoparticles. J. Electron Spectrosc. Relat. Phenom. 2007, 156–158, 172–175. [Google Scholar] [CrossRef]

- Ben-Dor, L.; Shimony, Y. Crystal structure, magnetic susceptibility and electrical conductivity of pure and NiO-doped MoO2 and WO2. Mat. Res. Bull. 1974, 9, 837–844. [Google Scholar] [CrossRef]

- Palmer, D.J.; Dickens, P.G. Tungsten dioxide: Structure refinement by powder neutron diffraction. Acta. Cryst. B 1979, 35, 2199–2201. [Google Scholar] [CrossRef]

- Koltypin, Y.; Nikitenko, S.I.; Gedanken, A. The sonochemical preparation of tungsten oxide nanoparticles. J. Mater. Chem. 2002, 12, 1107–1110. [Google Scholar] [CrossRef]

- Coşkun, S.; Koziol, K.K.K. A facile water-assisted route for synthesis of tungsten dioxide (WO2) nanopowders. Powder Technol. 2014, 256, 1–4. [Google Scholar] [CrossRef]

- Heda, N.L.; Ahuja, U. Electronic properties and Compton scattering studies of monoclinic tungsten dioxide. Radait. Phys. Chem. 2015, 106, 33–39. [Google Scholar] [CrossRef]

- Knowles, W.V.; Nutt, M.O.; Wong, M.S. Supported Metal Oxides and the Surface Density Metric. In Catalyst Preparation, Science & Engineering; Regalbuto, J., Ed.; CRC Press: Boca Raton, FL, USA, 2007; Chapter 11; pp. 251–282. [Google Scholar]

- Murrell, L.L.; Grenoble, D.C.; Baker, R.T.K.; Prestridge, E.B.; Fung, S.C.; Chianelli, R.R.; Cramer, S.P. The Structure and Properties of Tungsten Oxide on Silica and on Alumina. J. Catal. 1983, 79, 203–206. [Google Scholar] [CrossRef]

- Kim, D.S.; Ostromecki, M.; Wachs, I.E. Surface structures of supported tungsten oxide catalysts under dehydrated conditions. J. Mol. Catal. A 1996, 106, 93–102. [Google Scholar] [CrossRef]

- Lee, E.L.; Wachs, I.E. In Situ Raman Spectroscopy of SiO2-Supported Transition Metal Oxide Catalysts: An Isotopic 18O-16O Exchange Study. J. Phys. Chem. C 2008, 112, 6487–6498. [Google Scholar] [CrossRef]

- Ross-Medgaarden, E.I.; Wachs, I.E. Structural determination of bulk and surface tungsten oxides with UV-vis diffuse reflectance spectroscopy and Raman spectroscopy. J. Phys. Chem. C 2007, 111, 15089–15099. [Google Scholar] [CrossRef]

- Kiani, D.; Sourav, S.; Taifan, W.; Calatayud, M.; Tielens, F.; Wachs, I.E.; Baltrusaitis, J. Existence and Properties of Isolated Catalytic Sites on the Surface of β-Cristobalite-Supported, Doped Tungsten Oxide Catalysts (WOx/β-SiO2, Na-WOx/β-SiO2, Mn-WOx/β-SiO2) for Oxidative Coupling of Methane (OCM): A Combined Periodic DFT and Experimental Study. ACS Catal. 2020, 10, 4580–4592. [Google Scholar]

- Chauvin, J.; Thomas, K.; Clet, G.; Houalla, M. Comparative influence of surface tungstate species and bulk amorphous WO3 particles on the acidity and catalytic activity of tungsten oxide supported on silica. J. Phys. Chem. C 2015, 119, 12345–12355. [Google Scholar] [CrossRef]

- Chan, S.C.; Wachs, I.E.; Murrell, L.L.; Dispenziere, N.C., Jr. Laser raman characterization of tungsten oxide supported on alumina: Influence of calcination temperatures. J. Catal. 1985, 92, 1–10. [Google Scholar] [CrossRef]

- Chen, X.; Clet, G.; Thomas, K.; Houalla, M. Correlation between structure, acidity and catalytic performance of WOx/Al2O3 catalysts. J. Catal. 2010, 273, 236–244. [Google Scholar] [CrossRef]

- Lebarbier, V.; Clet, G.; Houalla, M. Relations between structure, acidity, and activity of WOx/TiO2: Influence of the initial state of the support, titanium oxyhydroxide, or titanium oxide. J. Phys. Chem. C 2006, 110, 22608–22617. [Google Scholar] [CrossRef]

- Tribalis, A.; Panagiotou, G.D.; Tsilomelekis, G.; Kalampounias, A.G.; Bourikas, K.; Kordulis, C.; Boghosian, S.; Lycourghiotis, A. Temperature-dependent evolution of the molecular configuration of oxo-tungsten(VI) species deposited on the surface of titania. J. Phys. Chem. C 2014, 118, 11319–11332. [Google Scholar] [CrossRef]

- Onfroy, T.; Clet, G.; Houalla, M. Acidity, surface structure, and catalytic performance of WOx supported on monoclinic zirconia. J. Phys. Chem. B 2005, 109, 3345–3354. [Google Scholar] [CrossRef]

- Song, K.; Zhang, H.; Zhang, Y.; Tang, Y.; Tang, K. Preparation and characterization of WOx/ZrO2 nanosized catalysts with high WOx dispersion threshold and acidity. J. Catal. 2013, 299, 119–128. [Google Scholar] [CrossRef]

- Zhou, W.; Soultanidis, N.; Xu, H.; Wong, M.S.; Neurock, M.; Kiely, C.J.; Wachs, I.E. Nature of Catalytically Active Sites in the Supported WO3/ZrO2 Solid acid system: A current perspective. ACS Catal. 2017, 7, 2181–2198. [Google Scholar] [CrossRef] [Green Version]

- Wachs, I.E.; Kim, T.; Ross, E.I. Catalysis science of the solid acidity of model supported tungsten oxide catalysts. Catal. Today 2006, 116, 162–168. [Google Scholar] [CrossRef]

- Barton, D.G.; Soled, S.L.; Meitzner, G.D.; Fuentes, G.A.; Iglesia, E. Structural and catalytic characterization of solid acids based on zirconia modified by tungsten oxide. J. Catal. 1999, 181, 57–72. [Google Scholar] [CrossRef] [Green Version]

- Soultanidis, N.; Zhou, W.; Psarras, A.C.; Gonzalez, A.J.; Iliopoulou, E.F.; Kiely, C.r.J.; Wachs, I.E.; Wong, M.S. Relating n-pentane isomerization activity to the tungsten surface density of WOx/ZrO2. J. Am. Chem. Soc. 2010, 132, 13462–13471. [Google Scholar] [CrossRef]

- Zhou, W.; Wachs, I.E.; Kiely, C.J. Nanostructural and chemical characterization of supported metal oxide catalysts by aberration corrected analytical electron microscopy. Curr. Opin. Solid State Mater. Sci. 2012, 16, 10–22. [Google Scholar] [CrossRef]

- Del Angel, P.; Hernandez-Pichardo, M.L.; Montoya de la Fuente, A. Aberration-corrected HRTEM study of Mn-doped tungstated zirconia catalysts. Catal. Today 2013, 212, 201–205. [Google Scholar] [CrossRef]

- Dos Santos, V.C.; Wilson, K.; Lee, A.F.; Nakagaki, S. Physicochemical properties of WOx/ZrO2 catalysts for palmitic acid esterification. Appl. Catal. B 2015, 162, 75–84. [Google Scholar] [CrossRef]

- Carabineiro, H.; Villanneau, R.; Carrier, X.; Herson, P.; Lemos, F.; Ramôa Ribeiro, F.; Proust, A.; Che, M. Zirconium-Substituted isopolytungstates: Structural models for zirconia-supported tungsten catalysts. Inorg. Chem. 2006, 45, 1915–1923. [Google Scholar] [CrossRef]

- Kim, H.; Jeong, S.; Kim, D.H.; Park, Y.K.; Jeon, J.K. Preparation of highly dispersed tungsten oxide on MCM-41 via atomic layer deposition and its application to butanol dehydration. J. Nanosci. Nanotechnol. 2012, 12, 6074–6079. [Google Scholar] [CrossRef] [PubMed]

- Bhuiyan, T.I.; Arudra, P.; Akhtar, M.N.; Aitani, A.M.; Abudawoud, R.H.; Al-Yami, M.A.; Al-Khattaf, S.S. Metathesis of 2-butene to propylene over W-mesoporous molecular sieves: A comparative study between tungsten containing MCM-41 and SBA-15. Appl. Catal. A 2013, 467, 224–234. [Google Scholar] [CrossRef]

- Ramanathan, A.; Maheswari, R.; Grady, B.P.; Moore, D.S.; Barich, D.H.; Subramaniam, B. Tungsten-incorporated cage-type mesoporous silicate: W-KIT-5. Microporous Mesoporous Mater. 2013, 175, 43–49. [Google Scholar] [CrossRef]

- Wu, J.-F.; Ramanathan, A.; Snavely, W.K.; Zhu, H.; Rokicki, A.; Subramaniam, B. Enhanced metathesis of ethylene and 2-butene on tungsten incorporated ordered mesoporous silicates. Appl. Catal. A 2016, 528, 142–149. [Google Scholar] [CrossRef] [Green Version]

- Herrera, J.E.; Kwak, J.H.; Hu, J.Z.; Wang, Y.; Peden, C.H.F.; Macht, J.; Iglesia, E. Synthesis, characterization, and catalytic function of novel highly dispersed tungsten oxide catalysts on mesoporous silica. J. Catal. 2006, 239, 200–211. [Google Scholar] [CrossRef]

- Maheswari, R.; Pachamuthu, M.P.; Ramanathan, A.; Subramaniam, B. Synthesis, characterization, and epoxidation activity of tungsten incorporated SBA-16 (W-SBA-16). Ind. Eng. Chem. Res. 2014, 53, 18833–18839. [Google Scholar] [CrossRef]

- Meyer, S.; Beyer, H.; Köhler, K.; Hindhede Jensen, A.; Christensen, E.; Bjerrum, N.J. Space confined preparation of high surface area tungsten oxide and tungsten nitride inside the pores of mesoporous silica SBA-15. Microporous Mesoporous Mater. 2015, 211, 147–151. [Google Scholar] [CrossRef]

- Telalović, S.; Ramanathan, A.; Mul, G.; Hanefeld, U. TUD-1: Synthesis and application of a versatile catalyst, carrier, material. J. Mater. Chem. 2010, 20, 642–658. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pachamuthu, M.P.; Maheswari, R.; Ramanathan, A. Synthesis and characterizations of isolated WO4 anchored on mesoporous TiTUD-1 support. Appl. Surf. Sci. 2017, 402, 286–293. [Google Scholar] [CrossRef]

- Maksasithorn, S.; Praserthdam, P.; Suriye, K.; Debecker, D.P. Preparation of super-microporous WO3-SiO2 olefin metathesis catalysts by the aerosol-assisted sol-gel process. Microporous Mesoporous Mater. 2015, 213, 125–133. [Google Scholar] [CrossRef]

- Bouhoute, Y.; Garron, A.; Grekov, D.; Merle, N.; Szeto, K.C.; De Mallmann, A.; Del Rosal, I.; Maron, L.; Girard, G.; Gauvin, R.M.; et al. Well-defined supported mononuclear tungsten oxo species as olefin metathesis pre-catalysts. ACS Catal. 2014, 4, 4232–4241. [Google Scholar] [CrossRef]

- Coperet, C.; Comas-Vives, A.; Conley, M.P.; Estes, D.P.; Fedorov, A.; Mougel, V.; Nagae, H.; Nunez-Zarur, F.; Zhizhko, P.A. Surface organometallic and coordination chemistry toward single-site heterogeneous catalysts: Strategies, methods, structures, and activities. Chem. Rev. 2016, 116, 323–421. [Google Scholar] [CrossRef]

- Busca, G. The surface acidity of solid oxides and its characterization by IR spectroscopic methods. An attempt at systematization. Phys. Chem. Chem. Phys. 1999, 1, 723–736. [Google Scholar] [CrossRef]

- Kanan, S.M.; Lu, Z.; Cox, J.K.; Bernhardt, G.; Tripp, C.P. Identification of surface sites on monoclinic WO3 powders by infrared spectroscopy. Langmuir 2002, 18, 1707–1712. [Google Scholar] [CrossRef]

- Choi, H.; Lee, E.; Jin, M.; Park, Y.K.; Kim, J.M.; Jeon, J.K. Catalytic properties of highly ordered crystalline nanoporous tungsten oxide in butanol dehydration. J. Nanosci. Nanotechnol. 2014, 14, 8828–8833. [Google Scholar] [CrossRef] [Green Version]

- Kasian, N.; Yaremov, P.S.; Shvets, O.V.; Burel, L.; Puzenat, E.; Tuel, A. Influence of thermal treatments on phase composition and acidity of mesoporous tungsten oxide. Microporous Mesoporous Mater. 2014, 194, 15–23. [Google Scholar] [CrossRef]

- Yue, C.; Zhu, X.; Rigutto, M.; Hensen, E. Acid catalytic properties of reduced tungsten and niobium tungsten oxides. Appl. Catal. B 2015, 163, 370–381. [Google Scholar] [CrossRef]

- Li, Z.; Fang, Z.; Kelley, M.S.; Kay, B.D.; Rousseau, R.; Dohnálek, Z.; Dixon, D.A. Ethanol conversion on cyclic (MO3)3 (M = Mo, W) clusters. J. Phys. Chem. C 2014, 118, 4869–4877. [Google Scholar] [CrossRef]

- Rousseau, R.; Dixon, D.A.; Kay, B.D.; Dohnálek, Z. Dehydration, dehydrogenation, and condensation of alcohols on supported oxide catalysts based on cyclic (WO3)3 and (MoO3)3 clusters. Chem. Soc. Rev. 2014, 43, 7664–7680. [Google Scholar] [CrossRef] [PubMed]

- Barton, D.G.; Soled, S.L.; Iglesia, E. Solid acid catalysts based on supported tungsten oxides. Top. Catal. 1998, 6, 87–99. [Google Scholar] [CrossRef]

- Zaki, M.I.; Mekhemer, G.A.H.; Fouad, N.E.; Rabee, A.I.M. Structure-acidity correlation of supported tungsten(VI)-oxo-species: FT-IR and TPD studies of adsorbed pyridine and catalytic decomposition of 2-propanol. Appl. Surf. Sci. 2014, 308, 380–387. [Google Scholar] [CrossRef]

- Martin, D.; Duprez, D. Evaluation of the acid-base surface properties of several oxides and supported metal catalysts by means of model reactions. J. Mol. Catal. A 1997, 118, 113–128. [Google Scholar] [CrossRef]

- Hu, J.Z.; Kwak, J.H.; Wang, Y.; Hu, M.Y.; Turcu, R.V.; Peden, C.H.F. Characterizing surface acidic sites in mesoporous-silica-supported tungsten oxide catalysts using solid-state NMR and quantum chemistry calculations. J. Phys. Chem. C 2011, 115, 23354–23362. [Google Scholar] [CrossRef]

- González, J.; Wang, J.A.; Chen, L.F.; Manríquez, M.E.; Dominguez, J.M. Structural defects, lewis acidity, and catalysis properties of mesostructured WO3/SBA-15 nanocatalysts. J. Phys. Chem. C 2017, 121, 23988–23999. [Google Scholar] [CrossRef]

- Kulal, A.B.; Dongare, M.K.; Umbarkar, S.B. Sol-gel synthesised WO3 nanoparticles supported on mesoporous silica for liquid phase nitration of aromatics. Appl. Catal. B 2016, 182, 142–152. [Google Scholar] [CrossRef]

- Bhaumik, P.; Dhepe, P.L. From lignocellulosic biomass to furfural: Insight into the active species of a silica-supported tungsten oxide catalyst. ChemCatChem 2017, 9, 2709–2716. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Ramanathan, A.; Wu, J.F.; Subramaniam, B. Genesis of strong brønsted acid sites in WZr-KIT-6 catalysts and enhancement of ethanol dehydration activity. ACS Catal. 2018, 8, 4848–4859. [Google Scholar] [CrossRef]

- DePuccio, D.P.; Ruíz-Rodríguez, L.; Rodríguez-Castellón, E.; Botella, P.; López Nieto, J.M.; Landry, C.C. Investigating the influence of Au nanoparticles on porous SiO2-WO3 and WO3 methanol transformation catalysts. J. Phys. Chem. C 2016, 120, 27954–27963. [Google Scholar] [CrossRef] [Green Version]

- Shi, G.; Cao, Z.; Xu, J.; Jin, K.; Bao, Y.; Xu, S. Effect of WOx doping into Pt/SiO2 catalysts for glycerol hydrogenolysis to 1,3-propanediol in liquid phase. Catal. Lett. 2018, 148, 2304–2314. [Google Scholar] [CrossRef]

- Soled, S.L.; McVicker, G.B.; Murrell, L.L.; Sherman, L.G.; Dispenziere, N.C.; Hsu, S.L.; Waldman, D. Comparison of the acidities of WO3/Al2O3 and ultrastable faujasite catalysts. J. Catal. 1988, 111, 286–295. [Google Scholar] [CrossRef]

- Zhang, R.; Jagiello, J.; Hu, J.F.; Huang, Z.Q.; Schwarz, J.A.; Datye, A. Effect of WO3 loading on the surface acidity of WO3/Al2O3 composite oxides. Appl. Catal. A 1992, 84, 123–139. [Google Scholar] [CrossRef]

- Kitano, T.; Hayashi, T.; Uesaka, T.; Shishido, T.; Teramura, K.; Tanaka, T. Effect of high-temperature calcination on the generation of Brønsted acid sites on WO3/Al2O3. ChemCatChem 2014, 6, 2011–2020. [Google Scholar] [CrossRef]

- Barrault, J.; Boulinguiez, M.; Forquy, C.; Maurel, R. Synthesis of methyl mercaptan from carbon oxides and H2S with tungsten-alumina catalysts. Appl. Catal. 1987, 33, 309–330. [Google Scholar] [CrossRef]

- Mashkin, V.Y.; Kudenkov, V.M.; Mashkina, A.V. Kinetics of the catalytic reaction between methanol and hydrogen sulfide. Ind. Eng. Chem. Res. 1995, 34, 2964–2970. [Google Scholar] [CrossRef]

- Cordova, A.; Blanchard, P.; Salembier, H.; Lancelot, C.; Frémy, G.; Lamonier, C. Direct synthesis of methyl mercaptan from H2/CO/H2S using tungsten based supported catalysts: Investigation of the active phase. Catal. Today 2017, 292, 143–153. [Google Scholar] [CrossRef]

- Taifan, W.; Baltrusaitis, J. Minireview: Direct catalytic conversion of sour natural gas (CH4 + H2S + CO2) components to high value chemicals and fuels. Catal. Sci. Technol. 2017, 7, 2919–2929. [Google Scholar] [CrossRef]

- Wang, W.; Li, Y.; Zhang, X.; Fang, W.; Yang, Y. Catalytic synthesis of methanethiol from methanol and carbon disulfide over KW/Al2O3 catalysts. Catal. Commun. 2015, 69, 104–108. [Google Scholar] [CrossRef]

- Zhu, M.; Li, B.; Jehng, J.M.; Sharma, L.; Taborda, J.; Zhang, L.; Stach, E.; Wachs, I.E.; Wu, Z.; Baltrusaitis, J. Molecular structure and sour gas surface chemistry of supported K2O/WO3/Al2O3 catalysts. Appl. Catal. B 2018, 232, 146–154. [Google Scholar] [CrossRef]

- Kiani, D.; Belletti, G.; Quaino, P.; Tielens, F.; Baltrusaitis, J. Structure and vibrational properties of potassium-promoted tungsten oxide catalyst monomeric sites supported on alumina (K2O/WO3/Al2O3) characterized using periodic density functional theory. J. Phys. Chem. C 2018, 122, 24190−24201. [Google Scholar] [CrossRef]

- Hino, M.; Arata, K. Synthesis of Solid Superacid of tungsten oxide supported on zirconia and its catalytic action for reactions of butane and pentane. J. Chem. Soc. Chem. Commun. 1988, 18, 1259–1260. [Google Scholar] [CrossRef]

- Li, S.; Zhou, H.; Jin, C.; Feng, N.; Liu, F.; Deng, F.; Wang, J.Q.; Huang, W.; Xiao, L.; Fan, J. Formation of subnanometer Zr-WOx clusters within mesoporous W−Zr mixed oxides as strong solid acid catalysts for Friedel−Crafts alkylation. J. Phys. Chem. C 2014, 118, 6283–6290. [Google Scholar] [CrossRef]

- Kuba, S.; Heydorn, P.C.; Grasselli, R.K.; Gates, B.C.; Che, M. Knözinger, H. Redox properties of tungstated zirconia catalysts: Relevance to the activation of n-alkanes. Phys. Chem. Chem. Phys. 2001, 3, 146–154. [Google Scholar] [CrossRef]

- Santiesteban, J.G.; Vartuli, J.C.; Han, S.; Bastian, R.D.; Chang, C.D. Influence of the preparative method on the activity of highly acidic WOx/ZrO2 and the relative acid activity compared with zeolites. J. Catal. 1997, 168, 431–441. [Google Scholar] [CrossRef]

- Afanasiev, P.; Geantet, C.; Breysse, M.; Coudurier, G.; Vedrine, J.C. Influence of preparation method on the acidity of MoO3(WO3)/ZrO2 catalysts. J. Chem. Soc. Faraday Trans. 1994, 90, 193–202. [Google Scholar] [CrossRef]

- Baertsch, C.D.; Soled, S.L.; Iglesia, E. Isotopic and Chemical titration of acid sites in tungsten oxide domains supported on zirconia. J. Phys. Chem. B 2001, 105, 1320–1330. [Google Scholar] [CrossRef]

- Iglesia, E.; Barton, D.G.; Biscardi, J.A.; Gines, M.J.L.; Soled, S.L. Bifunctional pathways in catalysis by solid acids and bases. Catal. Today 1997, 38, 339–360. [Google Scholar] [CrossRef]

- Di Gregorio, F.; Keller, V. Activation and isomerization of hydrocarbons over WO3/ZrO2 catalysts I. Preparation, characterization, and X-ray photoelectron spectroscopy studies. J. Catal. 2004, 225, 45–55. [Google Scholar] [CrossRef]

- Galano, A.; Rodriguez-Gattorno, G.; Torres-García, E. A combined theoretical-experimental study on the acidity of WOx-ZrO2 systems. Phys. Chem. Chem. Phys. 2008, 10, 4181–4188. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Shin, C.H.; Suh, Y.W. Higher Brønsted acidity of WOx/ZrO2 catalysts prepared using a high surface area zirconium oxyhydroxide. Mol. Catal. 2017, 438, 272–279. [Google Scholar] [CrossRef]

- Yamamoto, T.; Teramachi, A.; Orita, A.; Kurimoto, A.; Motoi, T.; Tanaka, T. Generation of strong acid sites on yttrium-doped tetragonal ZrO2-supported tungsten oxides: Effects of dopant amounts on acidity, crystalline phase, kinds of tungsten species, and their dispersion. J. Phys. Chem. C 2016, 120, 19705–19713. [Google Scholar] [CrossRef]

- Kourieh, R.; Bennici, S.; Marzo, M.; Gervasini, A.; Auroux, A. Investigation of the WO3/ZrO2 surface acidic properties for the aqueous hydrolysis of cellobiose. Catal. Commun. 2012, 19, 119–126. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; He, L.; Liu, Z. Supporting Tungsten Oxide on Zirconia by Hydrothermal and Impregnation Methods and Its Use as a Catalyst To Reduce the Viscosity of Heavy Crude Oil. Energy Fuels 2012, 26, 6518–6527. [Google Scholar] [CrossRef]

- Signoretto, M.; Ghedini, E.; Menegazzo, F.; Cerrato, G.; Crocellà, V.; Bianchi, C.L. Aerogel and xerogel WO3/ZrO2 samples for fine chemicals production. Microporous Mesoporous Mater. 2013, 165, 134–141. [Google Scholar] [CrossRef] [Green Version]

- Miao, Z.; Zhao, H.; Song, H.; Chou, L. Ordered mesoporous zirconium oxophosphate supported tungsten oxide solid acid catalysts: The improved Brønsted acidity for benzylation of anisole. RSC Adv. 2014, 4, 22509–22519. [Google Scholar] [CrossRef]

- Miao, Z.; Song, H.; Zhao, H.; Xu, L.; Chou, L. One-pot synthesis of mesoporous ZrPW solid acid catalyst for liquid phase benzylation of anisole. Catal. Sci. Technol. 2014, 4, 838–850. [Google Scholar] [CrossRef]

- Vilcocq, L.; Koerin, R.; Cabiac, A.; Especel, C.; Lacombe, S.; Duprez, D. New bifunctional catalytic systems for sorbitol transformation into biofuels. Appl. Catal. B 2014, 148–149, 499–508. [Google Scholar] [CrossRef]

- Chen, J.P.; Yang, R.T. Role of WO3 in mixed V2O5-WO3/TiO2 catalysts for selective catalytic reduction of nitric oxide with ammonia. Appl. Catal. A 1992, 80, 135–148. [Google Scholar] [CrossRef]

- Alemany, L.J.; Lietti, L.; Ferlazzo, N.; Forzatti, P.; Busca, G.; Giamello, E.; Bregani, F. Reactivity and physico-chemical characterisation of V2O5-WO3/TiO2 De-NOx catalysts. J. Catal. 1995, 155, 117–130. [Google Scholar] [CrossRef]

- Forzatti, P. Present status and perspectives in de-NOx SCR catalysis. Appl. Catal. A 2001, 222, 221–236. [Google Scholar] [CrossRef]

- Paganini, M.C.; Dall’Acqua, L.; Giamello, E.; Lietti, L.; Forzatti, P.; Busca, G. An EPR Study of the surface chemistry of the V2O5-WO3/tio2 catalyst: Redox behaviour and state of V(IV). J. Catal. 1997, 166, 195–205. [Google Scholar] [CrossRef]

- Wang, C.; Yang, S.; Chang, H.; Peng, Y.; Li, J. Dispersion of tungsten oxide on SCR performance of V2O5-WO3/TiO2: Acidity, surface species and catalytic activity. Chem. Eng. J. 2013, 225, 520–527. [Google Scholar] [CrossRef]

- Kompio, P.G.W.A.; Brückner, A.; Hipler, F.; Auer, G.; Löffler, E.; Grünert, W. A new view on the relations between tungsten and vanadium in V2O5-WO3/TiO2 catalysts for the selective reduction of NO with NH3. J. Catal. 2012, 286, 237–247. [Google Scholar] [CrossRef]

- Lai, J.K.; Wachs, I.E. A Perspective on the selective catalytic reduction (SCR) of NO with NH3 by supported V2O5−WO3/TiO2 catalysts. ACS Catal. 2018, 8, 6537–6551. [Google Scholar] [CrossRef]

- Topsøe, N.Y.; Dumesic, J.A.; Topsøe, H. Vanadia/Titania Catalysts for Selective catalytic reduction of nitric oxide by ammonia. II studies of active sites and formulation of catalytic cycles. J. Catal. 1995, 151, 241–252. [Google Scholar] [CrossRef]

- Dumesic, J.A.; Topsøe, N.Y.; Topsøe, H.; Chen, Y.; Slabiak, T. Kinetics of Selective catalytic reduction of nitric oxide by ammonia over vanadia/titania. J. Catal. 1996, 163, 409–417. [Google Scholar] [CrossRef]

- Han, L.; Cai, S.; Gao, M.; Hasagawa, J.; Wang, P.; Zhang, J.; Shi, L.; Zhang, D. Selective Catalytic Reduction of NOx with NH3 by Using Novel Catalysts: State of the Art and Future Prospects. Chem. Rev. 2019, 119, 10916–10976. [Google Scholar] [CrossRef]

- Lietti, L.; Ramis, G.; Berti, F.; Toledo, G.; Robba, D.; Busca, G.; Forzatti, P. Chemical, structural and mechanistic aspects on NOx SCR over commercial and model oxide catalyst. Catal. Today 1998, 42, 101–116. [Google Scholar] [CrossRef]

- Montzka, S.A.; Dlugokencky, E.J.; Butler, J.H. Review: Non-CO2 greenhouse gases and climate change. Nature 2011, 476, 43–50. [Google Scholar] [CrossRef]

- Van Groenigen, K.J.; Osenberg, C.W.; Hungate, B.A. Increased soil emissions of potent greenhouse gases under increased atmospheric CO2. Nature 2011, 475, 214–216. [Google Scholar] [CrossRef]

- Djerad, S.; Tifouti, L.; Crocoll, M.; Weisweiler, W. Effect of vanadia and tungsten loadings on the physical and chemical characteristics of V2O5-WO3/TiO2 catalysts. J. Mol. Catal. A 2004, 208, 257–265. [Google Scholar] [CrossRef]

- Liu, X.; Li, J.; Li, X.; Peng, Y.; Wang, H.; Jiang, X.; Wang, L. NH3 selective catalytic reduction of NO: A large surface TiO2 support and its promotion of V2O5 dispersion on the prepared catalyst. Chin. J. Catal. 2016, 37, 878–887. [Google Scholar] [CrossRef]

- Zhu, M.; Lai, J.-K.; Tumuluri, U.; Wu, Z.; Wachs, I.E. Nature of active sites and surface intermediates during SCR of NO with NH3 by supported V2O5−WO3/TiO2 catalysts. J. Am. Chem. Soc. 2017, 139, 15624–15627. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; You, C.; Wang, H. Time-resolved in-situ IR and DFT study: NH3 adsorption and redox cycle of acid site on vanadium-based catalysts for NO abatement via selective catalytic reduction. Chem. Eng. J. 2020, 382, 122756–122764. [Google Scholar] [CrossRef]

- Giraud, F.; Couble, J.; Geantet, C.; Guilhaume, N.; Loridant, S.; Gros, S.; Porcheron, L.; Kanniche, M.; ianchi, D. Experimental Microkinetic Approach of De-NOx by NH3 on V2O5/WO3/TiO2 Catalysts. 5. Impacts of the NH3-H2O Coadsorption on the Coverage of Sulfated TiO2-Based Solids. J. Phys. Chem. C 2018, 122, 24619–24633. [Google Scholar] [CrossRef]

- Zhao, X.; Yan, Y.; Mao, L.; Fu, M.; Zhao, H.; Sun, L.; Xiao, Y.; Dong, G. A relationship between the V4+/V5+ ratio and the surface dispersion, surface acidity, and redox performance of V2O5–WO3/TiO2 SCR catalysts. RSC Adv. 2018, 8, 31081–31093. [Google Scholar] [CrossRef] [Green Version]

- He, G.; Lian, Z.; Yu, Y.; Yang, Y.; Liu, K.; Shi, X.; Yan, Z.; Shan, W.; He, H. Polymeric vanadyl species determine the low-temperature activity of V-based catalysts for the SCR of NOx with NH3. Sci. Adv. 2018, 4, eaau4637. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, H.; Xia, Y.; Fang, R.; Huang, H.; Gan, Y.; Liang, C.; Zhang, J.; Zhang, W.; Liu, X. The effects of tungsten and hydrothermal aging in promoting NH3-SCR activity on V2O5/WO3-TiO2 catalysts. Appl. Surf. Sci. 2018, 459, 639–646. [Google Scholar] [CrossRef]

- Kompio, P.G.W.A.; Brückner, A.; Hipler, F.; Manoylova, O.; Auer, G.; Mestl, G.; Grünert, W. V2O5-WO3/TiO2 catalysts under thermal stress: Responses of structure and catalytic behavior in the selective catalytic reduction of NO by NH3. Appl. Catal. B 2017, 217, 365–377. [Google Scholar] [CrossRef]

- Kwon, D.W.; Park, K.H.; Hong, S.C. Effect of vanadium structure and lattice oxygen in V-based TiO2 catalysts on selective catalytic reduction of NOx by NH3. J. Chem. Eng. Jpn. 2016, 49, 526–533. [Google Scholar] [CrossRef]

- Marberger, A.; Elsener, M.; Nuguid, R.J.G.; Ferri, D.; Kröcher, O. Thermal activation and aging of a V2O5-WO3/TiO2 catalyst for the selective catalytic reduction of NO with NH3. Appl. Catal. A 2019, 573, 64–72. [Google Scholar] [CrossRef]

- Liang, Q.; Li, J.; He, H.; Yue, T.; Tong, L. Effects of SO2 and H2O on low-temperature NO conversion over F-V2O5-WO3/TiO2 catalysts. J. Environ. Sci. 2020, 90, 253–261. [Google Scholar] [CrossRef]

- Beale, A.M.; Lezcano-Gonzalez, I.; Maunula, T.; Palgrave, R.G. Development and characterization of thermally stable supported V–W–TiO2 catalysts for mobile NH3–SCR applications. Catal. Struct. React. 2015, 1, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Marberger, A.; Ferri, D.; Rentsch, D.; Krumeich, F.; Elsener, M.; Kröcher, O. Effect of SiO2 on co-impregnated V2O5/WO3–TiO2 catalysts for the selective catalytic reduction of NO with NH3. Catal. Today 2019, 320, 123–132. [Google Scholar] [CrossRef]

- Shin, J.B.; Dung, T.W.; Lee, H. Structure, surface acidity and catalytic activity of WO3-TiO2 catalyst for NH3-SCR of NOx. J. Ceram. Proc. Res. 2014, 15, 125–129. [Google Scholar]

- He, Y.; Ford, M.E.; Zhu, M.; Liu, Q.; Tumuluri, U.; Wu, Z.; Wachs, I.E. Influence of catalyst synthesis method on selective catalytic reduction(SCR) of NO by NH3 with V2O5-WO3/TiO2 catalysts. Appl. Catal. B 2016, 193, 141–150. [Google Scholar] [CrossRef] [Green Version]

- Ferjani, W.; Khalfallah Boudali, L.; Delahay, G.; Petitto, C. Reduction of nitrogen oxide by ammonia over vanadium supported on mixed tungsten–titanium-pillared clays. Chem. Lett. 2016, 45, 872–874. [Google Scholar] [CrossRef]

- Wang, J.; Miao, J.; Yu, W.; Chen, Y.; Chen, J. Study on the local difference of monolithic honeycomb V2O5-WO3/TiO2 denitration catalyst. Mater. Chem. Phys. 2017, 198, 193–199. [Google Scholar] [CrossRef]

- Zhao, K.; Han, W.; Tang, Z.; Zhang, G.; Lu, J.; Lu, G.; Zhen, X. Investigation of coating technology and catalytic performance over monolithic V2O5-WO3/TiO2 catalyst for selective catalytic reduction of NOx with NH3. Colloids Surf. A Physicochem. Eng. Asp. 2016, 503, 53–60. [Google Scholar] [CrossRef]

- Johnson, T.V. Review of selective catalytic reduction (SCR) and related technologies for mobile applications. In Urea-SCR Technology for deNOx after Treatment of Diesel Exhausts. Fundamental and Applied Catalysis; Nova, I., Tronconi, I.E., Eds.; Springer: New York, NY, USA, 2014; pp. 3–31. [Google Scholar]

- Jung, Y.; Shin, Y.J.; Pyo, Y.D.; Cho, C.P.; Jang, J.; Kim, G. NOx and N2O emissions over a Urea-SCR system containing both V2O5-WO3/TiO2 and Cu-zeolite catalysts in a diesel engine. Chem. Eng. J. 2017, 326, 853–862. [Google Scholar] [CrossRef]

- Cho, C.P.; Pyo, Y.D.; Jang, J.Y.; Kim, G.C.; Shin, Y.J. NOx reduction and N2O emissions in a diesel engine exhaust using Fe-zeolite and vanadium based SCR catalysts. Appl. Therm. Eng. 2017, 110, 18–24. [Google Scholar] [CrossRef]

- Szymaszek, A.; Samojeden, B.; Motak, M. The Deactivation of Industrial SCR Catalysts—A Short Review. Energies 2020, 13, 3870. [Google Scholar] [CrossRef]

- Kröcher, O.; Elsener, M. Chemical deactivation of V2O5/WO3–TiO2 SCR catalysts by additives and impurities from fuels, lubrication oils, and urea solution I. Catalytic studies. Appl. Catal. B 2008, 75, 215–227. [Google Scholar] [CrossRef]

- Nicosia, D.; Czekaj, I.; Kröcher, O. Chemical deactivation of V2O5/WO3–TiO2 SCR catalysts by additives and impurities from fuels, lubrication oils, and urea solution Part II. Characterization study of the effect of alkali and alkaline earth metals. Appl. Catal. B 2008, 75, 228–236. [Google Scholar] [CrossRef]

- Xie, X.; Lu, J.; Hums, E.; Huang, Q.; Lu, Z. Study on the deactivation of V2O5−WO3/TiO2 selective catalytic reduction catalysts through transient kinetics. Energy Fuel 2015, 29, 3890–3896. [Google Scholar] [CrossRef]

- Siaka, H.; Dujardin, C.; Moissette, A.; Granger, P. Structural Induced Effect of Potassium on the Reactivity of Vanadate Species in V2O5–WO3/TiO2 SCR-Catalyst. Top. Catal. 2019, 62, 55–62. [Google Scholar] [CrossRef]

- Chen, C.; Wu, X.; Yu, W.; Gao, Y.; Weng, D.; Shi, L.; Geng, C. Potassium poisoning of titania supported deNOx catalysts: Preservation of vanadia and sacrifice of tungsten oxide. Chin. J. Catal. 2015, 36, 1287–1294. [Google Scholar] [CrossRef]

- Wu, X.; Yu, W.; Si, Z.; Weng, D. Chemical deactivation of V2O5−WO3/TiO2 SCR catalyst by combined effect of potassium and chloride. Front. Environ. Sci. Eng. 2013, 7, 420–427. [Google Scholar] [CrossRef]

- Reddy Putluru, S.S.; Schill, L.; Godiksena, A.; Poreddy, R.; Mossina, S.; Jensen, A.D.; Fehrmann, R. Promoted V2O5/TiO2 catalysts for selective catalytic reduction of NO with NH3 at low temperatures. Appl. Catal. B 2016, 183, 282–290. [Google Scholar] [CrossRef] [Green Version]

- Miao, J.; Yi, X.; Su, Q.; Li, H.; Chen, J.; Wang, J. Poisoning Effects of Phosphorus, Potassium and Lead on V2O5-WO3/TiO2 Catalysts for Selective Catalytic Reduction with NH3. Catalysts 2020, 10, 345. [Google Scholar] [CrossRef] [Green Version]

- Xiang, J.; Du, X.; Wan, Y.; Chen, Y.; Ran, J.; Zhang, L. Alkali-driven active site shift of fast SCR with NH3 on V2O5-WO3/TiO2 catalyst via a novel Eley-Rideal mechanism. Catal. Sci. Technol. 2019, 9, 6085–6091. [Google Scholar] [CrossRef]

- Li, H.; Miao, J.; Su, Q.; Yu, Y.; Chen, Y.; Chen, J.; Wang, J. Improvement in alkali metal resistance of commercial V2O5–WO3/TiO2 SCR catalysts modified by Ce and Cu. J. Mater. Sci. 2019, 54, 14707–14719. [Google Scholar] [CrossRef]

- Li, X.; Li, X.-S.; Chen, J.; Li, J.; Hao, J. An efficient novel regeneration method for Ca-poisoning V2O5/WO3–TiO2 catalysts. Catal. Commun. 2016, 87, 45–48. [Google Scholar] [CrossRef]

- Li, X.; Li, X.S.; Yang, R.T.; Mo, J.; Li, J.; Hao, J. The poisoning effects of calcium on V2O5/WO3–TiO2 catalysts for the SCR reaction: Comparison of different forms of calcium. Mol. Catal. 2017, 434, 16–24. [Google Scholar] [CrossRef]

- Odenbrand, C.U.I. CaSO4 deactivated V2O5-WO3/TiO2 SCR catalyst for a diesel power plant. Characterization and simulation of the kinetics of the SCR reactions. Appl. Catal. B 2018, 234, 365–377. [Google Scholar] [CrossRef]

- Phil, H.H.; Reddy, M.P.; Kumar, P.A.; Ju, L.K.; Hyo, J.S. SO2 resistant antimony promoted V2O5/TiO2 catalyst for NH3-SCR of NOx at low temperatures. Appl. Catal. B 2008, 78, 301–308. [Google Scholar] [CrossRef]

- Kwon, D.W.; Park, K.H.; Hong, S.C. Enhancement of SCR activity and SO2 resistance on VOx/TiO2 catalyst by addition of molybdenum. Chem. Eng. J. 2016, 284, 315–324. [Google Scholar] [CrossRef]

- Zhu, N.; Shan, W.; Lian, Z.; Zhang, Y.; Liu, K.; He, H. A superior Fe-V-Ti catalyst with high activity and SO2 resistance for the selective catalytic reduction of NOx with NH3. J. Hazard. Mater. 2020, 382, 120970–120978. [Google Scholar] [CrossRef]

- Xu, T.; Wu, X.; Gao, Y.; Lin, Q.; Hu, J.; Wen, D. Comparative study on sulfur poisoning of V2O5-Sb2O3/TiO2 and V2O5-WO3/TiO2 monolithic catalysts for low-temperature NH3-SCR. Catal. Commun. 2017, 93, 33–36. [Google Scholar] [CrossRef]

- Xu, L.; Wang, C.; Chang, H.; Wu, Q.; Zhang, T.; Li, J. New Insight into SO2 Poisoning and Regeneration of CeO2-WO3/TiO2 and V2O5-WO3/TiO2 Catalysts for Low-Temperature NH3-SCR. Environ. Sci. Technol. 2018, 52, 7064–7071. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, W.; Yu, J.; Zeng, J.; Chang, H. A novel method for assessing SO2 poisoning effect and thermal regeneration possibility of MOx-WO3/TiO2 (M = Fe, Mn, Cu, V) catalysts for NH3-SCR. Environ. Sci. Technol. 2020, 54, 12612–12620. [Google Scholar] [CrossRef]

- Cao, L.; Wu, X.; Chen, Z.; Ma, Y.; Ma, Z.; Ran, R.; Si, Z.; Weng, D.; Wang, B. A comprehensive study on sulfur tolerance of niobia modified CeO2/WO3-TiO2 catalyst for low-temperature NH3-SCR. Appl. Catal. A 2019, 580, 121–130. [Google Scholar] [CrossRef]

- Jeong, B.; Ye, B.; Kim, E.-S.; Kim, H.D. Characteristics of selective catalytic reduction (SCR) catalyst adding graphene-tungsten nanocomposite. Catal. Commun. 2017, 93, 15–19. [Google Scholar] [CrossRef]

- Xu, T.; Wu, X.; Liu, X.; Cao, L.; Lin, Q.; Wen, D. Effect of barium sulfate modification on the SO2 tolerance of V2O5/TiO2 catalyst for NH3-SCR reaction. J. Environ. Sci. 2017, 57, 110–117. [Google Scholar] [CrossRef] [PubMed]

- Senior, C.L.; Lignell, D.O.; Sarofim, A.F.; Mehta, A. Modeling arsenic partitioning in coal-fired power plants. Comb. Flame 2006, 147, 209–221. [Google Scholar] [CrossRef]

- Peng, Y.; Li, J.; Si, W.; Luo, J.; Dai, Q.; Luo, X.; Liu, X.; Hao, J. Insight into Deactivation of Commercial SCR Catalyst by Arsenic: An Experiment and DFT Study. Environ. Sci. Technol. 2014, 48, 13895–13900. [Google Scholar] [CrossRef]

- Peng, Y.; Si, W.; Li, X.; Luo, J.; Li, J.; Crittenden, J.; Hao, J. Comparison of MoO3 and WO3 on arsenic poisoning V2O5–WO3/TiO2 catalyst: DRIFTS and DFT study. Appl. Catal. B 2016, 181, 692–698. [Google Scholar] [CrossRef]

- Kong, M.; Liu, Q.; Wang, X.; Ren, S.; Yang, J.; Zhao, D.; Xi, W.; Yao, L. Performance impact and poisoning mechanism of arsenic over commercial V2O5–WO3/TiO2 SCR catalyst. Catal. Commun. 2015, 72, 121–126. [Google Scholar] [CrossRef]

- Zhang, H.; Kong, M.; Cai, Z.; Jiang, L.; Liu, Q.; Yang, J.; Ren, S.; Li, J.; Duan, M. Synergistic effect of arsenic and different potassium species on V2O5-WO3/TiO2 catalyst poisoning: Comparison of Cl−, SO42− and NO3− anions. Catal. Commun. 2020, 144, 106069. [Google Scholar] [CrossRef]

- Li, L.; Chen, L.; Kong, M.; Liu, Q.; Ren, S. New insights into the deactivation mechanism of V2O5-WO3/TiO2 catalyst during selective catalytic reduction of NO with NH3: Synergies between arsenic and potassium species. RSC Adv. 2019, 9, 37724–37732. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, J.; Liu, L.; Liu, Q.; Kong, B.; Lin, F.; Kong, M.; Hu, G. Insight into regeneration mechanism with sulfuric acid for arsenic poisoned commercial SCR catalyst. J. Energy Inst. 2020, 93, 387–394. [Google Scholar] [CrossRef]

- Qi, L.; Li, J.; Yao, Y.; Zhang, Y. Heavy metal poisoned and regeneration of selective catalytic reduction catalysts. J. Hazard. Mater. 2019, 366, 492–500. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Wang, Y. Effective industrial regeneration of arsenic poisoning waste selective catalytic reduction catalyst: Contaminants removal and activity recovery. Environ. Sci. Pollut. Res. 2018, 25, 34114–34122. [Google Scholar] [CrossRef] [PubMed]

- Chapman, D.M. Behavior of titania-supported vanadia and tungsta SCR catalysts at high temperatures in reactant streams: Tungsten and vanadium oxide and hydroxide vapor pressure reduction by surficial stabilization. Appl. Catal. A 2011, 392, 143–150. [Google Scholar] [CrossRef]

- Liu, Z.G.; Ottinger, N.A.; Cremeens, C.M. Vanadium and tungsten release from V-based selective catalytic reduction diesel aftertreatment. Atmos. Environ. 2015, 104, 154–161. [Google Scholar] [CrossRef]

- Wu, W.C.; Tsai, T.Y.; Shen, Y.H. Tungsten recovery from spent SCR catalyst using alkaline leaching and ion exchange. Minerals 2016, 6, 107. [Google Scholar] [CrossRef] [Green Version]

- Huo, Y.; Chang, Z.; Li, W.; Liu, S.; Dong, B. Reuse and valorization of vanadium and tungsten from waste V2O5–WO3/TiO2 SCR catalyst. Waste Biomass Valor. 2015, 6, 159–165. [Google Scholar] [CrossRef]

- Giordano, F.; Trovarelli, A.; de Leitenburg, C.; Giona, M. A model for the temperature-programmed reduction of low and high surface area ceria. J. Catal. 2000, 193, 273–282. [Google Scholar] [CrossRef]

- Montini, T.; Melchionna, M.; Monai, M.; Fornasiero, P. Fundamentals and catalytic applications of CeO2-based materials. Chem. Rev. 2016, 116, 5987–6041. [Google Scholar] [CrossRef]

- Martin, D.; Duprez, D. Mobility of surface species on oxides. 1. isotopic exchange of 18O2 with 16O of SiO2, Al2O3, ZrO2, MgO, CeO2, and CeO2-Al2O3. activation by noble metals. correlation with oxide basicity. J. Phys. Chem. 1996, 100, 9429–9438. [Google Scholar] [CrossRef]

- Madier, Y.; Descorme, C.; Le Govic, A.M.; Duprez, D. Oxygen mobility in CeO2 and CexZr(1−x)O2 compounds: Study by CO transient oxidation and 18O/16o isotopic exchange. J. Phys. Chem. B 1999, 103, 10999–11006. [Google Scholar] [CrossRef]

- Liu, F.; Yu, Y.; He, H. Environmentally-benign catalysts for the selective catalytic reduction of NOx from diesel engines: Structure–activity relationship and reaction mechanism aspects. Chem. Commun. 2014, 50, 8445–8463. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Li, J.; Ge, M. Promotional Effect of Ce-doped V2O5-WO3/TiO2 with low vanadium loadings for selective catalytic reduction of NOx by NH3. J. Phys. Chem. C 2009, 113, 21177–21184. [Google Scholar] [CrossRef]

- Wang, X.; Shi, A.; Duan, Y.; Wang, J.; Shen, M. Catalytic performance and hydrothermal durability of CeO2-V2O5-ZrO2/WO3-TiO2 based NH3-SCR catalysts. Catal. Sci. Technol. 2012, 2, 1386–1395. [Google Scholar] [CrossRef]

- Shen, M.; Xu, L.; Wang, J.-Q.; Li, C.; Wang, W.; Wang, J.; Zhai, Y. Effect of synthesis methods on activity of V2O5/CeO2/WO3-TiO2 catalyst for selective catalytic reduction of NOx with NH3. J. Rare Earths 2016, 34, 256–267. [Google Scholar] [CrossRef]

- Youn, S.; Song, I.; Kim, D.H. Roles of promoters in V2O5/TiO2 catalysts for selective catalytic reduction of NOx with NH3: Effect of order of impregnation. J. Nanosci. Nanotechnol. 2016, 16, 4350–4356. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Z.; Ning, R.; Qin, Y.; Zhu, T.; Liu, F. Ce-Doped V2O5-WO3/TiO2 with Low Vanadium Loadings as SCR Catalysts and the Resistance of H2O and SO2. Catal. Lett. 2019, 150, 375–383. [Google Scholar] [CrossRef]

- Tian, X.; Xiao, Y.; Zhang, W.; Luo, X. Investigation on performance of V2O5–WO3–TiO2–cordierite catalyst modified with Cu, Mn and Ce for urea-SCR of NO. Mater. Res. Innov. 2014, 18, 202–206. [Google Scholar] [CrossRef]

- Liang, Q.; Li, J.; He, H.; Liang, W.; Zhang, T.; Fan, X. Effects of SO2 on the low temperature selective catalytic reduction of NO by NH3 over CeO2-V2O5-WO3/TiO2 catalysts. Front. Environ. Sci. Eng. 2017, 11, 4. [Google Scholar] [CrossRef]

- Zhao, X.; Mao, L.; Dong, G. Mn-Ce-V-WOx/TiO2 SCR Catalysts: Catalytic activity, stability and interaction among catalytic oxides. Catalysts 2018, 8, 76. [Google Scholar] [CrossRef] [Green Version]

- Cao, J.; Yao, X.; Yang, F.; Chen, L.; Fu, M.; Tang, C.; Dong, L. Improving the denitration performance and K-poisoning resistance of the V2O5-WO3/TiO2 catalyst by Ce4+ and Zr4+ co-doping. Chin. J. Catal. 2019, 40, 95–104. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Ge, M. DRIFT study on cerium-tungsten/titania catalyst for selective catalytic reduction of NOx with NH3. Environ. Sci. Technol. 2010, 44, 9590–9596. [Google Scholar] [CrossRef]

- Chen, L.; Weng, D.; Wang, J.; Weng, D.; Cao, L. Low-temperature activity and mechanism of WO3-modified CeO2-TiO2 catalyst under NH3-NO/NO2 SCR conditions. Chin. J. Catal. 2018, 39, 1804–1813. [Google Scholar] [CrossRef]

- Geng, Y.; Shan, W.; Xiong, S.; Liao, Y.; Yang, S.; Liu, F. Effect of CeO2 for a high-efficiency CeO2/WO3-TiO2 catalyst on N2O formation in NH3-SCR: A kinetic study. Catal. Sci. Technol. 2016, 6, 3149–3155. [Google Scholar] [CrossRef]

- Michalow-Mauke, K.A.; Lu, Y.; Ferri, D.; Graule, T.; Kowalski, K.; Elsener, M.; Kröcher, O. WO3/CeO2/TiO2 catalysts for selective catalytic reduction of NOx by NH3: Effect of the synthesis method. Chimia 2015, 69, 220–224. [Google Scholar] [CrossRef] [Green Version]

- Michalow-Mauke, K.A.; Lu, Y.; Kowalski, K.; Graule, T.; Nachtegaal, M.; Kröcher, O.; Ferri, D. Flame-made WO3/CeOx-TiO2 catalysts for selective catalytic reduction of NOx by NH3. ACS Catal. 2015, 5, 5657–5672. [Google Scholar] [CrossRef]

- Jiang, Y.; Xing, Z.; Wang, X.; Huang, S.; Wang, X.; Liu, Q. Activity and characterization of a Ce-W-Ti oxide catalyst prepared by a single step sol-gel method for selective catalytic reduction of NO with NH3. Fuel 2015, 151, 124–129. [Google Scholar] [CrossRef]

- Shan, W.; Liu, F.; He, H.; Shi, X.; Zhang, C. A superior Ce-W-Ti mixed oxide catalyst for the selective catalytic reduction of NOx with NH3. Appl. Catal. B 2012, 115–116, 100–106. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, Z.-B.; Zhou, F.; Lu, W.; Jin, J.; Ding, S.-F. Promotional effect of H2O2 modification on the cerium-tungsten-titanium mixed oxide catalyst for selective catalytic reduction of NO with NH3. J. Phys. Chem. Solids 2018, 121, 360–366. [Google Scholar] [CrossRef]

- Dankeaw, A.; Gualandris, F.; Silva, R.H.; Norrman, K.; Gudik-Sørensen, M.; Kammer Hansen, K.; Ksapabutr, B.; Esposito, V.; Marani, D. Amorphous saturated cerium–tungsten–titanium oxide nanofiber catalysts for NOx selective catalytic reaction. New J. Chem. 2018, 42, 9501–9509. [Google Scholar] [CrossRef] [Green Version]

- Salazar, M.; Becker, R.; Grünert, W. A close-up to the promoting effect of tungsten in Ce/TiO2 catalysts for the selective catalytic reduction of NO with NH3. Mol. Catal. 2018, 451, 66–75. [Google Scholar] [CrossRef]

- Cao, L.; Wu, X.; Xu, Y.; Lin, Q.; Hu, J.; Chen, Y.; Ran, R.; Weng, D. Ceria-modified WO3-TiO2-SiO2 monolithic catalyst for high-temperature NH3-SCR. Catal. Commun. 2019, 120, 55–58. [Google Scholar] [CrossRef]

- Zhang, Q.; Song, Z.; Ning, P.; Liu, X.; Li, H.; Gu, J. Novel promoting effect of acid modification on selective catalytic reduction of NO with ammonia over CeO2 catalysts. Catal. Commun. 2015, 59, 170–174. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, Q.; Ning, P.; Fan, J.; Duan, Y.; Liu, X.; Huang, Z. Effect of CeO2 support on the selective catalytic reduction of NO with NH3 over P-W/CeO2. J. Taiwan Inst. Chem. Eng. 2016, 65, 149–161. [Google Scholar] [CrossRef]

- Wang, D.; Peng, Y.; Yang, Q.; Hu, F.; Li, J.; Crittenden, J. NH3-SCR performance of WO3 blanketed CeO2 with different morphology: Balance of surface reducibility and acidity. Catal. Today 2019, 332, 42–48. [Google Scholar] [CrossRef]

- Peng, R.; Sun, X.; Li, S.; Chen, L.; Fu, M.; Wu, J.; Ye, D. Shape effect of Pt/CeO2 catalysts on the catalytic oxidation of toluene. Chem. Eng. J. 2016, 306, 1234–1246. [Google Scholar] [CrossRef]

- Ma, Z.; Wu, X.; Feng, Y.; Si, Z.; Weng, D. Effects of WO3 doping on stability and N2O escape of MnOx–CeO2 mixed oxides as a low-temperature SCR catalyst. Catal. Commun. 2015, 69, 188–192. [Google Scholar] [CrossRef]

- Daturi, M.; Finocchio, E.; Binet, C.; Lavalley, J.-C.; Fally, F.; Perrichon, V.; Vidal, H.; Hickey, N.; Kašpar, J. Reduction of high surface area CeO2-ZrO2 mixed oxides. J. Phys. Chem. B 2000, 104, 9186–9194. [Google Scholar] [CrossRef]

- Aneggi, E.; Boaro, M.; de Leitenburg, C.; Dolcetti, G.; Trovarelli, A. Insights into the redox properties of ceria-based oxides and their implications in catalysis. J. Alloy Compd. 2006, 408–412, 1096–1102. [Google Scholar] [CrossRef]

- Ning, P.; Song, Z.; Li, H.; Zhang, Q.; Liu, X.; Zhang, J.; Tang, X.; Huang, Z. Selective catalytic reduction of NO with NH3 over CeO2-ZrO2-WO3 catalysts prepared by different methods. Appl. Surf. Sci. 2015, 332, 130–137. [Google Scholar] [CrossRef]

- Song, Z.; Yin, L.; Zhang, Q.; Ning, P.; Duan, Y.; Wang, J.; Liu, X.; Long, K.; Huang, Z. Relationship between the WO3 states and reaction pathway over CeO2-ZrO2-WO3 catalysts for selective catalytic reduction of NO with NH3. Mol. Catal. 2017, 437, 95–104. [Google Scholar] [CrossRef]

- Liu, S.; Lin, Q.; Liu, J.; Xu, S.; Wang, Y.; Xu, H.; Wang, J.; Chen, Y. Enhancement of the Hydrothermal Stability of WO3/Ce0.68Zr0.32O2 Catalyst by Silica Modification for NH3-SCR. ACS Appl. Energy Mater. 2020, 3, 1161–1170. [Google Scholar] [CrossRef] [Green Version]

- Xu, H.; Liu, S.; Wang, Y.; Lin, Q.; Lin, C.; Lan, L.; Wang, Q.; Chen, Y. Promotional effect of Al2O3 on WO3/CeO2-ZrO2 monolithic catalyst for selective catalytic reduction of nitrogen oxides with ammonia after hydrothermal aging treatment. Appl. Surf. Sci. 2018, 427, 656–669. [Google Scholar] [CrossRef]

- Can, F.; Berland, S.; Royer, S.; Courtois, X.; Duprez, D. Composition-dependent performance of CexZr1−x O2 mixed-oxide supported WO3 catalysts for the NOx storage reduction-selective catalytic reduction coupled process. ACS Catal. 2013, 3, 1120–1132. [Google Scholar] [CrossRef]

- Martin, N.; Vennestrom, P.N.R.; Thogersen, J.R.; Moliner, M.; Corma, A. Iron-containing SSZ-39 (AEI) zeolite: An active and stable high-temperature NH3-SCR catalyst. ChemCatChem 2017, 9, 1754–1757. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Li, J.; Peng, Y.; Zhang, T.; Liu, S.; Hao, J. Selective catalytic reduction of NO with NH3 over novel iron–tungsten mixed oxide catalyst in a broad temperature range. Catal. Sci. Technol. 2015, 5, 4556–4564. [Google Scholar] [CrossRef]

- Wang, H.; Qu, Z.; Dong, S.; Xie, H.; Tang, C. Superior performance of Fe1−xWxOδ for the selective catalytic reduction of NOx with NH3: Interaction between Fe and W. Environ. Sci. Technol. 2016, 50, 13511–13519. [Google Scholar] [CrossRef]

- Wang, H.; Qu, Z.; Dong, S.; Tang, C. Mechanistic investigation into the effect of sulfuration on the FeW catalysts for the selective catalytic reduction of NOx with NH3. ACS Appl. Mater. Interfaces 2017, 9, 7017−7028. [Google Scholar] [CrossRef]

- Liu, F.; Shan, W.; Lian, Z.; Liu, J.; He, H. The smart surface modification of Fe2O3 by WOx for significantly promoting the selective catalytic reduction of NOx with NH3. Appl. Catal. B 2018, 230, 165–176. [Google Scholar] [CrossRef]

- Li, C.; Huang, Z.; Chen, Y.; Liu, X.; Chen, J.; Qu, W.; Ma, Z.; Tang, X. Optimizing selective catalytic reduction of NO with NH3 on Fe2O3/WO3 via redox-acid synergy. ChemCatChem 2018, 10, 3990–3994. [Google Scholar] [CrossRef]

- Foo, R.; Vazhnova, T.; Lukyanov, D.B.; Millington, P.; Collier, J.; Rajaram, R.; Golunski, S. Formation of reactive Lewis acid sites on Fe/WO3-ZrO2 catalysts for higher temperature SCR applications. Appl. Catal. B 2015, 162, 174–179. [Google Scholar] [CrossRef]

- Xu, H.; Li, Y.; Xu, B.; Cao, Y.; Feng, X.; Sun, M.; Gong, M.; Chen, Y. Effectively promote catalytic performance by adjusting W/Fe molar ratio of FeWx/Ce0.68Zr0.32O2 monolithic catalyst for NH3-SCR. J. Ind. Eng. Chem. 2016, 36, 334–345. [Google Scholar] [CrossRef]

- Xiong, Z.B.; Peng, B.; Zhou, F.; Wu, C.; Lu, W.; Jin, J.; Ding, S.F. Magnetic iron-cerium-tungsten mixed oxide pellets prepared through citric acid sol-gel process assisted by microwave irradiation for selective catalytic reduction of NOx with NH3. Powder Technol. 2017, 319, 19–25. [Google Scholar] [CrossRef]

- Ma, S.; Zhao, X.; Li, Y.; Zhang, T.; Yuan, F.; Niu, X.; Zhu, Y. Effect of W on the acidity and redox performance of the Cu0.02Fe0.2WαTiOx (α= 0.01, 0.02, 0.03) catalysts for NH3-SCR of NO. Appl. Catal. B 2019, 248, 226–238. [Google Scholar] [CrossRef]

- Su, Y.; Dong, G.; Zhao, Y.; Zhang, Y.; Wang, Y. FeOx-VOx-WOx-MnOx-CeOx/TiO2 as a catalyst for selective catalytic reduction of NOx with NH3 and the role of iron. Indian J. Chem. 2015, 54A, 744–751. [Google Scholar]

- Kong, Z.; Wang, C.; Ding, Z.; Chen, Y.; Zhang, Z. Enhanced activity of MnxW0.05Ti0.95−xO2−δ for selective catalytic reduction of NOx with ammonia by self-propagating high-temperature synthesis. Catal. Commun. 2015, 64, 27–31. [Google Scholar] [CrossRef]

- Shin, B.; Lee, H.; Park, H. Catalytic Activity and surface characteristics of WO3-doped MnOx-TiO2 catalysts for low-temperature selective catalytic reduction of NOx with NH3. Korean J. Met. Mater. 2016, 54, 787–792. [Google Scholar]

- Wang, X.; Li, X.; Zhao, Q.; Sun, W.; Tade, M.; Liu, S. Improved activity of W-modified MnOx–TiO2 catalysts for the selective catalytic reduction of NO with NH3. Chem. Eng. J. 2016, 288, 216–222. [Google Scholar] [CrossRef]

- Phule, A.D.; Choi, J.H.; Kim, J.H. High performance of catalytic sheet filters of V2O5-WO3/TiO2 for NOx reduction. Environ. Sci. Pollut. Res. 2020. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Ma, Z.; Wang, B.; Sun, Q.; Xu, W.; Zhu, T. Effects of MOx (M=Mn, Cu, Sb, La) on V-Mo-Ce/Ti selective catalytic reduction catalysts. J. Rare Earth 2020, 38, 157–166. [Google Scholar] [CrossRef]

- Nie, J.; Wu, X.; Ma, Z.; Xu, T.; Si, Z.; Chen, L.; Wen, D. Tailored temperature window of MnOx-CeO2 SCR catalyst by addition of acidic metal oxides. Chin. J. Catal. 2014, 35, 1281–1288. [Google Scholar] [CrossRef]

- Zhang, T.; Qiu, F.; Chang, H.; Peng, Y.; Li, J. Novel W-modified SnMnCeOx catalyst for the selective catalytic reduction of NOx with NH3. Catal. Commun. 2017, 100, 117–120. [Google Scholar] [CrossRef]

- Kwon, D.W.; Nam, K.B.; Hong, S.C. Influence of tungsten on the activity of a Mn/Ce/W/Ti catalyst for the selective catalytic reduction of NO with NH3 at low temperatures. Appl. Catal. A 2015, 497, 160–166. [Google Scholar] [CrossRef]

- Nam, K.B.; Kwon, D.W.; Hong, S.C. DRIFT study on promotion effects of tungsten-modified Mn/Ce/Ti catalysts for the SCR reaction at low-temperature. Appl. Catal. A 2017, 542, 55–62. [Google Scholar] [CrossRef]

- Nam, K.B.; Kim, D.H.; Hong, S.C. Enhancement of Mn/Ce/W/Ti catalysts through control of pH and oxygen mobility during their preparation. Appl. Catal. A 2019, 572, 107–114. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Y.; Li, Y.; Su, H.; Ma, L. WO3 promoted Mn–Zr mixed oxide catalyst for the selective catalytic reduction of NOx with NH3. Chem. Eng. J. 2016, 283, 1044–1050. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, N.; Luo, Z.; Yang, W.; Liang, X.; Xu, R.; Chen, B.; Duprez, D.; Royer, S. A remarkable catalyst combination to widen the operating temperature window of the selective catalytic reduction of NO by NH3. ChemCatChem 2014, 6, 2263–2269. [Google Scholar] [CrossRef]

- Can, F.; Courtois, X.; Duprez, D. Chapter 3 NSR catalytic materials. In NOx Trap Catalysts and Technologies: Fundamentals and Industrial Applications; Catalysis Series; Lietti, L., Castoldi, L., Eds.; RSC Publishing: Cambridge, UK, 2018; pp. 67–103. [Google Scholar]

- Can, F.; Courtois, X.; Royer, S.; Blanchard, G.; Rousseau, S.; Duprez, D. An overview of the production and use of ammonia in NSR + SCR coupled system for NOx reduction from lean exhaust gas. Catal. Today 2012, 197, 144–154. [Google Scholar] [CrossRef]

- Shinjoh, H.; Takahashi, N.; Yokota, K. Synergic effect of Pd/gamma-alumina and Cu/ZSM-5 on the performance of NOx storage reduction catalyst. Top. Catal. 2007, 42–43, 215–219. [Google Scholar] [CrossRef]

- Corbos, E.C.; Haneda, M.; Courtois, X.; Marecot, P.; Duprez, D.; Hamada, H. NOx abatement for lean burn engines under lean-rich atmosphere over mixed NSR-SCR catalysts: Influences of the addition of a SCR catalyst and of the operational conditions. Appl. Catal. A 2009, 365, 187–193. [Google Scholar] [CrossRef]

- De La Torre, U.; Pereda-Ayo, B.; Moliner, M.; González-Velasco, J.R.; Corma, A. Cu-zeolite catalysts for NOx removal by selective catalytic reduction with NH3 and coupled to NO storage/reduction monolith in diesel engine exhaust aftertreatment systems. Appl. Catal. B 2016, 187, 419–427. [Google Scholar] [CrossRef] [Green Version]

- Cortés-Reyes, M.; Herrera, C.; Larrubia, M.Á.; Alemany, L.J. Hybrid technology for DeNOxing by LNT-SCR system for efficient diesel emission control: Influence of operation parameters in H2O + CO2 atmosphere. Catalysts 2020, 10, 228. [Google Scholar] [CrossRef] [Green Version]

- Zukerman, R.; Vradman, L.; Herskowitz, M.; Liverts, E.; Liverts, M.; Massner, A.; Weibel, M.; Brilhac, J.F.; Blakeman, P.G.; Peace, L.J. Modeling and simulation of a smart catalytic converter combining NOx storage, ammonia production and SCR. Chem. Eng. J. 2009, 155, 419–426. [Google Scholar] [CrossRef]

- Castoldi, L.; Bonzi, R.; Lietti, L.; Forzatti, P.; Morandi, S.; Ghiotti, G.; Dzwigaj, S. Catalytic behaviour of hybrid LNT/SCR systems: Reactivity and in situ FTIR study. J. Catal. 2011, 282, 128–144. [Google Scholar] [CrossRef]

- Can, F.; Courtois, X.; Berland, S.; Seneque, M.; Royer, S.; Duprez, D. Composition dependent performance of alumina-based oxide supported WO3 catalysts for the NH3-SCR reaction and the NSR + SCR coupled process. Catal. Today 2015, 257, 41–50. [Google Scholar] [CrossRef]

- Väliheikki, A.; Petallidou, K.C.; Kalamaras, C.M.; Kolli, T.; Huuhtanen, M.; Maunula, T.; Keiski, R.L.; Efstathiou, A.M. Selective catalytic reduction of NOx by hydrogen (H2-SCR) on WOx-promoted CezZr1−zO2 solids. Appl. Catal. B 2014, 156–157, 72–83. [Google Scholar] [CrossRef]

- Shibata, J.; Hashimoto, M.; Shimizu, K.I.; Yoshida, H.; Hattori, T.; Satsuma, A. Factors Controlling activity and selectivity for SCR of NO by hydrogen over supported platinum catalysts. J. Phys. Chem. B 2004, 108, 18327–18335. [Google Scholar] [CrossRef]

- Costa, C.N.; Efstathiou, A.M. Mechanistic Aspects of the H2-SCR of NO on a Novel Pt/MgO-CeO2 Catalyst. J. Phys. Chem. C 2007, 111, 3010–3020. [Google Scholar] [CrossRef]

- Savva, P.G.; Costa, C.N. Hydrogen Lean-DeNO(x) as an alternative to the ammonia and hydrocarbon selective catalytic reduction (SCR). Catal. Rev. Sci. Eng. 2011, 53, 91–151. [Google Scholar] [CrossRef]

- Schott, F.J.P.; Balle, P.; Adler, J.; Kureti, S. Reduction of NOx by H2 on Pt/WO3/ZrO2 catalysts in oxygen-rich exhaust. Appl. Catal. B 2009, 87, 18–29. [Google Scholar] [CrossRef]

- Yang, S.; Wang, X.; Chu, W.; Song, Z.; Zhao, S. An investigation of the surface intermediates of H2-SCR of NOx over Pt/H-FER. Appl. Catal. B 2011, 107, 380–385. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, X.; Zhao, X.; Xu, Y.; Liu, Y.; Yu, Q. Promotion effect of tungsten on the activity of Pt/HZSM-5 for H2-SCR. Chem. Eng. J. 2015, 260, 419–426. [Google Scholar] [CrossRef]

- Sun, M.; Wang, S.; Li, Y.; Xu, H.; Chen, Y. Promotion of catalytic performance by adding W into Pt/ZrO2 catalyst for selective catalytic oxidation of ammonia. Appl. Surf. Sci. 2017, 402, 323–329. [Google Scholar] [CrossRef]

- Wang, H.; Ning, P.; Zhang, Q.; Liu, X.; Zhang, T.; Fan, J.; Wang, J.; Long, K. Promotional mechanism of WO3 over RuO2-Fe2O3 catalyst for NH3-SCO reaction. Appl. Catal. A 2018, 561, 158–167. [Google Scholar] [CrossRef]

- Miyadera, T. Alumina-supported silver catalysts for the selective reduction of nitric oxide with propene and oxygen-containing organic compounds. Appl. Catal. B 1993, 2, 199–205. [Google Scholar] [CrossRef]

- Bion, N.; Saussey, J.; Hedouin, C.; Seguelong, T.; Daturi, M. Evidence by in situ FTIR spectroscopy and isotopic effect of new assignments for isocyanate species vibrations on Ag/Al2O3. Phys. Chem. Chem. Phys. 2011, 3, 4811–4816. [Google Scholar] [CrossRef]

- Bion, N.; Saussey, J.; Haneda, M.; Daturi, M. Study by in situ FTIR spectroscopy of the SCR of NOx by ethanol on Ag/Al2O3-Evidence of the role of isocyanate species. J. Catal. 2003, 217, 47–58. [Google Scholar] [CrossRef]

- Kameoka, S.; Ukisu, Y.; Miyadera, T. Selective catalytic reduction of NOx with and CH3OH, C2H5OH and C3H6 in the presence of O2 over Ag/Al2O3 catalyst: Role of surface nitrate species. Phys. Chem. Chem. Phys. 2000, 2, 367–372. [Google Scholar] [CrossRef]

- Yeom, Y.H.; Li, M.; Sachtler, W.M.H.; Weitz, E. A study of the mechanism for NOx reduction with ethanol on γ-alumina supported silver. J. Catal. 2006, 238, 100–110. [Google Scholar] [CrossRef]

- Barreau, M.; Tarot, M.-L.; Duprez, D.; Courtois, X.; Can, F. Remarkable enhancement of the selective catalytic reduction of NO at low temperature by collaborative effect of ethanol and NH3 over silver supported catalyst. Appl. Catal. B 2018, 220, 19–30. [Google Scholar] [CrossRef]

- Barreau, M.; Delporte, M.; Iojoiu, E.; Courtois, X.; Can, F. Lean NOx removal by a bifunctional (EtOH + NH3) mixture dedicated to (Ag/Al2O3+ NH3-SCR) dual-bed catalytic system: Comparison between WO3/CeZrO2 and Cu–FER as NH3-SCR catalyst. Top. Catal. 2019, 62, 79–85. [Google Scholar] [CrossRef]

- Barreau, M.; Courtois, X.; Can, F. Selective catalytic reduction of NO at low temperature using a (ethanol+ammonia) mixture over a Ag/Al2O3+WO3/CexZryO2 dual-bed catalytic system: Reactivity insight of WO3/CexZryO2. Catal. Today 2020, 355, 375–384. [Google Scholar] [CrossRef]

- Altman, E.I.; Schwarz, U.D. Mechanisms, Kinetics, and Dynamics of Oxidation and Reactions on Oxide Surfaces Investigated by Scanning Probe Microscopy. Adv. Mater. 2010, 22, 2854–2869. [Google Scholar] [CrossRef]

- Balzer, R.; Drago, V.; Schreiner, W.H.; Probst, L.F.D. Synthesis and structure-activity relationship of a WO3 catalyst for the total oxidation of BTX. J. Braz. Chem. Soc. 2014, 25, 2026–2031. [Google Scholar]

- Pansare, S.S.; Goodwin, J.G., Jr.; Gangwal, S. Simultaneous ammonia and toluene decomposition on tungsten-based catalysts for hot gas cleanup. Ind. Eng. Chem. Res. 2008, 47, 8602–8611. [Google Scholar] [CrossRef]

- Debecker, D.P.; Delaigle, R.; Bouchmella, K.; Eloy, P.; Gaigneaux, E.M.; Mutin, P.H. Total oxidation of benzene and chlorobenzene with MoO3- and WO3-promoted V2O5/TiO2 catalysts prepared by a nonhydrolytic sol-gel route. Catal. Today 2010, 157, 125–130. [Google Scholar] [CrossRef]

- Lu, S.-Y.; Wang, Q.-L.; Stevens, W.R.; Lee, C.W.; Gullett, B.K.; Zhao, Y.-X. Study on the decomposition of trace benzene over V2O5–WO3/TiO2-based catalysts in simulated flue gas. Appl. Catal. B 2014, 147, 322–329. [Google Scholar] [CrossRef]

- Gullett, B.; Touati, A.; Oudejans, L. Use of REMPI–TOFMS for real-time measurement of trace aromatics during operation of aircraft ground equipment. Atmos. Environ. 2008, 42, 2117–2128. [Google Scholar] [CrossRef]

- Gancheva, M.; Naydenov, A.; Iordanova, R.; Nihtianova, D.; Stefanov, P. Mechanochemically assisted solid state synthesis, characterization, and catalytic properties of MgWO4. J. Mater. Sci. 2015, 50, 3447–3456. [Google Scholar] [CrossRef]

- Blanch-Raga, N.; Soriano, M.D.; Palomares, A.E.; Concepción, P.; Martínez-Triguero, J.; López-Nieto, J.M. Catalytic abatement of trichloroethylene over Mo and/or W-based bronzes. Appl. Catal. B 2013, 130–131, 36–43. [Google Scholar] [CrossRef]

- Haneda, M.; Suzuki, K.; Sasaki, M.; Hamada, H.; Ozawa, M. Catalytic performance of bimetallic PtPd/Al2O3 for diesel hydrocarbon oxidation and its implementation by acidic additives. Appl. Catal. A 2014, 475, 109–115. [Google Scholar] [CrossRef]

- Le, Y.; Qi, L.F.; Wang, C.; Song, S.X. Hierarchical Pt/WO3 nanoflakes assembled hollow microspheres for room-temperature formaldehyde oxidation activity. Appl. Surf. Sci. 2020, 512, 145763. [Google Scholar] [CrossRef]

- Fukushi, D.; Sato, A.; Kusaka, T.; Kataoka, Y.; Kobayashi, K. Enhancing the rate of organic material decomposition photo catalyzed by high performance visible light activated tungsten oxide. ECS Trans. 2014, 61, 43–49. [Google Scholar] [CrossRef]

- Fukushi, D.; Sato, A.; Yoshida, K.; Kitano, M. Decomposition of gas-phase organic pollutants over nanocrystalline tungsten oxide photocatalysts under visible-light irradiation. Bull. Chem. Soc. Jpn. 2017, 90, 885–892. [Google Scholar] [CrossRef]

- Fukumura, T.; Sambandan, E.; Yamashita, H. Synthesis and VOC degradation ability of a CeO2/WO thin-layer visible-light photocatalyst. Mater. Res. Bull. 2017, 94, 493–499. [Google Scholar] [CrossRef]

- Balayeva, N.O.; Fleisch, M.; Bahnemann, D.W. Surface-grafted WO3/TiO2 photocatalysts: Enhanced visible-light activity towards indoor air purification. Catal. Today 2018, 313, 63–71. [Google Scholar] [CrossRef]

- Caudillo-Flores, U.; Munoz-Batista, M.J.; Hungria, A.B.; Haro, M.L.; Fernandez-Garcia, M.; Kubacka, A. Toluene and styrene photo-oxidation quantum efficiency: Comparison between doped and composite tungsten-containing anatase-based catalysts. Appl. Catal. B 2019, 245, 49–61. [Google Scholar] [CrossRef]

- Li, Y.; Wu, X.; Li, J.; Wang, K.; Zhang, G. Z-scheme g-C3N4@CsxWO3 heterostructure as smart window coating for UV isolating, Vis penetrating, NIR shielding and full spectrum photocatalytic decomposing VOCs. Appl. Catal. B 2018, 229, 218–226. [Google Scholar] [CrossRef]

- Dong, C.; Zhao, R.; Yao, L.; Ran, Y.; Zhang, X.; Wang, Y. A review on WO3 based gas sensors: Morphology control and enhanced sensing properties. J. Alloy Compd. 2020, 820, 153194. [Google Scholar] [CrossRef]

- Rickerby, D.G. Metal oxides: Nanostructured metal oxide for gas sensing application. In CRC Concise Encyclopedia of Nanotechnology; Ildusovich Kharisov, B., Kharissova, O.V., Ortiz-Mendez, U., Eds.; CRC Press: Boca Raton, FL, USA, 2016; pp. 481–492. [Google Scholar]

- Kaur, M.; Aswal, D.K.; Yakhmi, J.V. Chapter 2 Chemiresistor Gas Sensors: Materials, mechanisms and fabrication. In Science and Technology of Chemiresistor Gas Sensors; Aswal, D.K., Gupta, S.K., Eds.; Nova Publishers: Hauppauge, NY, USA, 2007; pp. 33–94. [Google Scholar]

- Gardner, J.W. Electrical conduction in solid-state gas sensors. Sens. Actuators 1989, 18, 373–387. [Google Scholar] [CrossRef]

- Gardner, J.W. Detection of vapours and odours from a multisensor array using pattern recognition Part 1. Principal component and cluster analysis. Sens. Actuators B 1991, 4, 109–115. [Google Scholar] [CrossRef]

- Han, X.; Yin, X. Density functional theory study of the NO2-sensing mechanism on a WO3 (0 0 1) surface: The role of surface oxygen vacancies in the formation of NO and NO3. Mol. Phys. 2016, 114, 3546–3555. [Google Scholar] [CrossRef]

- Yang, L.; Marikutsa, A.; Rumyantseva, M.; Konstantinova, E.; Khmelevsky, N.; Gaskov, A. Quasi similar routes of NO2 and NO sensing by nanocrystalline WO3: Evidence by in situ DRIFT spectroscopy. Sensors 2019, 19, 3405. [Google Scholar] [CrossRef] [Green Version]

- Chandrasekaran, G.; Sundararaj, A.; Therese, H.A.; Jeganathan, K. Ni-catalysed WO3 nanostructures grown by electron beam rapid thermal annealing for NO2 gas sensing. J. Nanopart Res. 2015, 17, 292. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Cui, J.; Sun, J. Hydrothermal synthesis of self-assembled hierarchical tungsten oxides hollow spheres and their gas sensing properties. ACS Appl. Mater. Interfaces 2015, 7, 10108–10114. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cheng, X.; Zhang, X.; Major, Z.; Xu, Y.; Gao, S.; Zhao, H.; Huo, L. Ionic liquid-assisted synthesis of tungsten oxide nanoparticles with enhanced NO2 sensing properties at near room temperature. Appl. Surf. Sci. 2020, 505, 144533. [Google Scholar] [CrossRef]

- Cao, P.J.; Li, M.; Rao, C.N.; Han, S.; Xu, W.-Y.; Fang, M.; Liu, X.-K.; Zeng, Y.-X.; Liu, W.J.; Zhu, D.L.; et al. High Sensitivity NO2 Gas Sensor Based on 3D WO3 Microflowers Assembled by Numerous Nanoplates. J. Nanosci. Nanotechnol. 2020, 20, 1790–1798. [Google Scholar] [CrossRef]

- Liu, D.; Ren, X.; Li, Y.; Tang, Z.; Zhang, Z. Nanowires-assembled WO3 nanomesh for fast detection of ppb-level NO2 at low temperature. J. Adv. Ceram. 2020, 9, 17–26. [Google Scholar] [CrossRef] [Green Version]

- Lu, N.; Yang, C.; Liu, P.; Su, X. Preparation of 2 nm tungsten oxide nanowires based on two-phase strategy and their ultra-sensitive NO2 gas sensing properties. J. Colloid Interfaces Sci. 2019, 557, 311–317. [Google Scholar] [CrossRef]

- Song, W.; Zhang, R.; Bai, X.; Jia, Q.; Ji, H. Exposed crystal facets of WO3 nanosheets by phase control on NO2-sensing performance. J. Mater. Sci. Mater. Electr. 2020, 31, 610–620. [Google Scholar] [CrossRef]

- Zheng, E.X.; Zhang, C.; Xia, J.; Zhou, G.; Jiang, D.; Wang, S.; Li, X.; Shen, Y.; Dai, M.; Wang, B.; et al. Mesoporous tungsten oxide electrodes for YSZ-based mixed potential sensors to detect NO2 in the sub ppm-range. Sens. Actuators B Chem. 2019, 284, 575–581. [Google Scholar] [CrossRef]

- Ma, S.; Hu, M.; Zeng, P.; Yan, W.; Li, M. Growth of tungsten oxide nanorods onto porous silicon and their sensing properties for NO2. Mater. Lett. 2013, 99, 57–60. [Google Scholar] [CrossRef]

- Ma, S.; Hu, M.; Zeng, P.; Li, M.; Yan, W.; Li, C. Synthesis of tungsten oxide nanowires/porous silicon composites and their application in NO2 sensors. Mater. Lett. 2013, 112, 12–15. [Google Scholar] [CrossRef]

- Ma, S.; Hu, M.; Zeng, P.; Li, M.; Yan, W.; Qin, Y. Synthesis and low-temperature gas sensing properties of tungstenoxide nanowires/porous silicon composite. Sens. Actuators B Chem. 2014, 192, 341–349. [Google Scholar] [CrossRef]

- Li, M.; Hu, M.; Jia, D.; Ma, S.; Yan, W. NO2-sensing properties based on the nanocomposite of n-WO3−x/n-porous silicon at room temperature. Sens. Actuators B Chem. 2013, 186, 140–147. [Google Scholar] [CrossRef]

- Lee, K.; Beak, D.-H.; Na, H.; Choi, J.; Kim, J. Simple fabrication method of silicon/tungsten oxide nanowires heterojunction for NO2 gas sensors. Sens. Actuators B Chem. 2018, 265, 522–528. [Google Scholar] [CrossRef]

- Godbole, R.; Vedpathak, A.; Godbole, V.; Bhagwat, S. Tungsten oxide thin films: Detection and trapping of hazardous gases. Mater. Res. Express 2017, 4, 1–7. [Google Scholar] [CrossRef]

- Najafi-Ashtiani, H. The effect of different surface morphologies on WO3 and WO3-Au gas-sensors performance. J. Mater. Sci. Mater. Electr. 2019, 30, 12224–12233. [Google Scholar] [CrossRef]