Benchmarking Acidic and Basic Catalysis for a Robust Production of Biofuel from Waste Cooking Oil

Abstract

:1. Introduction

2. Results and Discussion

2.1. Basic Catalysis

2.2. Acidic Catalysis

2.3. Characterization

2.3.1. Acidity of WCO

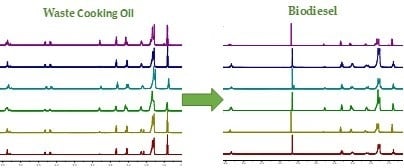

2.3.2. NMR Characterization

2.3.3. FT-IR Analysis

2.3.4. Gas Chromatographic Analysis

3. Materials and Methods

3.1. Chemicals and Material

3.2. General Reaction Procedures

3.2.1. Homogeneous Basic Catalysis

3.2.2. Homogeneous Acidic Catalysis

3.2.3. Acidic Catalysis Supported by Silica

3.3. Acidity Percentage

3.4. Analysis Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huber, G.W.; Corma, A. Synergies between Bio- and Oil Refineries for the Production of Fuels from Biomass. Angew. Chem. Int. Ed. 2007, 46, 7184–7201. [Google Scholar] [CrossRef] [PubMed]

- Thanh, L.T.; Okitsu, K.; Van Boi, L.; Maeda, Y. Catalytic technologies for biodiesel fuel production and utilization of glycerol: A review. Catalysts 2012, 2, 191–222. [Google Scholar] [CrossRef] [Green Version]

- Meher, L.C.; Vidya Sagar, D.; Naik, S.N. Technical aspects of biodiesel production by transesterification—A review. Renew. Sustain. Energy Rev. 2006, 10, 248–268. [Google Scholar] [CrossRef]

- Marchetti, J.M.; Miguel, V.U.; Errazu, A.F. Possible methods for biodiesel production. Renew. Sustain. Energy Rev. 2007, 11, 1300–1301. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: A review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef] [PubMed]

- Leone, G.P.; Balducchi, R.; Mehariya, S.; Martino, M.; Larocca, V.; Sanzo, G.D.; Iovine, A.; Casella, P.; Marino, T.; Karatza, D.; et al. Selective extraction of ω-3 fatty acids from Nannochloropsis sp. using supercritical CO2 Extraction. Molecules 2019, 24, 2406. [Google Scholar] [CrossRef] [Green Version]

- Machmudah, S.; Wahyu, D.; Kanda, H.; Goto, M. Supercritical fluids extraction of valuable compounds from algae: Future perspectives and challenges. Eng. J. 2018, 22, 13–30. [Google Scholar] [CrossRef]

- Di Sanzo, G.; Mehariya, S.; Martino, M.; Larocca, V.; Casella, P.; Chianese, S.; Musmarra, D.; Balducchi, R.; Molino, A. Supercritical carbon dioxide extraction of astaxanthin, lutein, and fatty acids from haematococcus pluvialis microalgae. Mar. Drugs 2018, 16, 334. [Google Scholar] [CrossRef] [Green Version]

- Catchpole, O.; Moreno, T.; Montañes, F.; Tallon, S. Perspectives on processing of high value lipids using supercritical fluids. J. Supercrit. Fluids 2018, 134, 260–268. [Google Scholar] [CrossRef]

- Schablitzky, H.W.; Lichtscheidl, J.; Hutter, K.; Hafner, C.; Rauch, R.; Hofbauer, H. Hydroprocessing of Fischer-Tropsch biowaxes to second-generation biofuels. Biomass Convers. Biorefinery 2011, 1, 29–37. [Google Scholar] [CrossRef] [Green Version]

- Canakci, M. The potential of restaurant waste lipids as biodiesel feedstocks. Bioresour. Technol. 2007, 98, 183–190. [Google Scholar] [CrossRef] [PubMed]

- Ki-Teak, I.; Foglia, T.A. Production of alkyl ester and biodiesel from fractionated lard and restaurant grease. J. Am. Oil Chem. Soc. 2002, 79, 191–195. [Google Scholar]

- Zhang, Y.; Dubé, M.A.; McLean, D.D.; Kates, M. Biodiesel production from waste cooking oil: Process design and technological assessment. Bioresour. Technol. 2003, 89, 1–16. [Google Scholar] [CrossRef]

- Chhetri, A.B.; Watts, K.C.; Islam, M.R. Waste cooking oil as an alternative feedstock for biodiesel production. Energies 2008, 15, 3–18. [Google Scholar] [CrossRef] [Green Version]

- Enweremadu, C.C.; Mbarawa, M.M. Technical aspects of production and analysis of biodiesel from used cooking oil—A review. Renew. Sustain. Energy Rev. 2009, 13, 2205–2224. [Google Scholar] [CrossRef]

- Glisic, S.B.; Pajnik, J.M.; Orlovic, A.M. Process and techno-economic analysis of green diesel production from waste vegetable oil and the comparison with ester type biodiesel production. Appl. Energy 2016, 170, 176–185. [Google Scholar] [CrossRef]

- Refaat, A.A. Different techniques for the production of biodiesel from waste vegetable oil. Int. J. Environ. Sci. Technol. 2010, 7, 183–213. [Google Scholar] [CrossRef] [Green Version]

- Yaakob, Z.; Mohammada, M.; Alherbawi, M.; Alam, Z.; Sopian, K. Overview of the production of biodiesel from Waste cooking oil. Renew. Sustain. Energy Rev. 2013, 18, 184–193. [Google Scholar] [CrossRef]

- Talebian-Kiakalaieh, A.; Amin, N.A.S.; Mazaheri, H. A review on novel processes of biodiesel production from waste cooking oil. Appl. Energy 2013, 104, 683–710. [Google Scholar] [CrossRef]

- Glisic, S.B.; Orlović, A.M. Review of biodiesel synthesis from waste oil under elevated pressure and temperature: Phase equilibrium, reaction kinetics, process design and techno-economic study. Renew. Sustain. Energy Rev. 2014, 31, 708–725. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Guo, Y. Transesterification of neat and used frying oil: Optimization for biodiesel production. Fuel Process. Technol. 2006, 87, 883–890. [Google Scholar] [CrossRef]

- Demirbas, A. Biodiesel from waste cooking oil via base-catalytic and supercritical methanol transesterification. Energy Convers. Manag. 2009, 50, 923–927. [Google Scholar] [CrossRef]

- Alcantara, R.; Amores, J.; Canoira, L.; Fidalgo, E.; Franco, M.J.; Navarro, A. Catalytic production of biodiesel from soybean oil. Used frying oil and tallow. Biomass Bioenergy 2000, 18, 515–527. [Google Scholar] [CrossRef]

- Supple, B.; Holward-Hildige, R.; Gonzalez-Gomez, E.; Leahy, J.J. The effect of steam treating waste cooking oil on the yield of methyl ester. J. Am. Oil Chem. Soc. 2002, 79, 175–178. [Google Scholar] [CrossRef]

- Lotero, E.; Liu, Y.; Lopez, D.E.; Suwannakarn, K.; Bruce, D.A.; Goodwin, J.G., Jr. Synthesis of biodiesel via acid catalysis. Ind. Eng. Chem. Res. 2005, 44, 5353–5363. [Google Scholar] [CrossRef]

- Gebremariam, S.N.; Marchetti, J.M. Biodiesel production through sulfuric acid catalyzed transesterification of acidic oil: Techno economic feasibility of different process alternatives. Energy Convers. Manag. 2018, 174, 639–648. [Google Scholar] [CrossRef]

- Schwab, A.W.; Bagby, M.O.; Freedman, B. Preparation and properties of diesel fuels from vegetable oils. Fuel 1987, 66, 1372–1378. [Google Scholar] [CrossRef]

- Liu, K. Preparation of fatty acid methyl esters for gaschromatographic analysis of lipids in biological materials. J. Am. Oil Chem. Soc. 1994, 71, 1179–1187. [Google Scholar] [CrossRef]

- Nye, M.J.; Williamson, T.W.; Deshpande, S.; Schrader, J.H.; Snively, W.H.; Yurkewich, T.P.; French, C.L. Conversion of used frying oil to diesel fuel by transesterification: Preliminary tests. J. Am. Oil Chem. Soc. 1983, 60, 1598–1601. [Google Scholar] [CrossRef]

- Canakci, M.; Van Gerpen, J. Biodiesel production via acidic catalysis. Trans. ASAE 2009, 42, 1203–1210. [Google Scholar] [CrossRef]

- Guana, G.; Kusakabe, K. Biodiesel Production from waste oily sludge by acid-catalyzed esterification. Int. J. Biomass Renew. 2012, 1, 1–5. [Google Scholar]

- Lee, A.F.; Bennett, J.A.; Manayil, J.C.; Wilson, K. Heterogeneous catalysis for sustainable biodiesel production via esterification and transesterification. Chem. Soc. Rev. 2014, 43, 7887–7916. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carlucci, C.; Degennaro, L.; Luisi, R. Titanium dioxide as a catalyst in biodesel production. Catalysts 2019, 9, 75. [Google Scholar] [CrossRef] [Green Version]

- Isbell, T.A.; Frykman, H.B.; Abbott, T.P.; Lohr, J.E.; Drozd, J.C. Optimization of the sulfuric acid-catalyzed estolide synthesis from oleic acid. J. Am. Oil Chem. Soc. 1997, 74, 473–476. [Google Scholar] [CrossRef]

- Yang, B.; Leclercq, L.; Clacens, J.M.; Nardello-Rataj, V. Acid/amphiphilic silica nanoparticles: New eco-friendly pickering interfacial catalysis for biodiesel production. Green Chem. 2017, 19, 4552–4562. [Google Scholar] [CrossRef]

- Gelbard, G.; Bres, O.; Vargas, R.M.; Vielfaure, F.; Schuchardt, U.F. 1H nuclear magnetic resonance determination of the yield of the transesterification of rapeseed oil with methanol. J. Am. Oil Chem. Soc. 1995, 72, 1239–1241. [Google Scholar] [CrossRef]

- Oliveira, J.S.; Montalvão, R.; Daher, L.; Suarez, P.A.Z.; Rubim, J.C. Determination of methyl ester contents in biodiesel blends by FTIR-ATR and FTNIR spectroscopies. Talanta 2006, 69, 1278–1284. [Google Scholar] [CrossRef]

- Issariyakul, T.; Kulkarni, M.G.; Dalai, A.K.; Bakhshi, N.N. Production of biodiesel form waste fryer grease using mixed methanol/ethanol system. Fuel Process. Technol. 2007, 88, 429–436. [Google Scholar] [CrossRef]

| Entry | Source | Crude weight 1 (g) | Conversion 2 (%) |

|---|---|---|---|

| 1 | WCO olive oil | 68.4 a | 94 |

| 2 | WCO seed oil | 65.4 a | >99 |

| 3 | WCO mix 1 | 73.0 a | 97 |

| 4 | WCO mix 2 | 62.0 a | 91 |

| 5 | WCO mix 3 | 4.4 b | >99 |

| 6 | WCO mix 4 | 73.0 a | >99 |

| Entry | Source | Temperature (°C) | Time (h) | MeOH/Oil Ratio | Crude Weight 1 (g) | Conversion 2 (%) |

|---|---|---|---|---|---|---|

| 1 | WCO olive oil | 65 | 12 | 6:1 | 8.3 a | 66 |

| 2 | WCO seed oil | 65 | 12 | 6:1 | 6.3 a | 63 |

| 3 | WCO mix 1 | 65 | 12 | 6:1 | 7.5 a | 45 |

| 4 | WCO mix 2 | 65 | 12 | 6:1 | 6.2 a | 48 |

| 5 | WCO mix 3 | 65 | 12 | 6:1 | 7.2 a | 34 |

| 6 | WCO mix 4 | 65 | 12 | 6:1 | 7.1 a | 40 |

| 7 | WCO mix 2 | 85 | 6 | 3:1 | 7.4 a | 75 |

| 8 | WCO mix 2 | 85 | 6 | 6:1 | 4.2 a | 72 |

| 9 | WCO mix 2 | 85 | 6 | 12:1 | 9.6 a | 42 |

| 10 | WCO olive oil | 85 | 12 | 3:1 | 5.4 a | 79 |

| 11 | WCO seed oil | 85 | 12 | 3:1 | 6.3 a | 74 |

| 12 | WCO mix 1 | 85 | 12 | 3:1 | 9.3 a | 68 |

| 13 | WCO mix 2 | 85 | 12 | 3:1 | 7.2 a | 98 |

| 14 | WCO mix 2 | 85 | 12 | 3:1 | 72.0 b | 96 |

| 15 | WCO mix 3 | 85 | 12 | 3:1 | 7.5 a | 69 |

| 16 | WCO mix 4 | 85 | 12 | 3:1 | 7.9 a | 85 |

| 17 | WCO olive oil | 85 | 12 | 6:1 | 6.8 a | 92 |

| 18 | WCO seed oil | 85 | 12 | 6:1 | 8.5 a | 85 |

| 19 | WCO mix 1 | 85 | 12 | 6:1 | 8.4 a | 91 |

| 20 | WCO mix 2 | 85 | 12 | 6:1 | 6.6 a | 99 |

| 21 | WCO mix 2 | 85 | 12 | 6:1 | 88.0 b | 99 |

| 22 | WCO mix 3 | 85 | 12 | 6:1 | 9.9 a | 86 |

| 23 | WCO mix 4 | 85 | 12 | 6:1 | 8.9 a | 91 |

| 24 | WCO olive oil | 85 | 12 | 12:1 | 8.0 a | 61 |

| 25 | WCO seed oil | 85 | 12 | 12:1 | 7.5 a | 63 |

| 26 | WCO mix 1 | 85 | 12 | 12:1 | 8.1 a | 35 |

| 27 | WCO mix 2 | 85 | 12 | 12:1 | 7.6 a | 70 |

| 28 | WCO mix 3 | 85 | 12 | 12:1 | 7.4 a | 37 |

| 29 | WCO mix 4 | 85 | 12 | 12:1 | 7.2 a | 60 |

| Entry | Catalyst | Time (h) | Crude weight 1 (g) | Conversion 2 (%) |

|---|---|---|---|---|

| 1 | SiO2 | 6 | - | - |

| 2 | SiO2/Amberlyst 15 (3%) | 6 | - | - |

| 3 | SiO2/HCl 4M in dioxane | 6 | 5.3 a | 16 |

| 4 | SiO2/H2SO4 (20%) | 6 | 8.7 a | 23 |

| 5 | SiO2/H2SO4 (20%) | 12 | 8.5 b | 92 |

| 6 | SiO2/H2SO4 (20%) | 12 | 10.5 + 5.3 b,c | 85 |

| Entry | Source | Acidity % 1 | Acidity % 2 |

|---|---|---|---|

| 1 | WCO olive oil | 1.79 | 1.47 |

| 2 | WCO seed oil | 1.73 | 1.61 |

| 3 | WCO mix 1 | 3.16 | 2.80 |

| 4 | WCO mix 2 | 0.68 | 0.84 |

| 5 | WCO mix 2 3 | 0.68 | 0.57 |

| 6 | WCO mix 3 | 2.05 | 2.22 |

| 7 | WCO mix 3 3 | 2.05 | 2.02 |

| 8 | WCO mix 4 | 0.34 | 0.31 |

| Entry | Source | Palmitoleate | Palmitate | Linoleate | Oleate | Stearate |

|---|---|---|---|---|---|---|

| 1 | WCO olive oil | 1.441 | 12.284 | 8.701 | 75.255 | 2.319 |

| 2 | WCO seed oil | 1.324 | 12.015 | 13.430 | 70.655 | 2.574 |

| 3 | WCO mix 1 | - | 6.908 | 53.366 | 35.618 | 4.108 |

| 4 | WCO mix 2 | - | 7.484 | 37.064 | 52.017 | 3.434 |

| 5 | WCO mix 3 | 2.400 | 13.046 | 10.163 | 71.785 | 2.515 |

| 6 | WCO mix 4 | - | 9.027 | 55.759 | 29.864 | 5.350 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carlucci, C.; Andresini, M.; Degennaro, L.; Luisi, R. Benchmarking Acidic and Basic Catalysis for a Robust Production of Biofuel from Waste Cooking Oil. Catalysts 2019, 9, 1050. https://doi.org/10.3390/catal9121050

Carlucci C, Andresini M, Degennaro L, Luisi R. Benchmarking Acidic and Basic Catalysis for a Robust Production of Biofuel from Waste Cooking Oil. Catalysts. 2019; 9(12):1050. https://doi.org/10.3390/catal9121050

Chicago/Turabian StyleCarlucci, Claudia, Michael Andresini, Leonardo Degennaro, and Renzo Luisi. 2019. "Benchmarking Acidic and Basic Catalysis for a Robust Production of Biofuel from Waste Cooking Oil" Catalysts 9, no. 12: 1050. https://doi.org/10.3390/catal9121050

APA StyleCarlucci, C., Andresini, M., Degennaro, L., & Luisi, R. (2019). Benchmarking Acidic and Basic Catalysis for a Robust Production of Biofuel from Waste Cooking Oil. Catalysts, 9(12), 1050. https://doi.org/10.3390/catal9121050