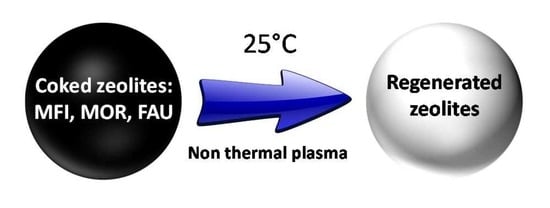

Impact of the Framework Type on the Regeneration of Coked Zeolites by Non-Thermal Plasma in a Fixed Bed Dielectric Barrier Reactor

Abstract

:1. Introduction

2. Results

2.1. Properties and Characterization of the FAU, MOR and MFI Zeolites

2.2. Coke Characterization and Toxicity on the FAU, MOR and MFI Zeolites

2.3. Kinetic of Coke Removal by a NTP

3. Materials and Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guisnet, M.; Ramoa Ribeiro, F. Deactivation and regeneration of solid catalysts. In Deactivation and Regeneration of Zeolite Catalysts; Imperial College Press: London, UK, 2011; pp. 3–18. [Google Scholar]

- Dejaifve, P.; Auroux, A.; Gravelle, P.C.; Védrine, J.C.; Gabelica, Z.; Derouane, E.J. Methanol conversion on acidic ZSM-5, offretite, and mordenite zeolites: A comparative study of the formation and stability of coke deposits. J. Catal. 1981, 70, 123–136. [Google Scholar] [CrossRef]

- Schulz, H.; Siwei, Z.; Baumgartner, W. Coke forming reactions during methanol conversion on zeolite catalysts. Stud. Surf. Sci. Catal. 1987, 34, 479–492. [Google Scholar]

- Sexton, B.A.; Hughes, A.E.; Bibby, D.M. An XPS study of coke distribution on ZSM-5. J. Catal. 1988, 109, 126–131. [Google Scholar] [CrossRef]

- Meinhold, R.H.; Bibby, D.M. 13C CPMAS n.m.r. study of coke formation on HZSM-5. Zeolites 1990, 10, 121–130. [Google Scholar] [CrossRef]

- Magnoux, P.; Cerqueira, H.S.; Guisnet, M. Evolution of coke composition during ageing under nitrogen. Appl. Catal. A Gen. 2002, 235, 93–99. [Google Scholar] [CrossRef]

- Aguayo, T.; Gayubo, A.G.; Erena, J.; Atutxa, A.; Bilbao, J. Coke Aging and Its Incidence on Catalyst Regeneration. Ind. Eng. Chem. Res. 2003, 42, 3914–3921. [Google Scholar] [CrossRef]

- Ortega, J.M.; Gayubo, A.G.; Aguyo, A.T.; Benito, P.L. Role of coke characteristics in the regeneration of a catalyst for the MTG process. Ind. Eng. Chem. Res. 1997, 36, 60–66. [Google Scholar] [CrossRef]

- Pinard, L.; Bichon, B.; Popov, A.; Lemberton, J.L.; Canaff, C.; Maugé, F.; Bazin, P.; Falabella, E.S.; Magnoux, P. Identification of the carbonaceous compounds present on a deactivated cobalt based Fischer–Trospch catalyst resistant to “rejuvenation treatment”. Appl. Catal. A Gen. 2011, 406, 73–80. [Google Scholar] [CrossRef]

- Dmitriadis, V.D.; Lappas, A.A.; Vasalos, I.A. Kinetics of combustion of carbon in carbonaceous deposits on zeolite catalysts for fluid catalytic cracking units (FCCU). Comparison between Pt and non Pt-containing catalysts. Fuel 1998, 77, 1377–1383. [Google Scholar] [CrossRef]

- Le Minh, C.; Jones, R.A.; Craven, I.E.; Brown, T.C. Temperature-Programmed oxidation of coke deposited on cracking catalysts: Combustion mechanism dependence. Energy Fuels 1997, 11, 463–469. [Google Scholar] [CrossRef]

- Marcilla, A.; Beltran, M.I.; Navarro, R.J. Anal Effect of regeneration temperature and time on the activity of HUSY and HZSM5 zeolites during the catalytic pyrolysis of polyethylene. J. Anal. Appl. Pyrolysis 2005, 74, 361–369. [Google Scholar] [CrossRef]

- Villegas, J.I.; Kumar, N.; Heikkilä, T.; Lehto, V.P.; Salmia, T.; MurzinIsomerization, D.Y. Isomerization of n-butane to isobutane over Pt-modified Beta and ZSM-5 zeolite catalysts: Catalyst deactivation and regeneration. Chem. Eng. J. 2006, 120, 83–89. [Google Scholar] [CrossRef]

- Kosinov, N.; Ferdy, J.A.; Coumans, G.; Uslamin, E.; Kapteijn, F.; Hensen, E.J.M. Selective Coke Combustion by Oxygen Pulsing During Mo/ZSM-5-Catalyzed Methane Dehydroaromatization. Chem. Int. Ed. 2016, 55, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, V.J.; Araujo, A.S. Kinetic study of HY zeolite regeneration by thermogravimetry. Thermochim. Acta 1995, 255, 273–280. [Google Scholar] [CrossRef]

- Magnoux, P.; Guisnet, M. Coking ageing and regeneration of zeolites: VI. comparison of the rates of coke oxidation of HY, H-mordenite and HZSM-5. Appl. Catal. 1988, 38, 341–352. [Google Scholar] [CrossRef]

- Novakova, J.; Dolejsek, Z. A comment on the oxidation of coke deposited on zeolites. Zeolites 1990, 10, 189–192. [Google Scholar] [CrossRef]

- Jong, S.J.; Pradhan, A.R.; Wu, J.F.; Tsai, T.C.; Liu, S.B. On the regeneration of coked H-ZSM-5 catalysts. J. Catal. 1998, 174, 210–218. [Google Scholar] [CrossRef]

- Hashimoto, K.; Masuada, T.; Mori, T. Kinetics of combustion of carbonaceous deposits on HZSM-5 zeolites. Chem. Eng. Sci. 1988, 43, 2275–2280. [Google Scholar] [CrossRef]

- Bilbao, J.; Romero, A.; Arandes, J.M. Kinetic equation for the regeneration of a solid catalyst by coke-burning. Chem. Eng. Sci. 1983, 38, 1356–1360. [Google Scholar] [CrossRef]

- Moljord, K.; Magnoux, P.; Guisnet, M. Evidence for a participation of zeolite acid sites in the coke removal through oxidative treatment. Catal. Lett. 1994, 25, 141–147. [Google Scholar] [CrossRef]

- Stepanov, V.G.; Paukshtis, E.A.; Chesnokov, V.V. Mechanism of coking and regeneration of catalysts containing ZSM-5 zeolite. Stud. Surf. Sci. Catal. 2000, 130, 2969–2974. [Google Scholar]

- Sen, H.; Shen, B.-X.; Liu, J.-C. Oxidative regeneration of deactivated binderless 5A molecular sieves for the adsorption–separation of normal hydrocarbons. Fuel Chem. Technol. 2009, 37, 734–739. [Google Scholar] [CrossRef]

- Lakiss, L.; Ngoye, F.; Canaff, C.; Gilson, J.-P.; Laforge, S.; Qin, Z.; Tarighi, M.; Thomas, K.; Valtchev, V.; Vicente, A.; et al. On the remarkable resistance to coke formation of nanometer-sized and hierarchical MFI zeolites during ethanol to hydrocarbons transformation. J. Catal. 2015, 328, 165–172. [Google Scholar] [CrossRef]

- Astafan, A.; Benghalem, M.A.; Michelin, L.; Patarin, J.; Pinard, L.; Daou, T.J. Synthesis of hierarchical ZSM-48 nano-zeolites. N. J. Chem. 2018, 42, 4457–4464. [Google Scholar] [CrossRef]

- Astafan, A.; Benghalem, M.A.; Patarin, J.; Pouilloux, Y.; Bats, N.; Bouchy, C.; Daou, T.J.; Pinard, P. Particular properties of the coke formed on nano-sponge *BEA zeolite during ethanol-to-hydrocarbons transformation. J. Catal. 2016, 336, 1–10. [Google Scholar] [CrossRef]

- Qin, Z.; Pinard, L.; Benghalem, M.A.; Daou, T.J.; Melinte, G.; Ersen, O.; Asahina, S.; Gilson, J.-P.; Valtchech, V. Preparation of Single-Crystal “House-of-Cards”-like ZSM-5 and Their Performance in Ethanol-to-Hydrocarbon Conversion. Chem. Mater. 2019, 31, 4639–4648. [Google Scholar] [CrossRef]

- Jia, L.; Al Farouha, L.; Pinard, L.; Heden, S.; Comparot, J.-D.; Ben Tayeb, K.; Dufour, A.; Vezin, H.; Batiot-Dupeyrat, C. New routes for complete regeneration of coked zeolite. Appl. Catal. B Environ. 2017, 219, 82–91. [Google Scholar] [CrossRef]

- Pinard, L.; Batiot-Dupeyrat, C. Method for Decontaminanting a Catalyst Conataminated with Carbon, Patent No. WO/2018/087505. 17 May 2018. [Google Scholar]

- Pinard, L.; Ayoub, N.; Batiot-Dupeyrat, C. Regeneration of a Coked Zeolite via Nonthermal Plasma Process: A Parametric Study. Plasma Chem. Plasma Process. 2019, 39, 929–936. [Google Scholar] [CrossRef]

- Astafan, A.; Batiot-Dupeyrat, C.; Pinard, L. Mechanism and Kinetic of Coke Oxidation by Nonthermal Plasma in Fixed-Bed Dielectric Barrier Reactor. J. Phys. Chem. C 2019, 123, 9168–9175. [Google Scholar] [CrossRef]

- Chaouati, N.; Soualah, A.; Chater, M.; Tarighi, M.; Pinard, L. Mechanisms of coke growth on mordenite zeolite. J. Catal. 2016, 344, 354–364. [Google Scholar] [CrossRef]

- Chaouati, N.; Soualah, A.; Chater, M.; Pinard, L. Beneficial changes in coke properties with alkaline treatment on aluminum-rich mordenite. J. Catal. 2017, 353, 28–36. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, J.; Liang, X.; Long, C. Plasma-catalytic removal of toluene over the supported manganese oxides in DBD reactor: Effect of the structure of zeolites support. Chemosphere 2018, 208, 922–930. [Google Scholar] [CrossRef] [PubMed]

- Cerqueira, H.S.; Rabeharitsara, A.; Ayrault, P.; Datka, J.; Magnoux, P.; Guisnet, M. Mechanisms of coke growth on mordenite zeolite. Stud. Surf. Sci. Catal. 2001, 139, 29–36. [Google Scholar]

- Cerqueira, H.S.; Ayrault, P.; Datka, J.; Guisnet, M. Influence of coke on the acid properties of a USHY zeolite. Microporous Mesoporous Mater. 2000, 38, 197–205. [Google Scholar] [CrossRef]

- Miranda, C.; Urresta, J.; Cruchade, H.; Tran, A.; Benghalem, M.; Astafan, A.; Gaudin, P.; Daou, T.J.; Ramirez, A.; Pouilloux, Y.; et al. Exploring the impact of zeolite porous voids in liquid phase reactions: The case of glycerol etherification by tert-butyl alcohol. J. Catal. 2018, 365, 249–260. [Google Scholar] [CrossRef]

| Catalyst | Pore Aperture | Si/Al | Vmicro a | Vmeso a | [PyH+] b | [PyL] c |

|---|---|---|---|---|---|---|

| mol/mol | cm3 g−1 | cm3 g−1 | µmol g−1 | µmol g−1 | ||

| MOR | 12 6.5 × 7.0 *↔ 8 2.6 × 5.7 * | 38 | 0.20 | 0.08 | 254 | 35 |

| FAU | 12 7.4 × 7.4 ***, supercage ø 12 Å | 17 | 0.30 | 0.15 | 271 | 101 |

| MFI | {10 (5.1x5.5 *↔10 5.3 × 5.6} *** | 40 | 0.17 | 0.07 | 304 | 44 |

| Catalyst | % C a | Vmicro b | Vmeso b | [PyH+] c | [PyL] c |

|---|---|---|---|---|---|

| wt.% | cm3 g−1 | cm3 g−1 | µmol g−1 | µmol g−1 | |

| MOR | 10.3 | 0.00 | 0.06 | 0 | 0 |

| FAU | 14.4 | 0.10 | 0.12 | 25 | 42 |

| MFI | 3.9 | 0.15 | 0.05 | 244 | 31 |

| Catalyst | Coke | Tox c | NAR | Initial Oxidation Rate | |||

|---|---|---|---|---|---|---|---|

| External a | Soluble b | Insoluble b | ≤2 | ≥3 | gcoke min−1 (×1000) | ||

| wt.% | wt.% | wt.% | (K) | wt.% | wt.% | ||

| MOR | 1.1 | 8.3 | 0.9 | 848 | 2.6 | 6.8 | 1.5 |

| FAU | 0.7 | 10.9 | 2.8 | 798 | 7.4 | 5.9 | 1.0 |

| MFI | 0.6 | 3.3 | 0.1 | 798 | 1.5 | 1.8 | 1.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Astafan, A.; Sachse, A.; Batiot-Dupeyrat, C.; Pinard, L. Impact of the Framework Type on the Regeneration of Coked Zeolites by Non-Thermal Plasma in a Fixed Bed Dielectric Barrier Reactor. Catalysts 2019, 9, 985. https://doi.org/10.3390/catal9120985

Astafan A, Sachse A, Batiot-Dupeyrat C, Pinard L. Impact of the Framework Type on the Regeneration of Coked Zeolites by Non-Thermal Plasma in a Fixed Bed Dielectric Barrier Reactor. Catalysts. 2019; 9(12):985. https://doi.org/10.3390/catal9120985

Chicago/Turabian StyleAstafan, Amir, Alexander Sachse, Catherine Batiot-Dupeyrat, and Ludovic Pinard. 2019. "Impact of the Framework Type on the Regeneration of Coked Zeolites by Non-Thermal Plasma in a Fixed Bed Dielectric Barrier Reactor" Catalysts 9, no. 12: 985. https://doi.org/10.3390/catal9120985

APA StyleAstafan, A., Sachse, A., Batiot-Dupeyrat, C., & Pinard, L. (2019). Impact of the Framework Type on the Regeneration of Coked Zeolites by Non-Thermal Plasma in a Fixed Bed Dielectric Barrier Reactor. Catalysts, 9(12), 985. https://doi.org/10.3390/catal9120985