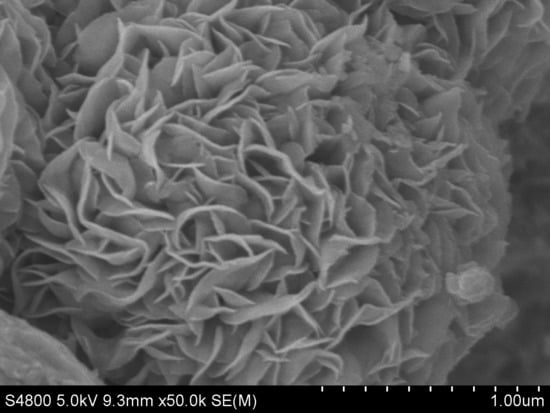

Si Quantum Dots Assist Synthesized Microflower-Like Si/MoS2 Composites for Supercapacitors

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fu, H.; Zhang, X.D.; Fu, J.Z.; Shen, G.Z.; Ding, Y.L.; Chen, Z.J.; Du, H. Single layers of MoS2/Graphene nanosheets embedded in activated carbon nanofibers for high-performance supercapacitor. J. Alloy Compd. 2020, 829, 154557. [Google Scholar] [CrossRef]

- Wang, C.; Xu, J.; Yuen, M.; Zhang, J.; Li, Y.; Chen, X.; Zhang, W. Hierarchical composite electrodes of nickel oxide nanoflake 3D graphene for high-performance pseudocapacitors. Adv. Funct. Mater. 2014, 24, 6372–6380. [Google Scholar] [CrossRef]

- Reddy, B.P.; Sekhar, M.C.; Vattikuti, S.V.P.; Suh, Y.; Park, S.H. Solution-based spin-coated tin sulfide thin films for photovoltaic and supercapacitor applications. Mater. Res. Bull. 2018, 103, 13–15. [Google Scholar] [CrossRef]

- Vikraman, D.; Karuppasamy, K.; Hussain, S.; Kathalingam, A.; Sanmugam, A.; Jung, J.; Kim, H.S. One-pot facile methodology to synthesize MoS2-graphene hybrid nanocomposites for supercapacitors with improved electrochemical capacitance. Compos. Part B Eng. 2019, 161, 555–563. [Google Scholar] [CrossRef]

- Vattikuti, S.V.P.; Reddy, B.P.; Byon, C.; Shim, J. Carbon/CuO nanosphere-anchored g-C3N4 nanosheets as ternary electrode material for supercapacitors. J. Solid State Chem. 2018, 262, 106. [Google Scholar] [CrossRef]

- Masikhwa, T.M.; Madito, M.J.; Bello, A.; Dangbegnon, J.K.; Manyala, N. High performance asymmetric supercapacitor based on molybdenum disulphide/graphene foam and activated carbon from expanded graphite. J. Colloid Interf. Sci. 2017, 488, 155–165. [Google Scholar] [CrossRef]

- Yadav, S.K.; Kumar, R.; Sundramoorthy, A.K.; Singh, R.K.; Koo, C.M. Simultaneous reduction and covalent grafting of polythiophene on graphene oxide sheets for excellent capacitance retention. RSC Adv. 2016, 6, 52945–52949. [Google Scholar] [CrossRef] [Green Version]

- Vattikuti, S.V.P.; Devarayapalli, K.C.; Nagajyothi, P.C.; Shim, J. Microwave synthesized dry leaf-like mesoporous MoSe2 nanostructure as an efficient catalyst for enhanced hydrogen evolution and supercapacitor applications. Microchem. J. 2020, 153, 104446. [Google Scholar] [CrossRef]

- Zhao, C.H.; Zhou, Y.N.; Ge, Z.X.; Zhao, C.G.; Qian, X.Z. Facile construction of MoS2/RCF electrode for high-performance supercapacitor. Carbon 2018, 127, 699–706. [Google Scholar] [CrossRef]

- Xu, C.Y.; Jiang, L.; Li, X.; Li, C.; Shao, C.X.; Zuo, P.; Liang, M.S.; Qu, L.T.; Cui, T.H. Miniaturized high-performance metallic 1T-Phase MoS2 micro-supercapacitors fabricated by temporally shaped femtosecond pulses. Nano Energy 2020, 67, 104260. [Google Scholar] [CrossRef]

- Lia, J.F.; Chen, D.D.; Wu, Q.S. Facile synthesis of CoS porous nanoflake for high performance supercapacitor electrode materials. J. Energy Storage 2019, 23, 511–514. [Google Scholar] [CrossRef]

- Harish, S.; Naveen, A.N.; Abinaya, R.; Archana, J.; Ramesh, R.; Navaneethan, M.; Shimomura, M.; Hayakawa, Y. Enhanced performance on capacity retention of hierarchical NiS hexagonal nanoplate for highly stable asymmetric supercapacitor. Electrochim. Acta 2018, 283, 1053–1062. [Google Scholar] [CrossRef]

- Himasree, P.; Durga, I.K.; Krishna, T.N.V.; Rao, S.S.; Gopi, C.V.V.M.; Revathi, S.; Prabakar, K.; Kim, H.J. One-step hydrothermal synthesis of CuS@MnS on Ni foam for high performance supercapacitor electrode material. Electrochim. Acta 2019, 305, 467–473. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E.; Singh, R.K.; Yadav, R.M.; Verma, R.K.; Singh, D.P.; Tan, W.K.; del Pino, A.P.; Moshkalev, S.A.; et al. A review on synthesis of graphene, h-BN and MoS2 for energy storage applications: Recent progress and perspectives. Nano Res. 2019, 12, 2655–2694. [Google Scholar] [CrossRef]

- Manuraj, M.; Chacko, J.; Unni, K.N.N.; Rakhi, R.B. Heterostructured MoS2-RuO2 nanocomposite: A promising electrode material for supercapacitors. J. Alloy Compd. 2020, 836, 155420. [Google Scholar] [CrossRef]

- Lien, C.W.; Vedhanarayanan, B.; Chen, J.H.; Lin, J.Y.; Tsai, H.H.; Shao, L.D.; Lin, T.W. Optimization of acetonitrile/water content in hybrid deep eutectic solvent for graphene/MoS2 hydrogel-based supercapacitors. Chem. Eng. J. 2021, 405, 126706. [Google Scholar] [CrossRef]

- Vattikuti, S.V.P.; Nagajyothi, P.C.; Reddy, P.A.K.; Kumar, M.K.; Shim, J.; Byon, C. Tiny MoO3 nanocrystals self-assembled on folded molybdenum disulfide nanosheets via a hydrothermal method for supercapacitor. Mater. Res. Lett. 2018, 6, 432–439. [Google Scholar] [CrossRef] [Green Version]

- Feng, D.; Pan, X.X.; Xia, Q.Y.; Qin, J.H.; Zhang, Y.; Chen, X.M. Metallic MoS2 nanosphere electrode for aqueous symmetric supercapacitors with high energy and power densities. J. Mater. Sci. 2020, 55, 713–723. [Google Scholar] [CrossRef]

- Voiry, D.; Salehi, M.; Silva, R.; Fujita, T.; Chen, M.W.; Asefa, T.; Shenoy, V.B.; Eda, G.; Chhowalla, M. Conducting MoS2 Nanosheets as Catalysts for Hydrogen Evolution Reaction. Nano Lett. 2013, 13, 6222−6227. [Google Scholar] [CrossRef]

- Mishra, S.; Maurya, P.K.; Mishra, A.K. 2H–MoS2 nanoflowers based high energy density solid state supercapacitor. Mater. Chem. Phys. 2020, 255, 123551. [Google Scholar] [CrossRef]

- Wu, D.; Lou, Z.; Wang, Y.; Yao, Z.; Xu, T.; Shi, Z.; Xu, J.; Tian, Y.; Li, X.; Tsang, Y.H. Photovoltaic high-performance broadband photodetector based on MoS2/Si nanowire array heterojunction. Sol. Energ. Mat. Sol. C. 2018, 182, 272–280. [Google Scholar] [CrossRef]

- Feng, Z.; Yang, P.P.; Wen, G.S.; Li, H.B.; Liu, Y.; Zhao, X.C. One-step synthesis of MoS2 nanoparticles with different morphologies for electromagnetic wave absorption. Appl. Surf. Sci. 2020, 502, 144129. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.K.; Yadav, S.K.; Savu, R.; Moshkalev, S.A. Mechanical pressure induced chemical cutting of boron nitride sheets into boron nitride quantum dots and optical properties. J. Alloy. Compd. 2016, 683, 38–47. [Google Scholar] [CrossRef]

- Singh, R.K.; Kumar, R.; Singh, D.P.; Savu, R.; Moshkalev, S.A. Progress in microwave-assisted synthesis of quantum dots (graphene/carbon/semiconducting) for bioapplications: A review. Mater. Today Chem. 2019, 12, 282–332. [Google Scholar] [CrossRef]

- Erogbogbo, F.; Yong, K.T.; Roy, I.; Hu, R.; Law, W.C.; Zhao, W.W.; Ding, H.; Wu, F.; Kumar, R.; Swihart, M.T.; et al. In vivo targeted cancer imaging, sentinel lymph node mapping and multi-channel imaging with biocompatible silicon nanocrystals. ACS Nano 2011, 5, 413–423. [Google Scholar] [CrossRef]

- Arefi-Oskoui, S.; Khataee, A.; Safarpour, M.; Vatanpour, V. Modification of polyethersulfone ultrafiltration membrane using ultrasonicassisted functionalized MoS2 for treatment of oil refinery wastewater. Sep. Purif. Technol. 2020, 238, 116495. [Google Scholar] [CrossRef]

- Zhang, X.L.; Ma, L.; Gan, M.Y.; Fu, G.; Jin, M.; Zhai, Y.F. Controllable constructing of hollow MoS2/PANI core/shell microsphere for energy storage. Appl. Surf. Sci. 2018, 460, 48–57. [Google Scholar] [CrossRef]

- Raza, A.; Ikram, M.; Aqeel, M.; Imran, M.; Ul-Hamid, A.; Riaz, K.N.; Ali, S. Enhanced industrial dye degradation using Co doped in chemically exfoliated MoS2 nanosheets. Appl. Nanosci. 2020, 10, 1535–1539. [Google Scholar] [CrossRef]

- Zhong, Y.; Sun, X.; Wang, S.; Peng, F.; Bao, F.; Su, Y.; Li, Y.; Lee, S.T.; He, Y. Facile, Large-Quantity Synthesis of Stable, Tunable-Color Silicon Nanoparticles and Their Application for Long-Term Cellular Imaging. ACS Nano 2015, 9, 5958–5959. [Google Scholar] [CrossRef]

- Liu, Z.P.; Hou, J.Z.; Wang, X.F.; Hou, C.J.; Ji, Z.; He, Q.; Huo, D.Q. A novel fluorescence probe for rapid and sensitive detection of tetracyclines residues based on silicon quantum dots. Spectrochim. Acta A 2020, 240, 118463. [Google Scholar] [CrossRef]

- Xu, X.X.; Jiao, S.L.; Liu, Z.Q.; Liu, L. Synergistic lubrication of a porous MoS2-POSS nanohybrid. RSC Adv. 2020, 10, 20579. [Google Scholar] [CrossRef]

- Yang, Z.M.; Zhang, D.Z.; Chen, H.N. MOF-derived indium oxide hollow microtubes/MoS2 nanoparticles for NO2 gas sensing. Sensor. Actuat. B Chem. 2019, 300, 127037. [Google Scholar] [CrossRef]

- Zhao, P.; Tang, Y.; Mao, J.; Chen, Y.; Song, H.; Wang, J.; Song, Y.; Liang, Y.; Zhang, X. One-dimensional MoS2-decorated TiO2 nanotube gas sensors for efficient alcohol sensing. J. Alloy. Compd. 2016, 674, 252–258. [Google Scholar] [CrossRef]

- Zhao, S.; Li, Z.; Wang, G.; Liao, J.; Lv, S.; Zhu, Z. Highly enhanced response of MoS2/porous silicon nanowire heterojunctions to NO2 at room temperature. RSC Adv. 2018, 8, 11070–11077. [Google Scholar] [CrossRef] [Green Version]

- Luo, J.H.; Zhang, K.; Cheng, M.L.; Gu, M.M.; Sun, X.K. MoS2 spheres decorated on hollow porous ZnO microspheres with strong wideb and microwave absorption. Chem. Eng. J. 2020, 380, 122625. [Google Scholar] [CrossRef]

- Arasi, S.E.; Ranjithkumar, R.; Devendran, P.; Krishnakumar, M.; Arivarasan, A. Electrochemical evaluation of binary Ni2V2O7 nanorods as pseudocapacitor electrode material. Ceram. Int. 2020, 46, 22709–22717. [Google Scholar] [CrossRef]

- Guan, B.; Li, Y.; Yin, B.Y.; Liu, K.F.; Wang, D.W.; Zhang, H.H.; Cheng, C.J. Synthesis of hierarchical NiS microflower for high performance asymmetric supercapacitor. Chem. Eng. J. 2017, 308, 1165–1173. [Google Scholar] [CrossRef]

- Huo, H.H.; Zhao, Y.Q.; Xu, C.L. 3D Ni3S2 nanosheet arrays supported on Ni foam for high-performance supercapacitor and nonenzymatic glucose detection. J. Mater. Chem. A 2014, 2, 15111–15117. [Google Scholar] [CrossRef]

- Peng, W.J.; Wang, W.; Han, G.H.; Huang, Y.K.; Zhang, Y.S. Fabrication of 3D flower-like MoS2/graphene composite as highperformance electrode for capacitive deionization. Desalination 2020, 473, 114191. [Google Scholar] [CrossRef]

- Thakur, A.K.; Majumder, M.; Choudhary, R.B.; Singh, S.B. MoS2 flakes integrated with boron and nitrogen-doped carbon: Striking gravimetric and volumetric capacitive performance for supercapacitor applications. J. Power Sources 2018, 402, 163–173. [Google Scholar] [CrossRef]

- Palsaniya, S.; Nemade, H.B.; Dasmahapatra, A.K. Synthesis of polyaniline/graphene/MoS2 nanocomposite for high performance supercapacitor electrode. Polymer 2018, 150, 150–158. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Cheng, K.; Zhang, R.; Yang, Y.; Wu, Y.; Yu, P. Si Quantum Dots Assist Synthesized Microflower-Like Si/MoS2 Composites for Supercapacitors. Crystals 2020, 10, 846. https://doi.org/10.3390/cryst10090846

Zheng J, Cheng K, Zhang R, Yang Y, Wu Y, Yu P. Si Quantum Dots Assist Synthesized Microflower-Like Si/MoS2 Composites for Supercapacitors. Crystals. 2020; 10(9):846. https://doi.org/10.3390/cryst10090846

Chicago/Turabian StyleZheng, Jiahong, Kangkang Cheng, Runmei Zhang, Yamei Yang, Yuntao Wu, and Pengfei Yu. 2020. "Si Quantum Dots Assist Synthesized Microflower-Like Si/MoS2 Composites for Supercapacitors" Crystals 10, no. 9: 846. https://doi.org/10.3390/cryst10090846

APA StyleZheng, J., Cheng, K., Zhang, R., Yang, Y., Wu, Y., & Yu, P. (2020). Si Quantum Dots Assist Synthesized Microflower-Like Si/MoS2 Composites for Supercapacitors. Crystals, 10(9), 846. https://doi.org/10.3390/cryst10090846