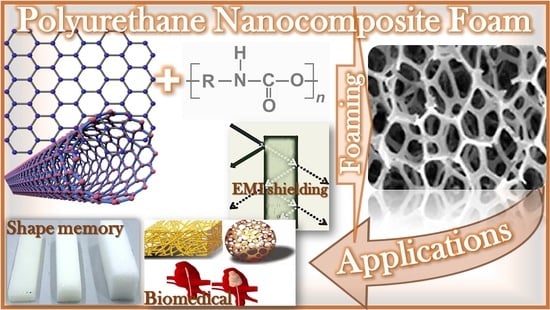

Nanocomposite Foams of Polyurethane with Carbon Nanoparticles—Design and Competence towards Shape Memory, Electromagnetic Interference (EMI) Shielding, and Biomedical Fields

Abstract

:1. Introduction

2. Polyurethane and Polyurethane Foam

3. Polyurethane-Derived Nanocomposite Foam

3.1. Polyurethane- and Graphene-Based Nanocomposite Foam

3.2. Polyurethane- and Carbon Nanotube-Derived Nanocomposite Foam

4. Technical Significance of Polyurethane Nanocomposite Foam

4.1. Shape Memory Nanomaterials

4.2. Electromagnetic Interference Shielding

4.3. Biomedical Field Applications

5. Prospects

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, H.; Liu, D.; Liang, L.; Tian, Z.; Shen, P. Nitrogen-doped graphene sheets as efficient nanofillers at ultra-low content for reinforcing mechanical and wear-resistant properties of acrylic polyurethane coatings. Crystals 2022, 12, 1820. [Google Scholar] [CrossRef]

- Fanali, S.; Tumedei, M.; Pignatelli, P.; Petrini, M.; Piattelli, A.; Iezzi, G. The effect of threads geometry on insertion torque (IT) and periotest implant primary stability: A high-density polyurethane simulation for the anterior mandible. Crystals 2021, 11, 308. [Google Scholar] [CrossRef]

- Zhang, C.; Kessler, M.R. Bio-based polyurethane foam made from compatible blends of vegetable-oil-based polyol and petroleum-based polyol. ACS Sustain. Chem. Eng. 2015, 3, 743–749. [Google Scholar] [CrossRef]

- Engels, H.W.; Pirkl, H.G.; Albers, R.; Albach, R.W.; Krause, J.; Hoffmann, A.; Casselmann, H.; Dormish, J. Polyurethanes: Versatile materials and sustainable problem solvers for today’s challenges. Angew. Chem. Int. Ed. 2013, 52, 9422–9441. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, R.; Moon, K.S.; Liu, Y.; Hansen, K.; Le, T.; Wong, C. Highly Conductive, Flexible, Polyurethane-Based Adhesives for Flexible and Printed Electronics. Adv. Funct. Mater. 2013, 23, 1459–1465. [Google Scholar] [CrossRef]

- Shikha; Meena, M.; Jacob, J. Pentaerythritol derived phosphorous based bicyclic compounds as promising flame retardants for thermoplastic polyurethane films. J. Appl. Polym. Sci. 2020, 138, 50375. [Google Scholar] [CrossRef]

- Du, Y.; Wang, M.; Ye, X.; Liu, B.; Han, L.; Jafri, S.H.M.; Liu, W.; Zheng, X.; Ning, Y.; Li, H. Advances in the Field of Graphene-Based Composites for Energy–Storage Applications. Crystals 2023, 13, 912. [Google Scholar] [CrossRef]

- Sharif, M.; Heidari, A.; Aghaeinejad Meybodi, A. Polythiophene/Zinc Oxide/Graphene Oxide Ternary Photocatalyst: Synthesis, characterization and application. Polym.-Plast. Technol. Mater. 2021, 60, 1450–1460. [Google Scholar] [CrossRef]

- Zhang, R.; Palumbo, A.; Kim, J.C.; Ding, J.; Yang, E.H. Flexible Graphene-, Graphene-Oxide-, and Carbon-Nanotube-Based Supercapacitors and Batteries. Ann. Phys. 2019, 531, 1800507. [Google Scholar] [CrossRef] [Green Version]

- Ding, H.; Zhang, X. Sodium Intercalation in Nitrogen-Doped Graphene-Based Anode: A First-Principles Study. Crystals 2023, 13, 1011. [Google Scholar] [CrossRef]

- Jibin, K.P.; Augustine, S.; Velayudhan, P.; George, J.S.; Krishnageham Sidharthan, S.; Poulose, S.V.; Thomas, S. Unleashing the Power of Graphene-Based Nanomaterials for Chromium (VI) Ion Elimination from Water. Crystals 2023, 13, 1047. [Google Scholar] [CrossRef]

- Zhang, X.; Xiang, D.; Zhu, W.; Zheng, Y.; Harkin-Jones, E.; Wang, P.; Zhao, C.; Li, H.; Wang, B.; Li, Y. Flexible and high-performance piezoresistive strain sensors based on carbon nanoparticles@ polyurethane sponges. Compos. Sci. Technol. 2020, 200, 108437. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Li, J.; Fan, X.; Jing, Z.; Li, J.; Shi, X. Lightweight, multifunctional microcellular PMMA/Fe3O4@MWCNTs nanocomposite foams with efficient electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2017, 100, 128–138. [Google Scholar] [CrossRef]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane foams: Past, present, and future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef] [Green Version]

- Yadav, A.; de Souza, F.M.; Dawsey, T.; Gupta, R.K. Recent advancements in flame-retardant polyurethane foams: A review. Ind. Eng. Chem. Res. 2022, 61, 15046–15065. [Google Scholar] [CrossRef]

- Haridevan, H.; Evans, D.A.; Ragauskas, A.J.; Martin, D.J.; Annamalai, P.K. Valorisation of technical lignin in rigid polyurethane foam: A critical evaluation on trends, guidelines and future perspectives. Green Chem. 2021, 23, 8725–8753. [Google Scholar] [CrossRef]

- Mohamad, M.; Abd Razak, J.; Mohamad, N.; Ahmad, S.H.; Junid, R.; Puspitasari, P. A short review on polyurethane-based nanocomposites for various applications. In Proceedings of the IOP Conference Series: Materials Science and Engineering, International Conference on Sustainable Materials (ICoSM 2020), Pahang, Malaysia, 30 March 2020; IOP Publishing: Bristol, UK, 2020; p. 012029. [Google Scholar]

- Sang, G.; Xu, P.; Yan, T.; Murugadoss, V.; Naik, N.; Ding, Y.; Guo, Z. Interface engineered microcellular magnetic conductive polyurethane nanocomposite foams for electromagnetic interference shielding. Nano-Micro Lett. 2021, 13, 153. [Google Scholar] [CrossRef]

- Ahmadijokani, F.; Molavi, H.; Ahmadipouya, S.; Rezakazemi, M.; Ghaffarkhah, A.; Kamkar, M.; Shojaei, A.; Arjmand, M. Polyurethane-based membranes for CO2 separation: A comprehensive review. Prog. Energy Combust. Sci. 2023, 97, 101095. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, C.; Li, Y.; Feng, L.; Huang, S. Performance development of polyurethane elastomer composites in different construction and curing environments. Constr. Build. Mater. 2023, 365, 130047. [Google Scholar] [CrossRef]

- Asensio, M.; Ferrer, J.-F.; Nohales, A.; Culebras, M.; Gómez, C.M. The Role of Diisocyanate Structure to Modify Properties of Segmented Polyurethanes. Materials 2023, 16, 1633. [Google Scholar] [CrossRef]

- Mukhametshin, T.I.; Vinogradov, D.B.; Bulatov, P.V.; Nikitin, V.G.; Petrov, V.A. Synthesis of segmented polyurethanes based on furazan units. Mendeleev Commun. 2023, 33, 408–410. [Google Scholar] [CrossRef]

- Chen, J.; Li, F.; Luo, Y.; Shi, Y.; Ma, X.; Zhang, M.; Boukhvalov, D.; Luo, Z. A self-healing elastomer based on an intrinsic non-covalent cross-linking mechanism. J. Mater. Chem. A 2019, 7, 15207–15214. [Google Scholar] [CrossRef]

- Kaikade, D.S.; Sabnis, A.S. Polyurethane foams from vegetable oil-based polyols: A review. Polym. Bull. 2023, 80, 2239–2261. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Xie, J.; Liu, J.; Zhang, Q.; Luo, Y.; Li, M.; Zhou, W.; Chen, K.; Li, Z.; Yang, P. Highly conductive, stretchable, durable, breathable electrodes based on electrospun polyurethane mats superficially decorated with carbon nanotubes for multifunctional wearable electronics. Chem. Eng. J. 2023, 451, 138549. [Google Scholar] [CrossRef]

- Gao, H.; Sun, Y.; Jian, J.; Dong, Y.; Liu, H. Study on mechanical properties and application in communication pole line engineering of glass fiber reinforced polyurethane composites (GFRP). Case Stud. Constr. Mater. 2023, 18, e01942. [Google Scholar] [CrossRef]

- Choe, J.A.; Uthamaraj, S.; Dragomir-Daescu, D.; Sandhu, G.S.; Tefft, B.J. Magnetic and biocompatible polyurethane nanofiber biomaterial for tissue engineering. Tissue Eng. Part A 2023. [Google Scholar] [CrossRef]

- Recupido, F.; Lama, G.C.; Ammendola, M.; Bossa, F.D.L.; Minigher, A.; Campaner, P.; Morena, A.G.; Tzanov, T.; Ornelas, M.; Barros, A. Rigid composite bio-based polyurethane foams: From synthesis to LCA analysis. Polymer 2023, 267, 125674. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.; Chaleat, C.; Martin, D.J.; Annamalai, P.K. A systematic study substituting polyether polyol with palm kernel oil based polyester polyol in rigid polyurethane foam. Ind. Crops Prod. 2015, 66, 16–26. [Google Scholar] [CrossRef]

- Marcovich, N.; Kurańska, M.; Prociak, A.; Malewska, E.; Kulpa, K. Open cell semi-rigid polyurethane foams synthesized using palm oil-based bio-polyol. Ind. Crops Prod. 2017, 102, 88–96. [Google Scholar] [CrossRef]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer 2020, 190, 122164. [Google Scholar] [CrossRef]

- Saint-Michel, F.; Chazeau, L.; Cavaillé, J.-Y.; Chabert, E. Mechanical properties of high density polyurethane foams: I. Effect of the density. Compos. Sci. Technol. 2006, 66, 2700–2708. [Google Scholar] [CrossRef]

- Langanke, J.; Wolf, A.; Hofmann, J.; Böhm, K.; Subhani, M.; Müller, T.; Leitner, W.; Gürtler, C. Carbon dioxide (CO2) as sustainable feedstock for polyurethane production. Green Chem. 2014, 16, 1865–1870. [Google Scholar] [CrossRef]

- Annaz, B.; Hing, K.; Kayser, M.; Buckland, T.; Silvio, L.D. Porosity variation in hydroxyapatite and osteoblast morphology: A scanning electron microscopy study. J. Microsc. 2004, 215, 100–110. [Google Scholar] [CrossRef] [PubMed]

- Ling, Z.; Liu, J.; Wang, Q.; Lin, W.; Fang, X.; Zhang, Z. MgCl2·6H2O-Mg(NO3)2·6H2O eutectic/SiO2 composite phase change material with improved thermal reliability and enhanced thermal conductivity. Sol. Energy Mater. Sol. Cells 2017, 172, 195–201. [Google Scholar] [CrossRef]

- Fu, W.; Zou, T.; Liang, X.; Wang, S.; Gao, X.; Zhang, Z.; Fang, Y. Thermal properties and thermal conductivity enhancement of composite phase change material using sodium acetate trihydrate–urea/expanded graphite for radiant floor heating system. Appl. Therm. Eng. 2018, 138, 618–626. [Google Scholar] [CrossRef]

- Tan, S.; Abraham, T.; Ference, D.; Macosko, C.W. Rigid polyurethane foams from a soybean oil-based polyol. Polymer 2011, 52, 2840–2846. [Google Scholar] [CrossRef]

- Zhang, Y.; Choi, J.R.; Park, S.-J. Interlayer polymerization in amine-terminated macromolecular chain-grafted expanded graphite for fabricating highly thermal conductive and physically strong thermoset composites for thermal management applications. Compos. Part A Appl. Sci. Manuf. 2018, 109, 498–506. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z. High performance nano-zinc amino-tris-(methylenephosphonate) in rigid polyurethane foam with improved mechanical strength, thermal stability and flame retardancy. Polym. Degrad. Stab. 2018, 154, 62–72. [Google Scholar] [CrossRef]

- Patil, A.; Patel, A.; Purohit, R. An overview of polymeric materials for automotive applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Kausar, A. Role of thermosetting polymer in structural composite. Am. J. Polym. Sci. Eng. 2017, 5, 1–12. [Google Scholar]

- Choong, P.S.; Hui, Y.L.E.; Lim, C.C. CO2-Blown Nonisocyanate Polyurethane Foams. ACS Macro Lett. 2023, 12, 1094–1099. [Google Scholar] [CrossRef] [PubMed]

- Soundhar, A.; Rajesh, M.; Jayakrishna, K.; Sultan, M.; Shah, A. Investigation on mechanical properties of polyurethane hybrid nanocomposite foams reinforced with roselle fibers and silica nanoparticles. Nanocomposites 2019, 5, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Bonab, S.A.; Moghaddas, J.; Rezaei, M. In-situ synthesis of silica aerogel/polyurethane inorganic-organic hybrid nanocomposite foams: Characterization, cell microstructure and mechanical properties. Polymer 2019, 172, 27–40. [Google Scholar] [CrossRef]

- Bi, J.; Du, Z.; Sun, J.; Liu, Y.; Wang, K.; Du, H.; Ai, W.; Huang, W. On the Road to the Frontiers of Lithium-Ion Batteries: A Review and Outlook of Graphene Anodes. Adv. Mater. 2023, 35, 2210734. [Google Scholar] [CrossRef]

- Garcia de Abajo, F.J. Graphene plasmonics: Challenges and opportunities. ACS Photonics 2014, 1, 135–152. [Google Scholar] [CrossRef] [Green Version]

- Dimiev, A.M.; Tour, J.M. Mechanism of graphene oxide formation. ACS Nano 2014, 8, 3060–3068. [Google Scholar] [CrossRef]

- Gupta, V.; Sharma, N.; Singh, U.; Arif, M.; Singh, A. Higher oxidation level in graphene oxide. Optik 2017, 143, 115–124. [Google Scholar] [CrossRef]

- Hidayah, N.; Liu, W.-W.; Lai, C.-W.; Noriman, N.; Khe, C.-S.; Hashim, U.; Lee, H.C. Comparison on graphite, graphene oxide and reduced graphene oxide: Synthesis and characterization. In Proceedings of the International Conference of Global Network for Innovative Technology and Awam International Conference in Civil Engineering (IGNITE-AICCE’17): Sustainable Technology and Practice for Infrastructure and Community Resilience, Penang, Malaysia, 8–9 August 2017; AIP Publishing LLC: Melville, NY, USA, 2007; p. 150002. [Google Scholar]

- Zhang, Y.; Wu, J.; Jia, L.; Qu, Y.; Yang, Y.; Jia, B.; Moss, D.J. Graphene oxide for nonlinear integrated photonics. Laser Photonics Rev. 2023, 17, 2200512. [Google Scholar] [CrossRef]

- Tiwari, S.; Chhaunker, S.; Maiti, P. Bio-based polyurethane-graphene composites for adhesive application. SPE Polym. 2023, 4, 41–48. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Khanra, P.; Kim, N.H.; Rhee, K.Y.; Lee, J.H. Characterization and properties of in situ emulsion polymerized poly (methyl methacrylate)/graphene nanocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1856–1861. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Tang, M.; Zhou, L.; Li, J.; Fan, X.; Shi, X.; Qin, J. Synergistic effect of carbon nanotube and graphene nanoplates on the mechanical, electrical and electromagnetic interference shielding properties of polymer composites and polymer composite foams. Chem. Eng. J. 2018, 353, 381–393. [Google Scholar] [CrossRef]

- Yan, D.; Xu, L.; Chen, C.; Tang, J.; Ji, X.; Li, Z. Enhanced mechanical and thermal properties of rigid polyurethane foam composites containing graphene nanosheets and carbon nanotubes. Polym. Int. 2012, 61, 1107–1114. [Google Scholar] [CrossRef]

- Ramasamy, R.P.; Somanathan, S.; Rafailovich, M.H.; Aswal, V.K. Broadband dielectric spectroscopy and small-angle neutron scattering investigations of polyurethane–graphene foams. J. Mater. Sci. Mater. Electron. 2020, 31, 15843–15851. [Google Scholar] [CrossRef]

- Mundinamani, S. The choice of noble electrolyte for symmetric polyurethane-graphene composite supercapacitors. Int. J. Hydrogen Energy 2019, 44, 11240–11246. [Google Scholar] [CrossRef]

- Jiang, Q.; Liao, X.; Li, J.; Chen, J.; Wang, G.; Yi, J.; Yang, Q.; Li, G. Flexible thermoplastic polyurethane/reduced graphene oxide composite foams for electromagnetic interference shielding with high absorption characteristic. Compos. Part A Appl. Sci. Manuf. 2019, 123, 310–319. [Google Scholar] [CrossRef]

- Zaaba, N.; Foo, K.; Hashim, U.; Tan, S.; Liu, W.-W.; Voon, C. Synthesis of graphene oxide using modified hummers method: Solvent influence. Procedia Eng. 2017, 184, 469–477. [Google Scholar] [CrossRef]

- Tas, M.; Altin, Y.; Bedeloglu, A.C. Reduction of graphene oxide thin films using a stepwise thermal annealing assisted by L-ascorbic acid. Diam. Relat. Mater. 2019, 92, 242–247. [Google Scholar] [CrossRef]

- Li, J.; Liao, X.; Han, W.; Xiao, W.; Ye, J.; Yang, Q.; Li, G.; Ran, Q. Microcellular nanocomposites based on millable polyurethane and nano-silica by two-step curing and solid-state supercritical CO2 foaming: Preparation, high-pressure viscoelasticity and mechanical properties. J. Supercrit. Fluids 2017, 130, 198–209. [Google Scholar] [CrossRef]

- Li, Y.; Shen, B.; Yi, D.; Zhang, L.; Zhai, W.; Wei, X.; Zheng, W. The influence of gradient and sandwich configurations on the electromagnetic interference shielding performance of multilayered thermoplastic polyurethane/graphene composite foams. Compos. Sci. Technol. 2017, 138, 209–216. [Google Scholar] [CrossRef]

- Feng, C.; Yi, Z.; Jin, X.; Seraji, S.M.; Dong, Y.; Kong, L.; Salim, N. Solvent crystallization-induced porous polyurethane/graphene composite foams for pressure sensing. Compos. Part B Eng. 2020, 194, 108065. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Y.; Xu, D.; Zhai, W. Fabrication of stretchable, flexible conductive thermoplastic polyurethane/graphene composites via foaming. RSC Adv. 2015, 5, 82034–82041. [Google Scholar] [CrossRef]

- Hodlur, R.; Rabinal, M. Self assembled graphene layers on polyurethane foam as a highly pressure sensitive conducting composite. Compos. Sci. Technol. 2014, 90, 160–165. [Google Scholar] [CrossRef]

- Ola, O.; Chen, Y.; Zhu, Y. Three-dimensional carbon foam nanocomposites for thermal energy storage. Sol. Energy Mater. Sol. Cells 2019, 191, 297–305. [Google Scholar] [CrossRef]

- Kim, J.M.; Kim, D.H.; Kim, J.; Lee, J.W.; Kim, W.N. Effect of graphene on the sound damping properties of flexible polyurethane foams. Macromol. Res. 2017, 25, 190–196. [Google Scholar] [CrossRef]

- Qin, L.-C.; Zhao, X.; Hirahara, K.; Miyamoto, Y.; Ando, Y.; Iijima, S. The smallest carbon nanotube. Nature 2000, 408, 50. [Google Scholar] [CrossRef]

- Abubakre, O.K.; Medupin, R.O.; Akintunde, I.B.; Jimoh, O.T.; Abdulkareem, A.S.; Muriana, R.A.; James, J.A.; Ukoba, K.O.; Jen, T.-C.; Yoro, K.O. Carbon nanotube-reinforced polymer nanocomposites for sustainable biomedical applications: A review. J. Sci. Adv. Mater. Devices 2023, 8, 100557. [Google Scholar] [CrossRef]

- Wei, M.; Robin, M.; Portilla, L.; Ren, Y.; Shao, S.; Bai, L.; Cao, Y.; Pecunia, V.; Cui, Z.; Zhao, J. Air-stable N-type printed carbon nanotube thin film transistors for CMOS logic circuits. Carbon 2020, 163, 145–153. [Google Scholar] [CrossRef]

- Wang, R.; Sun, L.; Zhu, X.; Ge, W.; Li, H.; Li, Z.; Zhang, H.; Huang, Y.; Li, Z.; Zhang, Y.F. Carbon nanotube-based strain sensors: Structures, fabrication, and applications. Adv. Mater. Technol. 2023, 8, 2200855. [Google Scholar] [CrossRef]

- Koziol, K.; Vilatela, J.; Moisala, A.; Motta, M.; Cunniff, P.; Sennett, M.; Windle, A. High-performance carbon nanotube fiber. Science 2007, 318, 1892–1895. [Google Scholar] [CrossRef]

- Dong, F.; Yang, X.; Guo, L.; Qian, Y.; Sun, P.; Huang, Z.; Xu, X.; Liu, H. A tough, healable, and recyclable conductive polyurethane/carbon nanotube composite. J. Colloid Interface Sci. 2023, 631, 239–248. [Google Scholar] [CrossRef]

- Zeng, C.; Hossieny, N.; Zhang, C.; Wang, B. Synthesis and processing of PMMA carbon nanotube nanocomposite foams. Polymer 2010, 51, 655–664. [Google Scholar] [CrossRef]

- Wang, X.; Qu, M.; Wu, K.; Schubert, D.W.; Liu, X. High sensitive electrospun thermoplastic polyurethane/carbon nanotubes strain sensor fitting by a novel optimization empirical model. Adv. Compos. Hybrid Mater. 2023, 6, 63. [Google Scholar] [CrossRef]

- Wang, G.; Wang, M.; Zheng, M.; Ebo, B.; Xu, C.; Liu, Z.; He, L. Thermoplastic Polyurethane/Carbon Nanotube Composites for Stretchable Flexible Pressure Sensors. ACS Appl. Nano Mater. 2023, 6, 9865–9873. [Google Scholar] [CrossRef]

- Huang, W.; Dai, K.; Zhai, Y.; Liu, H.; Zhan, P.; Gao, J.; Zheng, G.; Liu, C.; Shen, C. Flexible and lightweight pressure sensor based on carbon nanotube/thermoplastic polyurethane-aligned conductive foam with superior compressibility and stability. ACS Appl. Mater. Interfaces 2017, 9, 42266–42277. [Google Scholar] [CrossRef]

- Yan, D.X.; Dai, K.; Xiang, Z.D.; Li, Z.M.; Ji, X.; Zhang, W.Q. Electrical conductivity and major mechanical and thermal properties of carbon nanotube-filled polyurethane foams. J. Appl. Polym. Sci. 2011, 120, 3014–3019. [Google Scholar] [CrossRef]

- Fan, Q.; Qin, Z.; Gao, S.; Wu, Y.; Pionteck, J.; Mäder, E.; Zhu, M. The use of a carbon nanotube layer on a polyurethane multifilament substrate for monitoring strains as large as 400%. Carbon 2012, 50, 4085–4092. [Google Scholar] [CrossRef]

- Ramôa, S.D.; Barra, G.M.; Oliveira, R.V.; de Oliveira, M.G.; Cossa, M.; Soares, B.G. Electrical, rheological and electromagnetic interference shielding properties of thermoplastic polyurethane/carbon nanotube composites. Polym. Int. 2013, 62, 1477–1484. [Google Scholar] [CrossRef]

- You, K.M.; Park, S.S.; Lee, C.S.; Kim, J.M.; Park, G.P.; Kim, W.N. Preparation and characterization of conductive carbon nanotube-polyurethane foam composites. J. Mater. Sci. 2011, 46, 6850–6855. [Google Scholar] [CrossRef]

- Al-Saleh, M.H. Electrically conductive carbon nanotube/polypropylene nanocomposite with improved mechanical properties. Mater. Des. 2015, 85, 76–81. [Google Scholar] [CrossRef]

- Ahn, C.; Kim, S.-M.; Jung, J.-W.; Park, J.; Kim, T.; Lee, S.E.; Jang, D.; Hong, J.-W.; Han, S.M.; Jeon, S. Multifunctional polymer nanocomposites reinforced by 3D continuous ceramic nanofillers. ACS Nano 2018, 12, 9126–9133. [Google Scholar] [CrossRef]

- Madaleno, L.; Pyrz, R.; Crosky, A.; Jensen, L.R.; Rauhe, J.C.M.; Dolomanova, V.; de Barros, A.M.M.V.; Pinto, J.J.C.; Norman, J. Processing and characterization of polyurethane nanocomposite foam reinforced with montmorillonite–carbon nanotube hybrids. Compos. Part A Appl. Sci. Manuf. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Zhai, T.; Li, D.; Fei, G.; Xia, H. Piezoresistive and compression resistance relaxation behavior of water blown carbon nanotube/polyurethane composite foam. Compos. Part A Appl. Sci. Manuf. 2015, 72, 108–114. [Google Scholar] [CrossRef]

- Feng, D.; Liu, P.; Wang, Q. Selective Microwave Sintering to Prepare Multifunctional Poly (ether imide) Bead Foams Based on Segregated Carbon Nanotube Conductive Network. Ind. Eng. Chem. Res. 2020, 59, 5838–5847. [Google Scholar] [CrossRef]

- De Luca Bossa, F.; Santillo, C.; Verdolotti, L.; Campaner, P.; Minigher, A.; Boggioni, L.; Losio, S.; Coccia, F.; Iannace, S.; Lama, G.C. Greener nanocomposite polyurethane foam based on sustainable polyol and natural fillers: Investigation of chemico-physical and mechanical properties. Materials 2020, 13, 211. [Google Scholar] [CrossRef]

- Wang, T.; Yu, W.-C.; Sun, W.-J.; Jia, L.-C.; Gao, J.-F.; Tang, J.-H.; Su, H.-J.; Yan, D.-X.; Li, Z.-M. Healable polyurethane/carbon nanotube composite with segregated structure for efficient electromagnetic interference shielding. Compos. Sci. Technol. 2020, 200, 108446. [Google Scholar] [CrossRef]

- Patle, V.K.; Kumar, R.; Sharma, A.; Dwivedi, N.; Muchhala, D.; Chaudhary, A.; Mehta, Y.; Mondal, D.; Srivastava, A. Three dimension phenolic resin derived carbon-CNTs hybrid foam for fire retardant and effective electromagnetic interference shielding. Compos. Part C Open Access 2020, 2, 100020. [Google Scholar] [CrossRef]

- Espadas-Escalante, J.; Avilés, F.; Gonzalez-Chi, P.; Oliva, A. Thermal conductivity and flammability of multiwall carbon nanotube/polyurethane foam composites. J. Cell. Plast. 2017, 53, 215–230. [Google Scholar] [CrossRef]

- Holder, K.M.; Cain, A.A.; Plummer, M.G.; Stevens, B.E.; Odenborg, P.K.; Morgan, A.B.; Grunlan, J.C. Carbon nanotube multilayer nanocoatings prevent flame spread on flexible polyurethane foam. Macromol. Mater. Eng. 2016, 301, 665–673. [Google Scholar] [CrossRef]

- Akbari-Azar, S.; Baghani, M.; Zakerzadeh, M.-R.; Shahsavari, H.; Sohrabpour, S. Analytical investigation of composite sandwich beams filled with shape memory polymer corrugated core. Meccanica 2019, 54, 1647–1661. [Google Scholar] [CrossRef]

- Del Nero, D.; Joshi-Imre, A.; Voit, W. Measuring the Electric Properties of Thin Film Shape Memory Polymers in Simulated Physiological Conditions. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1848–1852. [Google Scholar]

- Zheng, N.; Fang, Z.; Zou, W.; Zhao, Q.; Xie, T. Thermoset shape-memory polyurethane with intrinsic plasticity enabled by transcarbamoylation. Angew. Chem. 2016, 128, 11593–11597. [Google Scholar] [CrossRef]

- Kim, N.E.; Park, S.; Kim, S.; Choi, J.H.; Kim, S.E.; Choe, S.H.; Kang, T.w.; Song, J.E.; Khang, G. Development of Gelatin-Based Shape-Memory Polymer Scaffolds with Fast Responsive Performance and Enhanced Mechanical Properties for Tissue Engineering Applications. ACS Omega 2023, 8, 6455–6462. [Google Scholar] [CrossRef] [PubMed]

- Leng, J.; Lu, H.; Liu, Y.; Huang, W.M.; Du, S. Shape-memory polymers—A class of novel smart materials. MRS Bull. 2009, 34, 848–855. [Google Scholar] [CrossRef]

- Pineda-Castillo, S.A.; Stiles, A.M.; Bohnstedt, B.N.; Lee, H.; Liu, Y.; Lee, C.-H. Shape Memory Polymer-Based Endovascular Devices: Design Criteria and Future Perspective. Polymers 2022, 14, 2526. [Google Scholar] [CrossRef] [PubMed]

- Hager, M.D.; Bode, S.; Weber, C.; Schubert, U.S. Shape memory polymers: Past, present and future developments. Prog. Polym. Sci. 2015, 49, 3–33. [Google Scholar] [CrossRef]

- Zhao, X.; Guo, B.; Wu, H.; Liang, Y.; Ma, P.X. Injectable antibacterial conductive nanocomposite cryogels with rapid shape recovery for noncompressible hemorrhage and wound healing. Nat. Commun. 2018, 9, 2784. [Google Scholar] [CrossRef] [Green Version]

- Peterson, G.I.; Dobrynin, A.V.; Becker, M.L. Biodegradable shape memory polymers in medicine. Adv. Healthc. Mater. 2017, 6, 1700694. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez, J.N.; Zhu, C.; Duoss, E.B.; Wilson, T.S.; Spadaccini, C.M.; Lewicki, J.P. Shape-morphing composites with designed micro-architectures. Sci. Rep. 2016, 6, 27933. [Google Scholar] [CrossRef] [Green Version]

- Singhal, P.; Rodriguez, J.N.; Small, W.; Eagleston, S.; Van de Water, J.; Maitland, D.J.; Wilson, T.S. Ultra low density and highly crosslinked biocompatible shape memory polyurethane foams. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 724–737. [Google Scholar] [CrossRef] [Green Version]

- Berg, G.J.; McBride, M.K.; Wang, C.; Bowman, C.N. New directions in the chemistry of shape memory polymers. Polymer 2014, 55, 5849–5872. [Google Scholar] [CrossRef]

- Kausar, A.; Ur Rahman, A. Effect of graphene nanoplatelet addition on properties of thermo-responsive shape memory polyurethane-based nanocomposite. Fuller. Nanotub. Carbon Nanostruct. 2016, 24, 235–242. [Google Scholar] [CrossRef]

- Kim, H.M.; Park, J.; Huang, Z.M.; Youn, J.R.; Song, Y.S. Carbon nanotubes embedded shape memory polyurethane foams. Macromol. Res. 2019, 27, 919–925. [Google Scholar] [CrossRef]

- Kang, S.; Kwon, S.; Park, J.; Kim, B. Carbon nanotube reinforced shape memory polyurethane foam. Polym. Bull. 2013, 70, 885–893. [Google Scholar] [CrossRef]

- Tobushi, H.; Shimada, D.; Hayashi, S.; Endo, M. Shape fixity and shape recovery of polyurethane shape-memory polymer foams. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2003, 217, 135–143. [Google Scholar] [CrossRef]

- Kinkelaar, M.R.; Critchfield, F.E.; Lambach, J.L. One-Shot Cold Molded Flexible Polyurethane Foam from Low Primary Hydroxyl Polyols and Process for the Preparation Thereof. U.S. Patent 5,668,191, 16 September 1997. [Google Scholar]

- Kausar, A. Shape memory polyurethane/graphene nanocomposites: Structures, properties, and applications. J. Plast. Film. Sheeting 2020, 36, 151–166. [Google Scholar] [CrossRef]

- Zhou, J.; Li, H.; Liu, W.; Dugnani, R.; Tian, R.; Xue, W.; Chen, Y.; Guo, Y.; Duan, H.; Liu, H. A facile method to fabricate polyurethane based graphene foams/epoxy/carbon nanotubes composite for electro-active shape memory application. Compos. Part A Appl. Sci. Manuf. 2016, 91, 292–300. [Google Scholar] [CrossRef]

- Serrano, M.C.; Ameer, G.A. Recent insights into the biomedical applications of shape-memory polymers. Macromol. Biosci. 2012, 12, 1156–1171. [Google Scholar] [CrossRef]

- Guitart, J.; Carrera, D.; Beltran, V.; Torres, J.; Ayguadé, E. Dynamic CPU provisioning for self-managed secure web applications in SMP hosting platforms. Comput. Netw. 2008, 52, 1390–1409. [Google Scholar] [CrossRef]

- Yu, K.; Yin, W.; Liu, Y.; Leng, J. Application of SMP composite in designing a morphing wing. In Proceedings of the ICEM 2008: International Conference on Experimental Mechanics 2008, Nanjing, China, 8–11 November 2008; SPIE: Bellingham, WA, USA, 2009; pp. 1367–1372. [Google Scholar]

- Ghosh, S.; Ganguly, S.; Remanan, S.; Mondal, S.; Jana, S.; Maji, P.K.; Singha, N.; Das, N.C. Ultra-light weight, water durable and flexible highly electrical conductive polyurethane foam for superior electromagnetic interference shielding materials. J. Mater. Sci. Mater. Electron. 2018, 29, 10177–10189. [Google Scholar] [CrossRef]

- Shen, B.; Li, Y.; Zhai, W.; Zheng, W. Compressible graphene-coated polymer foams with ultralow density for adjustable electromagnetic interference (EMI) shielding. ACS Appl. Mater. Interfaces 2016, 8, 8050–8057. [Google Scholar] [CrossRef]

- Yang, J.; Liao, X.; Wang, G.; Chen, J.; Guo, F.; Tang, W.; Wang, W.; Yan, Z.; Li, G. Gradient structure design of lightweight and flexible silicone rubber nanocomposite foam for efficient electromagnetic interference shielding. Chem. Eng. J. 2020, 390, 124589. [Google Scholar] [CrossRef]

- Li, H.; Yuan, D.; Li, P.; He, C. High conductive and mechanical robust carbon nanotubes/waterborne polyurethane composite films for efficient electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2019, 121, 411–417. [Google Scholar] [CrossRef]

- Gavgani, J.N.; Adelnia, H.; Zaarei, D.; Gudarzi, M.M. Lightweight flexible polyurethane/reduced ultralarge graphene oxide composite foams for electromagnetic interference shielding. RSC Adv. 2016, 6, 27517–27527. [Google Scholar] [CrossRef]

- Wang, P.; Pyo, S.-H.; Zhu, W.; Hwang, H.; Chen, S. 3D Printing of Polyurethanes for Biomedical Applications. In Emerging Technologies in Biophysical Sciences: A World Scientific Reference: Volume 1: Emerging Technologies for Biofabrication and Biomanufacturing; World Scientific: Singapore, 2023; pp. 389–406. [Google Scholar]

- Joseph, J.; Patel, R.; Wenham, A.; Smith, J. Biomedical applications of polyurethane materials and coatings. Trans. IMF 2018, 96, 121–129. [Google Scholar] [CrossRef] [Green Version]

- Barrioni, B.R.; de Carvalho, S.M.; Oréfice, R.L.; de Oliveira, A.A.R.; de Magalhães Pereira, M. Synthesis and characterization of biodegradable polyurethane films based on HDI with hydrolyzable crosslinked bonds and a homogeneous structure for biomedical applications. Mater. Sci. Eng. C 2015, 52, 22–30. [Google Scholar] [CrossRef]

- Batool, J.A.; Rehman, K.; Qader, A.; Akash, M.S. Biomedical Applications of Carbohydrate-Based Polyurethane: From Biosynthesis to Degradation. Curr. Pharm. Des. 2022, 28, 1669–1687. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Singh, S.; Gill, R. Applications of biopolymer coatings in biomedical engineering. J. Electrochem. Sci. Eng. 2023, 13, 63–81. [Google Scholar] [CrossRef]

- Ye, H.; Zhang, K.; Kai, D.; Li, Z.; Loh, X.J. Polyester elastomers for soft tissue engineering. Chem. Soc. Rev. 2018, 47, 4545–4580. [Google Scholar] [CrossRef]

- Jetté, B.; Brailovski, V.; Simoneau, C.; Dumas, M.; Terriault, P. Development and in vitro validation of a simplified numerical model for the design of a biomimetic femoral stem. J. Mech. Behav. Biomed. Mater. 2018, 77, 539–550. [Google Scholar] [CrossRef]

- Ribeiro, C.; Sencadas, V.; Correia, D.M.; Lanceros-Méndez, S. Piezoelectric polymers as biomaterials for tissue engineering applications. Colloids Surf. B Biointerfaces 2015, 136, 46–55. [Google Scholar] [CrossRef] [Green Version]

- Caba, V.; Borgese, L.; Agnelli, S.; Depero, L.E. A green and simple process to develop conductive polyurethane foams for biomedical applications. Int. J. Polym. Mater. Polym. Biomater. 2019, 68, 126–133. [Google Scholar] [CrossRef]

- Guelcher, S.A.; Patel, V.; Gallagher, K.M.; Connolly, S.; Didier, J.E.; Doctor, J.S.; Hollinger, J.O. Synthesis and in vitro biocompatibility of injectable polyurethane foam scaffolds. Tissue Eng. 2006, 12, 1247–1259. [Google Scholar] [CrossRef]

- Pina, S.; Oliveira, J.M.; Reis, R.L. Natural-based nanocomposites for bone tissue engineering and regenerative medicine: A review. Adv. Mater. 2015, 27, 1143–1169. [Google Scholar] [CrossRef] [Green Version]

- Schreader, K.J.; Bayer, I.S.; Milner, D.J.; Loth, E.; Jasiuk, I. A polyurethane-based nanocomposite biocompatible bone adhesive. J. Appl. Polym. Sci. 2013, 127, 4974–4982. [Google Scholar] [CrossRef]

- Hafeman, A.E.; Li, B.; Yoshii, T.; Zienkiewicz, K.; Davidson, J.M.; Guelcher, S.A. Injectable biodegradable polyurethane scaffolds with release of platelet-derived growth factor for tissue repair and regeneration. Pharm. Res. 2008, 25, 2387–2399. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zawadzak, E.; Bil, M.; Ryszkowska, J.; Nazhat, S.N.; Cho, J.; Bretcanu, O.; Roether, J.A.; Boccaccini, A.R. Polyurethane foams electrophoretically coated with carbon nanotubes for tissue engineering scaffolds. Biomed. Mater. 2008, 4, 015008. [Google Scholar] [CrossRef] [PubMed]

- Chetyrkina, M.R.; Fedorov, F.S.; Nasibulin, A.G. In vitro toxicity of carbon nanotubes: A systematic review. RSC Adv. 2022, 12, 16235–16256. [Google Scholar] [CrossRef] [PubMed]

- Cherng, J.Y.; Hou, T.Y.; Shih, M.F.; Talsma, H.; Hennink, W.E. Polyurethane-based drug delivery systems. Int. J. Pharm. 2013, 450, 145–162. [Google Scholar] [CrossRef]

- Shin, Y.C.; Kang, S.H.; Lee, J.H.; Kim, B.; Hong, S.W.; Han, D.-W. Three-dimensional graphene oxide-coated polyurethane foams beneficial to myogenesis. J. Biomater. Sci. Polym. Ed. 2018, 29, 762–774. [Google Scholar] [CrossRef]

- Rahimidehgolan, F.; Altenhof, W. Compressive behavior and deformation mechanisms of rigid polymeric foams: A review. Compos. Part B Eng. 2023, 253, 110513. [Google Scholar] [CrossRef]

- Harun-Ur-Rashid, M.; Imran, A.B.; Susan, M.A.B.H. Fire-Resistant Polymeric Foams and Their Applications. In Polymeric Foams: Applications of Polymeric Foams (Volume 2); ACS Publications: Washington, DC, USA, 2023; pp. 97–121. [Google Scholar]

- Banerjee, R.; Gebrekrstos, A.; Orasugh, J.T.; Ray, S.S. Nanocarbon-Containing Polymer Composite Foams: A Review of Systems for Applications in Electromagnetic Interference Shielding, Energy Storage, and Piezoresistive Sensors. Ind. Eng. Chem. Res. 2023, 62, 6807–6842. [Google Scholar] [CrossRef]

- Adlie, T.A.; Ali, N.; Huzni, S.; Ikramullah, I.; Rizal, S. Impact of Zinc Oxide Addition on Oil Palm Empty Fruit Bunches Foamed Polymer Composites for Automotive Interior Parts. Polymers 2023, 15, 422. [Google Scholar] [CrossRef]

- Kong, W.; Li, R.; Zhao, X.; Ye, L. Construction of a Highly Oriented Poly (lactic acid)-Based Block Polymer Foam and Its Self-Reinforcing Mechanism. ACS Sustain. Chem. Eng. 2023, 11, 1133–1145. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

| Nanocomposite Foam Matrix | Nanofiller | Conductivity | EMI Shielding Effectiveness | Ref. |

|---|---|---|---|---|

| Polyurethane | Reduced graphene oxide3.17 vol.% | 2.53 × 10−1 Sm−1 | 22 dB | [57] |

| Polyurethane | Graphene oxide 20 wt.% | 3 Scm−1 | 17–24 dB | [61] |

| Polyurethane | Carbon nanotube | 0.23 Scm−1 | - | [80] |

| Polyurethane | Carbon nanotube | Percolation threshold 1.2 wt.%; 2.03 × 10−6 Sm−1 | - | [77] |

| Waterborne polyurethane | Carbon nanotube | 362 Sm−1 | 25 dB | [116] |

| Polyurethane | Reduced graphene oxide | 4 Sm−1 | 253 dB | [117] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I.; Zhao, T.; Aldaghri, O.; Ibnaouf, K.H.; Eisa, M.H. Nanocomposite Foams of Polyurethane with Carbon Nanoparticles—Design and Competence towards Shape Memory, Electromagnetic Interference (EMI) Shielding, and Biomedical Fields. Crystals 2023, 13, 1189. https://doi.org/10.3390/cryst13081189

Kausar A, Ahmad I, Zhao T, Aldaghri O, Ibnaouf KH, Eisa MH. Nanocomposite Foams of Polyurethane with Carbon Nanoparticles—Design and Competence towards Shape Memory, Electromagnetic Interference (EMI) Shielding, and Biomedical Fields. Crystals. 2023; 13(8):1189. https://doi.org/10.3390/cryst13081189

Chicago/Turabian StyleKausar, Ayesha, Ishaq Ahmad, Tingkai Zhao, Osamah Aldaghri, Khalid H. Ibnaouf, and M. H. Eisa. 2023. "Nanocomposite Foams of Polyurethane with Carbon Nanoparticles—Design and Competence towards Shape Memory, Electromagnetic Interference (EMI) Shielding, and Biomedical Fields" Crystals 13, no. 8: 1189. https://doi.org/10.3390/cryst13081189

APA StyleKausar, A., Ahmad, I., Zhao, T., Aldaghri, O., Ibnaouf, K. H., & Eisa, M. H. (2023). Nanocomposite Foams of Polyurethane with Carbon Nanoparticles—Design and Competence towards Shape Memory, Electromagnetic Interference (EMI) Shielding, and Biomedical Fields. Crystals, 13(8), 1189. https://doi.org/10.3390/cryst13081189