Ni-Co Alloy and Multisegmented Ni/Co Nanowire Arrays Modulated in Composition: Structural Characterization and Magnetic Properties

Abstract

:1. Introduction

2. Experimental Details

2.1. Synthesis of Nanoporous Anodic Alumina Membranes

2.2. Surface Functionalization by Atomic Layer Deposition, Au Sputtering and Electrodeposition

2.3. Electrodeposition of Magnetic Nanowires and Their Morphological, Structural, and Magnetic Characterization

3. Results and Discussion

3.1. Morphological and Structural Characterizations by SEM and TEM

3.2. XRD Analysis

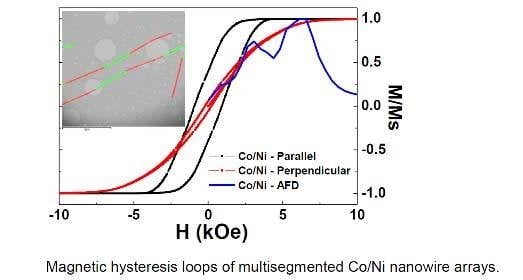

3.3. Magnetic Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ferry, D.K. Nanowires in Nanoelectronics. Science 2008, 319, 579–580. [Google Scholar] [CrossRef] [PubMed]

- Ferry, D.K.; Gilbert, M.J.; Akis, R. Some Considerations on Nanowires in Nanoelectronics. IEEE Trans. Electron Devices 2008, 55, 2820–2826. [Google Scholar] [CrossRef]

- Zhou, W.; Dai, X.; Fu, T.-M.; Xie, C.; Liu, J.; Lieber, C.M. Long Term Stability of Nanowire Nanoelectronics in Physiological Environments. Nano Lett. 2014, 14, 1614–1619. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Qian, F.; Xiang, J.; Lieber, C.M. Nanowire Electronic and Optoelectronic Devices. Mater. Today 2006, 9, 19–27. [Google Scholar] [CrossRef]

- Liu, Q.; Zheng, X.; He, J.; Wang, W.; Fu, M.; Cao, Y.; Li, H.; Wu, Y.; Chen, T.; Zhang, C.; et al. Enhanced Magneto-Optical Effects in Composite Coaxial Nanowires Embedded with Ag Nanoparticles. Sci. Rep. 2016, 6, 29170. [Google Scholar] [CrossRef] [PubMed]

- Valente, J.; Ou, J.-Y.; Plum, E.; Youngs, I.J.; Zheludev, N.I. A Magneto-Electro-Optical Effect in a Plasmonic Nanowire Material. Nat. Commun. 2015, 6, 7021. [Google Scholar] [CrossRef] [PubMed]

- Armelles, G.; Cebollada, A.; García-Martín, A.; Montero-Moreno, J.M.; Waleczek, M.; Nielsch, K. Magneto-optical Properties of Core−Shell Magneto-plasmonic Au-CoxFe3-xO4 Nanowires. Langmuir 2012, 28, 9127–9130. [Google Scholar] [CrossRef] [PubMed]

- Armelles, G.; Dmitriev, A. Focus on Magnetoplasmonics. New J. Phys. 2014, 16, 045012. [Google Scholar] [CrossRef]

- Gong, S.; Cheng, W. One-dimensional Nanomaterials for Soft Electronics. Adv. Electron. Mater. 2016. [Google Scholar] [CrossRef]

- Terris, B.D.; Thomson, T. Nanofabricated and Self-Assembled Magnetic Structures as Data Storage Media. J. Phys. D Appl. Phys. 2005, 38, R199–R222. [Google Scholar] [CrossRef]

- Ai, Y.; Lou, Z.; Li, L.; Chen, S.; Park, H.S.; Wang, Z.M.; Shen, G. Meters-Long Flexible CoNiO2-Nanowires@Carbon-Fibers Based Wire-Supercapacitors for Wearable Electronics. Adv. Mater. Technol. 2016, 1, 1600142. [Google Scholar] [CrossRef]

- Niemann, A.C.; Böhnert, T.; Michel, A.-K.; Bäßler, S.; Gotsmann, B.; Neuróhr, K.; Tóth, B.; Péter, L.; Bakonyi, I.; Vega, V.; et al. Thermoelectric Power Factor Enhancement by Spin-Polarized Currents-A Nanowire Case Study. Adv. Electron. Mater. 2016, 2, 1600058. [Google Scholar] [CrossRef]

- Athanassiou, E.K.; Grossmann, P.; Grass, R.N.; Stark, W.J. Template free, large scale synthesis of cobalt nanowires using magnetic fields for alignment. Nanotechnology 2007, 18, 165606. [Google Scholar] [CrossRef]

- Liu, C.; Li, C.; Ahmed, K.; Mutlu, Z.; Ozkan, C.S.; Ozkan, M. Template Free and Binderless NiO Nanowire Foam for Li-ion Battery Anodes with Long Cycle Life and Ultrahigh Rate Capability. Sci. Rep. 2016, 6, 29183. [Google Scholar] [CrossRef] [PubMed]

- Lopes, M.C.; de Oliveira, C.P.; Pereira, E.C. Computational modeling of the template-assisted deposition of nanowires. Electrochim. Acta 2008, 53, 4359–4369. [Google Scholar] [CrossRef]

- Stępniowski, W.J.; Salerno, M. Fabrication of nanowires and nanotubes by anodic alumina template-assisted electrodeposition. In Manufacturing Nanostructures; Ahmed, W., Ali, N., Eds.; One Central Press (OCP): Manchester, UK, 2014; Chapter 12; pp. 321–357. [Google Scholar]

- Sousa, C.T.; Leitao, D.C.; Proenca, M.P.; Ventura, J.; Pereira, A.M.; Araujo, J.P. Nanoporous Alumina as Templates for Multifunctional Applications. Appl. Phys. Rev. 2014, 1, 031102. [Google Scholar] [CrossRef]

- Prida, V.M.; Vega, V.; García, J.; Iglesias, L.; Hernando, B.; Minguez-Bacho, I. 1—Electrochemical methods for template-assisted synthesis of nanostructured materials. In Magnetic Nano- and Microwires: Design, Synthesis, Properties and Applications; Vazquez, M., Ed.; Woodhead Publishing Series in Electronic and Optical Materials; Elsevier: Amsterdam, The Netherlands, 2015; Chapter 1; pp. 3–39. [Google Scholar]

- Da Câmara Santa Clara Gomes, T.; De La Torre Medina, J.; Lemaitre, M.; Piraux, L. Magnetic and Magnetoresistive Properties of 3D Interconnected NiCo Nanowire Networks. Nanoscale Res. Lett. 2016, 11, 466. [Google Scholar] [CrossRef] [PubMed]

- Prida, V.M.; García, J.; Hernando, B.; Bran, C.; Vivas, L.G.; Vázquez, M. 2—Electrochemical synthesis of magnetic nanowires with controlled geometry and magnetic anisotropy. In Magnetic Nano- and Microwires: Design, Synthesis, Properties and Applications; Vazquez, M., Ed.; Woodhead Publishing Series in Electronic and Optical Materials; Elsevier: Amsterdam, The Netherlands, 2015; Chapter 2; pp. 41–104. [Google Scholar]

- García, J.; Prida, V.M.; Vivas, L.G.; Hernando, B.; Barriga-Castro, E.D.; Mendoza-Reséndez, R.; Luna, C.; Escrig, J.; Vázquez, M. Magnetization reversal dependence on effective magnetic anisotropy in electroplated Co–Cu nanowire arrays. J. Mater. Chem. C 2015, 3, 4688–4697. [Google Scholar] [CrossRef]

- Prida, V.M.; García, J.; Iglesias, L.; Vega, V.; Görlitz, D.; Nielsch, K.; Barriga-Castro, E.D.; Mendoza-Reséndez, R.; Ponce, A.; Luna, C. Electroplating and Magnetostructural Characterization of Multisegmented Co54Ni46/Co85Ni15 Nanowires From Single Electrochemical Bath in Anodic Alumina Templates. Nanoscale Res. Lett. 2013, 8, 263. [Google Scholar] [CrossRef] [PubMed]

- Jang, B.; Pellicer, E.; Guerrero, M.; Chen, X.; Choi, H.; Nelson, B.J.; Sort, J.; Pané, S. Fabrication of Segmented Au/Co/Au Nanowires: Insights in the Quality of Co/Au Junctions. ACS Appl. Mater. Interfaces 2014, 6, 14583–14589. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, Y.P.; Chuvilin, A.; Lopatin, S.; Kosel, J. Modulated Magnetic Nanowires for Controlling Domain Wall Motion: Toward 3D Magnetic Memories. ACS Nano 2016, 10, 5326–5332. [Google Scholar] [CrossRef] [PubMed]

- Minguez-Bacho, I.; Rodriguez-López, S.; Vázquez, M.; Hernández-Vélez, M.; Nielsch, K. Electrochemical synthesis and magnetic characterization of periodically modulated Co nanowires. Nanotechnology 2014, 25, 145301. [Google Scholar] [CrossRef] [PubMed]

- Iglesias-Freire, O.; Bran, C.; Berganza, E.; Mínguez-Bacho, I.; Magén, C.; Vázquez, M.; Asenjo, A. Spin configuration in isolated FeCoCu nanowires modulated in diameter. Nanotechnology 2015, 26, 395702. [Google Scholar] [CrossRef] [PubMed]

- Bran, C.; Berganza, E.; Palmero, E.M.; Fernandez-Roldan, J.A.; Del Real, R.P.; Aballe, L.; Foerster, M.; Asenjo, A.; Rodríguez, A.F.; Vazquez, M. Spin configuration of cylindrical bamboo-like magnetic nanowires. J. Mater. Chem. C 2016, 4, 978–984. [Google Scholar] [CrossRef]

- Berganza, E.; Bran, C.; Vazquez, M.; Asenjo, A. Domain wall pinning in FeCoCu bamboo-like nanowires. Sci. Rep. 2016, 6, 29702. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, L.A.; Bran, C.; Reyes, D.; Berganza, E.; Vázquez, M.; Gatel, C.; Snoeck, E.; Asenjo, A. Quantitative Nanoscale Magnetic Study of Isolated Diameter-Modulated FeCoCu Nanowires. ACS Nano 2016, 10, 9669–9678. [Google Scholar] [CrossRef] [PubMed]

- Montazer, A.H.; Ramazani, A.; Kashiab, M.A.; Zavašnikc, J. Angular-dependent magnetism in Co(001) single-crystal nanowires: Capturing the vortex nucleation fields. J. Mater. Chem. C 2016, 4, 10664–10674. [Google Scholar] [CrossRef]

- Zhang, J.; Pané, S.; Sort, J.; Pellicer, E. Toward Robust Segmented Nanowires: Understanding the Impact of Crystallographic Texture on the Quality of Segment Interfaces in Magnetic Metallic Nanowires. Adv. Mater. Interfaces 2016, 3, 1600336. [Google Scholar] [CrossRef]

- Agramunt-Puig, S.; Del-Valle, N.; Pellicer, E.; Zhang, J.; Nogués, J.; Navau, C.; Sanchez, A.; Sort, J. Modeling the collective magnetic behavior of highly-packed arrays of multi-segmented nanowires. New J. Phys. 2016, 18, 013026. [Google Scholar] [CrossRef]

- Geng, X.; Podlaha, E.J. Coupled, Simultaneous Displacement and Dealloying Reactions into Fe–Ni–Co Nanowires for Thinning Nanowire Segments. Nano Lett. 2016, 16, 7439–7445. [Google Scholar] [CrossRef] [PubMed]

- Reyes, D.; Biziere, N.; Warot-Fonrose, B.; Wade, T.; Gatel, C. Magnetic Configurations in Co/Cu Multilayered Nanowires: Evidence of Structural and Magnetic Interplay. Nano Lett. 2016, 16, 1230–1236. [Google Scholar] [CrossRef] [PubMed]

- Özkale, B.; Shamsudhin, N.; Chatzipirpiridis, G.; Hoop, M.; Gramm, F.; Chen, X.; Martí, X.; Sort, J.; Pellicer, E.; Pané, S. Multisegmented FeCo/Cu Nanowires: Electrosynthesis, Characterization, and Magnetic Control of Biomolecule Desorption. ACS Appl. Mater. Interfaces 2015, 7, 7389–7396. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Agramunt-Puig, S.; Del-Valle, N.; Navau, C.; Baró, M.D.; Estradé, S.; Peiró, F.; Pané, S.; Nelson, B.J.; Sanchez, A.; et al. Tailoring Staircase-like Hysteresis Loops in Electrodeposited Trisegmented Magnetic Nanowires: A Strategy toward Minimization of Interwire Interactions. ACS Appl. Mater. Interfaces 2016, 8, 4109–4117. [Google Scholar] [CrossRef] [PubMed]

- Ramulu, T.S.; Venu, R.; Sinha, B.; Yoon, S.S.; Kim, C.G. Electrodeposition of CoPtP/Au Multisegment Nanowires: Synthesis and DNA Functionalization. Int. J. Electrochem. Sci. 2012, 7, 7762–7769. [Google Scholar]

- Masuda, H.; Fukuda, K. Ordered metal nanohole arrays made by s two-step replication of honeycomb structures of anodic alumina. Science 1995, 268, 1466–1468. [Google Scholar] [CrossRef] [PubMed]

- Prida, V.M.; Pirota, K.R.; Navas, D.; Asenjo, A.; Hernández-Vélez, M.; Vázquez, M. Self-Organized Magnetic Nanowire Arrays Based on Alumina and Titania Templates. J. Nanosci. Nanotechnol. 2007, 7, 272–285. [Google Scholar] [PubMed]

- Romero, V.; Vega, V.; García, J.; Zierold, R.; Nielsch, K.; Prida, V.M.; Hernando, B.; Benavente, J. Changes in Morphology and Ionic Transport Induced by ALD SiO2 Coating of Nanoporous Alumina Membranes. ACS Appl. Mater. Interfaces 2013, 5, 3556–3564. [Google Scholar] [CrossRef] [PubMed]

- Bachmann, J.; Zierold, R.; Chong, Y.T.; Hauert, R.; Sturm, C.; Schmidt-Grund, R.; Rheinlander, B.; Grundmann, M.; Gosele, U.; Nielsch, K. A Practical, Self-Catalytic, Atomic Layer Deposition of Silicon Dioxide. Angew. Chem. 2008, 47, 6177–6179. [Google Scholar] [CrossRef] [PubMed]

- Vega, V.; Böhnert, T.; Martens, S.; Waleczek, M.; Montero-Moreno, J.M.; Görlitz, D.; Prida, V.M.; Nielsch, K. Tuning the Magnetic Anisotropy of Co-Ni Nanowires: Comparison Between Single Nanowires and Nanowire Arrays in Hard-Anodic Aluminum Oxide Membranes. Nanotechnology 2012, 23, 465709. [Google Scholar] [CrossRef] [PubMed]

- Materials Analysis Using Diffraction. Available online: http://maud.radiographema.com (accessed on 26 February 2017).

- Lutterotti, L. Total pattern fitting for the combined size-strain-stress-texture determination in thin film diffraction. Nuclear Instrum. Methods Phys. Res. B 2010, 268, 334–340. [Google Scholar] [CrossRef]

- Lutterotti, L.; Bortolotti, M.; Ischia, G.; Lonardelli, I.; Wenk, H.-R. Rietveld texture analysis from diffraction images. Z. Kristallogr. 2007, Suppl. 26, 125–130. [Google Scholar] [CrossRef]

- Lutterotti, L.; Chateigner, D.; Ferrari, S.; Ricote, J. Texture, Residual Stress and Structural Analysis of Thin Films using a Combined X-Ray Analysis. Thin Solid Films 2004, 450, 34–41. [Google Scholar] [CrossRef]

- García, J.; Vega, V.; Iglesias, L.; Prida, V.M.; Hernando, B.; Barriga-Castro, E.D.; Mendoza-Reséndez, R.; Luna, C.; Görlitz, D.; Nielsch, K. Template-assisted Co-Ni Alloys and Multisegmented Nanowires with Tuned Magnetic Anisotropy. Phys. Status Solidi A 2014, 211, 1041–1047. [Google Scholar] [CrossRef]

- Hertel, R. Micromagnetic simulations of magnetostatically coupled Nickel nanowires. J. Appl. Phys. 2001, 90, 5752–5758. [Google Scholar] [CrossRef]

- Zighem, F.; Maurer, T.; Ott, F.; Chaboussant, G. Dipolar interactions in arrays of ferromagnetic nanowires: A micromagnetic study. J. Appl. Phys. 2011, 109, 013910. [Google Scholar] [CrossRef]

- Vega, V.; Prida, V.M.; García, J.A.; Vázquez, M. Torque magnetometry analysis of magnetic anisotropy distribution in Ni nanowire arrays. Phys. Stat. Solidi A 2011, 208, 553–558. [Google Scholar] [CrossRef]

- Salem, M.S.; Sergelius, P.; Corona, R.M.; Escrig, J.; Görlitz, D.; Nielsch, K. Magnetic properties of cylindrical diameter modulated Ni80Fe20 nanowires: Interaction and coercive fields. Nanoscale 2013, 5, 3941–3947. [Google Scholar] [CrossRef] [PubMed]

- Raposo, V.; Zazo, M.; Flores, A.G.; García, J.; Vega, V.; Iñiguez, J.; Prida, V.M. Ferromagnetic resonance in low interacting permalloy nanowire arrays. J. Appl. Phys. 2016, 114, 143903. [Google Scholar] [CrossRef]

- Barandiaran, J.M.; Vázquez, M.; Hernando, A.; González, J.; Rivero, G. Distribution of the Magnetic Anisotropy in Amorphous Alloys Ribbons. IEEE Trans. Magn. 1989, 25, 3330–3332. [Google Scholar] [CrossRef]

- De la Torre Medina, J.; Darques, M.; Piraux, L.; Encinas, A. Application of the anisotropy field distribution method to arrays of magnetic nanowires. J. Appl. Phys. 2009, 105, 023909. [Google Scholar] [CrossRef]

| Diffraction Peak | Lhkl (nm) | Sample Relative Intensity (%) | Bulk Relative Intensity (%) |

|---|---|---|---|

| (100) | 25 | 100 | 20 |

| (002) | 21 | 14 | 60 |

| (101) | - | 2 | 100 |

| (110) | 21 | 16 | 80 |

| (103) | - | - | 80 |

| (200) | 20 | 3 | 20 |

| (112) | 17 | 4 | 80 |

| (201) | 16 | 4 | 60 |

| (004) | - | - | 20 |

| Diffraction Peak | Lhkl (nm) | Sample Relative Intensity (%) | Bulk Relative Intensity (%) |

|---|---|---|---|

| (111) | 29 | ~1 | 100 |

| (200) | 6 | ~1 | 42 |

| (220) | 116 | 100 | 21 |

| (311) | 16 | <1 | 20 |

| (222) | - | - | 7 |

| Diffraction Peak | Lhkl (nm) | Sample Relative Intensity (%) | Bulk Relative Intensity (%) |

|---|---|---|---|

| (100)hcp | 36 | 18 | 20 |

| (111)fcc/(002)hcp | 43 | 100 | 100/60 |

| (101)hcp | - | 4 | 100 |

| (200)fcc | 20 | 8 | 42 |

| (220)fcc/(110)hcp | 37 | 13 | 21/80 |

| (103)hcp | - | 4 | 80 |

| (311)fcc/(112)hcp | 30 | 14 | 20/80 |

| (222)fcc | - | 4 | 7 |

| Diffraction Peak | Lhkl (nm) | Sample Relative Intensity (%) | Bulk Relative Intensity (%) |

|---|---|---|---|

| (100)hcp | 20 | 15 | 20 |

| (111)fcc/(002)hcp | 42 | 100 | 100/60 |

| (101)hcp | 15 | 4 | 100 |

| (200)fcc | 15 | 9 | 42 |

| (110)hcp | 81 | 80 | |

| (103)hcp | - | - | 80 |

| (311)fcc | - | 9 | 20 |

| (112)hcp | - | 64 | 80 |

| (222)fcc | - | 4 | 7 |

| H (Oe); m | Ni | Co | Ni/Co | Ni-Co |

|---|---|---|---|---|

| Hc (//) | 1098 | 971 | 930 | 337 |

| Hc (⊥) | 103 | 205 | 216 | 231 |

| mr (//) | 0.86 | 0.30 | 0.40 | 0.13 |

| mr (⊥) | 0.04 | 0.04 | 0.06 | 0.29 |

| Han | 3064 | 6532 | 3076/6348 | 896/4154 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Méndez, M.; González, S.; Vega, V.; Teixeira, J.M.; Hernando, B.; Luna, C.; Prida, V.M. Ni-Co Alloy and Multisegmented Ni/Co Nanowire Arrays Modulated in Composition: Structural Characterization and Magnetic Properties. Crystals 2017, 7, 66. https://doi.org/10.3390/cryst7030066

Méndez M, González S, Vega V, Teixeira JM, Hernando B, Luna C, Prida VM. Ni-Co Alloy and Multisegmented Ni/Co Nanowire Arrays Modulated in Composition: Structural Characterization and Magnetic Properties. Crystals. 2017; 7(3):66. https://doi.org/10.3390/cryst7030066

Chicago/Turabian StyleMéndez, Miguel, Silvia González, Víctor Vega, Jose M. Teixeira, Blanca Hernando, Carlos Luna, and Víctor M. Prida. 2017. "Ni-Co Alloy and Multisegmented Ni/Co Nanowire Arrays Modulated in Composition: Structural Characterization and Magnetic Properties" Crystals 7, no. 3: 66. https://doi.org/10.3390/cryst7030066

APA StyleMéndez, M., González, S., Vega, V., Teixeira, J. M., Hernando, B., Luna, C., & Prida, V. M. (2017). Ni-Co Alloy and Multisegmented Ni/Co Nanowire Arrays Modulated in Composition: Structural Characterization and Magnetic Properties. Crystals, 7(3), 66. https://doi.org/10.3390/cryst7030066