Parametric Study of Effects of Atmospheric Pressure Plasma Treatment on the Wettability of Cotton Fabric

Abstract

:1. Introduction

2. Experimental

2.1. Cotton Fabric

2.2. Atmospheric Pressure Plasma Treatment

2.3. Wicking Rate Measurement

2.4. Drop Test

2.5. Data Analysis

3. Results and Discussion

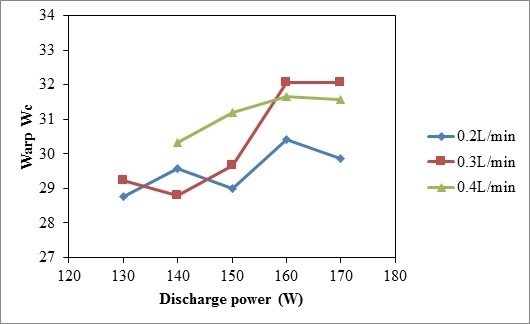

3.1. Discharge Power

3.2. Oxygen Flow Rate

3.3. Jet Travelling Speed

3.4. Jet-to-Substrate Distance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Morent, R.; De Geyter, N.; Verschuren, J.; De Clerck, K.; Kiekens, P.; Leys, C. Non-thermal plasma treatment of textiles. Surf. Coat. Technol. 2008, 202, 3427–3449. [Google Scholar] [CrossRef]

- Luo, S.; Van Ooik, W.J. Surface modification of textile fibres for improvement of adhesion to polymeric matrices: A review. J. Adhes. Sci. Technol. 2002, 16, 1715–1735. [Google Scholar] [CrossRef]

- Yasuda, H. Glow discharge discharges polymerization. Macromol. Rev. 1981, 16, 199–293. [Google Scholar] [CrossRef]

- Rakowski, W. Plasma treatment of wool today, part I—Fibre properties, spinning and shrinkproofing. J. Soc. Dyers Colour. 1997, 113, 250–255. [Google Scholar] [CrossRef]

- Buyle, G.; Heyse, P.; Ferreira, I. Tuning the surface properties of textile materials. In Plasma Technology for Hyperfunctional Surface, 1st ed.; Rausher, H., Perucca, M., Buyle, G., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2010; p. 137. [Google Scholar]

- Karahan, H.A.; Özdoğan, E. Improvements of surface functionality of cotton fibres by atmospheric plasma treatment. Fibers Polym. 2008, 9, 21–26. [Google Scholar] [CrossRef]

- Leroux, F.; Campagne, C.; Perwuelz, A.; Gengembre, L. Fluorocarbon nano-coating of polyester fabrics by atmospheric air plasma with aerosol. Surf. Coat. Technol. 2008, 254, 3902–3908. [Google Scholar] [CrossRef]

- Leroux, F.; Perwuelz, A.; Campagne, C.; Behary, N. Atmospheric air-plasma treatments of polyester textile structures. J. Adhes. Sci. Technol. 2006, 20, 939–957. [Google Scholar] [CrossRef]

- Samanta, K.K.; Jassal, M.; Agrawal, A.K. Improvement in water and oil absorbency of textile substrate by atmospheric pressure cold plasma treatment. Surf. Coat. Technol. 2009, 203, 1336–1342. [Google Scholar] [CrossRef]

- Wang, C.X.; Qiu, Y.P. Tow sided modification of wool fabric by atmospheric pressure plasma jet: Influence of processing parameter on plasma penetration. Surf. Coat. Technol. 2007, 201, 6273–6277. [Google Scholar] [CrossRef]

- Hodak, S.K.; Supasai, T.; Paosawatyanyong, B.; Kamlangkla, K.; Pavarajarn, V. Enhancement of the hydrophobicity of silk fabrics by SF6 plasma. Appl. Surf. Sci. 2008, 254, 4744–4749. [Google Scholar] [CrossRef]

- Lei, J.; Shi, M.; Zhang, J. Surface graft copolymerization of hydrogen silicon fluid onto fabric through corona discharge and water repellency of grafted fabric. Eur. Polym. J. 2000, 36, 1277–1281. [Google Scholar] [CrossRef]

- Kan, C.W.; Lam, C.F.; Chan, C.K.; Ng, S.P. Using atmospheric pressure plasma treatment for treating grey cotton fabric. Carbohydr. Polym. 2014, 102, 167–173. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.S.; Qiu, Y.P. The mechanism of air/oxygen/helium atmospheric plasma action on PVA. J. Appl. Polym. Sci. 2006, 99, 2233–2237. [Google Scholar] [CrossRef]

- Jocic, D.; Vilchez, S.; Topalovic, T.; Molina, R.; Navarro, A.; Jovancic, P.; Julia, M.R.; Erra, P. Effect of low-temperature plasma and chitosan treatment on wool dyeing with acid red 27. J. Appl. Polym. Sci. 2005, 97, 2204–2214. [Google Scholar] [CrossRef]

- Ren, C.S.; Wang, D.Z.; Wang, Y.N. Improvement of the graft and dyeability of linen by DBD treatment in ambient air. J. Mater. Process. Technol. 2008, 206, 216–220. [Google Scholar] [CrossRef]

- Tokino, S.; Wakida, T.; Uchiyama, H.; Lee, M. Laundering shrinkage of wool fabric treated with low-temperature plasmas under atmospheric pressure. J. Soc. Dyers Colour. 1993, 109, 334–335. [Google Scholar] [CrossRef]

- Šimor, M.; Ráhel, J.; Černák, M.; Imahori, Y.; Štefečka, M.; Kando, M. Atmospheric-pressure plasma treatment of polyester nonwoven fabrics for electroless plating. Surf. Coat. Technol. 2003, 172, 1–6. [Google Scholar] [CrossRef]

- Szabová, R.; Černáková, L.; Wolfová, M.; Černák, M. Coating of TiO2 nanoparticles on the plasma activated polypropylene fibres. Acta Chim. Slovaca 2009, 2, 70–76. [Google Scholar]

- Zhou, C.E.; Kan, C.W.; Matinlinna, J.P.; Tsoi, J.K.H. Regenerable antibacterial cotton fabric by plasma treatment with dimethylhydantoin: Antibacterial activity against S. aureus. Coatings 2017, 7, 11. [Google Scholar] [CrossRef]

- Zhou, C.E.; Kan, C.W.; Yuen, C.W.M. Orthogonal analysis for rechargeable antimicrobial finishing of plasma pretreated cotton. Cellulose 2015, 22, 3465–3475. [Google Scholar] [CrossRef]

- Kan, C.W.; Man, W.S. Enhancing dark shade pigment dyeing of cotton fabric with plasma treatment. Coatings 2017, 7, 104. [Google Scholar]

- Kan, C.W.; Man, W.S.; Ng, S.P. A study of pigment application on atmospheric pressure plasma treated cotton fabric. Fibers Polym. 2014, 15, 2313–2318. [Google Scholar] [CrossRef]

- Kan, C.W.; Lo, C.K.Y.; Man, W.S. Mini review—Environmentally friendly aspects in coloration. Color. Technol. 2016, 132, 4–8. [Google Scholar] [CrossRef]

- Diamy, A.M.; Legrand, J.C.; Rybkin, V.V.; Smimov, S.A. Experimental study and modelling of formation and decay of active species in an oxygen discharge. Contrib. Plasma Phys. 2005, 45, 5–21. [Google Scholar] [CrossRef]

- Kan, C.W.; Kwong, C.H.; Ng, S.P. Atmospheric pressure plasma surface treatment of rayon flock synthetic leather with tetramethylsilane. Appl. Sci. 2016, 6, 59. [Google Scholar] [CrossRef]

- Jeong, J.Y.; Park, J.; Henins, I.; Babayan, S.E.; Tu, V.J.; Selwyn, G.S.; Ding, G.; Hicks, R.F. Reaction chemistry in the afterglow of an oxygen-helium, atmospheric-pressure plasma. J. Phys. Chem. A 2000, 104, 8027–8032. [Google Scholar] [CrossRef]

- Schütze, A.; Jeong, J.Y.; Babayan, S.E.; Park, J.; Selwyn, G.S.; Hicks, R.F. The atmospheric-pressure plasma jet: A review and comparison to other plasma sources. IEEE Trans. Plasma Sci. 1998, 26, 1685–1694. [Google Scholar] [CrossRef]

- Man, W.S.; Kan, C.W.; Ng, S.P. The use of atmospheric pressure plasma treatment on enhancing the pigment application to cotton fabric. Vacuum 2014, 99, 7–11. [Google Scholar] [CrossRef]

- Sun, S.Y.; Sun, J.; Yao, L.; Qiu, Y.P. Wettability and sizing property improvement of raw cotton yarns treated with He/O2 atmospheric pressure plasma jet. Appl. Surf. Sci. 2011, 257, 2377–2382. [Google Scholar] [CrossRef]

- Kan, C.W.; Lam, C.F. Atmospheric pressure plasma treatment for grey cotton knitted fabric. Polymers 2018, 10, 53. [Google Scholar]

- Kan, C.W.; Cheung, H.F.; Kooh, F.M. An investigation of colour fading of sulphur-dyed cotton fabric by plasma treatment. Fibers Polym. 2017, 18, 767–772. [Google Scholar] [CrossRef]

| Parameter | Plasma Treated | Conventional Chemical Process |

|---|---|---|

| Solvent | None (gas phase) | Water |

| Energy | Electricity | Heat |

| Type of reaction | Complex | Simple |

| Deepness of the treatment | Very thin layer | Bulk of the fiber |

| New treatment equipment | Totally new | Slow evolution |

| Water and energy consumption | Low | High |

| Pollution | Very low | High |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kan, C.-W.; Man, W.-S. Parametric Study of Effects of Atmospheric Pressure Plasma Treatment on the Wettability of Cotton Fabric. Polymers 2018, 10, 233. https://doi.org/10.3390/polym10030233

Kan C-W, Man W-S. Parametric Study of Effects of Atmospheric Pressure Plasma Treatment on the Wettability of Cotton Fabric. Polymers. 2018; 10(3):233. https://doi.org/10.3390/polym10030233

Chicago/Turabian StyleKan, Chi-Wai, and Wai-Shan Man. 2018. "Parametric Study of Effects of Atmospheric Pressure Plasma Treatment on the Wettability of Cotton Fabric" Polymers 10, no. 3: 233. https://doi.org/10.3390/polym10030233

APA StyleKan, C. -W., & Man, W. -S. (2018). Parametric Study of Effects of Atmospheric Pressure Plasma Treatment on the Wettability of Cotton Fabric. Polymers, 10(3), 233. https://doi.org/10.3390/polym10030233