Effects of Graphene Nanoplatelet Size and Surface Area on the AC Electrical Conductivity and Dielectric Constant of Epoxy Nanocomposites

Abstract

:1. Introduction

2. Materials and Experimental Details

2.1. GNP and Epoxy Materials

2.2. Nanocomposite Fabrication

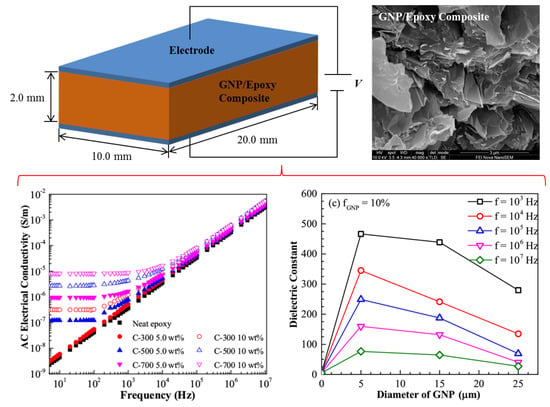

2.3. Sample Fabrication and Test

2.4. Scanning Electron Microscopy for Evaluation of Interfiller Spacing and Filler Diameter

3. Results and Discussion

3.1. Effect of GNP Content on AC Electrical Conductivity and Dielectric Constant

3.2. Effect of GNP Surface Area on AC Electrical Conductivity and Dielectric Constant

3.3. Effect of GNP Size on AC Electrical Conductivity and Dielectric Constant

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Samori, P.; Kinloch, I.; Feng, X.; Palermo, V. Graphene-based nanocomposites for structural and functional applications: Using 2-dimensional materials in a 3-dimensional world. 2D Mater. 2015, 2, 030205. [Google Scholar] [CrossRef]

- Yang, K.; Feng, L.; Hong, H.; Cai, W.; Liu, Z. Preparation and functionalization of graphene nanocomposites for biomedical applications. Nat. Protoc. 2013, 8, 2392–2403. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.; Tsukruk, V.V. Seriography-guided reduction of graphene oxide biopapers for wearable sensory electronics. Adv. Funct. Mater. 2017, 27. [Google Scholar] [CrossRef]

- Hu, K.; Gupta, M.K.; Kulkarni, D.D.; Tsukruk, V.V. Ultra-robust graphene oxide-silk fibroin nanocomposite membranes. Adv. Mater. 2013, 25, 2301–2307. [Google Scholar] [CrossRef] [PubMed]

- Moussa, M.; Shi, G.; Wu, H.; Zhao, Z.; Voelcker, N.H.; Losic, D.; Ma, J. Development of flexible supercapacitors using an inexpensive graphene/pedot/MNO2 sponge composite. Mater. Des. 2017, 125, 1–10. [Google Scholar] [CrossRef]

- Qin, Y.; Peng, Q.; Ding, Y.; Lin, Z.; Wang, C.; Li, Y.; Xu, F.; Li, J.; Yuan, Y.; He, X. Lightweight, superelastic, and mechanically flexible graphene/polyimide nanocomposite foam for strain sensor application. ACS Nano 2015, 9, 8933–8941. [Google Scholar] [CrossRef] [PubMed]

- Song, W.-L.; Cao, M.-S.; Lu, M.-M.; Bi, S.; Wang, C.-Y.; Liu, J.; Yuan, J.; Fan, L.-Z. Flexible graphene/polymer composite films in sandwich structures for effective electromagnetic interference shielding. Carbon 2014, 66, 67–76. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Wu, S.; Ladani, R.B.; Zhang, J.; Bafekrpour, E.; Ghorbani, K.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites. Carbon 2015, 94, 607–618. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Cho, J.; Roether, J.A.; Thomas, B.J.C.; Jane Minay, E.; Shaffer, M.S.P. Electrophoretic deposition of carbon nanotubes. Carbon 2006, 44, 3149–3160. [Google Scholar] [CrossRef]

- Feng, C.; Wang, Y.; Yang, J. Effects of reorientation of graphene platelets (gpls) on young’s modulus of polymer composites under bi-axial stretching. Nanomaterials 2018, 8, 27. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Feng, C.; Wang, Y.; Yang, J. Bending and vibration analysis of functionally graded trapezoidal nanocomposite plates reinforced with graphene nanoplatelets (gpls). Compos. Struct. 2017, 180, 799–808. [Google Scholar] [CrossRef]

- Feng, C.; Kitipornchai, S.; Yang, J. Nonlinear free vibration of functionally graded polymer composite beams reinforced with graphene nanoplatelets (gpls). Eng. Struct. 2017, 140, 110–119. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, C.; Zhao, Z.; Yang, J. Buckling of graphene platelet reinforced composite cylindrical shell with cutout. Int. J. Struct. Stab.Dyn. 2017, 18, 1850040. [Google Scholar] [CrossRef]

- Feng, C.; Kitipornchai, S.; Yang, J. Nonlinear bending of polymer nanocomposite beams reinforced with non -uniformly distributed graphene platelets (gpls). Compos. Part B-Eng. 2017, 110, 132–140. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.S.; Bae, H.S.; Yu, J.; Kim, S.Y. Thermal conductivity of polymer composites with the geometrical characteristics of graphene nanoplatelets. Sci. Rep. 2016, 6, 26825. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.; Chen, B.; Feng, J. Fracture mechanism and toughness optimization of macroscopic thick graphene oxide film. Sci. Rep. 2015, 5, 13102. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, H.; Porwal, H.; Huang, Z.; Bilotti, E.; Peijs, T. Mechanical, electrical and thermal properties of in-situ exfoliated graphene/epoxy nanocomposites. Compos. Part A Appl. Sci. Manuf. 2017, 95, 229–236. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Kudus, M.H.A.; Akil, H.M.; Thirmizir, M.Z.M. Comparative study of graphene nanoparticle and multiwall carbon nanotube filled epoxy nanocomposites based on mechanical, thermal and dielectric properties. Compos. Part B Eng. 2017, 119, 57–66. [Google Scholar] [CrossRef]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Mechanical properties and thermal conductivity of graphene nanoplatelet/epoxy composites. J. Mater. Sci. 2015, 50, 1082–1093. [Google Scholar] [CrossRef]

- Lee, J.K.; Song, S.; Kim, B. Functionalized graphene sheets-epoxy based nanocomposite for cryotank composite application. Polym. Compos. 2012, 33, 1263–1273. [Google Scholar] [CrossRef]

- Tang, L.-C.; Wan, Y.-J.; Yan, D.; Pei, Y.-B.; Zhao, L.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 2013, 60, 16–27. [Google Scholar] [CrossRef]

- Feng, C.; Wang, Y.; Kitipornchai, S.; Yang, J. Effects of reorientation of graphene platelets (gpls) on young’s modulus of polymer nanocomposites under uni-axial stretching. Polymers 2017, 9, 532. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Tang, L.-C.; Gong, L.-X.; Yan, D.; Li, Y.-B.; Wu, L.-B.; Jiang, J.-X.; Lai, G.-Q. Grafting of epoxy chains onto graphene oxide for epoxy composites with improved mechanical and thermal properties. Carbon 2014, 69, 467–480. [Google Scholar] [CrossRef]

- Gu, J.; Xie, C.; Li, H.; Dang, J.; Geng, W.; Zhang, Q. Thermal percolation behavior of graphene nanoplatelets/polyphenylene sulfide thermal conductivity composites. Polym. Compos. 2014, 35, 1087–1092. [Google Scholar] [CrossRef]

- Sun, R.; Li, L.; Feng, C.; Kitipornchai, S.; Yang, J. Tensile behavior of polymer nanocomposite reinforced with graphene containing defects. Eur. Polym. J. 2018, 98, 475–482. [Google Scholar] [CrossRef]

- Kandare, E.; Khatibi, A.A.; Yoo, S.; Wang, R.; Ma, J.; Olivier, P.; Gleizes, N.; Wang, C.H. Improving the through-thickness thermal and electrical conductivity of carbon fibre/epoxy laminates by exploiting synergy between graphene and silver nano-inclusions. Compos. Part A Appl. Sci. Manuf. 2015, 69, 72–82. [Google Scholar] [CrossRef]

- Araby, S.; Li, J.; Shi, G.; Ma, Z.; Ma, J. Graphene for flame-retarding elastomeric composite foams having strong interface. Compos. Part A Appl. Sci. Manuf. 2017, 101, 254–264. [Google Scholar] [CrossRef]

- Alam, A.; Meng, Q.; Shi, G.; Arabi, S.; Ma, J.; Zhao, N.; Kuan, H.-C. Electrically conductive, mechanically robust, ph-sensitive graphene/polymer composite hydrogels. Compos. Sci. Technol. 2016, 127, 119–126. [Google Scholar] [CrossRef]

- Yuan, B.; Wang, B.; Hu, Y.; Mu, X.; Hong, N.; Liew, K.M.; Hu, Y. Electrical conductive and graphitizable polymer nanofibers grafted on graphene nanosheets: Improving electrical conductivity and flame retardancy of polypropylene. Compos. Part A Appl. Sci. Manuf. 2016, 84, 76–86. [Google Scholar] [CrossRef]

- Nag, A.; Mitra, A.; Mukhopadhyay, S.C. Graphene and its sensor-based applications: A review. Sens. Actuators A Phys. 2018, 270, 177–194. [Google Scholar] [CrossRef]

- Chen, S.J.; Yao, X.P.; Wang, Q.; Duan, W.H. Snubbing effect in atomic scale friction of graphene. Compos. Part B Eng. 2018, 136, 119–125. [Google Scholar] [CrossRef]

- Wang, Q.; Arash, B. A review on applications of carbon nanotubes and graphenes as nano-resonator sensors. Comput. Mater. Sci. 2014, 82, 350–360. [Google Scholar] [CrossRef]

- Diba, M.; Fam, D.W.H.; Boccaccini, A.R.; Shaffer, M.S.P. Electrophoretic deposition of graphene-related materials: A review of the fundamentals. Prog. Mater. Sci. 2016, 82, 83–117. [Google Scholar] [CrossRef]

- Chavez-Valdez, A.; Shaffer, M.S.P.; Boccaccini, A.R. Applications of graphene electrophoretic deposition. A review. J. Phys. Chem. B 2013, 117, 1502–1515. [Google Scholar] [CrossRef] [PubMed]

- Gojny, F.H.; Wichmann, M.H.; Fiedler, B.; Kinloch, I.A.; Bauhofer, W.; Windle, A.H.; Schulte, K. Evaluation and identification of electrical and thermal conduction mechanisms in carbon nanotube/epoxy composites. Polymer 2006, 47, 2036–2045. [Google Scholar] [CrossRef]

- Kim, Y.J.; Shin, T.S.; Do Choi, H.; Kwon, J.H.; Chung, Y.-C.; Yoon, H.G. Electrical conductivity of chemically modified multiwalled carbon nanotube/epoxy composites. Carbon 2005, 43, 23–30. [Google Scholar] [CrossRef]

- Feng, C.; Jiang, L. Micromechanics modeling of bi-axial stretching effects on the electrical conductivity of cnt-polymer composites. Int. J. Appl. Mech. 2015, 7, 1550005. [Google Scholar] [CrossRef]

- Hu, N.; Masuda, Z.; Yan, C.; Yamamoto, G.; Fukunaga, H.; Hashida, T. The electrical properties of polymer nanocomposites with carbon nanotube fillers. Nanotechnology 2008, 19, 215701. [Google Scholar] [CrossRef] [PubMed]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Feng, C.; Jiang, L. Investigation of uniaxial stretching effects on the electrical conductivity of cnt–polymer nanocomposites. J. Phys. D Appl. Phys. 2014, 47, 405103. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Feng, C.; Jiang, L.Y. Micromechanics modeling of the electrical conductivity of carbon nanotube (cnt)-polymer nanocomposites. Compos. Part A Appl. Sci. Manuf. 2013, 47, 143–149. [Google Scholar] [CrossRef]

- Chizari, K.; Daoud, M.A.; Ravindran, A.R.; Therriault, D. 3d printing of highly conductive nanocomposites for the functional optimization of liquid sensors. Small 2016, 12, 6076–6082. [Google Scholar] [CrossRef] [PubMed]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Zhang, J.; Mouritz, A.P.; Wang, C.H. Multifunctional properties of epoxy nanocomposites reinforced by aligned nanoscale carbon. Mater. Des. 2016, 94, 554–564. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, J.; Ladani, R.B.; Ravindran, A.R.; Mouritz, A.P.; Kinloch, A.J.; Wang, C.H. Novel electrically conductive porous pdms/carbon nanofiber composites for deformable strain sensors and conductors. ACS Appl. Mater. Interfaces 2017, 9, 14207–14215. [Google Scholar] [CrossRef] [PubMed]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Mouritz, A.P.; Wang, C.H. Enhancing fatigue resistance and damage characterisation in adhesively-bonded composite joints by carbon nanofibres. Compos. Sci. Technol. 2017, 149, 116–126. [Google Scholar] [CrossRef]

- Du, X.; Zhou, H.; Sun, W.; Liu, H.-Y.; Zhou, G.; Zhou, H.; Mai, Y.-W. Graphene/epoxy interleaves for delamination toughening and monitoring of crack damage in carbon fibre/epoxy composite laminates. Compos. Sci. Technol. 2017, 140, 123–133. [Google Scholar] [CrossRef]

- Krushnamurty, K.; Rini, M.; Srikanth, I.; Ghosal, P.; Das, A.P.; Deepa, M.; Subrahmanyam, C. Conducting polymer coated graphene oxide reinforced c–epoxy composites for enhanced electrical conduction. Compos. Part A Appl. Sci. Manuf. 2016, 80, 237–243. [Google Scholar] [CrossRef]

- Savchak, M.; Borodinov, N.; Burtovyy, R.; Anayee, M.; Hu, K.; Ma, R.; Grant, A.; Li, H.; Cutshall, D.B.; Wen, Y.; et al. Highly conductive and transparent reduced graphene oxide nanoscale films via thermal conversion of polymer-encapsulated graphene oxide sheets. ACS Appl. Mater. Interfaces 2018, 10, 3975–3985. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.; Hao, J.; Wang, Y.; Zhong, Z.; Weng, G.J. Theory of electrical conductivity and dielectric permittivity of highly aligned graphene-based nanocomposites. J. Phys. Condens. Matter 2017, 29, 205702. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.; Zhong, Z.; Weng, G.J. Maxwell–wagner–sillars mechanism in the frequency dependence of electrical conductivity and dielectric permittivity of graphene-polymer nanocomposites. Mech. Mater. 2017, 109, 42–50. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Zheng, W.-G.; Yan, Q.; Yang, Y.; Wang, J.-W.; Lu, Z.-H.; Ji, G.-Y.; Yu, Z.-Z. Electrically conductive polyethylene terephthalate/graphene nanocomposites prepared by melt compounding. Polymer 2010, 51, 1191–1196. [Google Scholar] [CrossRef]

- Cui, L.; Lu, X.; Chao, D.; Liu, H.; Li, Y.; Wang, C. Graphene-based composite materials with high dielectric permittivity via an in situ reduction method. Phys. Status Solidi (a) 2011, 208, 459–461. [Google Scholar] [CrossRef]

- Yousefi, N.; Sun, X.Y.; Lin, X.Y.; Shen, X.; Jia, J.J.; Zhang, B.; Tang, B.Z.; Chan, M.S.; Kim, J.K. Highly aligned graphene/polymer nanocomposites with excellent dielectric properties for high-performance electromagnetic interference shielding. Adv. Mater. 2014, 26, 5480–5487. [Google Scholar] [CrossRef] [PubMed]

- Fan, P.; Wang, L.; Yang, J.; Chen, F.; Zhong, M. Graphene/poly (vinylidene fluoride) composites with high dielectric constant and low percolation threshold. Nanotechnology 2012, 23, 365702. [Google Scholar] [CrossRef] [PubMed]

- Cauchy, X.; Klemberg-Sapieha, J.E.; Therriault, D. Synthesis of highly conductive, uniformly silver-coated carbon nanofibers by electroless deposition. ACS Appl. Mater. Interfaces 2017, 9, 29010–29020. [Google Scholar] [CrossRef] [PubMed]

- Gagné, M.; Therriault, D. Lightning strike protection of composites. Prog. Aerosp. Sci. 2014, 64, 1–16. [Google Scholar] [CrossRef]

- Pegorin, F.; Pingkarawat, K.; Mouritz, A.P. Electrical-based delamination crack monitoring in composites using z-pins. Compos. Part A Appl. Sci. Manuf. 2018, 104, 120–128. [Google Scholar] [CrossRef]

- Pegorin, F.; Pingkarawat, K.; Mouritz, A.P. Controlling the electrical conductivity of fibre-polymer composites using z-pins. Compos. Sci. Technol. 2017, 150, 167–173. [Google Scholar] [CrossRef]

- West System Engineering Data. Available online: http://atlcomposites.com.au/icart/products/44/images/main/WEST%20SYSTEM%20R105.pdf (accessed on 5 January 2018).

- Ravindran, A.R.; Ladani, R.B.; Wu, S.; Kinloch, A.J.; Wang, C.H.; Mouritz, A.P. The electric field alignment of short carbon fibres to enhance the toughness of epoxy composites. Compos. Part A Appl. Sci. Manuf. 2018, 106, 11–23. [Google Scholar] [CrossRef]

- Ladani, R.B.; Ravindran, A.R.; Wu, S.; Pingkarawat, K.; Kinloch, A.J.; Mouritz, A.P.; Ritchie, R.O.; Wang, C.H. Multi-scale toughening of fibre composites using carbon nanofibres and z-pins. Compos. Sci. Technol. 2016, 131, 98–109. [Google Scholar] [CrossRef]

- ASTM. ASTM D3380-14. In Standard Test Method for Relative Permittivity (Dielectric Constant) and Dissipation Factor of Polymer-Based Microwave Circuit Substrates; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Buhr, E.; Senftleben, N.; Klein, T.; Bergmann, D.; Gnieser, D.; Frase, C.G.; Bosse, D. Characterization of nanoparticles by scanning electron microscopy in transmission mode. Meas. Sci. Technol. 2009, 20, 084025. [Google Scholar] [CrossRef]

- Noh, Y.J.; Joh, H.I.; Yu, J.; Hwang, S.H.; Lee, S.; Lee, C.H.; Kim, S.Y.; Youn, J.R. Ultra-high dispersion of graphene in polymer composite via solvent free fabrication and functionalization. Sci. Rep. 2015, 5, 9141. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.; Wang, Y.; Zhong, Z.; Weng, G.J. A frequency-dependent theory of electrical conductivity and dielectric permittivity for graphene-polymer nanocomposites. Carbon 2017, 111, 221–230. [Google Scholar] [CrossRef]

- Kim, G.; Shkel, Y.M. Polymeric composites tailored by electric field. J. Mater. Res. 2004, 19, 1164–1174. [Google Scholar] [CrossRef]

- Qin, Z.; Taylor, M.; Hwang, M.; Bertoldi, K.; Buehler, M.J. Effect of wrinkles on the surface area of graphene: Toward the design of nanoelectronics. Nano Lett. 2014, 14, 6520–6525. [Google Scholar] [CrossRef] [PubMed]

- Ayatollahi, M.R.; Shadlou, S.; Shokrieh, M.M.; Chitsazzadeh, M. Effect of multi-walled carbon nanotube aspect ratio on mechanical and electrical properties of epoxy-based nanocomposites. Polym. Test. 2011, 30, 548–556. [Google Scholar] [CrossRef]

| Sample | Dielectric Constant | Improvement (%) | AC Electrical Conductivity (S m−1) | Improvement (%) |

|---|---|---|---|---|

| Effect of GNP (C-300 series) content in epoxy | ||||

| Neat Epoxy (unmodified) | 6.31 (±0.12) | - | 3.69 × 10−7 (±0.29 × 10−7) | - |

| 0.10 wt % GNP | 6.31 (±0.14) | - | 3.69 × 10−7 (±0.14 × 10−7) | - |

| 0.50 wt % GNP | 6.44 (±0.07) | 2.0% | 4.05 × 10−7 (±0.11 × 10−7) | 9.9% |

| 1.00 wt % GNP | 6.69 (±0.13) | 5.9% | 4.24 × 10−7 (±0.18 × 10−7) | 15.0% |

| 1.50 wt % GNP | 6.85 (±0.11) | 8.4% | 4.31 × 10−7 (±0.32 × 10−7) | 16.9% |

| 2.00 wt % GNP | 7.18 (±0.08) | 13.6% | 4.56 × 10−7 (±0.12 × 10−7) | 23.5% |

| 5.00 wt % GNP | 7.32 (±0.08) | 16.1% | 5.19 × 10−7 (±0.25 × 10−7) | 40.6% |

| 10.0 wt % GNP | 20.2 (±0.35) | 220% | 1.25 × 10−6 (±0.08 × 10−6) | 239.5% |

| 20.0 wt % GNP | 81.1 (±0.91) | 1180% | 6.84 × 10−6 (±0.11 × 10−6) | 1750% |

| Effect of supplied GNP surface area (C-series) at 10 wt % in epoxy | ||||

| Neat Epoxy (unmodified) | 6.31 (±0.12) | - | 3.69 × 10−7 (±0.29 × 10−7) | - |

| 300 m2 g−1 GNP | 20.2 (±0.41) | 220% | 1.25 × 10−6 (±0.08 × 10−6) | 240% |

| 500 m2 g−1 GNP | 36.1 (±0.85) | 470% | 4.29 × 10−6 (±0.13 × 10−6) | 1060% |

| 750 m2 g−1 GNP | 32.7 (±0.61) | 420% | 8.76 × 10−6 (±0.12 × 10−6) | 2270% |

| Effect of supplied GNP diameter (H-series) at 10 wt % in epoxy | ||||

| Neat Epoxy (unmodified) | 6.31 (±0.12) | - | 3.69 × 10−7 (±0.29 × 10−7) | - |

| 5 µm | 467 (±2.8) | 7280% | 1.75 × 10−5 (±0.14 × 10−5) | 4630% |

| 15 µm | 438 (±3.1) | 6840% | 1.05 × 10−4 (±0.21 × 10−4) | 28,500% |

| 25 µm | 280 (±2.7) | 4320% | 2.80 × 10−4 (±0.17 × 10−4) | 75,800% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ravindran, A.R.; Feng, C.; Huang, S.; Wang, Y.; Zhao, Z.; Yang, J. Effects of Graphene Nanoplatelet Size and Surface Area on the AC Electrical Conductivity and Dielectric Constant of Epoxy Nanocomposites. Polymers 2018, 10, 477. https://doi.org/10.3390/polym10050477

Ravindran AR, Feng C, Huang S, Wang Y, Zhao Z, Yang J. Effects of Graphene Nanoplatelet Size and Surface Area on the AC Electrical Conductivity and Dielectric Constant of Epoxy Nanocomposites. Polymers. 2018; 10(5):477. https://doi.org/10.3390/polym10050477

Chicago/Turabian StyleRavindran, Anil Raj, Chuang Feng, Shu Huang, Yu Wang, Zhan Zhao, and Jie Yang. 2018. "Effects of Graphene Nanoplatelet Size and Surface Area on the AC Electrical Conductivity and Dielectric Constant of Epoxy Nanocomposites" Polymers 10, no. 5: 477. https://doi.org/10.3390/polym10050477

APA StyleRavindran, A. R., Feng, C., Huang, S., Wang, Y., Zhao, Z., & Yang, J. (2018). Effects of Graphene Nanoplatelet Size and Surface Area on the AC Electrical Conductivity and Dielectric Constant of Epoxy Nanocomposites. Polymers, 10(5), 477. https://doi.org/10.3390/polym10050477