High Mechanical and Thermal Properties of Epoxy Composites with Liquid Crystalline Polyurethane Modified Graphene

Abstract

:1. Instruction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Biphenylnate Liquid Crystalline (BP6)

2.3. Synthesis of the Perylene Bisimide Derivatives

2.4. Preparation of GNs/PBI-OH/Liquid Crystalline Polyurethane (GPLP)

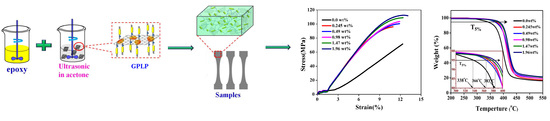

2.5. Preparation of Epoxy/GPLP Composites

2.6. Characterization

3. Results and Discussion

3.1. Characterization of the BP6, PBI-OH, and GPLP

3.2. Thermal Dynamic Properties of Epoxy/GPLP Composites

3.3. The Morphologies of the Fracture Surfaces of Epoxy/GPLP Composites

3.4. Thermal Properties of Epoxy/GPLP Composites

3.5. Mechanical Properties of Epoxy/GPLPcomposites

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Singh, V.; Joung, D.; Zhai, L.; Das, S.; Khondaker, S.I.; Seal, S. Graphene based materials: Past, present and future. Prog. Mater. Sci. 2011, 56, 1178–1271. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/Polymer Nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Tan, Y.W.; Stormer, H.L.; Kim, P. Experimental observation of the quantum Hall effect and Berry’s phase in graphene. Nature 2005, 438, 201–204. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Multifunctional graphene nanoplatelets/cellulose nanocrystals composite paper. Compos. Part B 2015, 79, 521–529. [Google Scholar] [CrossRef]

- Bolotin, K.I.; Sikes, K.J.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H.L. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.B.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Niyogi, S.; Bekyarova, E.; Itkis, M.E.; Mcwilliams, J.L.; Hamon, M.A.; Haddon, R.C. Solution properties of graphite and graphene. J. Am. Chem. Soc. 2006, 128, 7720–7721. [Google Scholar] [CrossRef] [PubMed]

- Ni, Y.; Chen, L.; Teng, K.; Shi, J.; Qian, X.; Xu, Z.; Tian, X.; Hu, C.; Ma, M. Superior Mechanical Properties of Epoxy Composites Reinforced by 3D Interconnected Graphene Skeleton. ACS Appl. Mater. Interfaces 2015, 7, 11583–11591. [Google Scholar] [CrossRef] [PubMed]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/Polyurethane Nanocomposites for Improved Gas Barrier and Electrical Conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.A.; Song, L.; Yang, H.Y.; Xing, W.Y.; Lu, H.D. In situ polymerization of graphene nanosheets and polyurethane with enhanced mechanical and thermal properties. J. Mater. Chem. 2011, 21, 4222–4227. [Google Scholar] [CrossRef]

- Yang, H.; Li, F.; Shan, C.; Han, D.; Zhang, Q.; Niu, L.; Ivaska, A. Covalent functionalization of chemically converted graphene sheets via silane and its reinforcement. J. Mater. Chem. 2009, 19, 4632–4638. [Google Scholar] [CrossRef]

- Wan, Y.; Tang, L.; Gong, L.; Yan, D.; Li, Y.; Wu, L.; Jiang, J.; Lai, G. Grafting of epoxy chains onto graphene oxide for epoxy composites with improved mechanical and thermal properties. Carbon 2014, 69, 467–480. [Google Scholar] [CrossRef]

- Lyu, Q.; Yan, H.; Li, L.; Chen, Z.; Yao, H.; Nie, Y. Imidazolium Ionic Liquid Modified Graphene Oxide: As a Reinforcing Filler and Catalyst in Epoxy Resin. Polymers 2017, 9, 447. [Google Scholar] [CrossRef]

- Teng, C.C.; Ma, C.C.M.; Lu, C.H.; Yang, S.Y.; Lee, S.H.; Hsiao, M.C.; Yen, M.Y.; Chiou, K.C.; Lee, T.M. Thermal conductivity and structure of non-covalent functionalized graphene/epoxy composites. Carbon 2011, 49, 5107–5116. [Google Scholar] [CrossRef]

- Liu, J.; Yang, W.; Tao, L.; Li, D.; Boyer, C.; Davis, T.P. Thermosensitive graphene nanocomposites formed using pyrene-terminal polymers made by RAFT polymerization. J. Polym. Sci. Part A 2010, 48, 425–433. [Google Scholar] [CrossRef]

- Stankovich, S.; Piner, R.D.; Chen, X.; Wu, N.; Nguyen, S.B.T.; Ruoff, R.S. Stable aqueous dispersions of graphitic nanoplatelets via the reduction of exfoliated graphite oxide in the presence of poly(sodium 4-styrenesulfonate). J. Mater. Chem. 2005, 16, 155–158. [Google Scholar] [CrossRef]

- Li, P.; White, K.L.; Lin, C.H.; Kim, D.; Muliana, A.; Krishnamoorti, R.; Nishimura, R.; Sue, H.J. Mechanical Reinforcement of Epoxy with Self-Assembled Synthetic Clay in Smectic Order. ACS Appl. Mater. Interfaces 2014, 6, 10188–10195. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.Q.; Pan, D.Y.; Chen, S.B.; Wang, Q.H.; Pan, G.Q.; Wang, T.M. In situ polymerization and mechanical, thermal properties of polyurethane/graphene oxide/epoxy nanocomposites. Mater. Des. 2013, 47, 850–856. [Google Scholar] [CrossRef]

- Gao, J.; Yu, J.H.; Wu, X.F.; Rao, B.L.; Song, L.F.; He, Z.H.; Lu, S.R. Enhanced thermal properties for epoxy composites with a three-dimensional graphene oxide filler. Fib. Polym. 2015, 16, 2617–2626. [Google Scholar] [CrossRef]

- Sun, L.Y.; Boo, W.J.; Sun, D.Z.; Clearfield, A.A.; Sue, H.J. Preparation of α-zirconium phosphate nanoplatelets with wide variations in aspect ratios. New J. Chem. 2006, 31, 39–43. [Google Scholar] [CrossRef]

- Luo, Q.Y.; Li, Y.Q.; Pan, L.L.; Song, L.F.; Yang, J.; Wu, L.Y.; Lu, S.R. Effective reinforcement of epoxy composites with hyperbranched liquid crystals grafted on microcrystalline cellulose fibers. J. Mater. Sci. 2016, 51, 8888–8899. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Loh, K.P.; Bao, Q.; Eda, G.; Chhowalla, M. Graphene oxide as a chemically tunable platform for optical applications. Nat. Chem. 2010, 2, 1015–1024. [Google Scholar] [CrossRef] [PubMed]

- Eda, G.; Chhowalla, M. Chemically derived graphene oxide: Towards large-area thin-film electronics and optoelectronics. Adv. Mater. 2010, 22, 2392–2415. [Google Scholar] [CrossRef] [PubMed]

- Dutta, P.; Nandi, D.; Datta, S.; Chakraborty, S.; Das, N.; Chatterjee, S.; Ghosh, U.C.; Halder, A. Excitation wavelength dependent UV fluorescence of dispersed modified graphene oxide: Effect of pH. J. Lumin. 2015, 168, 269–275. [Google Scholar] [CrossRef]

- Krongauz, V.V. Crosslink density dependence of polymer degradation kinetics: Photocrosslinked acrylates. Thermochim. Acta 2010, 503–504, 70–84. [Google Scholar] [CrossRef]

- Rahman, M.M.; Zainuddin, S.; Hosur, M.V.; Robertson, C.J.; Kumar, A.; Trovillion, J.; Jeelani, S. Effect of NH2-MWCNTs on crosslink density of epoxy matrix and ILSS properties of e-glass/epoxy composites. Compos. Struct. 2013, 95, 213–221. [Google Scholar] [CrossRef]

- Xia, Y.; Larock, R.C. Castor oil-based thermosets with varied crosslink densities prepared by ring-opening metathesis polymerization (ROMP). Polymer 2010, 51, 2508–2514. [Google Scholar] [CrossRef]

- Bindu, S.T.K.; Nair, A.B.; Abraham, B.T.; Beegum, P.M.S.; Thachil, E.T. Microwave exfoliated reduced graphene oxide epoxy nanocomposites for high performance applications. Polymer 2014, 55, 3614–3627. [Google Scholar]

- Zhang, Y.L.; Wang, Y.; Yu, J.R.; Chen, L.; Zhu, J.; Hu, Z.M. Tuning the interface of graphene platelets/epoxy composites by the covalent grafting of polybenzimidazole. Polymer 2014, 55, 4990–5000. [Google Scholar] [CrossRef]

- Ahmadi-Moghadam, B.; Sharafimasooleh, M.; Shadlou, S.; Taheri, F. Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites. Mater. Des. 2015, 66, 142–149. [Google Scholar] [CrossRef]

- Fernández-Francos, X.; Ramis, X. Structural analysis of the curing of epoxy thermosets crosslinked with hyperbranched poly(ethyleneimine)s. Eur. Polym. J. 2015, 70, 286–305. [Google Scholar] [CrossRef] [Green Version]

| Specimen Category | Storage Modulus, E (MPa) at 50 °C | Glass Transition Temperature, Tg (°C) | Storage Modulus, E′ (MPa) at Tg + 50 °C | Crosslink Density, Ve (mol/m3) |

|---|---|---|---|---|

| 0.0 wt % | 2097 | 155 | 10.16 | 852.2 |

| 0.245 wt % | 2046 | 185 | 21.74 | 1715.8 |

| 0.49 wt % | 2158 | 184 | 22.98 | 1810.9 |

| 0.98 wt % | 2254 | 187 | 25.39 | 1996.0 |

| 1.47 wt % | 2210 | 187 | 26.97 | 2120.2 |

| 1.96 wt % | 2325 | 188 | 28.79 | 2258.9 |

| GNs Content | Impact Strength (kJ/m2) | Tensile Strength (MPa) | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|---|---|

| 0.0 wt % | 17.50 ± 0.92 | 71.51 ± 1.33 | 79.5 ± 2.5 | 1840 ± 40 |

| 0.245 wt % | 41.53 ± 1.16 | 96.00 ± 2.21 | 114.8 ± 0.3 | 2825 ± 30 |

| 0.49 wt % | 48.19 ± 0.75 | 100.45 ± 2.99 | 118.8 ± 3.8 | 2970 ± 15 |

| 0.98 wt % | 48.89 ± 2.26 | 103.45 ± 2.23 | 122.5 ± 4.5 | 2947 ± 18 |

| 1.47 wt % | 50.68 ± 0.92 | 108.84 ± 3.83 | 126.8 ± 4.0 | 3214 ± 32 |

| 1.96 wt % | 54.31 ± 1.41 | 112.33 ± 3.47 | 125.3 ± 3.6 | 3525 ± 50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Gao, J.; Li, X.; Xu, X.; Lu, S. High Mechanical and Thermal Properties of Epoxy Composites with Liquid Crystalline Polyurethane Modified Graphene. Polymers 2018, 10, 485. https://doi.org/10.3390/polym10050485

Li Y, Gao J, Li X, Xu X, Lu S. High Mechanical and Thermal Properties of Epoxy Composites with Liquid Crystalline Polyurethane Modified Graphene. Polymers. 2018; 10(5):485. https://doi.org/10.3390/polym10050485

Chicago/Turabian StyleLi, Yuqi, Jian Gao, Xiuyun Li, Xu Xu, and Shaorong Lu. 2018. "High Mechanical and Thermal Properties of Epoxy Composites with Liquid Crystalline Polyurethane Modified Graphene" Polymers 10, no. 5: 485. https://doi.org/10.3390/polym10050485

APA StyleLi, Y., Gao, J., Li, X., Xu, X., & Lu, S. (2018). High Mechanical and Thermal Properties of Epoxy Composites with Liquid Crystalline Polyurethane Modified Graphene. Polymers, 10(5), 485. https://doi.org/10.3390/polym10050485