Laboratory Investigation of Shear Behavior of High-Density Polyethylene Geomembrane Interfaces

Abstract

:1. Introduction

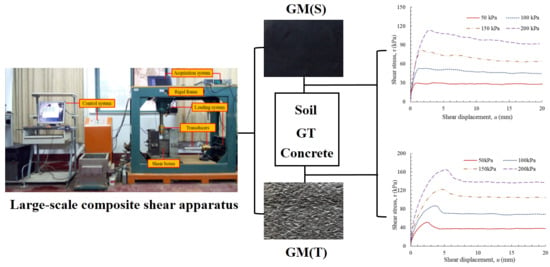

2. Test Apparatus and Scheme

- Upper shear box: ① For the GM–soil interface shear tests, a 360 mm × 360 mm × 100 mm upper square box with an inner cylindrical hole of diameter 300 mm was employed. The cylindrical loading area was chosen to avoid stress concentration. The soils were poured into cylindrical hole of the upper box in several layers and compacted using a hammer to attain the design density. ② For the GM–GT interface shear tests, the geotextile sample was fixed on a rigid, trapezoidal block that served as the upper box, and was then placed on the lower box. The upper box had smaller dimensions than the lower box to prevent displacement-induced loss of the area of the GM–GT interface during measurement. ③ For the GM–concrete interface shear tests, the concrete blocks were prepared with dimensions of 300 mm × 300 mm × 100 mm and were placed directly on the lower box during the shear tests. All upper shear boxes were fixed while the lower shear box moved horizontally. All upper shear boxes were fixed in space in horizontal direction, but it could freely move vertically during shearing.

- Lower shear box: The lower shear box was made of a 360 mm × 360 mm × 80 mm rigid block with an inner cylindrical hole of diameter 300 mm. A rigid cylindrical block was inserted in this cylindrical hole to form a smooth horizontal plane (Figure 2) when the GM interface shear tests are conducted. The GM sample was cut into a rectangle of size 480 mm × 300 mm. The rectangle sample was then glued onto the lower box and laterally clamped using four bolts and two steel blocks to prevent the sample from sliding. During the whole shearing process, there is no area loss for different GM interfaces. Further, when the rigid cylindrical block is removed, it could also be used for soil shearing tests with a corresponding upper shear box.

- Loading system: The loading system was comprised of a vertical actuator and a horizontal actuator. Vertical pressure was applied to the upper shear box through a pressure rod within a range of 0 kN to 100 kN. The shear force was horizontally applied to the lower shear box through a pull-rod at a displacement-controlled shear rate between 0.01 mm/min and 5.00 mm/min. The pull-rod could also act as a push-rod when the shear direction was reversed in cyclic shear tests. The precision error of the loading system was less than 1%.

- Acquisition system: Pressure and displacement transducers were employed for the automatic acquisition of the normal pressure, shear force, and shear displacement. The experimental data were recorded using a data logger. A personal computer was used to control the data logger and to store and manipulate the recorded information. The test curves of normal stress versus shear displacement were plotted automatically. Figure 3 shows the typical test curves for both monotonic and cyclic shear tests.

3. Test Materials

4. Test Results

4.1. GM–Soil Interface

4.2. GM–GT Interface

4.3. GM–Concrete Interface

5. Comparison and Discussion

5.1. GM–Soil Interface

5.2. GM–GT Interface

5.3. GM–Concrete Interface

6. Conclusions

- (1)

- The shear strength curves of GM–soil interfaces are clearly influenced by GM texturing. Compared to GM(S)–soil interfaces, higher peak shear stresses and corresponding shear displacements were observed for the GM(T)–soil interfaces. In general, the friction angles of the GM(T)–soil interfaces are 12–15% higher than those of GM(S)–soil interfaces. The friction angles of the GM–FS interface are typically lower than those of the GM–SG interface, owing to the effect of the gradation and particle size of these two types of soil. When compared to the results of previous studies, the strength parameters of the present study are in the range of typically observed values.

- (2)

- The shear behavior of the GM–GT interface is also affected by GM texturing. The experimental curves present an apparent difference in behavior between the GM(S)–GT and GM(T)–GT interfaces. The GM(T)–GT interface exhibits a more evident softening behavior, with a higher reduction in the peak shear stress than the GM(S)–GT interface. The friction angles of the GM(T)–GT interface are 6°–8° higher than those of the GM(S)–GT interface. The peak friction angle of the GM–GT interface in this study is approximately equal to the values in some previously reported studies.

- (3)

- The peak friction angle and adhesion of the GM(S)–OC interface are 17.57° and 1.83 kPa, respectively, and those of the GM(T)–OC interface are 18.81° and 2.1 kPa, respectively. Therefore, it can be stated that GM texturing exerts a negligible influence on the peak shear behavior of the GM–OC interface. By contrast, GM texturing increases the peak shear strength of the GM–NFC interface. The post-peak shear resistances of the GM–NFC interfaces remain approximately constant, notwithstanding the large shear displacement. Additionally, the friction angles of the GM–NFC interfaces are 2°–5° lower than those of the GM–OC interfaces, which may be attributed to the fact that the effective contact per unit area of the GM–NFC interface is smaller than that of the GM–OC interface.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Koerner, G.R.; Koerner, R.M. Long-term temperature monitoring of geomembranes at dry and wet landfills. Geotext. Geomembr. 2006, 241, 72–77. [Google Scholar] [CrossRef]

- Koerner, R.M. Designing with Geosynthetics, 6th ed.; Xlibris Corporation: Bloomington, IN, USA, 2012; Volume 1. [Google Scholar]

- Giroud, J.P. Geotextiles and geomembranes. Geotext. Geomembr. 1984, 1, 5–40. [Google Scholar] [CrossRef]

- Izgin, M.; Wasti, Y. Geomembrane–sand interface frictional properties as determined by inclined board and shear box tests. Geotext. Geomembr. 1998, 16, 207–219. [Google Scholar] [CrossRef]

- Wasti, Y.; Özdüzgün, Z.B. Geomembrane-geotextile interface shear properties as determined by inclined board and direct shear box tests. Geotext. Geomembr. 2001, 19, 45–57. [Google Scholar] [CrossRef]

- Stark, T.D.; Williamson, T.A.; Eid, H.T. HDPE geomembrane/geotextile interface shear strength. J. Geotech. Eng. 1996, 122, 197–203. [Google Scholar] [CrossRef]

- Jones, D.R.V.; Dixon, N. Shear strength properties of geomembrane/geotextile interfaces. Geotext. Geomembr. 1998, 16, 45–71. [Google Scholar] [CrossRef]

- Eid, H.T. Shear strength of geosynthetic composite systems for design of landfill liner and cover slopes. Geotext. Geomembr. 2011, 29, 335–344. [Google Scholar] [CrossRef]

- Stark, T.D.; Poeppel, A.R. Landfill liner interface strengths from torsional-ring-shear tests. J. Geotech. Eng. 1994, 120, 597–615. [Google Scholar] [CrossRef]

- Zabielsk-Adamska, K. Shear strength parameters of compacted fly ash–HDPE geomembrane interfaces. Geotext. Geomembr. 2006, 24, 91–102. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Seed, R.B.; Seed, H.B. Kettleman Hills waste landfill slope failure. I: Liner-System Properties. J. Geotech. Eng. 1990, 116, 647–668. [Google Scholar] [CrossRef]

- Triplett, E.J.; Fox, P.J. Shear strength of HDPE geomembrane/geosynthetic clay liner interfaces. J. Geotech. Geoenviron. Eng. 2001, 127, 543–552. [Google Scholar] [CrossRef]

- Chiu, P.; Fox, P.J. Internal and interface shear strengths of unreinforced and needle-punched geosynthetic clay liners. Geosynth. Int. 2004, 11, 176–199. [Google Scholar] [CrossRef]

- Hebeler, G.L.; Frost, J.D.; Myers, A.T. Quantifying hook and loop interaction in textured geomembrane–geotextile systems. Geotext. Geomembr. 2005, 23, 77–105. [Google Scholar] [CrossRef]

- McCartney, J.S.; Zornberg, J.G.; Swan, R.H. Effect of geomembrane texturing on GCL–geomembrane interface shear strength. In Waste Containment and Remediation–GeoFrontiers; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2005; pp. 1–11. [Google Scholar]

- Bergado, D.T.; Ramana, G.V.; Sia, H.I. Evaluation of interface shear strength of composite liner system and stability analysis for a landfill lining system in Thailand. Geotext. Geomembr. 2006, 24, 371–393. [Google Scholar] [CrossRef]

- Fleming, I.R.; Sharma, J.S.; Jogi, M.B. Shear strength of geomembrane–soil interface under unsaturated conditions. Geotext. Geomembr. 2006, 24, 274–284. [Google Scholar] [CrossRef]

- Li, M.H.; Gilbert, R.B. Technical note mechanism of post-peak strength reduction for textured geomembrane-nonwoven geotextile interfaces. Geosynth. Int. 2006, 13, 206–209. [Google Scholar] [CrossRef]

- Bacas, B.M.; Cañizal, J.; Konietzky, H. Shear strength behavior of geotextile/geomembrane interfaces. J. Rock Mech. Geotech. Eng. 2015, 7, 638–645. [Google Scholar] [CrossRef]

- Fox, P.J.; Ross, J.D. Relationship between NP GCL internal and HDPE GMX/NP GCL interface shear strengths. J. Geotech. Geoenviron. Eng. 2010, 137, 743–753. [Google Scholar] [CrossRef]

- Fox, P.J.; Ross, J.D.; Sura, J.M.; Thiel, R.S. Geomembrane damage due to static and cyclic shearing over compacted gravelly sand. Geosynth. Int. 2011, 18, 272–279. [Google Scholar] [CrossRef]

- Frost, J.D.; Kim, D.; Lee, S.W. Microscale geomembrane-granular material interactions. KSCE J. Civ. Eng. 2011, 16, 79–92. [Google Scholar] [CrossRef]

- Mariappan, S.; Kamon, M.; Ali, F.H.; Katsumi, T.; Akai, T.; Inui, T.; Nishimura, M. Performances of landfill liners under dry and wet conditions. Geotech. Geol. Eng. 2011, 29, 881. [Google Scholar] [CrossRef]

- Bacas, B.M.; Konietzky, H.; Berini, J.C.; Sagaseta, C. A new constitutive model for textured geomembrane/geotextile interfaces. Geotext. Geomembr. 2011, 29, 137–148. [Google Scholar] [CrossRef]

- Brachman, R.W.I.; Sabir, A. Long-term assessment of a layered-geotextile protection layer for geomembranes. J. Geotech. Geoenviron. Eng. 2012, 139, 752–764. [Google Scholar] [CrossRef]

- Fox, P.J.; Thielmann, S.S. Interface shear damage to a HDPE geomembrane. II: Gravel drainage layer. J. Geotech. Geoenviron. Eng. 2014, 140, 04014040. [Google Scholar] [CrossRef]

- Fox, P.J.; Thielmann, S.S.; Stern, A.N.; Athanassopoulos, C. Interface shear damage to a HDPE geomembrane. I: Gravelly compacted clay liner. J. Geotech. Geoenviron. Eng. 2014, 140, 04014039. [Google Scholar] [CrossRef]

- Feng, S.J.; Cheng, D. Shear strength between soil/geomembrane and geotextile/geomembrane interfaces. In Tunneling and Underground Construction; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2014. [Google Scholar]

- Feng, S.J.; Lu, S.F. Repeated shear behaviors of geotextile/geomembrane and geomembrane/clay interfaces. Environ. Earth Sci. 2016, 75, 273. [Google Scholar] [CrossRef]

- Vangla, P.; Gali, M.L. Shear behavior of sand-smooth geomembrane interfaces through micro-topographical analysis. Geotext. Geomembr. 2016, 44, 592–603. [Google Scholar] [CrossRef]

- ASTM Standards: D 5321-Standard Test Method for Determining the Coefficient of Soil and Geosynthetic or Geosynthetic and Geosynthetic Friction by the Direct Shear Method; Voluntary Organization: West Conshohocken, PA, USA, 2002.

- Stark, T.D.; Santoyo, R.F. Soil/geosynthetic interface strengths from torsional ring shear tests. In Proceedings of the Geotechnical Frontiers 2017, Orlando, FL, USA, 12–15 March 2017; pp. 260–268. [Google Scholar]

- Mariappan, S.; Kamon, M.; Ali, F.H.; Katsumi, T.; Akai, T. Landfill interface study on liner member selection for stability. Electron. J. Geotech. Eng. 2008, 13, 1–14. [Google Scholar]

- Akpinar, M.V.; Benson, C.H. Effect of temperature on shear strength of two geomembrane–geotextile interfaces. Geotext. Geomembr. 2005, 23, 443–453. [Google Scholar] [CrossRef]

| Soils | Density (g/cm3) | d10 (mm) | d30 (mm) | d60 (mm) | Coefficients of Uniformity Cu | Coefficients of Curvature Cc |

|---|---|---|---|---|---|---|

| Fine sand (FS) | 1.77 | 0.16 | 0.34 | 0.65 | 4.06 | 1.11 |

| Sandy gravel (SG) | 1.96 | 0.16 | 1.42 | 7.50 | 46.86 | 1.68 |

| Concretes | Size Range of Aggregate (mm) | Porosity (%) | Water–Cement Ratio (w/c) | Unit Weight (kg/m3) | ||

|---|---|---|---|---|---|---|

| Water | Cement | Aggregate | ||||

| Ordinary concrete (OC) | 5–10 | - | 0.5 | 190 | 404 | 1806 |

| No-fines concrete (NFC) | 5–20 | 20 | 0.3 | 113 | 378 | 1343 |

| Interface | Peak Shear Strength | Residual Shear Strength | ||||

|---|---|---|---|---|---|---|

| Friction Angle (°) | Adhesion (kPa) | Correlation Coefficient R2 | Friction Angle (°) | Adhesion (kPa) | Correlation Coefficient R2 | |

| GM(S)–FS | 28.96 | 0.50 | 0.9891 | 22.75 | 4.66 | 0.9857 |

| GM(T)–FS | 32.72 | 20.65 | 0.9875 | 31.14 | 17.25 | 0.9926 |

| GM(S)–SG | 30.62 | 1.86 | 0.9875 | 24.64 | 5.59 | 0.9769 |

| GM(T)–SG | 36.81 | 12.79 | 0.9983 | 33.81 | 3.35 | 0.9991 |

| GM(S)–GT | 11.61 | 0 | 0.9841 | 10.75 | 0 | 0.9684 |

| GM(T)–GT | 20.88 | 5.62 | 0.9981 | 16.37 | 0 | 0.9937 |

| GM(S)–OC | 17.57 | 1.83 | 0.9990 | 14.32 | 0 | 0.9919 |

| GM(T)–OC | 18.81 | 2.1 | 0.9985 | 16.29 | 0 | 0.9920 |

| GM(S)–NFC | 12.68 | 2.52 | 0.9965 | 12.54 | 1.26 | 0.9986 |

| GM(T)–NFC | 16.77 | 4.76 | 0.9985 | 14.94 | 4.39 | 0.9971 |

| Source | Normal Stress (kPa) | Interface | Peak shear Strength | Residual Shear Strength | ||

|---|---|---|---|---|---|---|

| Friction Angle (°) | Adhesion (kPa) | Friction Angle (°) | Adhesion (kPa) | |||

| Mitchell et al. [11] | 158, 316, 479 | GM(S)–concrete sand | 18 | - | - | - |

| GM(S)–Ottawa sand | 18 | - | - | - | ||

| GM(S)–Misa Schist sand | 17 | - | - | - | ||

| Izgin and Wasti [4] | 5–50 | GM(S)–Ottawa sand | 22 | 2.76 | - | - |

| GM(T)–Ottawa sand | 32 | 5.00 | - | - | ||

| GM(S)–Ottawa stone | 31 | 4.25 | - | - | ||

| GM(T)–Ottawa stone | 37 | 2.89 | - | - | ||

| Bergado et al. [16] | 150–400 | GM(S)–compacted clay | 10.5 | - | - | - |

| Fleming et al. [17] | - | GM(S)–Silty sand | 21.4–23.7 | 1.77–3.10 | 23.6–25.1 | −12.6–−2.38 |

| GM(S)–6% Sand-bentonite | 19.8–21.1 | 2.43–2.80 | 16.6–19.2 | 2.30–3.57 | ||

| Mariappan et al. [33] | 100, 200, 300 | GM(S)–Native soil | 15.6 | 0.00 | - | - |

| GM(T)–Native soil | 23 | 0.00 | - | - | ||

| Mariappan et al. [23] | 100, 200, 300 | GM(S)–Silt: bentonite (100:10) | 5.2 | 0.00 | - | - |

| GM(S)–Sand: bentonite (100:10) | 6.1 | 0.00 | - | - | ||

| GM(S)–Native soil | 19.8 | 0.00 | - | - | ||

| GM(T)–Silt: bentonite (100:10) | 9.1 | 0.00 | - | - | ||

| GM(T)–Sand: bentonite (100:10) | 10.9 | 0.00 | - | - | ||

| GM(T)–Native soil | 15.2 | 9.30 | - | - | ||

| Frost et al. [22] | 100, 300 | GM(S)–Ottawa 20/30 sand | 24.4–25.5 | - | 15.5–16.5 | - |

| GM(T)–Ottawa 20/30 sand | 37.5–40.2 | - | 22.8–27.0 | - | ||

| GM(S)–Blasting sand | 24.9–25.5 | - | 19.5–20.0 | - | ||

| GM(T)–Blasting sand | 37.1–37.2 | - | 26.2–27.2 | - | ||

| Stark and Santoyo [32] | 17, 50, 100, 200, 400 | GM(S)–Urbana glacial till | 13–14 | - | - | - |

| GM(T)–Urbana glacial till | 30–36 | - | - | - | ||

| GM(S)–Ottawa sand GM(T)–Ottawa sand | 19–22 27–32 | - - | - - | - - | ||

| Source | Shear Apparatus | Normal Stress (kPa) | GM(S)–GT Interface | GM(T)–GT Interface | ||

|---|---|---|---|---|---|---|

| Friction Angle (°) | Adhesion (kPa) | Friction Angle (°) | Adhesion (kPa) | |||

| Mitchell et al. [11] | A modified Karol–Warner direct shear testing apparatus | 158, 316, 479 | 6–11 | - | - | - |

| Stark et al. [6] | A modified Bromhead ring shear apparatus | 48, 96, 192, 285 | - | - | 32 | - |

| Triplett and Fox [12] | Pullout shear machine | 1–486 | 9.9 | 0.3 | 31.7 | 7.4 |

| Wasti and Özdüzgün [5] | Inclined board apparatus | 5–50 | 12.28 | 3.34 | 27 | 30 |

| Akpinar and Benson [34] | A double-interface shear device | 7.5–49.5 | 11.6–14.5 | - | 25.4–27.7 | - |

| Li and Gilbert [18] | A small-scale direct shear apparatus | - | - | - | 24–28 | - |

| Feng et al. [29] | A large direct shear test device | 50, 100, 200 | - | - | 22.8 | 5.62 |

| Present study | A large-scale composite apparatus | 50, 100, 150, 200 | 12.96 | -3.38 | 20.88 | 5.62 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cen, W.-J.; Wang, H.; Sun, Y.-J. Laboratory Investigation of Shear Behavior of High-Density Polyethylene Geomembrane Interfaces. Polymers 2018, 10, 734. https://doi.org/10.3390/polym10070734

Cen W-J, Wang H, Sun Y-J. Laboratory Investigation of Shear Behavior of High-Density Polyethylene Geomembrane Interfaces. Polymers. 2018; 10(7):734. https://doi.org/10.3390/polym10070734

Chicago/Turabian StyleCen, Wei-Jun, Hui Wang, and Ying-Jie Sun. 2018. "Laboratory Investigation of Shear Behavior of High-Density Polyethylene Geomembrane Interfaces" Polymers 10, no. 7: 734. https://doi.org/10.3390/polym10070734

APA StyleCen, W. -J., Wang, H., & Sun, Y. -J. (2018). Laboratory Investigation of Shear Behavior of High-Density Polyethylene Geomembrane Interfaces. Polymers, 10(7), 734. https://doi.org/10.3390/polym10070734