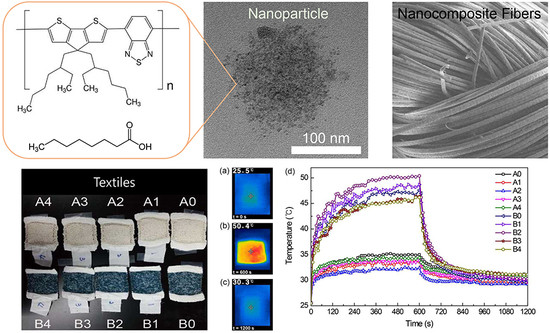

Machine-Washable Smart Textiles with Photothermal and Antibacterial Activities from Nanocomposite Fibers of Conjugated Polymer Nanoparticles and Polyacrylonitrile

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. CPN Preparation

2.3. Preparation of Nanocomposite Films, Fibers, and Textiles of PAN/CPNs

2.4. Characterization

2.5. Antibacterial Test

2.6. Washing by Launder-Ometer

3. Results and Discussion

3.1. Preparation of CPNs

3.2. Characterization of CPNs, Fibers, and Films

3.3. Characterization of Antibacterial Activity

3.4. Influence of Washing on Photothermal and Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef]

- Hu, J.; Meng, H.; Li, G.; Ibekwe, S.I. A review of stimuli-responsive polymers for smart textile applications. Smart Mater. Struct. 2012, 21, 053001. [Google Scholar] [CrossRef]

- Wenger, S.; Csapo, R.; Hasler, M.; Gatterer, H.; Wright, T.; Nachbauer, W. The effect of thermal insulation pads on heat flux, physical effort and perceived exertion during endurance exercise in cool environments. Fash. Text. 2018, 5. [Google Scholar] [CrossRef]

- Grancarić, A.M.; Jerković, I.J.; Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2018, 48, 612–642. [Google Scholar] [CrossRef]

- Ryan, J.D.; Mengistie, D.A.; Gabrielsson, R.; Lund, A.; Müller, C. Machine-washable PEDOT:PSS dyed silk yarns for electronic textiles. ACS Appl. Mater. Interfaces 2017, 9, 9045–9050. [Google Scholar] [CrossRef] [PubMed]

- Lund, A.; van der Velden, N.M.; Persson, N.-K.; Hamedi, M.M.; Müller, C. Electrically conducting fibres for E-textiles: An open playground for conjugated polymers and carbon nanomaterials. Mat. Sci. Eng. A-Struct. 2018, 126, 1–29. [Google Scholar] [CrossRef]

- Otley, M.T.; Alamer, F.A.; Guo, Y.; Santana, J.; Eren, E.; Li, M.; Lombardi, J.; Sotzing, G.A. Phase segregation of PEGOT:PSS on textile to produce materials of >10 A mm−2 current carrying capacity. Macromol. Mater. Eng. 2017, 302, 1600348. [Google Scholar] [CrossRef]

- Lee, T.H.; Kim, J.H.; Lee, J.Y. Fabrication of highly conductive fibers by metal ion-exchange using a simply modified wet-spinning process. Macromol. Res. 2017, 25, 1230–1236. [Google Scholar] [CrossRef]

- Andrew, T.L.; Zhang, L.; Cheng, N.; Baima, M.; Kim, J.J.; Allison, L.; Hoxie, S. Melding vapor-phase organic chemistry and textile manufacturing to produce wearable electronics. Acc. Chem. Res. 2018, 51, 850–859. [Google Scholar] [CrossRef]

- Kang, C.W.; Choi, J.; Ko, Y.-J.; Lee, S.M.; Kim, H.J.; Kim, J.P.; Son, S.U. Thin coating of microporous organic network makes a big difference: Sustainability issue of Ni electrodes on the PET textile for flexible lithium-ion batteries. ACS Appl. Mater. Interfaces 2017, 9, 36936–36943. [Google Scholar] [CrossRef]

- Müller, C.; Hamedi, M.; Karlsson, R.; Jansson, R.; Marcilla, R.; Hedhammar, M.; Inganäs, O. Woven electrochemical transistors on silk fibers. Adv. Mater. 2011, 23, 898–901. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.-C.; Wang, C.-T.; Liu, C.-L.; Liu, Y.-C.; Chen, W.-C. Full color light-emitting electrospun nanofibers prepared from PFO/MEH-PPV/PMMA ternary blends. J. Polym. Sci. B Polym. Phys. 2009, 47, 463–470. [Google Scholar] [CrossRef]

- Lu, L.; Zheng, T.; Wu, Q.; Schneider, A.M.; Zhao, D.; Yu, L. Recent advances in bulk heterojunction polymer solar cells. Chem. Rev. 2015, 115, 11666–12731. [Google Scholar] [CrossRef] [PubMed]

- Park, J. Visible and near infrared light active photocatalysis based on conjugated polymers. J. Ind. Eng. Chem. 2017, 51, 27–43. [Google Scholar] [CrossRef]

- Kahmann, S.; Fazzi, D.; Matt, G.J.; Thiel, W.; Loi, M.A.; Brabec, C.J. Polaron in narrow band gap polymers probed over the entire infrared range: A joint experimental and theoretical investigation. J. Phys. Chem. Lett. 2016, 7, 4438–4444. [Google Scholar] [CrossRef] [PubMed]

- Fischer, F.S.U.; Tremel, K.; Saur, A.-K.; Link, S.; Kayunkid, N.; Brinkmann, M.; Herrero-Carajal, D.; Navarrete, J.T.L.; Delgado, M.C.R.; Ludwigs, S. Influence of processing solvents on optical properties and morphology of a semicrystalline low bandgap polymer in the neutral and charged states. Macromolecules 2013, 46, 4924–4931. [Google Scholar] [CrossRef]

- Steyrleuthner, R.; Zhang, Y.; Zhang, L.; Kraffert, F.; Cherniawski, B.P.; Bittl, R.; Briseno, A.; Bredas, J.-L.; Behrends, J. Impact of morphology on polaron delocalization in a semicrystalline conjugated polymer. Phys. Chem. Chem. Phys. 2017, 19, 3627–3639. [Google Scholar] [CrossRef]

- Tautz, R.; Da Como, E.; Limmer, T.; Feldmann, J.; Egelhaaf, H.-J.; von Hauff, E.; Lemaur, V.; Beljonne, D.; Yilmaz, S.; Dumsch, I.; et al. Structural correlations in the generation of polaron Pairs in low-bandgap polymers for photovoltaics. Nat. Commun. 2012, 3, 970. [Google Scholar] [CrossRef]

- Di Nuzzo, D.; Viola, D.; Fischer, F.S.U.; Cerullo, G.; Ludwigs, S.; Da Como, E. Enhanced photogeneration of polaron Pairs in neat semicrystalline donor-acceptor copolymer films via direct excitation of interchain aggregates. J. Phys. Chem. Lett. 2015, 6, 1196–1203. [Google Scholar] [CrossRef]

- Bornbile, J.H.; Janik, M.J.; Milner, S.T. Polaron formation mechanisms in conjugated polymers. Phys. Chem. Chem. Phys. 2018, 20, 317–331. [Google Scholar] [CrossRef]

- Groff, L.C.; Jiang, Y.; Wang, X.; McNeil, J.D. Effect of swelling on multiple energy transfer in conjugated polymer nanoparticles. J. Phys. Chem. C 2017, 121, 7549–7557. [Google Scholar] [CrossRef]

- Cui, L.; Rao, J. Semiconducting polymer nanoparticles as photoacoustic molecular imaging probes. WIREs Nanomed. Nanobiotechnol. 2017, 9, e1418. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.; Kwag, J.; Shin, T.J.; Park, J.; Lee, Y.M.; Lee, Y.; Park, J.; Heo, J.; Joo, C.; Park, T.J.; et al. Nanoparticles of conjugated polymers prepared from phase-separated films of phospholipids and polymers for biomedical applications. Adv. Mater. 2014, 26, 4559–4564. [Google Scholar] [CrossRef] [PubMed]

- Kim, C.; Kim, S.-Y.; Lee, T.S. Synthesis of conjugated polymer nanoparticles with core-shell structure for cell imaging and photocynamic cancer therapy. Macromol. Res. 2017, 25, 572–577. [Google Scholar] [CrossRef]

- Zhang, L.; Baima, M.; Andrew, T.L. Transforming commercial textiles and threads into sewable and weavable electronic heaters. ACS Appl. Mater. Interfaces 2017, 9, 32299–32307. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Shin, T.J.; Yoo, P.J.; Oh, K.W.; Park, J. Conjugated polymer nano-ellipsoids assembled with octanoic acid and their polyurethane nanocomposites with simultaneous thermal storage and antibacterial activity. J. Ind. Eng. Chem. 2018, 63, 33–40. [Google Scholar] [CrossRef]

- McDonough, V.; Stukey, J.; Cavanagh, T. Mutations in erg4 affect the sensitivity of saccharomyces cerevisiae to medium-chain fatty acids. Biochim. Biophys. Acta 2002, 1581, 109–118. [Google Scholar] [CrossRef]

- Rodríguez-Moyá, M.; Gonzalez, R. Proteomic analysis of the response of escherichia coli to short-chain fatty acids. J. Proteomics 2015, 122, 86–99. [Google Scholar] [CrossRef]

- Huang, C.B.; Alimova, Y.; Myers, T.M.; Ebersole, J.L. Short- and medium-chain fatty acids exhibit antimicrobial activity for oral microorganisms. Arch. Oral Biol. 2011, 56, 650–654. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.; Kim, M.; Eo, K.; Hwang, D.; Choi, K.; Kwon, Y.K. Preparation and antimicrobial activity of silver nanoparticles immobilized on hollow mesoporous nanospheres. Macromol. Res. 2017, 25, 197–200. [Google Scholar] [CrossRef]

- Kim, T.-S.; Cha, J.-R.; Gong, M.-S. Preparation of silver-coated silk fabrics with antibacterial activity using silver carbamate and hydrogen reduction. Macromol. Res. 2017, 25, 856–863. [Google Scholar] [CrossRef]

- Bae, N.; Park, H.; Yoo, P.J.; Shin, T.J.; Park, J. Nanowires of amorphous conjugated polymers prepared via a surfactant-templating process using an alkylbenzoic acid. J. Ind. Eng. Chem. 2017, 51, 172–177. [Google Scholar] [CrossRef]

- Peet, J.; Kim, J.Y.; Coates, N.E.; Ma, W.L.; Moses, D.; Heeger, A.J.; Bazan, G.C. Efficiency enhancement in low-bandgap polymer solar cells by processing with alkane dithiols. Nat. Mater. 2007, 6, 497–500. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.K.; Lee, D.; Lee, S.Y.; Shin, T.J.; Park, J.; Ahn, D.J. Conjugated polymer nanoparticles in aqueous media by assembly with phospholipids via dense alkyl chain packing. Macromolecules 2017, 50, 6935–6944. [Google Scholar] [CrossRef]

- Seo, D.; Park, J.; Shin, T.J.; Yoo, P.J.; Park, J. Bathochromic shift in absorption spectra of conjugated polymer nanoparticles with displacement along backbones. Macromol. Res. 2015, 23, 574–577. [Google Scholar] [CrossRef]

- Fischer, F.S.U.; Trefz, D.; Back, J.; Kayunkid, N.; Tornow, B.; Albrecht, S.; Yager, K.G.; Singh, G.; Karim, A.; Neher, D.; et al. Highly crystalline films of PCPDTBT with branched side chains by solvent vapor crystallization: Influence on opto-electronic properties. Adv. Mater. 2015, 27, 1223–1228. [Google Scholar] [CrossRef] [PubMed]

- Fischer, F.S.U.; Kayunkid, N.; Trefz, D.; Ludwigs, S.; Brinkmann, M. Structural models of poly(cyclopentadithiophene-alt-benzothiadiazole) with branched side chains: Impact of a single fluorine atom on the crystal structure and polymorphism of a conjugated polymer. Macromolecules 2015, 48, 3974–3982. [Google Scholar] [CrossRef]

- Kim, J.S.; Kuk, E.; Yu, K.N.; Kim, J.H.; Park, S.J.; Lee, H.J.; Kim, S.H.; Park, Y.K.; Park, Y.H.; Hwang, C.Y.; et al. Antimicrobial effects of silver nanoparticles. Nanomed. Nanotechnol. Biol. Med. 2007, 3, 95–101. [Google Scholar] [CrossRef] [PubMed]

| Laundry Condition | Temperature (°C) | Time(min) | Detergent | Launder-Ometer |

|---|---|---|---|---|

| 0 | – | – | No washing | – |

| 1 | 40 ± 2 | 30 | 0.4 wt % standard | Used |

| 2 | 40 ± 2 | 30 | 0.4 wt % neutral | Used |

| 3 | 40 ± 2 | 30 | Not used | Used |

| 4 | 40 ± 2 | 30 | 0.4 wt % neutral | Not Used |

| Sample | Bacterium | Ma (CFU/mL) 1 | Mb (CFU/mL) | Mc (CFU/mL) | Antibacterial Activity (S) | Reduction of Bacteria (%) |

|---|---|---|---|---|---|---|

| PCPDTBT Film | S. aureus | 2.3 × 105 | 1.1 × 107 | 5.5 × 104 | 2.3 | 99.5 |

| PCPDTBT Film | E. coli | 2.3 × 105 | 1.2 × 107 | 3.6 × 104 | 2.5 | 99.7 |

| OA Film | S. aureus | 2.3 × 105 | 1.1 × 107 | <10 | 6 | 99.9 |

| OA Film | E. coli | 2.3 × 105 | 1.2 × 107 | <10 | 6.1 | 99.9 |

| PAN/CPN Film | S. aureus | 2.4 × 105 | 1.2 × 107 | <10 | 6.1 | 99.9 |

| PAN/CPN Film | E. coli | 2.3 × 105 | 1.3 × 107 | <10 | 6.1 | 99.9 |

| Fabric, No Wash | S. aureus | 1.4 × 105 | 6.7 × 106 | 5.4 × 104 | 2.1 | 99.2 |

| Fabric, No Wash | K. pneumoniae | 1.6 × 105 | 8.2 × 106 | 2.1 × 104 | 2.6 | 99.7 |

| Fabric, Washed | S. aureus | 1.4 × 105 | 6.7 × 106 | 1.3 × 104 | 2.7 | 99.8 |

| Fabric, Washed | K. pneumoniae | 1.6 × 105 | 8.2 × 106 | 4.9 × 104 | 2.2 | 99.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, D.; Sang, J.S.; Yoo, P.J.; Shin, T.J.; Oh, K.W.; Park, J. Machine-Washable Smart Textiles with Photothermal and Antibacterial Activities from Nanocomposite Fibers of Conjugated Polymer Nanoparticles and Polyacrylonitrile. Polymers 2019, 11, 16. https://doi.org/10.3390/polym11010016

Lee D, Sang JS, Yoo PJ, Shin TJ, Oh KW, Park J. Machine-Washable Smart Textiles with Photothermal and Antibacterial Activities from Nanocomposite Fibers of Conjugated Polymer Nanoparticles and Polyacrylonitrile. Polymers. 2019; 11(1):16. https://doi.org/10.3390/polym11010016

Chicago/Turabian StyleLee, Dabin, Jeong Seon Sang, Pil J. Yoo, Tae Joo Shin, Kyung Wha Oh, and Juhyun Park. 2019. "Machine-Washable Smart Textiles with Photothermal and Antibacterial Activities from Nanocomposite Fibers of Conjugated Polymer Nanoparticles and Polyacrylonitrile" Polymers 11, no. 1: 16. https://doi.org/10.3390/polym11010016

APA StyleLee, D., Sang, J. S., Yoo, P. J., Shin, T. J., Oh, K. W., & Park, J. (2019). Machine-Washable Smart Textiles with Photothermal and Antibacterial Activities from Nanocomposite Fibers of Conjugated Polymer Nanoparticles and Polyacrylonitrile. Polymers, 11(1), 16. https://doi.org/10.3390/polym11010016