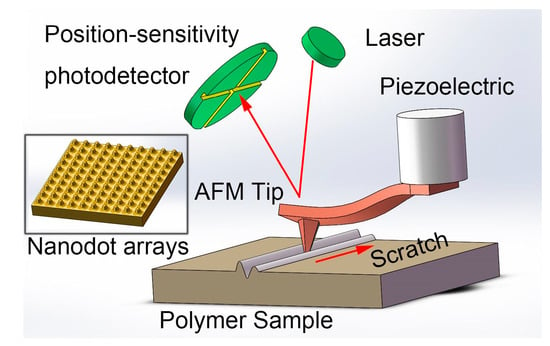

Scratch on Polymer Materials Using AFM Tip-Based Approach: A Review

Abstract

:1. Introduction

2. Theoretical Modeling of the Scratching Process

2.1. Existing Theoretical Models of the Scratching Process

2.2. Study of the Elastic Recovery of Polymer Materials in Scratching Process

3. Nanopatterns Fabricated by the Tip-Based Nanomachining/Nanoscratching (TBN) Approach

3.1. Fabrication of Nanodots/Pits

3.2. Fabrication of Nanogroove/Channel

3.2.1. Single/Multi-Pass Scratching Approach

3.2.2. Nanomilling Method

3.3. Fabrication of 3D Nanostructure

4. Applications

4.1. Applications Based on Material Removal Theory by TBN Method

4.2. Applications Based on Adding Material Theory by TBN Method

4.3. Other Applications by the TBN Method

5. Conclusions

Funding

Conflicts of Interest

References

- Hu, K.X.; Wu, S.; Huang, M.M.; Hu, X.D.; Wang, Q.K. Effect of the tip-sample contact force on the nanostructure size fabricated by local oxidation nanolithography. Ultramicroscopy 2012, 115, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Deng, J.; Dong, J.Y.; Cohen, P.H. Development and Characterization of Ultrasonic Vibration Assisted Nanomachining Process for Three-Dimensional Nanofabrication. IEEE Trans. Nanotechnol. 2018, 17, 559–566. [Google Scholar] [CrossRef]

- Tang, Q.T.; Shen, H.L.; Yao, H.Y.; Jiang, Y.; Li, Y.F.; Zhang, L.; Ni, Z.C.; Wei, Q.Z. Formation mechanism of inverted pyramid from sub-micro to micro scale on c-Si surface by metal assisted chemical etching temperature. Appl. Surf. Sci. 2018, 455, 283–294. [Google Scholar] [CrossRef]

- Wang, H.B.; Yu, B.J.; Jiang, S.L.; Chen, C.; Qian, L.M. Simple and low-cost nanofabrication process of nanoimprint templates for high-quality master gratings: Friction-induced selective etching. Appl. Surf. Sci. 2018, 454, 23–29. [Google Scholar] [CrossRef]

- Qin, Y.; Brockett, A.; Ma, Y.; Razali, A.; Zhao, J.; Harrison, C.; Pan, W.; Dai, X.; Loziak, D. Micro-manufacturing: Research, technology outcomes and development issues. Int. J. Adv. Manuf. Technol. 2010, 47, 821–837. [Google Scholar] [CrossRef]

- Smolyarova, T.E.; Lukyanenko, A.V.; Tarasov, A.S.; Sokolov, A.E. Dip-Pen Nanolithography Method for Fabrication of Biofunctionalized Magnetic Nanodiscs Applied in Medicine. Semiconductors 2018, 52, 675–677. [Google Scholar] [CrossRef]

- Chen, J.M.; Huang, Y.J.; Kannan, P.; Zhang, L.; Lin, Z.Y.; Zhang, J.W.; Chen, T.; Guo, L.H. Flexible and Adhesive Surface Enhance Raman Scattering Active Tape for Rapid Detection of Pesticide Residues in Fruits and Vegetables. Anal. Chem. 2016, 88, 2149–2155. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.Y.; Yi, J.; Li, J.F.; Ren, B.; Wu, D.Y.; Panneerselvam, R.; Tian, Z.Q. Nanostructure-based plasmon-enhanced Raman spectroscopy for surface analysis of materials. Nat. Rev. Mater. 2016, 1, 16. [Google Scholar] [CrossRef]

- Luo, H.R.; Huang, Y.Q.; Lai, K.Q.; Rasco, B.A.; Fan, Y.X. Surface-enhanced Raman spectroscopy coupled with gold nanoparticles for rapid detection of phosmet and thiabendazole residues in apples. Food Control 2016, 68, 229–235. [Google Scholar] [CrossRef]

- Sun, K.X.; Huang, Q. Detection of Chemical Residues in Food Oil via Surface-Enhanced Raman Spectroscopy. In Sensing for Agriculture and Food Quality and Safety VIII; Kim, M.S., Chao, K., Chin, B.A., Eds.; SPIE—International Society for Optics and Photonics: Bellingham, UK, 2016; Volume 9864. [Google Scholar]

- Xu, B.B.; Zhang, Y.L.; Zhang, W.Y.; Liu, X.Q.; Wang, J.N.; Zhang, X.L.; Zhang, D.D.; Jiang, H.B.; Zhang, R.; Sun, H.B. Silver-Coated Rose Petal: Green, Facile, Low-Cost and Sustainable Fabrication of a SERS Substrate with Unique Superhydrophobicity and High Efficiency. Adv. Opt. Mater. 2013, 1, 56–60. [Google Scholar] [CrossRef]

- Cappella, B.; Sturm, H.; Weidner, S.M. Breaking polymer chains by dynamic plowing lithography. Polymer 2002, 43, 4461–4466. [Google Scholar] [CrossRef]

- Fletcher, P.C.; Felts, J.R.; Dai, Z.T.; Jacobs, T.D.; Zeng, H.J.; Lee, W.; Sheehan, P.E.; Carlisle, J.A.; Carpick, R.W.; King, W.P. Wear-Resistant Diamond Nanoprobe Tips with Integrated Silicon Heater for Tip-Based Nanomanufacturing. ACS Nano 2010, 4, 3338–3344. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.K.; Sheehan, P.E. Scanning probe lithography of polymers: Tailoring morphology and functionality at the nanometer scale. Scanning 2008, 30, 172–183. [Google Scholar] [CrossRef] [PubMed]

- Choi, C.H.; Lee, D.J.; Sung, J.H.; Lee, M.W.; Lee, S.G.; Park, S.G.; Lee, E.H.; Beom-Hoan, O. A study of AFM-based scratch process on polycarbonate surface and grating application. Appl. Surf. Sci. 2010, 256, 7668–7671. [Google Scholar] [CrossRef]

- Schweikart, A.; Fery, A. Controlled wrinkling as a novel method for the fabrication of patterned surfaces. Microchim. Acta 2009, 165, 249–263. [Google Scholar] [CrossRef]

- Ye, S.S.; Zhang, X.M.; Chang, L.X.; Wang, T.Q.; Li, Z.B.; Zhang, J.H.; Yang, B. High-Performance Plasmonic Sensors Based on Two-Dimensional Ag Nanowell Crystals. Adv. Opt. Mater. 2014, 2, 779–787. [Google Scholar] [CrossRef]

- Lee, B.E.J.; Exir, H.; Weck, A.; Grandfield, K. Characterization and evaluation of femtosecond laser-induced sub-micron periodic structures generated on titanium to improve osseointegration of implants. Appl. Surf. Sci. 2018, 441, 1034–1042. [Google Scholar] [CrossRef]

- Pal, A.K.; Mohan, D.B. Label Free Detection of DNA on Au/ZnO/Ag Hybrid Structure Based SERS Substrate. In 2nd International Conference on Emerging Technologies: Micro to Nano 2015; Sharma, N.N., Gaol, F.L., Akhtar, J., Eds.; American Institute of Physics: Melville, NY, USA, 2016; Volume 1724. [Google Scholar]

- Xu, K.C.; Wang, Z.Y.; Tan, C.F.; Kang, N.; Chen, L.W.; Ren, L.; Thian, E.S.; Ho, G.W.; Ji, R.; Hong, M.H. Uniaxially Stretched Flexible Surface Plasmon Resonance Film for Versatile Surface Enhanced Raman Scattering Diagnostics. ASC Appl. Mater. Interf. 2017, 9, 26341–26349. [Google Scholar] [CrossRef]

- Zhang, H.; Kang, Y.; Liu, P.; Tao, X.; Pei, J.W.; Li, H.; Du, Y.P. Determination of Pesticides by Surface-Enhanced Raman Spectroscopy on Gold-Nanoparticle-Modified Polymethacrylate. Anal. Lett. 2016, 49, 2268–2278. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, C.X.; Deng, L.; Zhang, G.X.; Xu, H.J.; Sun, X.M. Cicada wing decorated by silver nanoparticles as low-cost and active/sensitive substrates for surface-enhanced Raman scattering. J. Appl. Phys. 2014, 115, 8. [Google Scholar] [CrossRef]

- Shi, G.C.; Wang, M.L.; Zhu, Y.Y.; Shen, L.; Wang, Y.H.; Ma, W.L.; Chen, Y.E.; Li, R.F. A flexible and stable surface-enhanced Raman scattering (SERS) substrate based on Au nanoparticles/Graphene oxide/Cicada wing array. Opt. Commun. 2018, 412, 28–36. [Google Scholar] [CrossRef]

- Gamo, K. Focused Ion-Beam Lithography. Nucl. Instrum. Methods Phys. Res. Sect. B BEAM Interact. Mater. Atoms 1992, 65, 40–49. [Google Scholar] [CrossRef]

- Menard, L.D.; Ramsey, J.M. Fabrication of Sub-5 nm Nanochannels in Insulating Substrates Using Focused Ion Beam Milling. Nano Lett. 2011, 11, 512–517. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Matsumoto, N. Flexible and in situ fabrication of nanochannels with high aspect ratios and nanopillar arrays in fused silica substrates utilizing focused ion beam. RSC Adv. 2015, 5, 50638–50643. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.N.; Yan, J.Y.; Shao, J.H.; Chen, Y.F.; Gong, Q. Electron beam lithography on uneven resist for uniform Bragg gratings in Ga-Sb based distributed-feedback laser. Microelectron. Eng. 2018, 195, 32–35. [Google Scholar] [CrossRef]

- Candeloro, P.; Iuele, E.; Perozziello, G.; Coluccio, M.L.; Gentile, F.; Malara, N.; Mollace, V.; Di Fabrizio, E. Plasmonic nanoholes as SERS devices for biosensing applications: An easy route for nanostructures fabrication on glass substrates. Microelectron. Eng. 2017, 175, 30–33. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Avouris, P.; Bucchignano, J.; Martel, R.; Sun, S.; Michl, J. Simple fabrication scheme for sub-10 nm electrode gaps using electron-beam lithography. Appl. Phys. Lett. 2002, 80, 865–867. [Google Scholar] [CrossRef]

- Potts, A.; Papakostas, A.; Bagnall, D.M.; Zheludev, N.I. Planar chiral meta-materials for optical applications. Microelectron. Eng. 2004, 73-4, 367–371. [Google Scholar] [CrossRef]

- Chung, P.Y.; Wang, P.Y.; Dou, X.; Jiang, P. Templated Nanodimple Arrays with Tunable Nanostructures for Sensitive Surface Plasmon Resonance Analysis. J. Phys. Chem. C 2013, 117, 8933–8940. [Google Scholar] [CrossRef]

- Phan, H.P.; Nguyen, T.K.; Dinh, T.; Iacopi, A.; Hold, L.; Shiddiky, M.J.A.; Dao, D.V.; Nguyen, N.T. Robust Free-Standing Nano-Thin SiC Membranes Enable Direct Photolithography for MEMS Sensing Applications. Adv. Eng. Mater. 2018, 20, 5. [Google Scholar] [CrossRef]

- Wang, X.L.; Tseng, L.T.; Kazazis, D.; Tasdemir, Z.; Vockenhuber, M.; Mochi, I.; Ekinci, Y. Studying resist performance for contact holes printing using EUV interference lithography. J. Micro-Nanolithogr. MEMS MOEMS 2019, 18, 11. [Google Scholar] [CrossRef]

- Zhou, W.; Gao, H.W.; Odom, T.W. Toward Broadband Plasmonics: Tuning Dispersion in Rhombic Plasmonic Crystals. ACS Nano 2010, 4, 1241–1247. [Google Scholar] [CrossRef] [PubMed]

- Binnig, G.; Quate, C.F.; Gerber, C. Atomic force microscope. J. Mater. Eng. 2018, 56, 930–933. [Google Scholar]

- Malshe, A.P.; Rajurkar, K.P.; Virwani, K.R.; Taylor, C.R.; Bourell, D.L.; Levy, G.; Sundaram, M.M.; McGeough, J.A.; Kalyanasundaram, V.; Samant, A.N. Tip-based nanomanufacturing by electrical, chemical, mechanical and thermal processes. CIRP Ann. Manuf. Technol. 2010, 59, 628–651. [Google Scholar] [CrossRef]

- Garcia, R.; Knoll, A.W.; Riedo, E. Advanced scanning probe lithography. Nat. Nanotechnol. 2014, 9, 577–587. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brousseau, E.B.; Krohs, F.; Caillaud, E.; Dimov, S.; Gibaru, O.; Fatikow, S. Development of a Novel Process Chain Based on Atomic Force Microscopy Scratching for Small and Medium Series Production of Polymer Nanostructured Components. J. Manuf. Sci. Eng. Trans. ASME 2010, 132, 8. [Google Scholar] [CrossRef]

- Yan, Y.D.; Geng, Y.Q.; Hu, Z.J.; Zhao, X.S.; Yu, B.W.; Zhang, Q. Fabrication of nanochannels with ladder nanostructure at the bottom using AFM nanoscratching method. Nanoscale Res. Lett. 2014, 9, 13. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.D.; Gao, D.W.; Hu, Z.J.; Sen Zhao, X.; Yan, J.C. Polymer Nanostructured Components Machined Directly by the Atomic Force Microscopy Scratching Method. Int. J. Precis. Eng. Manuf. 2012, 13, 269–273. [Google Scholar] [CrossRef]

- Zhao, X.S.; Geng, Y.Q.; Li, W.B.; Yan, Y.D.; Hu, Z.J.; Sun, T.; Liang, Y.C.; Dong, S. Fabrication and measurement of nanostructures on the micro ball surface using a modified atomic force microscope. Rev. Sci. Instr. 2012, 83, 7. [Google Scholar] [CrossRef]

- Chichti, E.; George, M.; Delenne, J.Y.; Radjai, F.; Lullien-Pellerin, V. Nano-mechanical properties of starch and gluten biopolymers from atomic force microscopy. Eur. Polymer J. 2013, 49, 3788–3795. [Google Scholar] [CrossRef]

- Jiang, X.H.; Wu, G.Y.; Zhou, J.F.; Wang, S.J.; Tseng, A.A.; Du, Z.L. Nanopatterning on silicon surface using atomic force microscopy with diamond-like carbon (DLC)-coated Si probe. Nanoscale Res. Lett. 2011, 6, 7. [Google Scholar] [CrossRef] [PubMed]

- Song, C.F.; Li, X.Y.; Cui, S.X.; Dong, H.S.; Yu, B.J.; Qian, L.M. Maskless and low-destructive nanofabrication on quartz by friction-induced selective etching. Nanoscale Res. Lett. 2013, 8, 8. [Google Scholar] [CrossRef] [PubMed]

- Tseng, A.A. Advancements and challenges in development of atomic force microscopy for nanofabrication. Nano Today 2011, 6, 493–509. [Google Scholar] [CrossRef]

- Wang, X.D.; Song, C.F.; Yu, B.J.; Chen, L.; Qian, L.M. Reprint of Nanowear behaviour of monocrystalline silicon against SiO2 tip in water. Wear 2013, 301, 795–801. [Google Scholar] [CrossRef]

- Gotsmann, B.; Durig, U. Thermally activated nanowear modes of a polymer surface induced by a heated tip. Langmuir 2004, 20, 1495–1500. [Google Scholar] [CrossRef]

- Iwata, F.; Yamaguchi, M.; Sasaki, A. Nanometer-scale layer modification of polycarbonate surface by scratching with tip oscillation using an atomic force microscope. Wear 2003, 254, 1050–1055. [Google Scholar] [CrossRef]

- Deng, J.; Zhang, L.; Dong, J.Y.; Cohen, P.H. AFM-based 3D nanofabrication using ultrasonic vibration assisted nanomachining. J. Manuf. Process. 2016, 24, 195–202. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Zhang, L.; Dong, J.Y.; Cohen, P.H. AFM-based 3D Nanofabrication using Ultrasonic Vibration Assisted Nanomachining. In 43rd North American Manufacturing Research Conference, Namrc 43; Shih, A.J., Wang, L.H., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2015; Volume 1, pp. 584–592. [Google Scholar]

- Kong, X.C.; Dong, J.Y.; Cohen, P.H. Modeling of the dynamic machining force of vibration-assisted nanomachining process. J. Manuf. Process. 2017, 28, 101–108. [Google Scholar] [CrossRef]

- Zhang, L.; Dong, J.Y. High-rate tunable ultrasonic force regulated nanomachining lithography with an atomic force microscope. Nanotechnology 2012, 23, 9. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.Y.; Chen, H.A.; Lin, H.N. Fabrication of a single metal nanowire connected with dissimilar metal electrodes and its application to chemical sensing. Anal. Chem. 2008, 80, 1937–1941. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.Q.; Yan, Y.D.; Geng, Y.Q.; Gan, Y.; Fang, Z. Fabrication of polydimethylsiloxane nanofluidic chips under AFM tip-based nanomilling process. Nanoscale Res. Lett. 2019, 14, 14. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Dong, J.Y.; Cohen, P.H. Material-Insensitive Feature Depth Control and Machining Force Reduction by Ultrasonic Vibration in AFM-Based Nanomachining. IEEE Trans. Nanotechnol. 2013, 12, 743–750. [Google Scholar] [CrossRef]

- Guo, J.; Song, C.F.; Li, X.Y.; Yu, B.J.; Dong, H.S.; Qian, L.M.; Zhou, Z.R. Fabrication mechanism of friction-induced selective etching on Si(100) surface. Nanoscale Res. Lett. 2012, 7, 9. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Yu, B.J.; Wang, X.D.; Qian, L.M. Nanofabrication on monocrystalline silicon through friction-induced selective etching of Si3N4 mask. Nanoscale Res. Lett. 2014, 9, 7. [Google Scholar] [CrossRef] [PubMed]

- Song, C.F.; Li, X.Y.; Yu, B.J.; Dong, H.S.; Qian, L.M.; Zhou, Z.R. Friction-induced nanofabrication method to produce protrusive nanostructures on quartz. Nanoscale Res. Lett. 2011, 6, 9. [Google Scholar] [CrossRef] [PubMed]

- Song, C.F.; Yu, B.J.; Qian, L.M. Effect of scan parameters and etching temperature on low-destructive nanofabrication of quartz. Micro Nano Lett. 2013, 8, 735–739. [Google Scholar] [CrossRef]

- Liang, J.; Scoles, G. Nanografting of alkanethiols by tapping mode atomic force microscopy. Langmuir 2007, 23, 6142–6147. [Google Scholar] [CrossRef]

- Tseng, A.A. Three-dimensional patterning of nanostructures using atomic force microscopes. J. Vacuum Sci. Technol. B 2011, 29, 21. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Jiao, N.; Tung, S.; Dong, Z. Nanochannel system fabricated by MEMS microfabrication and atomic force microscopy. IET Nanobiotechnol. 2011, 5, 108–113. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Zhuo, Y.; Oruc, M.E.; Cunningham, B.T.; King, W.P. Nanofluidic channels of arbitrary shapes fabricated by tip-based nanofabrication. Nanotechnology 2014, 25, 8. [Google Scholar] [CrossRef]

- Milner, S.T. Polymer Brushes. Science 1991, 251, 905–914. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.J.; Ding, C.C.; Chi, F.T.; Pan, N.; Wen, J.; Xiong, J.; Hu, S. Polymer brushes on graphene oxide for efficient adsorption of heavy metal ions from water. J. Appl. Polym. Sci. 2019, 136, 9. [Google Scholar] [CrossRef]

- Ifra; Saha, S. Fabrication of topologically anisotropic microparticles and their surface modification with pH responsive polymer brush. Mater. Sci. Eng. Mater. Biol. Appl. 2019, 104, 109894. [Google Scholar] [CrossRef]

- He, M.; Wei, Y.; Wang, R.; Wang, C.; Zhang, B.; Han, L. Boronate affinity magnetic nanoparticles with hyperbranched polymer brushes for the adsorption of cis-diol biomolecules. Mikrochim. Acta 2019, 186, 683. [Google Scholar] [CrossRef] [PubMed]

- Merlitz, H.; He, G.L.; Sommer, J.U.; Wu, C.X. Chain expulsion out of dense polymer brushes. Macromol. Theory Simul. 2008, 17, 171–179. [Google Scholar] [CrossRef]

- Du, W.; Gao, C. Selective Adhesion and Directional Migration of Endothelial Cells Guided by Cys-Ala-Gly Peptide Density Gradient on Antifouling Polymer Brushes. Macromol. Biosci. 2019, e1900292. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.Q.; Hirtz, M.; Fuchs, H.; Zheng, Z.J. Development of Dip-Pen Nanolithography (DPN) and Its Derivatives. Small 2019, 15, 9. [Google Scholar] [CrossRef]

- Geng, Y.Q.; Yan, Y.D.; He, Y.; Hu, Z.J. Investigation on friction behavior and processing depth prediction of polymer in nanoscale using AFM probe-based nanoscratching method. Tribol. Int. 2017, 114, 33–41. [Google Scholar] [CrossRef]

- Yan, Y.D.; Zhou, E.C.; Geng, Y.Q.; He, Y.; Zhao, X.S. Modelling and experimental study of nanoscratching process on PMMA thin-film using AFM tip-based nanomachining approach. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2018, 54, 138–148. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Tung, S.; Dong, Z.L. Material removal model for AFM-based nanochannel fabrication. Wear 2012, 278, 71–76. [Google Scholar] [CrossRef]

- Malekian, M.; Park, S.S.; Strathearn, D.; Mostofa, M.G.; Jun, M.B.G. Atomic force microscope probe-based nanometric scribing. J. Micromech. Microeng. 2010, 20, 11. [Google Scholar] [CrossRef]

- Ding, Y.H.; Deng, X.H.; Jiang, X.; Zhang, P.; Yin, J.R.; Jiang, Y. Nanoscale mechanical characterization of PMMA by AFM nanoindentation: A theoretical study on the time-dependent viscoelastic recovery. J. Mater. Sci. 2013, 48, 3479–3485. [Google Scholar] [CrossRef]

- Geng, Y.Q.; Yan, Y.D.; Hu, Z.J.; Zhao, X.S. Investigation of the nanoscale elastic recovery of a polymer using an atomic force microscopy-based method. Meas. Sci. Technol. 2016, 27, 9. [Google Scholar] [CrossRef]

- Keyser, U.F.; Paesler, M.; Zeitler, U.; Haug, R.J.; Eberl, K. Direct fabrication of parallel quantum dots with an atomic force microscope. Phys. E-Low Dimens. Syst. Nanostruct. 2002, 13, 1155–1158. [Google Scholar] [CrossRef]

- Lin, H.Y.; Chen, H.A.; Wu, Y.J.; Huang, J.H.; Lin, H.N. Fabrication of Metal Nanostructures by Atomic Force Microscopy Nanomachining and Related Applications. J. Nanosci. Nanotechnol. 2010, 10, 4482–4485. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.J.; Yan, Y.D.; Zhao, X.S.; Gao, D.W.; Wei, Y.Y.; Wang, J.H. Fabrication of large scale nanostructures based on a modified atomic force microscope nanomechanical machining system. Rev. Sci. Instr. 2011, 82, 8. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.D.; Sun, Y.; Li, J.R.; Hu, Z.J.; Zhao, X.S. Controlled nanodot fabrication by rippling polycarbonate surface using an AFM diamond tip. Nanoscale Res. Lett. 2014, 9, 7. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Yan, Y.D.; Geng, Y.Q.; Brousseau, E. Fabrication of periodic nanostructures using dynamic plowing lithography with the tip of an atomic force microscope. Appl. Surf. Sci. 2018, 427, 1076–1083. [Google Scholar] [CrossRef]

- He, Y.; Geng, Y.Q.; Yan, Y.D.; Luo, X.C. Fabrication of Nanoscale Pits with High Throughput on Polymer Thin Film Using AFM Tip-Based Dynamic Plowing Lithography. Nanoscale Res. Lett. 2017, 12, 11. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Yan, Y.D.; Wang, J.Q.; Geng, Y.Q.; Xue, B.; Zhao, X.S. Study on the Effects of the Machining Parameters on the Fabrication of Nanoscale Pits Using the Dynamic Plowing Lithography Approach. IEEE Trans. Nanotechnol. 2019, 18, 351–357. [Google Scholar] [CrossRef]

- Geng, Y.Q.; Yan, Y.D.; Zhuang, Y.; Hu, Z.J. Effects of AFM tip-based direct and vibration assisted scratching methods on nanogrooves fabrication on a polymer resist. Appl. Surf. Sci. 2015, 356, 348–354. [Google Scholar] [CrossRef]

- Gozen, B.A.; Ozdoganlar, O.B. A Rotating-Tip-Based Mechanical Nano-Manufacturing Process: Nanomilling. Nanoscale Res. Lett. 2010, 5, 1403–1407. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Geng, Y.Q.; Li, H.; Yan, Y.D.; He, Y.; Zhao, X.S. Study on material removal for nanochannels fabrication using atomic force microscopy tip-based nanomilling approach. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 461–469. [Google Scholar] [CrossRef]

- Gozen, B.A.; Ozdoganlar, O.B. Design and evaluation of a mechanical nanomanufacturing system for nanomilling. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2012, 36, 19–30. [Google Scholar] [CrossRef]

- Geng, Y.; Wang, J.; Hao, L.; Yan, Y. Study on the effects of feed directions on chip formation and machined depth when implementing nanoscratching by nanomilling approach. Proc. CIRP 2018, 71, 285–288. [Google Scholar] [CrossRef]

- Geng, Y.Q.; Brousseau, E.B.; Zhao, X.S.; Gensheimer, M.; Bowen, C.R. AFM tip-based nanomachining with increased cutting speed at the tool-workpiece interface. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2018, 51, 536–544. [Google Scholar] [CrossRef] [Green Version]

- Deng, J.; Dong, J.Y.; Cohen, P. High Rate 3D Nanofabrication by AFM-Based Ultrasonic Vibration Assisted Nanomachining. In 44th North American Manufacturing Research Conference, Namrc 44; Shih, A., Wang, L., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2016; Volume 5, pp. 1283–1294. [Google Scholar]

- Kunze, U. Nanoscale devices fabricated by dynamic ploughing with an atomic force microscope. Superlattices Microstruct. 2002, 31, 3–17. [Google Scholar] [CrossRef]

- Wang, Y.; Hong, X.D.; Zeng, J.; Liu, B.Q.; Guo, B.; Yan, H. AFM Tip Hammering Nanolithography. Small 2009, 5, 477–483. [Google Scholar] [CrossRef]

- Leung, O.M.; Goh, M.C. Orientational Ordering of Polymers by Atomic force microscope tip-surface interaction. Science 1992, 255, 64–66. [Google Scholar] [CrossRef]

- Pires, D.; Hedrick, J.L.; De Silva, A.; Frommer, J.; Gotsmann, B.; Wolf, H.; Despont, M.; Duerig, U.; Knoll, A.W. Nanoscale Three-Dimensional Patterning of Molecular Resists by Scanning Probes. Science 2010, 328, 732–735. [Google Scholar] [CrossRef]

- Chen, Y.J.; Hsu, J.H.; Lin, H.N. Fabrication of metal nanowires by atomic force microscopy nanoscratching and lift-off process. Nanotechnology 2005, 16, 1112–1115. [Google Scholar] [CrossRef]

- Liu, L.Q.; Shi, J.L.; Li, M.; Yu, P.; Yang, T.; Li, G.Y. Fabrication of Sub-Micrometer-Sized MoS2 Thin-Film Transistor by Phase Mode AFM Lithography. Small 2018, 14, 6. [Google Scholar] [CrossRef] [PubMed]

- Geng, Y.Q.; Zhao, X.S.; Yan, Y.D.; Hu, Z.J. An AFM-based methodology for measuring axial and radial error motions of spindles. Meas. Sci. Technol. 2014, 25, 10. [Google Scholar] [CrossRef]

- Bouchiat, V.; Esteve, D. Lift-off lithography using an atomic force microscope. Appl. Phys. Lett. 1996, 69, 3098–3100. [Google Scholar] [CrossRef]

- Sohn, L.L.; Willett, R.L. Fabrication of Nanostructures using atomic-force-microscope-based lithography. Appl. Phys. Lett. 1995, 67, 1552–1554. [Google Scholar] [CrossRef]

- Hsu, J.H.; Lin, C.Y.; Lin, H.N. Fabrication of metallic nanostructures by atomic force microscopy nanomachining and lift-off process. J. Vacuum Sci. Technol. B 2004, 22, 2768–2771. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.A.; Lin, H.Y.; Lin, H.N. Localized Surface Plasmon Resonance in Lithographically Fabricated Single Gold Nanowires. J. Phys. Chem. C 2010, 114, 10359–10364. [Google Scholar] [CrossRef]

| Theory | Polymer | Application | Refs. |

|---|---|---|---|

| polymethyl methacrylate (PMMA) film | Etching resist | [52] | |

| Remove material | polycarbonate (PC) bulk sample | Preparation of nanofluidic chips | [54] |

| polymethyl methacrylate (PMMA) film | Data storage | [83] | |

| Add material | polymethyl methacrylate (PMMA) film | Sacrificial layer for lift-off process | [53,78,95] |

| polystyrene (PS) film | Sacrificial layer for lift-off process | [96] | |

| Theothers | polycarbonate (PC) bulk sample | Resist for AFM (atomic force microscope) scratching | [97] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Chang, S.; Wang, T.; Geng, Y. Scratch on Polymer Materials Using AFM Tip-Based Approach: A Review. Polymers 2019, 11, 1590. https://doi.org/10.3390/polym11101590

Yan Y, Chang S, Wang T, Geng Y. Scratch on Polymer Materials Using AFM Tip-Based Approach: A Review. Polymers. 2019; 11(10):1590. https://doi.org/10.3390/polym11101590

Chicago/Turabian StyleYan, Yongda, Shunyu Chang, Tong Wang, and Yanquan Geng. 2019. "Scratch on Polymer Materials Using AFM Tip-Based Approach: A Review" Polymers 11, no. 10: 1590. https://doi.org/10.3390/polym11101590

APA StyleYan, Y., Chang, S., Wang, T., & Geng, Y. (2019). Scratch on Polymer Materials Using AFM Tip-Based Approach: A Review. Polymers, 11(10), 1590. https://doi.org/10.3390/polym11101590