Further Exploration of Sucrose–Citric Acid Adhesive: Investigation of Optimal Hot-Pressing Conditions for Plywood and Curing Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Sucrose–Citric Acid (SC) Adhesives

2.3. Bond Performance

2.3.1. Manufacture of Plywood

2.3.2. Shear Strength Measurement

2.4. Curing Behaviour

2.4.1. Thermal Analysis

2.4.2. Insoluble Mass Proportion

2.4.3. Pyrolysis Gas Chromatography and Mass Spectrometry (Py-GC/MS)

3. Results and Discussion

3.1. Effects of Hot-Pressing Conditions on the Bond Performance

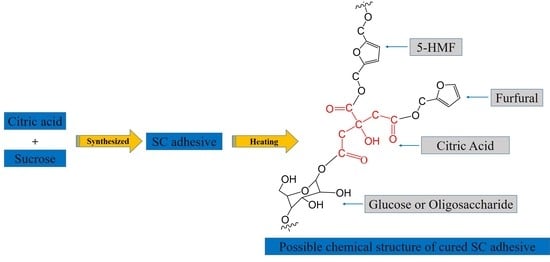

3.2. Curing Behaviour of SC Adhesive

3.2.1. TG Analysis

3.2.2. DSC Analysis

3.2.3. Insoluble Mass Proportion

3.2.4. Py-GC/MS

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, Y.; Tang, Q.W.; Yang, F.; Xu, L.; Wang, X.H.; Zhang, J.L. Mechanical and thermal properties of rice straw cellulose nanofibrils-enhanced polyvinyl alcohol films using freezing-and-thawing cycle method. Cellulose 2019, 26, 3193–3204. [Google Scholar] [CrossRef]

- Han, J.Q.; Lu, K.Y.; Yue, Y.Y.; Mei, C.T.; Huang, C.B.; Wu, Q.L.; Xu, X.W. Nanocellulose-templated assembly of polyaniline in natural rubber-based hybrid elastomers toward flexible electronic conductors. Ind. Crop. Prod. 2019, 128, 94–107. [Google Scholar] [CrossRef]

- Han, J.; Wang, S.; Zhu, S.; Huang, C.; Yue, Y.; Mei, C.; Xu, X.; Xia, C. Electrospun Core-Shell Nanofibrous Membranes with Nanocellulose-Stabilized Carbon Nanotubes for Use as High-Performance Flexible Supercapacitor Electrodes with Enhanced Water Resistance, Thermal Stability and Mechanical Toughness. ACS Appl. Mater. Interfaces 2019, 11, 44624–44635. [Google Scholar] [CrossRef] [PubMed]

- Han, J.Q.; Ding, Q.Q.; Mei, C.T.; Wu, Q.L.; Yue, Y.Y.; Xu, X.W. An intrinsically self-healing and biocompatible electroconductive hydrogel based on nanostructured nanocellulose-polyaniline complexes embedded in a viscoelastic polymer network towards flexible conductors and electrodes. Electrochim. Acta 2019, 318, 660–672. [Google Scholar] [CrossRef]

- Huang, C.X.; Lin, W.Q.; Lai, C.H.; Li, X.; Jin, Y.C.; Yong, Q. Coupling the post-extraction process to remove residual lignin and alter the recalcitrant structures for improving the enzymatic digestibility of acid-pretreated bamboo residues. Bioresour. Technol. 2019, 285, 121355. [Google Scholar] [CrossRef]

- Maloney, T.M. The Development of the United-States and Canada—Waferboard, Oriented Strand Board, and Medium Density Fiberboard—The Year 1984. Holz Roh Werkst. 1984, 42, 361–365. [Google Scholar] [CrossRef]

- Barbu, M.C.; Réh, R.; Irle, M. Wood-Based Composites. In Research Developments in Wood Engineering and Technology; IGI Global: Hershey, PA, USA, 2014; pp. 1–45. [Google Scholar]

- Xiong, X.Q.; Guo, W.J.; Fang, L.; Zhang, M.; Wu, Z.H.; Lu, R.; Miyakoshi, T. Current state and development trend of Chinese furniture industry. J. Wood Sci. 2017, 63, 433–444. [Google Scholar] [CrossRef]

- Wu, Y.; Sun, Y.C.; Yang, F.; Zhang, H.Q.; Wang, Y.J. The Implication of Benzene-Ethanol Extractive on Mechanical Properties of Waterborne Coating and Wood Cell Wall by Nanoindentation. Coatings 2019, 9, 449. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.Z.; Wang, S.Q.; Xie, X.Q.; Zhao, L.G.; Deng, Y.H.; Li, Y.J. Multi-scale evaluation of the effects of nanoclay on the mechanical properties of wood/phenol formaldehyde bondlines. Int. J. Adhes. 2017, 74, 92–99. [Google Scholar] [CrossRef]

- Pizzi, A. Wood products and green chemistry. Ann. For. Sci. 2016, 73, 185–203. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chen, X.; Xie, X.; Cai, S.; Yuan, Z.; Li, Y. Multi-Scale Evaluation of the Effect of Phenol Formaldehyde Resin Impregnation on the Dimensional Stability and Mechanical Properties of Pinus Massoniana Lamb. Forests 2019, 10, 646. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chen, X.; Xie, X.; Yuan, Z.; Cai, S.; Li, Y. Effect of Phenol Formaldehyde Resin Penetration on the Quasi-Static and Dynamic Mechanics of Wood Cell Walls Using Nanoindentation. Nanomaterials 2019, 9, 1409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Réh, R.; Igaz, R.; Krišťák, Ľ.; Ružiak, I.; Gajtanska, M.; Božíková, M.; Kučerka, M. Functionality of Beech Bark in Adhesive Mixtures Used in Plywood and Its Effect on the Stability Associated with Material Systems. Materials 2019, 12, 1298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ružiak, I.; Igaz, R.; Krišťák, Ľ.; Réh, R.; Mitterpach, J.; Očkajová, A.; Kučerka, M. Influence of Urea-formaldehyde Adhesive Modification with Beech Bark on Chosen Properties of Plywood. Bioresources 2017, 12, 3250–3264. [Google Scholar] [CrossRef] [Green Version]

- Mao, A.; Hassan, E.; Kim, M.G. Investigation of Low Mole Ratio UF and UMF Resins Aimed at Lowering the Formaldehyde Emission Potential of Wood Composite Boards. Bioresources 2013, 8, 2453–2469. [Google Scholar] [CrossRef] [Green Version]

- Barry, A.; Corneau, D. Effectiveness of barriers to minimize VOC emissions including formaldehyde. For. Prod. J. 2006, 56, 38–42. [Google Scholar]

- Pizzi, A. Bioadhesives for Wood and Fibres: A Critical Review. Rev. Adhes. 2013, 1, 88–113. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, S.J.; Kang, H.J.; Zhang, W.; Li, J.Z.; Zhang, S.F.; Huang, A.M. Reduction of energy consumption of green plywood production by implementing high-efficiency thermal conductive bio-adhesive: Assessment from pilot-scaled application. J. Clean. Prod. 2019, 210, 1366–1375. [Google Scholar] [CrossRef]

- Umemura, K.; Ueda, T.; Munawar, S.S.; Kawai, S. Application of Citric Acid as Natural Adhesive for Wood. J. Appl. Polym. Sci. 2012, 123, 1991–1996. [Google Scholar] [CrossRef]

- Umemura, K.; Ueda, T.; Kawai, S. Characterization of wood-based molding bonded with citric acid. J. Wood Sci. 2012, 58, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Umemura, K.; Kawai, S. Development of Wood-Based Materials Bonded with Citric Acid. For. Prod. J. 2015, 65, 38–42. [Google Scholar] [CrossRef]

- Umemura, K.; Sugihara, O.; Kawai, S. Investigation of a new natural adhesive composed of citric acid and sucrose for particleboard. J. Wood Sci. 2013, 59, 203–208. [Google Scholar] [CrossRef] [Green Version]

- Umemura, K.; Sugihara, O.; Kawai, S. Investigation of a new natural adhesive composed of citric acid and sucrose for particleboard II: effects of board density and pressing temperature. J. Wood Sci. 2015, 61, 40–44. [Google Scholar] [CrossRef]

- Sun, S.; Zhao, Z.; Umemura, K. Further Exploration of Sucrose-Citric Acid Adhesive: Synthesis and Application on Plywood. Polymers 2019, 11, 1875. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eggleston, G.; TraskMorrell, B.J.; Vercellotti, J.R. Use of differential scanning calorimetry and thermogravimetric analysis to characterize the thermal degradation of crystalline sucrose and dried sucrose-salt residues. J. Agric. Food Chem. 1996, 44, 3319–3325. [Google Scholar] [CrossRef]

- Barbooti, M.M.; Al-Sammerrai, D.A. Thermal decomposition of citric acid. Thermochim. Acta 1986, 98, 119–126. [Google Scholar] [CrossRef]

- Gintner, Z.; Végh, A.; Ritlop, B. Determination of sucrose content of cariogenic diets by thermal analysis. J. Therm. Anal. 1989, 35, 1399–1404. [Google Scholar] [CrossRef]

- Beckett, S.T.; Francesconi, M.G.; Geary, P.M.; Mackenzie, G.; Maulny, A.P.E. DSC study of sucrose melting. Carbohydr. Res. 2006, 341, 2591–2599. [Google Scholar] [CrossRef]

- Li, H.; Tang, X.Y.; Wu, C.J.; Yu, S.J. Formation of 2,3-dihydro-3,5-Dihydroxy-6-Methyl-4(H)-Pyran-4-One (DDMP) in glucose-amino acids Maillard reaction by dry-heating in comparison to wet-heating. LWT Food Sci. Technol. 2019, 105, 156–163. [Google Scholar] [CrossRef]

- Lu, Q.; Liao, H.T.; Zhang, Y.; Zhang, J.J.; Dong, C.Q. Reaction mechanism of low-temperature fast pyrolysis of fructose to produce 5-hydroxymethyl furfural. J. Fuel Chem. Technol. 2013, 41, 1070–1076. [Google Scholar] [CrossRef]

- Locas, C.P.; Yaylayan, V.A. Isotope labeling studies on the formation of 5-(hydroxymethyl)-2-furaldehyde (HMF) from sucrose by pyrolysis-GC/MS. J. Agric. Food Chem. 2008, 56, 6717–6723. [Google Scholar] [CrossRef] [PubMed]

- Nishibori, S.; Kawakishi, S. Formation of 2,3-Dihydro-3,5-dihydroxy-6-methyl-4(H)-pyran-4-one from Fructose and.beta.-Alanine under Conditions Used for Baking. J. Agric. Food Chem. 1994, 42, 1080–1084. [Google Scholar] [CrossRef]

- Wyrzykowski, D.; Hebanowska, E.; Nowak-Wiczk, G.; Makowski, M.; Chmurzyński, L. Thermal behaviour of citric acid and isomeric aconitic acids. J. Anal. Calorim. 2011, 104, 731–735. [Google Scholar] [CrossRef] [Green Version]

- Antal, M.J.; Mok, W.S.L.; Richards, G.N. Mechanism of formation of 5-(hydroxymethyl)-2-furaldehyde from d-fructose and sucrose. Carbohydr. Res. 1990, 199, 91–109. [Google Scholar] [CrossRef]

- Ito, H. The Formation of Maltol and Isomaltol through Degradation of Sucrose. Agric. Biol. Chem. Tokyo 1977, 41, 1307–1308. [Google Scholar] [CrossRef]

- Fagerson, I.S. Thermal degradation of carbohydrates; a review. J. Agric. Food Chem. 1969, 17, 747–750. [Google Scholar] [CrossRef]

- Del Menezzi, C.; Amirou, S.; Pizzi, A.; Xi, X.; Delmotte, L. Reactions with Wood Carbohydrates and Lignin of Citric Acid as a Bond Promoter of Wood Veneer Panels. Polymers 2018, 10, 833. [Google Scholar] [CrossRef] [Green Version]

| Groups | Hot-Pressing Temperature (°C) | Hot-Pressing Time (min) | Spread Tate (g/m2) |

|---|---|---|---|

| 130 | |||

| Group 1 | 150 | 7 | 140 |

| 170 | |||

| 190 | |||

| 3 | |||

| Group 2 | 190 | 5 | 140 |

| 7 | |||

| 9 | |||

| 100 | |||

| Group 3 | 190 | 7 | 120 |

| 140 | |||

| 160 |

| Samples | Peak Number | RT (min) | SI | Compound | CAS | MW | Formula |

|---|---|---|---|---|---|---|---|

| SC 100/0 | 1 | 6.79 | 93 | 2,5-Furandicarboxaldehyde | 823-82-5 | 124 | C6H4O3 |

| 2 | 7.39 | 87 | 2,3-Dihydro-3,5-dihydroxy-6-methyl-4(4H)-pyranone | 28564-83-2 | 144 | C6H8O4 | |

| 3 | 8.22 | 94 | 5-Hydrxoymethylfurfura | 67-47-0 | 126 | C6H6O3 | |

| SC 0/100 | 1’ | 6.23 | 97 | Citraconic acid anhydride or Itaconic anhydride | 616-02-4 or 2170-03-8 | 112 | C5H4O3 |

| 2’ | 7.26 | 97 | Citraconic acid anhydride or Itaconic anhydride | 616-02-4 or 2170-03-8 | 112 | C5H4O3 | |

| 3’ | 8.51 | Unknown | |||||

| SC 25/75 | 1” | 4.77 | 94 | Furfural | 98-01-1 | 96 | C5H4O2 |

| 2” | 6.25 | 97 | Citraconic acid anhydride or Itaconic anhydride | 616-02-4 or 2170-03-8 | 112 | C5H4O3 | |

| 3” | 7.13 | 97 | Citraconic acid anhydride or Itaconic anhydride | 616-02-4 or 2170-03-8 | 112 | C5H4O3 | |

| 4” | 7.62 | 81 | Levoglucosenone | 37112-31-5 | 126 | C6H6O3 | |

| 5” | 7.66 | 80 | Maltol | 118-71-8 | 126 | C6H6O3 | |

| 6” | 8.58 | Unknown |

| Peak Number | RT (min) | SI | Compound | CAS | MW | Formula | Chemical Structure Number |

|---|---|---|---|---|---|---|---|

| a | 1.72 | 96 | Methoxyethene | 107-25-5 | 58 | C3H6O | I |

| b | 2.32 | 94 | 2-Methylfuran | 534-22-5 | 82 | C5H6O | II |

| c | 3.33 | 96 | 2,5-Dimethylfuran | 625-86-5 | 96 | C6H8O | III |

| d | 4.77 | 94 | Furfural | 98-01-1 | 96 | C5H4O2 | IV |

| e | 5.15 | 90 | 2,3-Dihydro-5-methyl-2-furanone | 591-12-8 | 98 | C5H6O2 | V |

| f | 5.59 | 96 | 2-Acetylfuran | 1192-62-7 | 110 | C6H6O2 | VI |

| g | 6.01 | 97 | Citraconic acid anhydride or Itaconic anhydride | 616-02-4 or 2170-03-8 | 112 | C5H4O3 | VII VIII |

| h | 6.11 | 94 | 5-Methylfurfural | 620-02-0 | 110 | C6H6O2 | IX |

| i | 6.82 | 91 | 2,5-Furandicarboxaldehyde | 823-82-5 | 124 | C6H4O3 | X |

| j | 7.60 | Levoglucosenone | 37112-31-5 | 126 | C6H6O3 | XI | |

| k | 8.60 | Unknown |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Sakai, S.; Wu, D.; Chen, Z.; Zhu, N.; Huang, C.; Sun, S.; Zhang, M.; Umemura, K.; Yong, Q. Further Exploration of Sucrose–Citric Acid Adhesive: Investigation of Optimal Hot-Pressing Conditions for Plywood and Curing Behavior. Polymers 2019, 11, 1996. https://doi.org/10.3390/polym11121996

Zhao Z, Sakai S, Wu D, Chen Z, Zhu N, Huang C, Sun S, Zhang M, Umemura K, Yong Q. Further Exploration of Sucrose–Citric Acid Adhesive: Investigation of Optimal Hot-Pressing Conditions for Plywood and Curing Behavior. Polymers. 2019; 11(12):1996. https://doi.org/10.3390/polym11121996

Chicago/Turabian StyleZhao, Zhongyuan, Shunsuke Sakai, Di Wu, Zhen Chen, Nan Zhu, Caoxing Huang, Shijing Sun, Min Zhang, Kenji Umemura, and Qiang Yong. 2019. "Further Exploration of Sucrose–Citric Acid Adhesive: Investigation of Optimal Hot-Pressing Conditions for Plywood and Curing Behavior" Polymers 11, no. 12: 1996. https://doi.org/10.3390/polym11121996

APA StyleZhao, Z., Sakai, S., Wu, D., Chen, Z., Zhu, N., Huang, C., Sun, S., Zhang, M., Umemura, K., & Yong, Q. (2019). Further Exploration of Sucrose–Citric Acid Adhesive: Investigation of Optimal Hot-Pressing Conditions for Plywood and Curing Behavior. Polymers, 11(12), 1996. https://doi.org/10.3390/polym11121996