Study on Some Thermal and Electrical Properties of Basalt Fabric Modified with Metal and Ceramics as a Result of Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Deposition of Coatings on the Basalt Fabric Surface

2.3. Chemical Composition and Thickness Determination

2.4. Protective Thermal Properties

2.5. Comfort Thermal Properties

2.6. Electrical Properties

2.7. Surface Color Assessment

3. Results and Discussion

3.1. Chemical Composition and Thickness of the Coatings

3.2. Thermal Properties of Fabrics

3.3. Comfort Properties of Fabrics

3.4. Electrical Properties of Fabrics

3.5. Surface Color Assessment of Fabrics

4. Conclusions

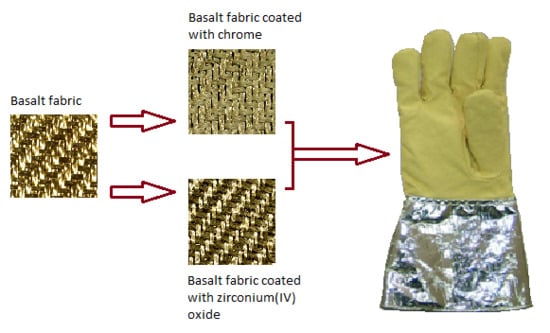

- The metal and ceramics can be applied as a coating on the surface of basalt fabric.

- The modification of basalt fabric with the zirconium(IV) oxide and chrome coatings enables the improvement of its thermal properties.

- In order to reach a compromise between providing adequate protective and functional properties of material intended for protective gloves, further research will be carried out.

Author Contributions

Funding

Conflicts of Interest

References

- Hrynyk, R.; Frydrych, I. Study on textile assemblies with aluminized basalt fabrics destined for protective gloves. Int. J. Cloth. Sci. Technol. 2015, 27, 1–17. [Google Scholar] [CrossRef]

- Liu, G.; Liu, Y.; Zhao, X. A study of the thermal protective performance of the outer fabric material for fire proximity suits. J. Text. Inst. 2018, 109, 851–857. [Google Scholar] [CrossRef]

- Miśkiewicz, P. Selected personal protective equipment for applications in a hot work environment. World Sci. News 2018, 109, 143–154. [Google Scholar]

- PN-EN 420+A1:2012. Protective Gloves. General Requirements and Test Methods. Available online: https://infostore.saiglobal.com/en-us/Standards/PN-EN-420-2005-A1-2012-931705_SAIG_PKN_PKN_2196407/ (accessed on 13 December 2019).

- Militký, J.; Kovačič, V.; Bajzík, V. Mechanical properties of basalt filaments. Fibers Text. East. Eur. 2007, 15, 49–53. [Google Scholar]

- Kumbhar, V.P. An overview: Basalt rock fibers—New construction material. Acta Eng. Int. 2014, 2, 11–18. [Google Scholar]

- Li, Z.; Ma, J.; Ma, H.; Xu, X. Properties and applications of basalt fiber and its composites. IOP Conf. Ser. Earth Environ. Sci. 2018, 186, 1–7. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B-Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Miśkiewicz, P.; Frydrych, I.; Pawlak, W.; Cichocka, A. Modification of surface of basalt fabric on protecting against high temperatures by the method of magnetron sputtering. Autex Res. J. 2019, 19, 36–43. [Google Scholar] [CrossRef] [Green Version]

- Jamshaid, H.; Mishra, R.; Tunakova, V.; Militky, J. Investigation of electrical properties of basalt and its hybrid structures. Text. Res. J. 2017, 87, 715–725. [Google Scholar] [CrossRef]

- Chelliah, A. Basalt fabric reinforced epoxy composites. Mater. Res. 2019, 22, 1–8. [Google Scholar]

- Hrynyk, R.; Frydrych, I.; Irzmińska, E.; Stefko, A. Thermal properties of aluminized and non-aluminized basalt fabrics. Text. Res. J. 2012, 83, 1860–1872. [Google Scholar] [CrossRef]

- Wei, Q. (Ed.) Surface Modification of Textiles; Woodhead Publishing: Sawston, UK, 2009. [Google Scholar]

- Zhai, Y.; Liu, X.; Xiao, L. Magnetron sputtering coating of protective fabric study on influence of thermal properties. J. Text. Sci. Technol. 2015, 1, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Han, H.R.; Kim, J.J. A study on the thermal and physical properties of nylon fabric treated by metal sputtering (Al, Cu, Ni). Text. Res. J. 2018, 88, 2397–2414. [Google Scholar] [CrossRef]

- Han, H.R.; Park, Y.; Yun, C.H.; Park, C.H.H. Heat transfer characteristics of aluminum sputtered fabrics. J. Eng. Fiber Fabr. 2018, 13, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Korzeniewska, E.; Józwik, J.; Zawiślak, R.; Krawczyk, A.; Michałowska, J. Resistance of metallic layers used in textronic systems to mechanical deformation (in Polish). Prz. Elektrotechniczn. 2017, 12, 111–114. [Google Scholar]

- Mokrzycki, W.S.; Tatol, M. Colour difference Delta E—A survey. Mach. Graph. Vis. 2011, 20, 383–412. [Google Scholar]

- Yonehara, M.; Matsui, T.; Kihara, K.; Isono, H.; Kijima, A.; Sugibayashi, T. Experimental relationships between surface roughness, glossiness and color of chromatic colored metals. Mater. Trans. 2004, 45, 1027–1032. [Google Scholar] [CrossRef] [Green Version]

- Matusiak, M. Digieye application in cotton colour measurement. Autex Res. J. 2015, 15, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Malm, V.; Straat, M.; Walkenstrom, P. Effects of surface structure and substrate color on color differences in textile coatings containing effect pigments. Text. Res. J. 2014, 84, 125–139. [Google Scholar] [CrossRef]

- ISO 12127-1:2016. Clothing for Protection Against Heat and Flame—Determination of Contact Heat Transmission Through Protective Clothing or Constituent Materials—Part 1: Contact Heat Produced by Heating Cylinder. Available online: https://www.beuth.de/en/standard/din-en-iso-12127-1/169901157 (accessed on 13 December 2019).

- EN 407:2004. Protective Gloves Against Thermal Risks (Heat and/or Fire). Available online: https://guidegloves.com/guidance/standards/en-407/ (accessed on 13 December 2019).

- ISO 6942:2002. Protective Clothing—Protection Against Heat and Fire—Method of Test: Evaluation of Materials and Materials Assemblies When Exposed to a Source of Radiant Heat. Available online: https://www.iso.org/standard/26327.html (accessed on 13 December 2019).

- Hes, L.; Dolezal, I. Indirect measurement of moisture absorptivity of functional textile fabrics. J. Phys. Conf. Ser. 2018, 1065, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Mangatasifmangat, A.E.; Hes, L.; Bajzik, V.; Mazari, A. Thermal absorptivity model of knitted rib fabric and its experimental verification. Autex Res. J. 2018, 18, 20–27. [Google Scholar] [CrossRef] [Green Version]

- ASTM D257-14:2014. Standard Test Methods for DC Resistance or Conductance of Insulating Materials. Available online: https://www.astm.org/Standards/D257.htm (accessed on 13 December 2019).

- ISO 11664-4:2008(E)(CIE S 014-4/E:2007). Colorimetry—Part 4: CIE 1976 L*a*b* Colour Space. Available online: https://www.iso.org/standard/52497.html (accessed on 13 December 2019).

- Fairchild, M.D. Color Appearance Models, 2nd ed.; Wiley: Chichester, UK, 2005. [Google Scholar]

- Dattner, M.; Bohn, D. Characterization of print quality in terms of colorimetric aspects. In Printing on Polymers: Fundamentals and Applications; Izdebska, J., Thomas, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 329–345. [Google Scholar]

- Miankafshe, M.A.; Bashir, T.; Persson, N.K. The role and importance of surface modification of polyester fabrics by chitosan and hexadecylpyridinium chloride for the electrical and electro-thermal performance of graphene-modified smart textiles. New J. Chem. 2019, 43, 6643–6658. [Google Scholar] [CrossRef]

| Fabric Description | Fabric Made of Basalt Fibers | Basalt Fabric Modified with a Chrome Coating 20 µm | Basalt Fabric Modified with an Zirconium(IV) Oxide Coating 18 µm |

|---|---|---|---|

| Fabric image |  |  |  |

| Coating | Target Material | Magnetron Sputtering Power/kW | Argon Pressure/Pa | Oxygen Partial Pressure/Pa | Deposition Time/ks |

|---|---|---|---|---|---|

| Chrome | Chromium (4N) | 3 | 0.5 | - | 26.4 |

| Zirconium(IV) oxide | Zirconium (2N5) | 3 | 0.5 | 0.04 | 37.6 |

| Pair of Squares | AF | FL | BG | GM | CH | HN | DI | IO | EK | KP | AB |

| x | −0.5 | 0.5 | −0.5 | 0.5 | −0.5 | 0.5 | −0.5 | 0.5 | −0.5 | 0.5 | −1.0 |

| y | 2.0 | 2.0 | 1.0 | 1.0 | 0.0 | 0.0 | −1.0 | −1.0 | −2.0 | −2.0 | 1.5 |

| Pair of Squares | BC | CD | DE | FG | GH | HI | IK | LM | MN | NO | OP |

| x | −1.0 | −1.0 | −1.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| y | 0.5 | −0.5 | −1.5 | 1.5 | 0.5 | −0.5 | −1.5 | 1.5 | 0.5 | −0.5 | −1.5 |

| Parameters | Basalt Fabric Modified with a Chrome Coating | Basalt Fabric | Basalt Fabric Modified with an Zirconium(IV) Oxide Coating |

|---|---|---|---|

| ΔEmax | 0.9 | 0.6 | 0.9 |

| ΔEav | 0.6 | 0.4 | 0.6 |

| Variation coefficient | 24% | 29% | 28% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miśkiewicz, P.; Frydrych, I.; Tokarska, M.; Pawlak, W. Study on Some Thermal and Electrical Properties of Basalt Fabric Modified with Metal and Ceramics as a Result of Magnetron Sputtering. Polymers 2019, 11, 2087. https://doi.org/10.3390/polym11122087

Miśkiewicz P, Frydrych I, Tokarska M, Pawlak W. Study on Some Thermal and Electrical Properties of Basalt Fabric Modified with Metal and Ceramics as a Result of Magnetron Sputtering. Polymers. 2019; 11(12):2087. https://doi.org/10.3390/polym11122087

Chicago/Turabian StyleMiśkiewicz, Pamela, Iwona Frydrych, Magdalena Tokarska, and Wojciech Pawlak. 2019. "Study on Some Thermal and Electrical Properties of Basalt Fabric Modified with Metal and Ceramics as a Result of Magnetron Sputtering" Polymers 11, no. 12: 2087. https://doi.org/10.3390/polym11122087

APA StyleMiśkiewicz, P., Frydrych, I., Tokarska, M., & Pawlak, W. (2019). Study on Some Thermal and Electrical Properties of Basalt Fabric Modified with Metal and Ceramics as a Result of Magnetron Sputtering. Polymers, 11(12), 2087. https://doi.org/10.3390/polym11122087