Thermal and Mechanical Properties of Biocomposites Made of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Potato Pulp Powder

Abstract

:1. Introduction

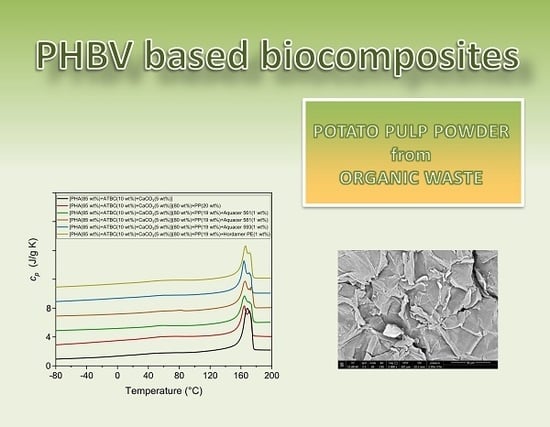

2. Materials and Methods

2.1. Materials

2.2. Composite Preparation

2.3. Composite Characterization

3. Results and Discussion

3.1. Thermogravimetric Analysis of the Potato Pulp Powder, the PHBV Based Matrix and Biocomposites [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %)+PP(20 wt %)

3.2. Scanning Electron Microscopy of the Potato Pulp Powder

3.3. Thermal, Mechanical and Viscoelastic Properties of the PHBV Matrix

3.4. Thermal and Mechanical Properties of the PHBV Based Biocomposites without and with Surface Treatment of the Potato Pulp Power with Waxes

3.5. Morphology of the PHBV Based Biocomposites without and with Surface Treatment of the Potato Pulp Power with Waxes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Padovani, G.; Carlozzi, P.; Seggiani, M.; Cinelli, P.; Vitolo, S.; Lazzeri, A. PHB-rich biomass and BioH2 production by means of photosynthetic microorganisms. Chem. Eng. Trans. 2016, 49, 55–60. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V. Polyhydroxyalkanoate (PHA): Review of synthesis, Characteristics, processing and potential applications in packaging. eXPRESS Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef]

- Sudesh, K.; Abe, H.; Doi, Y. Synthesis, structure and properties of polyhydroxyalkanoates: Biological polyesters. Prog. Polym. Sci. 2000, 25, 1503–1555. [Google Scholar] [CrossRef]

- Laycock, B.; Halley, P.; Pratt, S.; Werker, A.; Lant, P. The chemomechanical properties of microbial polyhydroxyalkanoates. Progr. Polym. Sci. 2013, 38, 536–583. [Google Scholar] [CrossRef]

- Keskin, G.; Kızıl, G.; Bechelany, M.; Pochat-Bohatier, C.; Öner, M. Potential of polyhydroxyalkanoate (PHA) polymers family as substitutes of petroleum based polymers for packaging applications and solutions brought by their composites to form barrier materials. Pure Appl. Chem. 2017, 89, 1841–1848. [Google Scholar] [CrossRef]

- Deroiné, M.; Le Duigou, A.; Corre, Y.M.; Le Gac, P.Y.; Davies, P.; César, G.; Bruzaud, S. Seawater accelerated ageing of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym. Degrad. Stab. 2014, 105, 237–247. [Google Scholar] [CrossRef]

- Volova, T.G.; Boyandin, A.N.; Vasiliev, A.D.; Karpov, V.A.; Prudnikova, S.V.; Mishukova, O.V.; Boyarskikh, U.A.; Filipenko, M.L.; Rudnev, V.P.; Xuân, B.B.; et al. Biodegradation of polyhydroxyalkanoates (PHAs) in tropical coastal waters and identification of PHA-degrading bacteria. Polym. Degrad. Stab. 2010, 95, 2350–2359. [Google Scholar] [CrossRef]

- Seggiani, M.; Cinelli, P.; Balestri, E.; Mallegni, N.; Stefanelli, E.; Rossi, A.; Lardicci, C.; Lazzeri, A. Novel Sustainable Composites Based on Poly(hydroxybutyrate-co-hydroxyvalerate) and Seagrass Beach-CAST Fibers: Performance and Degradability in Marine Environments. Materials 2018, 11, 772. [Google Scholar] [CrossRef]

- Misra, M.; Pandey, J.; Mohanty, A. Biocomposites: Design and Mechanical Performance, 1st ed.; Woodhead Publishing: Cambridge, UK, 2015; ISBN-10: 1782423737. [Google Scholar]

- Dipa, R. Biocomposites for High-Performance Applications, 1st ed.; Woodhead Publishing: Duxford, UK, 2017; ISBN 9780081007938. [Google Scholar]

- Jawaid, M.; Thariq, M.; Sabe, N. Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 1st ed.; Woodhead Publishing: Duxford, UK, 2019; ISBN 9780081022924. [Google Scholar]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibers. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibers, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Yua, L.; Deana, K.; Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Maya-Jacob, J.; Sabu, T. Review—Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga Guadalupe Carbajal, G.; Wypych, F. Polymer blends and composites from renewable resources Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Faruka, O.; Bledzkia, A.K.; Fink, H.P.; Saind, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Pandey, J.K.; Ahn, S.H.; Lee, C.S.; Mohanty, A.K.; Misra, M. Recent Advances in the Application of Natural Fiber Based Composites. Macromol. Mater. Eng. 2010, 295, 975–989. [Google Scholar] [CrossRef]

- Nielsen, L.E.; Landel, R.F. Mechanical Properties of Polymers and Composites, 2nd ed.; Marcel Dekker: New York, NY, USA, 1994; ISBN 0824761837. [Google Scholar]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Composites B 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Signori, F.; Pelagaggi, M.; Bronco, S.; Righetti, M.C. Amorphous/Crystal and Polymer/Filler Interphases in Biocomposites from Poly(butylene succinate). Thermochim. Acta 2012, 543, 74–81. [Google Scholar] [CrossRef]

- Jiang, L.; Huang, J.; Qian, J.; Chen, F.; Zhang, J.; Wolcott, M.P.; Zhu, Y. Study of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/Bamboo Pulp Fiber Composites: Effects of Nucleation Agent and Compatibilizer. J. Polym. Environ. 2008, 16, 83–93. [Google Scholar] [CrossRef]

- Shanks, R.A.; Hodzic, A.; Wong, S. Thermoplastic biopolyester natural fiber composites. J. Appl. Polym. Sci. 2004, 91, 2114–2121. [Google Scholar] [CrossRef]

- Keller, A. Compounding and mechanical properties of biodegradable hemp, fiber composites. Compos. Sci. Techol. 2003, 63, 1307–1316. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Reactive compatibilization and performance evaluation of miscanthus biofiber reinforced poly(hydroxybutyrate-co-hydroxyvalerate) biocomposites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Montano-Leyva, B.; Gontard, N.; Angellier-Coussy, H. Poly(3-hydroxybutyrate-co-hydroxyvalerate) and wheat straw fibers biocomposites produced by co-grinding: Processing and mechanical behavior. J. Compos. Mater. 2017, 51, 985–996. [Google Scholar] [CrossRef]

- Srubar, W.V.; Pilla, S.; Wright, Z.C.; Ryan, C.A.; Greene, J.P.; Frank, C.W.; Billington, S.L. Mechanisms and impact of fiber–matrix compatibilization techniques on the material characterization of PHBV/oak wood flour engineered biobased composites. Compos. Sci. Technol. 2012, 72, 708–715. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef]

- Fritsch, C.; Staebler, A.; Happel, A.; Cubero Márquez, M.A.; Aguiló-Aguayo, I.; Abadias, M.; Gallur, M.; Cigognini, I.M.; Montanari, A.; López, M.J.; et al. Processing, Valorization and Application of Bio-Waste Derived Compounds from Potato, Tomato, Olive and Cereals: A Review. Sustainability 2017, 9, 1492. [Google Scholar] [CrossRef]

- Schmid, M.; Herbst, C.; Mueller, K.; Staebler, A.; Schlemmer, D.; Coltelli, M.B.; Lazzeri, A. Effect of potato pulp filler on the mechanical properties and water vapor transmission rate of thermoplastic WPI/PBS blends. Polym. Plast. Technol. Eng. 2016, 55, 510–517. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, W.; Wang, X.; Chen, X.; Chen, G.Q.; Xu, K. Processability Modifications of Poly(3-hydroxybutyrate) by Plasticizing, Blending, and Stabilizing. J. Appl. Polym. Sci. 2008, 107, 166–173. [Google Scholar] [CrossRef]

- Quintana, R.; Persenaire, O.; Lemmouchi, Y.; Sampson, J.; Martin, S.; Bonnaud, L.; Dubois, P. Enhancement of cellulose acetate degradation under accelerated weathering by plasticization with eco-friendly plasticizers. Polym. Degrad. Stab. 2013, 98, 1556–1562. [Google Scholar] [CrossRef]

- European Food Safety Authority. Scientific Opinion on Flavouring Group Evaluation 10, Revision 3 (FGE.10Rev3): Aliphatic primary and secondary saturated and unsaturated alcohols, aldehydes, acetals, carboxylic acids and esters containing an additional oxygenated functional group and lactones from chemical groups 9, 13 and 30. EFSA J. 2012, 10, 25–63. [Google Scholar] [CrossRef]

- Sarge, S.M.; Hemminger, W.; Gmelin, E.; Höhne, G.W.H.; Cammenga, H.K.; Eysel, W. Metrologically based procedures for the temperature, heat and heat flow rate calibration of DSC. J. Therm. Anal. 1997, 49, 1125–1134. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristic of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Garcia-Perez, M.; Chaala, A.; Yang, J.; Roy, C. Co-pyrolysis of sugarcane bagasse with petroleum residue. Part I: Thermogravimetric analysis. Fuel 2001, 80, 1245–1258. [Google Scholar] [CrossRef]

- Aggarwal, P.; Dollimore, D.; Heon, K. Comparative thermal analysis study of two biopolymers, starch and cellulose. J. Therm. Anal. 1997, 50, 7–17. [Google Scholar] [CrossRef]

- Kamur, P.; Sandeep, K.P.; Alavi, S.; Truong, V.D.; Gorga, R.E. Preparation and characterization of bio-nanocomposite films based on soy protein isolate and montmorillonite using melt extrusion. J. Food Eng. 2010, 100, 480–489. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A.K.; Sugie, T.; Takai, Y.; Hamada, H. Renewable resource based biocomposites from natural fiber and polyhydroxybutyrate-co-valerate (PHBV) bioplastics. Composites Part A 2008, 39, 875–886. [Google Scholar] [CrossRef]

- Srithep, Y.; Ellingham, T.; Peng, J.; Sabo, R.; Clemons, C.; Turng, L.-S.; Pilla, S. Melt compounding of poly(3-hydroxybutyate-co-3-hydroxyvalerate)/nanofibrilled cellulose nanocomposites. Polym. Degrad. Stab. 2013, 98, 1439–1449. [Google Scholar] [CrossRef]

- Batista, K.C.; Silva, D.A.K.; Coelho, L.A.F.; Pezzin, S.H.; Pezzin, A.P.T. Soil Biodegradation of PHBV/Peach Palm Particles Biocomposites. J. Polym. Environ. 2010, 18, 346–354. [Google Scholar] [CrossRef]

- Czerniecka, A.; Magon, A.; Schliesser, J.; Woodfield, B.F.; Pyda, M. Heat capacity of poly(3-hydroxybutyrate). J. Chem. Thermodyn. 2014, 73, 76–84. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Gazzano, M.; Righetti, M.C. The role of the rigid amorphous fraction on cold crystallization of poly(3-hydroxybutyrate). Macromolecules 2012, 45, 5684–5691. [Google Scholar] [CrossRef]

- Yoshie, N.; Nakasato, K.; Fujiwara, M.; Kasuya, K.; Abe, H.; Doi, Y.; Inoue, Y. Effect of low molecular weight additives on enzymatic degradation of poly(3-hydroxybutyrate). Polymer 2000, 41, 3227–3234. [Google Scholar] [CrossRef]

- Minakov, A.A.; Mordvintsen, D.A.; Schick, C. Melting and reorganization of poly(ethylene terephthalate) on fast heating (1000 K/s). Polymer 2004, 45, 3755–3763. [Google Scholar] [CrossRef]

- Righetti, M.C.; Laus, M.; Di Lorenzo, M.L. Temperature dependence of the rigid amorphous fraction in poly(ethylene terephthalate). Eur. Polym. J. 2014, 58, 60–68. [Google Scholar] [CrossRef]

- Righetti, M.C.; Tombari, E.; Di Lorenzo, M.L. The role of the crystallization temperature on the nanophase structure evolution of poly([(R)-3-hydroxybutyrate). J. Phys. Chem. B 2013, 117, 12303–12311. [Google Scholar] [CrossRef]

- Baltieri, R.C.; Innocentini Mei, L.H.; Bartoli, J. Study of the influence of plasticizers on the thermal and mechanical properties of poly(3-hudroxybutyrate) compounds. Macromol. Symp. 2003, 197, 33–44. [Google Scholar] [CrossRef]

- Kurusu, R.S.; Siliki, C.A.; David, E.; Demarquette, N.R.; Gauthier, C.; Chenal, J.M. Incorporation of plasticizers in sugarcane-based poly(3-hydroxybutyrate)(PHB): Changes in microstructure and properties through ageing and annealing. Ind. Crop. Prod. 2015, 72, 166–174. [Google Scholar] [CrossRef]

- Berthet, M.-A.; Gontard, N.; Angellier-Coussy, H. Impact of fiber moisture content on the structural/mechanical properties relationships of PHBV/wheat straw fibers biocomposites. Composites A 2015, 72, 139–147. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Garkhail, S.K.; Peijs, T. Biodegradable composites based on flax/polyhydroxybutyrate, and its copolymer with hydroxyvalerate. Ind. Crops Prod. 2010, 31, 34–42. [Google Scholar] [CrossRef]

- Berthet, M.-A.; Angellier-Coussy, H.; Chea, V.; Guillard, V.; Gastaldi, E.; Gontard, N. Sustainable food packaging: Valorizing wheat straw fibers for tuning PHBV-based composites properties. Compos. Sci. Technol. 2015, 117, 386–391. [Google Scholar] [CrossRef]

- Reis, K.C.; Pereira, J.; Smith, A.C.; Carvalho, C.W.P.; Wellner, N.; Yakimets, I. Characterization of polyhydroxybutyartehydroxyvalerate (PHB-HV)/maize starch blend films. J. Food Eng. 2008, 89, 361–369. [Google Scholar] [CrossRef]

- Vandenburg, L.E.; Wilder, E.A. The Structural Constituents of Carnauba Wax. J. Am. Oil Chem. Soc. 1970, 47, 514–518. [Google Scholar] [CrossRef]

- Tulloch, A.P. The Composition of Beeswax and Other Waxes Secreted by Insect. Lipids 1970, 5, 247–258. [Google Scholar] [CrossRef]

| Potato Pulp | Natural Wax | |

|---|---|---|

| PHBV(100%) | - | - |

| PHBV(90 wt %)+ATBC(10 wt %) | ||

| PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %) | ||

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %) | PP(20 wt %) | |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %) | PP(19 wt %) | Aquacer 561 (1 wt %) |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %) | PP(19 wt %) | Aquacer 581 (1 wt %) |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %) | PP(19 wt %) | Aquacer 593 (1 wt %) |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %) | PP(19 wt %) | Hordamer PE (1 wt %) |

| Extrusion Temperature (°C) | Screw Speed (rpm) | Cycle Time (s) | Injection Temperature (°C) | Injection Pressure (bar) | Molding Time (s) | Mold Temperature (°C) |

|---|---|---|---|---|---|---|

| 180 | 100 | 90 | 180 | 150 | 60 | 80 |

| Δhm (J/g) | wC | |

|---|---|---|

| PHBV(100%) | 92 | 0.65 |

| PHBV(90 wt %)+ATBC(10 wt %) | 97 | 0.68 |

| PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %) | 103 | 0.72 |

| Δhm (J/g) | wC | |

|---|---|---|

| PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %) | 103 | 0.72 |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80wt %)+PP(20 wt %) | 103 | 0.72 |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %)+PP(19 wt %)+Aquacer 561 (1 wt %) | 103 | 0.68 |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %)+PP(19 wt %)+Aquacer 581 (1 wt %) | 101 | 0.71 |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %)+PP(19 wt %)+Aquacer 593 (1 wt %) | 101 | 0.71 |

| [PHBV(85 wt %)+ATBC(10 wt %)+CaCO3(5 wt %)](80 wt %)+PP(19 wt %)+Hordamer PE (1 wt %) | 101 | 0.71 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Righetti, M.C.; Cinelli, P.; Mallegni, N.; Stäbler, A.; Lazzeri, A. Thermal and Mechanical Properties of Biocomposites Made of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Potato Pulp Powder. Polymers 2019, 11, 308. https://doi.org/10.3390/polym11020308

Righetti MC, Cinelli P, Mallegni N, Stäbler A, Lazzeri A. Thermal and Mechanical Properties of Biocomposites Made of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Potato Pulp Powder. Polymers. 2019; 11(2):308. https://doi.org/10.3390/polym11020308

Chicago/Turabian StyleRighetti, Maria Cristina, Patrizia Cinelli, Norma Mallegni, Andreas Stäbler, and Andrea Lazzeri. 2019. "Thermal and Mechanical Properties of Biocomposites Made of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Potato Pulp Powder" Polymers 11, no. 2: 308. https://doi.org/10.3390/polym11020308

APA StyleRighetti, M. C., Cinelli, P., Mallegni, N., Stäbler, A., & Lazzeri, A. (2019). Thermal and Mechanical Properties of Biocomposites Made of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Potato Pulp Powder. Polymers, 11(2), 308. https://doi.org/10.3390/polym11020308