Comparison of Adhesive Properties of Polyurethane Adhesive System and Wood-plastic Composites with Different Polymers after Mechanical, Chemical and Physical Surface Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Selection

2.2. Contact Angle Measurement

2.3. Surface Treatment

2.3.1. Mechanical Treatment

2.3.2. Chemical Treatment

2.3.3. Physical Treatment

2.4. Specimen Preparation

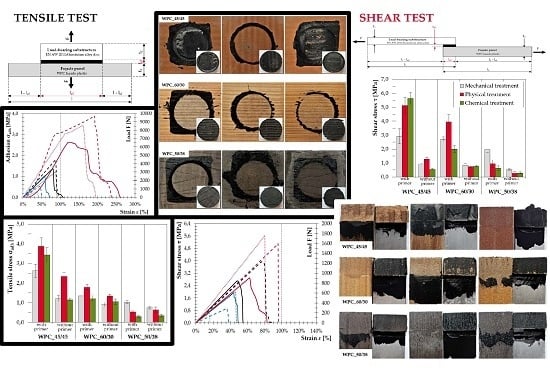

2.5. Strength Test

2.6. Data Analysis

3. Results and Discussion

3.1. Contact Angle Measurement

3.2. Failure Mode

3.3. Tensile/Shear Stress and Tensibility of Bonded Assemblies

4. Conclusions

- An improvement in the adhesive properties was demonstrated by the increase in the strength of the bonded joint after tensile as well as shear tests. In one combination, the achieved strength was nearing the maximum strength of the adhesive system declared by the manufacturer.

- A positive effect of surface modifications on the failure mode was observed. In two combinations substrate failure was the predominant failure mode after the tensile test.

- The selected surface treatments were more suitable for PVC-based WPCs than for PE-based WPCs. Furthermore, it was confirmed that the effect of the thermoplastic component of WPC on its adhesion properties is dominant.

- The effect of the wood fibers in WPCs was minor in all tested combinations. The assumption that a higher content of wood flour would have a positive effect on the adhesive properties was not confirmed.

- The most consistent results were achieved after physical modification of the bonded surface. However, different exposure period for each tested material seems to be necessary. Physical modification using the MHSDBD plasma source can be considered universal surface treatment for the selected WPCs. It is also the cleanest and the least time-consuming method.

- The presented results confirm the well proven fact that the adhesive properties of the surface of WPC materials are very poor, and without modification of the bonded surfaces, their bonding is almost impossible, or rather the effectiveness of the joint is negligible.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Park, S.-J.; Seo, M.-K. Chapter 7—Types of Composites. Interface Sci. Technol. 2011, 18, 501–629. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood-Plastic Composite Technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef]

- Clemons, C. Wood-plastic composites in the United States: The interfacing of two industries. For. Prod. J. 2002, 52, 10–18. [Google Scholar]

- Klyosov, A.A. Wood-Plastic Composites, 1st ed.; John Wiley & Sons, Inc.: London, UK, 2007; pp. 1–49. [Google Scholar]

- Spear, M.J.; Eder, A.; Carus, M. 10—Wood polymer composites. In Wood Composites, 1st ed.; Ansell, M.P., Ed.; Woodhead Publishing Elsevier Ltd.: Cambridge, UK, 2015; pp. 195–249. [Google Scholar]

- Otheguya, M.E.; Gibsona, A.G.; Robinsona, M.; Findonb, E.; Crippsb, B.; Ochoa Mendozac, A.; Aguinaco Castroc, M.T. Recycling of end-of-life thermoplastic composite boats. Plast. Rubber. Compos. 2009, 38, 406–411. [Google Scholar] [CrossRef]

- Kokta, B.V.; Raj, R.G.; Daneault, C. Use of wood flour as filler in polypropylene: Studies on mechanical properties. Polym.-Plast. Technol. Eng. 1989, 28, 247–259. [Google Scholar] [CrossRef]

- Sommerhuber, P.F.; Wang, T.; Krause, A. Wood-plastic composites as potential applications of recycled plastics of electronic waste and recycled particleboard. J. Clean. Prod. 2016, 121, 176–185. [Google Scholar] [CrossRef]

- Gordon, J.E. The New Science of Strong Materials (or Why You Don’t Fall through the Floor), 1st ed.; Princeton University Press: Princeton, NJ, 1998; p. 179. [Google Scholar]

- Simons, H.R.; Weith, A.J.; Shack, W. Extrusion of Plastics, Rubber, and Metals, 1st ed.; Reinhold Publishing: New York, NY, USA, 1952; p. 454. [Google Scholar]

- Kraus, E.; Baudrit, B.; Heidemeyer, P.; Bastian, M.; Stoyanov, O.V.; Starostina, I.A. Problems in Adhesion Bonding of WPC. Polym. Res. J. 2015, 9, 327–335. [Google Scholar]

- Friedrich, D.; Luible, A. Measuring the wind suction capacity of plastics-based cladding using foil bag tests: A comparative study. J. Build. Eng. 2016, 8, 152–161. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Stark, N.M.; Tshabalala, M.A.; Gao, J.; Fan, Y. Weathering Characteristics of Wood Plastic Composites Reinforced with Extracted or Delignified Wood Flour. Materials 2016, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Stark, N.M.; Matuana, L.M.; Clemons, C.M. Effect of processing method on surface and weathering characteristics of wood-flour/HDPE composites. J. Appl. Polym. Sci. 2004, 93, 1021–1030. [Google Scholar] [CrossRef] [Green Version]

- Cheng, R.; Zhang, L.; Li, Y. Study on bonding properties of PVC-based WPC bonded with acrylic adhesive. J. Adhes. Sci. Technol. 2012, 26, 2729–2735. [Google Scholar] [CrossRef]

- Soury, E.; Behravesh, A.H.; Rouhani Esfahani, E.; Zolfaghari, A. Design, optimization and manufacturing of wood-plastic composite pallet. Mater. Des. 2009, 30, 4183–4191. [Google Scholar] [CrossRef]

- Mohamadzadeh, A.; Rostampour Haftkhani, A.; Ebrahimi, G.; Yoshihara, Y. Numerical and experimental failure analysis of screwed single shear joints in wood plastic composite. Mater. Des. 2012, 35, 404–413. [Google Scholar] [CrossRef]

- Oporto, G.S.; Gardner, D.J.; Bernhardt, G.; Neivandt, D.J. Characterizing the mechanism of improved adhesion of modified wood plastic composite (WPC) surfaces. J. Adhes. Sci. Technol. 2007, 21, 1097–1116. [Google Scholar] [CrossRef]

- Gramlich, W.M.; Gardner, D.J.; Neivandt, D.J. Surface treatments of wood-plastic composites (WPCs) to improve adhesion. J. Adhes. Sci. Technol. 2006, 20, 1873–1887. [Google Scholar] [CrossRef]

- Moghadamzadeh, A.; Rahimi, H.; Asadollahzadeh, M.; Hemmati, A.R. Surface treatment of wood polymer composites for adhesive bonding. Int. J. Adhes. Adhes. 2011, 31, 816–821. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. 2009, 223, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Ebnesajjad, S. Adhesives Technology Handbook, 2nd ed.; William Andrew: New York, NY, USA, 2008; p. 387. [Google Scholar]

- Petrie, E.M. Handbook of Adhesives and Sealants, 2nd ed.; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2007; p. 765. [Google Scholar]

- Da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology, 1st ed.; Springer: Berlin, Germany, 2011; p. 1568. [Google Scholar]

- Nečasová, B.; Liška, P.; Šlanhof, J. Research summary: Analysis of selected adhesive systems intended for facade bonding. In Advances and Trends in Engineering Sciences and Technologies II. In Proceedings of the 2nd International Conference on Engineering Sciences and Technologies, ESaT 2016, Vysoké Tatry, Slovakia, 29 June–1 July 2016; Al Ali, M., Platko, P., Eds.; CRC Press/Balkema: London, UK, 2017; pp. 573–578. [Google Scholar]

- Wolkenhauer, A.; Avramidis, G.; Hauswald, E.; Militz, H.; Viöl, W. Plasma Treatment of Wood–Plastic Composites to Enhance Their Adhesion Properties. J. Adhes. Sci. Technol. 2008, 22, 2025–2037. [Google Scholar] [CrossRef]

- Kuczmaszewski, J. Fundamentals of Metal-Metal Adhesive Joint Design. Ph.D. Thesis, Lublin University of Technology, Lublin, Poland, 2006; p. 199. [Google Scholar]

- Ebnesajjad, S. Surface Treatment of Materials for Adhesive Bonding, 2nd ed.; William Andrew, Elsevier: London, UK, 2014; p. 341. [Google Scholar]

- Nečasová, B.; Liška, P.; Kelar, J. Study on Surface Treatments of Modified Wood Plastic Composite (WPC) to Improve Adhesion. Appl. Mech. Mater. 2016, 861, 96–103. [Google Scholar] [CrossRef]

- Nečasová, B.; Liška, P.; Šlanhof, J. Determination of Bonding Properties of Wood Plastic Composite Façade Cladding. J. News Eng. 2015, 3, 5–13. [Google Scholar]

- Saleema, N.; Sarkar, D.K.; Paynter, R.W.; Gallant, D.; Eskandarian, M. A simple surface treatment and characterization of AA 6061 aluminum alloy surface for adhesive bonding applications. Appl. Surf. Sci. 2012, 261, 742–748. [Google Scholar] [CrossRef] [Green Version]

- Oushabi, A.; Sair, S.; Oudrhiri Hassani, F.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF–Polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Agarwal, S.; Gupta, R.K. Chapter 5—Improving the mechanical properties of wood plastic composites. In Applied Researchers in Polysaccharides; Alsewailem, F.D., Ed.; Research Signpost: Kerala, India, 2015; pp. 103–124. [Google Scholar]

- Sihelnik, S. Activation and Cleaning of Glass Using Non-Thermal Plasma at Atmospheric Pressure. Master’s Thesis, Masaryk University, Brno, Czech Republic, 2018. [Google Scholar]

- Chlupová, S.; Kelar, J.; Slavíček, P. Changing the surface properties of ABS plastic by plasma. Plasma Phys. Technol. 2017, 4, 32–35. [Google Scholar] [CrossRef]

- Homola, T.; Krumpolec, R.; Zemánek, M.; Kelar, J.; Synek, P.; Hoder, T.; Černák, M. An Array of Micro-hollow Surface Dielectric Barrier Discharges for Large-Area Atmospheric-Pressure Surface Treatments. Plasma Chem. Plasma Process. 2017, 37, 1149–1163. [Google Scholar] [CrossRef]

- Auto-Color. Available online: http://www.a-c.cz/index.php?/dinitrol/stavebnictvi-lepeni-fasadnich-panelu/pu-lepidla-pro-lepeni-fasadnich-panelu/f500lp_fp-dinitrol-f500lp-polyflex/flypage.tpl.html (accessed on 11 January 2019).

- Perwood. Available online: https://www.perwood.cz/en/ (accessed on 11 January 2019).

- Woodplastic. Available online: https://www.woodplastic.eu/terasy/forest/ (accessed on 11 January 2019).

- Nextwood. Available online: https://www.nextwood.cz/plotovky-a-nosniky/ (accessed on 11 January 2019).

- ČSN EN 828. Adhesives—Wettability—Determination by Measurement of Contact Angle and Surface Free Energy of Solid Surface; Sorting No. 66 8621; Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2013; p. 16. [Google Scholar]

- ČSN 73 2577. Test for Surface Finish Adhesion of Building Structures to the Base; Sorting No. 32691; Czech Office for Technical Approvals and Measurements: Prague, Czech Republic, 1981; p. 4. [Google Scholar]

- ČSN EN 1465. Adhesives—Determination of Tensile Lap-Shear Strength of Bonded Assemblies; Sorting No. 66 8510; Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2009; p. 12. [Google Scholar]

- Dukes, W.A.; Bryant, R.W. The Effect of Adhesive Thickness on Joint Strength. J. Adhes. 1969, 1, 48–53. [Google Scholar] [CrossRef]

- Davies, P.; Sohier, L.; Cognard, J.-Y.; Bourmaud, A.; Choqueuse, D.; Rinnert, E.; Créac’hcadec, R. Influence of adhesive bond line thickness on joint strength. Int. J. Adhes. Adhes. 2009, 29, 724–736. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Campilho, R.D.S.G. The Effect of Adhesive Thickness on the Mechanical Behavior of a Structural Polyurethane Adhesive. J. Adhes. 2015, 91, 331–346. [Google Scholar] [CrossRef]

- Lijuan, L.; Chenguang, H.; Toshiyuki, S. Effect of adhesive thickness, adhesive type and scarf angle on the mechanical properties of scarf adhesive joints. Int. J. Solids Struct. 2013, 50, 4333–4340. [Google Scholar] [CrossRef] [Green Version]

- Boutar, Y.; Naïmi, S.; Mezlini, S.; da Silva, L.F.M.; Hamdaoui, M.; Ben Sik Ali, M. Effect of adhesive thickness and surface roughness on the shear strength of aluminium one-component polyurethane adhesive single-lap joints for automotive applications. J. Adhes. Sci. Technol. 2016, 30, 1913–1929. [Google Scholar] [CrossRef]

- Akhavan-safar, A.; Ayatollahi, M.R.; da Silva, L.F.M. Strength prediction of adhesively bonded single lap joints with different bondline thickness: A critical longitudinal strain approach. Int. J. Solids Struct. 2017, 109, 189–198. [Google Scholar] [CrossRef]

- ČSN ISO 10365. Adhesives. Designation of Main Failure Patterns; Sorting No. 66 8509; Czech Institute for Technical Approvals: Prague, Czech Republic, 1995; p. 5. [Google Scholar]

- ASTM D 5573. Standard Practice for Classifying Failure Modes in Fiber-Reinforced-Plastic (FRP) Joints; ASTM International: West Conshohocken, PA, USA, 2005; p. 3. [Google Scholar]

| Surface Treatment/WPC Type | WPC_45/45 [°] | WPC_60/30 [°] | WPC_50/38 [°] |

|---|---|---|---|

| Without Treatment | 90.94 ± 2.96 | 80.60 ± 4.29 | 98.89 ± 2.97 |

| Mechanical (P40) | 104.95 ± 2.26 | 103.83 ± 1.47 | 118.77 ± 1.28 |

| Physical (MHSDBD) | 63.51 ± 2.15 | 50.99 ± 2.61 | 45.29 ± 1.09 |

| Chemical (10% NaOH) | 67.98 ± 3.55 | 67.43 ± 3.03 | 67.13 ± 1.94 |

| Surface Treatment/ WPC Type | WPC_45/45 | WPC_60/30 | WPC_50/38 | |||

|---|---|---|---|---|---|---|

| With | Without | With | Without | With | Without | |

| Without Treatment | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% |

| Mechanical (P40) | SF 80% | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% |

| Physical (MHSDBD) | NF 60% | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% |

| Chemical (10% NaOH) | AF 80% | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% |

| Surface Treatment/ WPC Type | WPC_45/45 | WPC_60/30 | WPC_50/38 | |||

|---|---|---|---|---|---|---|

| With | Without | With | Without | With | Without | |

| Without treatment | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% |

| Mechanical (P40) | AF 80% | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% |

| Physical (MHSDBD) | SF 100% | AF 100% | AF 80% | AF 100% | AF 100% | AF 100% |

| Chemical (10% NaOH) | SF 80% | AF 100% | AF 100% | AF 100% | AF 100% | AF 100% |

| WPC Type/ Surface Treatment | Mechanical (P40) | Physical (MHSDBD) | Chemical (10% NaOH) | ||||

|---|---|---|---|---|---|---|---|

| With | Without | With | Without | With | Without | ||

| WPC_45/45 | σadh | 2.62 | 1.21 | 3.87 | 2.34 | 3.43 | 1.16 |

| VC 2 | 12.99 | 12.34 | 10.87 | 8.34 | 10.94 | 4.44 | |

| δ | 127.52 | 51.21 | 191.67 | 79.79 | 160.58 | 46.27 | |

| WPC_60/30 | σadh | 1.35 | 0.91 | 1.79 | 1.35 | 1.21 | 1.05 |

| VC | 17.79 | 11.45 | 7.41 | 6.81 | 13.10 | 13.26 | |

| δ | 87.67 | 59.17 | 87.54 | 64.54 | 87.67 | 71.63 | |

| WPC_50/38 | σadh | 1.02 | 0.73 | 0.54 | 0.63 | 0.29 | 0.34 |

| VC | 8.08 | 8.08 | 6.88 | 24.06 | 19.22 | 19.65 | |

| δ | 58.40 | 58.52 | 45.81 | 52.60 | 38.63 | 40.98 | |

| WPC Type/ Surface Treatment | Mechanical (P40) | Physical (MHSDBD) | Chemical (10% NaOH) | ||||

|---|---|---|---|---|---|---|---|

| With | Without | With | Without | With | Without | ||

| WPC_45/45 | τ | 2.91 | 0.93 | 5.11 | 1.21 | 5.63 | 0.56 |

| VC 2 | 18.58 | 0.78 | 11.68 | 11.27 | 7.54 | 8.70 | |

| δ | 62.41 | 24.95 | 95.38 | 33.46 | 79.93 | 16.76 | |

| WPC_60/30 | τ | 2.71 | 0.83 | 3.94 | 0.74 | 2.00 | 0.78 |

| VC | 5.80 | 14.54 | 13.25 | 4.77 | 11.44 | 7.60 | |

| δ | 47.92 | 25.04 | 76.44 | 23.44 | 46.24 | 29.01 | |

| WPC_50/38 | τ | 1.95 | 0.53 | 0.95 | 0.27 | 0.62 | 0.29 |

| VC | 12.07 | 12.73 | 29.77 | 38.39 | 27.14 | 24.23 | |

| δ | 44.29 | 17.11 | 36.31 | 10.70 | 15.99 | 8.88 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nečasová, B.; Liška, P.; Kelar, J.; Šlanhof, J. Comparison of Adhesive Properties of Polyurethane Adhesive System and Wood-plastic Composites with Different Polymers after Mechanical, Chemical and Physical Surface Treatment. Polymers 2019, 11, 397. https://doi.org/10.3390/polym11030397

Nečasová B, Liška P, Kelar J, Šlanhof J. Comparison of Adhesive Properties of Polyurethane Adhesive System and Wood-plastic Composites with Different Polymers after Mechanical, Chemical and Physical Surface Treatment. Polymers. 2019; 11(3):397. https://doi.org/10.3390/polym11030397

Chicago/Turabian StyleNečasová, Barbora, Pavel Liška, Jakub Kelar, and Jiří Šlanhof. 2019. "Comparison of Adhesive Properties of Polyurethane Adhesive System and Wood-plastic Composites with Different Polymers after Mechanical, Chemical and Physical Surface Treatment" Polymers 11, no. 3: 397. https://doi.org/10.3390/polym11030397

APA StyleNečasová, B., Liška, P., Kelar, J., & Šlanhof, J. (2019). Comparison of Adhesive Properties of Polyurethane Adhesive System and Wood-plastic Composites with Different Polymers after Mechanical, Chemical and Physical Surface Treatment. Polymers, 11(3), 397. https://doi.org/10.3390/polym11030397