Preparation and Performances of Warp-Knitted Hernia Repair Mesh Fabricated with Chitosan Fiber

Abstract

:1. Introduction

2. Experimental Setup

2.1. Material

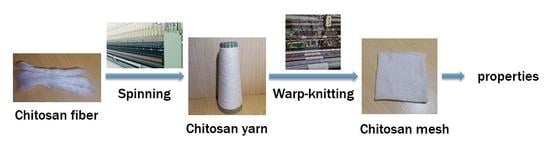

2.2. Preparation of Chitosan Knitted Fabric

2.3. Characterizations

2.4. Mechanical Properties

2.5. Acid and Alkali Resistance

2.6. Antibacterial Property

3. Results and Discussion

3.1. Properties of Chitosan Fiber

3.1.1. Basic Performances of Chitosan Fiber

3.1.2. XRD Test and FTIR Test

3.1.3. TG Test

3.2. Properties of Chitosan Yarn

3.2.1. Strength Test

3.2.2. Evenness Test

3.2.3. Twist Test

3.3. Properties of Chitosan Mesh

3.3.1. Basic Parameters of Chitosan Mesh

3.3.2. Mechanical Properties

3.3.3. Acid and Alkali Resistance

3.3.4. Antibacterial Property

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bilsel, Y.; Abci, I. The search for ideal hernia repair; mesh materials and types. Int. J. Surg. 2012, 10, 317–321. [Google Scholar] [CrossRef]

- Bouliaris, K.; Asprodini, E.; Liakos, P.; Diamantis, A.; Koukoulis, G.; Befani, C.; Tzika, S.; Tepetes, K. Adhesion Prevention to Polypropylene Meshes Using Combined Icodextrin Four Percent and Dimetindene Maleate. J. Surg. Res. 2019, 234, 325–333. [Google Scholar] [CrossRef] [PubMed]

- Cheng, H.; Zhang, Y.L.; Zhang, B. Biocompatibility of polypropylene mesh scaffold with adipose-derived stem cells. Exp. Ther. Med. 2017, 13, 2922–2926. [Google Scholar] [CrossRef] [PubMed]

- Klinge, U.; Klosterhalfen, B.; Öttinger, A.P.; Junge, K.; Schumpelick, V. PVDF as a new polymer for the construction of surgical meshes. Biomaterials 2002, 23, 3487–3493. [Google Scholar] [CrossRef]

- Conze, J.; Junge, K.; Weiß, C.; Anurov, M.; Oettinger, A.; Klinge, U.; Schumpelick, V. New polymer for intra-abdominal meshes—PVDF copolymer. J. Biomed. Mater. Res. Part B Appl. Biomater. 2008, 87, 321–328. [Google Scholar] [CrossRef]

- Berger, D.; Bientzle, M. Polyvinylidene fluoride: A suitable mesh material for laparoscopic incisional and parastomal hernia repair! Hernia 2009, 13, 167–172. [Google Scholar] [CrossRef] [PubMed]

- Cevasco, M.; Itani, K.M.F. Ventral Hernia Repair with Synthetic, Composite, and Biologic Mesh: Characteristics, Indications, and Infection Profile. Surg. Infect. 2012, 13, 209–215. [Google Scholar] [CrossRef] [PubMed]

- Jakob, M.O.; Spari, D.; Zindel, J.; Pinworasarn, T.; Candinas, D.; Beldi, G. Prophylactic, Synthetic Intraperitoneal Mesh Versus No Mesh Implantation in Patients with Fascial Dehiscence. J. Gastrointest. Surg. 2018, 22, 2158–2166. [Google Scholar] [CrossRef] [PubMed]

- Rinaudo, M. Chitin and chitosan: Properties and applications. Prog. Polym. Sci. 2006, 37, 603–632. [Google Scholar] [CrossRef]

- Kang, P.L.; Chang, S.J.; Manousakas, I.; Lee, C.W.; Yao, C.H.; Lin, F.H.; Kuo, S.M. Development and Assessment of Hemostasis Chitosan Dressings. Carbohydr. Polym. 2011, 85, 565–570. [Google Scholar] [CrossRef]

- Ma, L.; Gao, C.; Mao, Z.; Zhou, J.; Shen, J.; Hu, X.; Han, C. Collagen/chitosan porous scaffolds with improved biostability for skin tissue engineering. Biomaterials 2003, 24, 4833–4841. [Google Scholar] [CrossRef]

- Romanova, O.A.; Grigor’ev, T.E.; Goncharov, M.E.; Rudyak, S.G.; Solov’yova, E.V.; Krasheninnikov, S.T.; Saprykin, V.P.; Sytina, E.V.; Chvalun, S.N.; Pal’tsev, M.A.; et al. Chitosan as a Modifying Component of Artificial Scaffold for Human Skin Tissue Engineering. Bull. Exp. Biol. Med. 2015, 159, 557–566. [Google Scholar] [CrossRef]

- Schmidt-Bleek, K.; Kwee, B.J.; Mooney, D.J.; Duda, G.N. Boon and Bane of Inflammation in Bone Tissue Regeneration and Its Link with Angiogenesis. Tissue Eng. Part B Rev. 2015, 21, 354–364. [Google Scholar] [CrossRef]

- Pangon, A.; Saesoo, S.; Saengkrit, N.; Ruktanonchai, U.; Intasanta, V. Hydroxyapatite hybridized chitosan/chitin whisker bionanocomposite fibers for bone tissue engineering applications. Carbohydr. Polym. 2016, 144, 419–427. [Google Scholar] [CrossRef]

- Jiang, G.M.; Miao, X.H.; Lee, D. Process of warp knitting mesh for hernia repair and its mechanical properties. Fibres Text. East. Eur. 2005, 13, 44–46. [Google Scholar]

- Mirjavan, M.; Asayesh, A.; Jeddi, A.A.A. The effect of fabric structure on the mechanical properties of warp knitted surgical meshfor hernia repair. J. Mech. Vehav. Biomed. Mater. 2017, 66, 77–86. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, P.H. Fabrication and evaluation of a warp knitted polypropylene/polylactic acid composite mesh for pelvic floor repair. Text. Res. J. 2018, 88, 1099–1111. [Google Scholar] [CrossRef]

- Dumont, M.; Villet, R.; Guirand, M.; Montembault, A.; Delair, T.; Lack, S.; Barikosky, M.; Crepet, A.; Alcouffe, P.; Laurent, F.; et al. Processing and antibacterial properties of chitosan-coated alginate fibers. Carbohydr. Polym. 2018, 190, 31–42. [Google Scholar] [CrossRef] [PubMed]

- Amato, A.; Migneco, L.M.; Martinelli, A.; Pietrelli, L.; Piozzi, A.; Francolini, I. Antimicrobial activity of catechol functionalized-chitosan versus Staphylococcus epidermidis. Carbohydr. Polym. 2018, 179, 273–281. [Google Scholar] [CrossRef] [PubMed]

- Koch, A.; Bringman, S.; Myrelid, P.; Kald, A. Randomized clinical trial of groin hernia repair with titanium-coated lightweight mesh compared with standard polypropylene mesh. Br. J. Surg. 2008, 95, 1226–1231. [Google Scholar] [CrossRef] [PubMed]

- Melkemichel, M.; Bringman, S.; Widhe, B. Lower recurrence rate with heavyweight mesh compared to lightweight mesh in laparoscopic totally extra-peritoneal (TEP) repair of groin hernia: A nationwide population-based register study. Hernia 2008, 22, 989–997. [Google Scholar] [CrossRef] [PubMed]

- Pascual, G.; Mesa-Ciller, C.; Rodríguez, M.; Pérez-Köhler, B.; Gómez-Gil, V.; Fernández-Gutiérrez, M.; San Román, J.; Bellón, J.M. Pre-clinical assay of the tissue integration and mechanical adhesion of several types of cyanoacrylate adhesives in the fixation of lightweight polypropylene meshes for abdominal hernia repair. PLoS ONE 2018, 13, e0206515. [Google Scholar] [CrossRef] [PubMed]

- Klosterhalfen, B.; Junge, K.; Klinge, U. The lightweight and large porous mesh concept for hernia repair. Expert Rev. Med. Devices 2005, 2, 103–117. [Google Scholar] [CrossRef]

- Sanbhal, N.; Miao, L.; Xu, R.; Khatri, A.; Wang, L. Physical structure and mechanical properties of knitted hernia mesh materials: A review. J. Ind. Text. 2017, 48, 333–360. [Google Scholar] [CrossRef]

- Förstemann, T.; Trzewik, J.; Holste, J.; Batke, B.; Konerding, M.A.; Wolloscheck, T.; Hartung, C. Forces and deformations of the abdominal wall a mechanical and geometrical approach to the linea alba. J. Biomech. 2011, 44, 600–606. [Google Scholar] [CrossRef] [PubMed]

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial properties of chitosan and mode of action: A state of the art review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Roller, S.; Covill, N. The antifungal properties of chitosan in laboratory media and apple juice. Int. J. Food Microbiol. 1999, 47, 67–77. [Google Scholar] [CrossRef]

- Islam, S.; Arnold, L.; Padhye, R. Comparison and characterisation of regenerated Chitosan from 1-Butyl-3-methylimidazolium chloride and chitosan from Crab Shells. BioMed Res. Int. 2015, 2015, 6. [Google Scholar] [CrossRef]

- Chien, R.C.; Yen, M.T.; Mau, J.L. Antimicrobial and antitumor activities of chitosan from shiitake stipes, compared to commercial chitosan from crab shells. Carbohydr. Polym. 2016, 138, 259–264. [Google Scholar] [CrossRef]

- No, H.K.; Park, N.Y.; Lee, S.H.; Meyers, S.P. Antibacterial activity of chitosans and chitosan oligomers with different molecular weights. Int. J. Food Microbiol. 2002, 74, 65–72. [Google Scholar] [CrossRef]

- Liu, X.F.; Yang, Y.L.G.D.Z.; Li, Z.; Yao, K.D. Antibacterial action of chitosan and carboxymethylated chitosan. J. Appl. Polym. Sci. 2001, 79, 1324–1335. [Google Scholar]

| Appearance | Degree of Deacetylation/% | Ash/% | Linear Density/Dtex | Length/mm | Crimpness/mm | Moisture Regain/% | Breaking Strength/Cn | Elongation of Break/% |

|---|---|---|---|---|---|---|---|---|

| White | 86% | 0.94 | 1.6 | 38 ± 1 | 3.1 | 15.68 ± 0.03 | 3.18 ± 0.02 | 18.1 ± 0.09 |

| Parameters | U (%) | CVm (%) | Fine End (−50%)/km | Slub (50%)/km | Nep (200%)/km |

|---|---|---|---|---|---|

| Yarn of chitosan | 16.79 | 21.85 | 2240.00 | 0.00 | 1320.00 |

| Yarn of cotton | 13.87 | 15.88 | 520.00 | 0.00 | 20.00 |

| No. | Weight per Unit Area (g/m2) | Density | Thickness (mm) | Porosity (%) | |

|---|---|---|---|---|---|

| Course | Wale | ||||

| 1 | 39.42 ± 0.10 | 54 ± 0.00 | 22 ± 0.00 | 0.336 ± 0.00 | 29.59 ± 0.11 |

| 2 | 42.63 ± 0.09 | 26 ± 0.00 | 23 ± 0.00 | 0.332 ± 0.00 | 33.75 ± 0.06 |

| 3 | 42.70 ± 0.06 | 22 ± 0.00 | 28 ± 0.00 | 0.330 ± 0.00 | 37.43 ± 0.08 |

| No. | 1 | 2 | 3 | ||

|---|---|---|---|---|---|

| Breaking strength | Breaking strength (N) | Warp | 20.26 ± 1.78 | 17.36 ± 1.40 | 28.96 ± 1.46 |

| Weft | 26.80 ± 1.44 | 21.54 ± 1.21 | 22.28 ± 1.71 | ||

| Elongation at break (%) | Warp | 8.714 ± 1.070 | 10.360 ± 0.802 | 10.812 ± 0.970 | |

| Weft | 14.746 ± 0.846 | 14.786 ± 0.900 | 14.650 ± 0.721 | ||

| Bursting strength | Bursting strength (N) | 93.60 ± 4.74 | 71.00 ± 2.99 | 74.10 ± 5.76 | |

| Bursting height (mm) | 9.29 ± 0.95 | 11.80 ± 1.23 | 9.00 ± 0.10 | ||

| Bursting work (J) | 0.043 ± 0.89 × 10−4 | 0.040 ± 0.00 | 0.023 ± 0.22 × 10−4 | ||

| Tearing strength | Average peak value (N) | 1.134 ± 0.01 | 1.475 ± 0.02 | 1.895 ± 0.01 | |

| Maximum peak value (N) | 2.84 ± 0.02 | 3.45 ± 0.02 | 4.05 ± 0.03 | ||

| Minimum peak value (N) | 0.35 ± 0.25 × 10−2 | 0.35 ± 0.25 × 10−2 | 0.35 ± 0.25 × 10−2 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, S.; Ma, P.; Cong, H.; Jiang, G. Preparation and Performances of Warp-Knitted Hernia Repair Mesh Fabricated with Chitosan Fiber. Polymers 2019, 11, 595. https://doi.org/10.3390/polym11040595

Yu S, Ma P, Cong H, Jiang G. Preparation and Performances of Warp-Knitted Hernia Repair Mesh Fabricated with Chitosan Fiber. Polymers. 2019; 11(4):595. https://doi.org/10.3390/polym11040595

Chicago/Turabian StyleYu, Shuang, Pibo Ma, Honglian Cong, and Gaoming Jiang. 2019. "Preparation and Performances of Warp-Knitted Hernia Repair Mesh Fabricated with Chitosan Fiber" Polymers 11, no. 4: 595. https://doi.org/10.3390/polym11040595

APA StyleYu, S., Ma, P., Cong, H., & Jiang, G. (2019). Preparation and Performances of Warp-Knitted Hernia Repair Mesh Fabricated with Chitosan Fiber. Polymers, 11(4), 595. https://doi.org/10.3390/polym11040595