Pinned Hybrid Glass-Flax Composite Laminates Aged in Salt-Fog Environment: Mechanical Durability

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Pinned Joints with 4-mm Hole Diameter

- In the beginning phase, all curves are characterized by a linear relationship between the bearing stress and displacement. The slope of this trend could be related to the joint stiffness;

- Afterwards, at increasing displacement, a progressive deviation from the linear trend can be highlighted depending on aging time. This behavior is due to compression collapse of the matrix in correspondence of the composite laminate just behind the small hole/pin contact area;

- Eventually, all specimens tend to reach a plateau zone where the bearing stress is roughly constant, beyond which its failure occurs. All the specimens showed a bearing failure mechanism.

3.2. Pinned Joints with 8-mm Hole Diameter

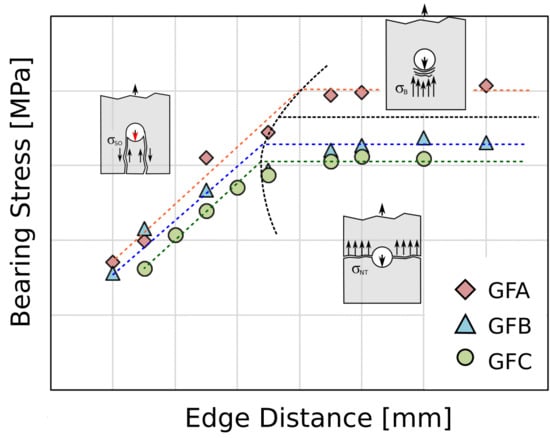

3.3. Evolution of Failure Mechanisms at Varying Joint Geometry

- D = 4 mm: For a small hole diameter, the fracture mechanism evolves from shear-out (i.e., low E values) to bearing mode (i.e., large E values). Nevertheless, a premature fracture caused by net-tension fracture mode was highlighted for large edge distance value due to environmental aging. For the aged samples, a mixed bearing/net tension fracture was identified. The maximum stress decreases at increasing aging time. This behavior is more sensitive for joint geometry having large edge distance and, therefore, large E/D ratio.

- D = 6–8 mm: For intermediate hole diameters, a dual failure damage mechanism occurs. A transition from shear-out to net-tension failure mechanism takes place at increasing edge distance. For this sample geometry, the cleavage mode is relevant, especially for aged specimens. This behavior can be related to the reduced tensile and shear strengths of the aged flax fibers that influences the triggering of combined failure mechanisms. GFB and GFC batches, compared to the unaged GFA one, are characterized by a clearly lower stress in the shear-out region (mainly for samples with hole diameter equal to 6 mm). This significant stress reduction is related to the specific joint geometry since the difference between hole diameter and sample width is still relevant, thus limiting net-tension fracture mechanism only at high E values. The low stress evidenced in the shear-out failure region could be related to a relevant reduction of the interfacial adhesion at the fiber/matrix interface that favors shear cracks activation and propagation in the pin/hole contact area. This stimulates a premature fracture by shear-out, thus preventing a mixed failure mechanism for cleavage.

- D = 10 mm: For large hole diameters, net-tension is the main failure mechanism for E > 10–12 mm for aged and unaged samples. This experimental evidence indicates that all samples, regardless of the applied aging time, exhibit quite similar fracture transitions. Nevertheless, a relevant discrepancy on the mechanical strength was observed. In particular, GFB and GFC samples showed a reduction of maximum stress of about 20% and 30% compared to unaged one for E > 12 mm, respectively. This trend can be attributed to the reduced tensile strength in the hydrophilic aged flax fibers. This degradation phenomenon is less relevant at low E/D ratio, where the shear-out mode is the main failure mechanisms.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pervaiz, M.; Panthapulakkal, S.; KC, B.; Sain, M.; Tjong, J. Emerging Trends in Automotive Lightweighting through Novel Composite Materials. Mater. Sci. Appl. 2016, 7, 26–38. [Google Scholar] [CrossRef] [Green Version]

- Fragassa, C. Marine applications of natural fibre-reinforced composites: A manufacturing case study. In Advances in Applications of Industrial Biomaterials; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 21–47. ISBN 9783319627670. [Google Scholar]

- Pošvář, Z.; Růžička, M.; Kulíšek, V.; Mareš, T.; Doubrava, K.; Uher, O. Design of Composite Hybrid Structures “on Request”. Mater. Today Proc. 2016, 3, 1129–1134. [Google Scholar]

- Mastura, M.T.; Sapuan, S.M.; Mansor, M.R.; Nuraini, A.A. Environmentally conscious hybrid bio-composite material selection for automotive anti-roll bar. Int. J. Adv. Manuf. Technol. 2017, 89, 2203–2219. [Google Scholar] [CrossRef]

- Zou, P.; Cheng, H. Effect of interference-fit percentage and preload on the mechanical behaviour of single-shear lap composite joint. In Proceedings of the IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing, Suzhou, China, 29–31 March 2019; Volume 531. [Google Scholar]

- Calabrese, L.; Fiore, V.; Scalici, T.; Bruzzaniti, P.; Valenza, A. Failure maps to assess bearing performances of glass composite laminates. Polym. Compos. 2019, 40, 1087–1096. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Proverbio, E.; Passari, R.; Valenza, A. Salt spray fog ageing of hybrid composite/metal rivet joints for automotive applications. Compos. Part B Eng. 2017, 108, 65–74. [Google Scholar] [CrossRef]

- Lv, J.; Xiao, Y.; Xue, Y. Time–temperature-dependent response and analysis of preload relaxation in bolted composite joints. J. Reinf. Plast. Compos. 2018, 37, 460–474. [Google Scholar] [CrossRef]

- Valenza, A.; Fiore, V.; Calabrese, L. Three-Point Flexural Behaviour of GFRP Sandwich Composites: A Failure Map. Adv. Compos. Mater. 2010, 19, 79–90. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Mandal, S.; Alam, S. Dynamic mechanical analysis and morphological studies of glass/bamboo fiber reinforced unsaturated polyester resin-based hybrid composites. J. Appl. Polym. Sci. 2012, 125, E382–E387. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Mechanical behavior of carbon/flax hybrid composites for structural applications. J. Compos. Mater. 2012, 46, 2089–2096. [Google Scholar] [CrossRef] [Green Version]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Influence of fiber orientation and fiber content on properties of sisal-jute-glass fiber-reinforced polyester composites. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Pan, Y.; Zhong, Z. The effect of hybridization on moisture absorption and mechanical degradation of natural fiber composites: An analytical approach. Compos. Sci. Technol. 2015, 110, 132–137. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Di Bella, G.; Scalici, T.; Galtieri, G.; Valenza, A.; Proverbio, E. Effects of aging in salt spray conditions on flax and flax/basalt reinforced composites: Wettability and dynamic mechanical properties. Compos. Part B Eng. 2016, 93, 35–42. [Google Scholar] [CrossRef]

- Retegi, A.; Arbelaiz, A.; Alvarez, P.; Llano-Ponte, R.; Labidi, J.; Mondragon, I. Effects of hygrothermal ageing on mechanical properties of flax pulps and their polypropylene matrix composites. J. Appl. Polym. Sci. 2006, 102, 3438–3445. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Sarasini, F.; Tirilló, J.; Calabrese, L. Salt-fog spray aging of jute-basalt reinforced hybrid structures: Flexural and low velocity impact response. Compos. Part B Eng. 2017, 116, 99–112. [Google Scholar] [CrossRef]

- Garcia-Espinel, J.D.; Castro-Fresno, D.; Parbole Gayo, P.; Ballester-Muñoz, F. Effects of sea water environment on glass fiber reinforced plastic materials used for marine civil engineering constructions. Mater. Des. 2015, 66, 46–50. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Scalici, T.; Valenza, A. Experimental assessment of the improved properties during aging of flax/glass hybrid composite laminates for marine applications. J. Appl. Polym. Sci. 2019, 136, 47203. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Assarar, M.; Sabhi, H.; Ayad, R. Hybridisation effect on diffusion kinetic and tensile mechanical behaviour of epoxy based flax-glass composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 153–160. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Machado, J.J.M.; Gamarra, P.M.R.; Marques, E.A.S.; da Silva, L.F.M. Improvement in impact strength of composite joints for the automotive industry. Compos. Part B Eng. 2018, 138, 243–255. [Google Scholar] [CrossRef]

- Esendemir, Ü.; Ayşe, A.M. Investigating bearing strength of pin-loaded composite plates in different environmental conditions. J. Reinf. Plast. Compos. 2013, 32, 1685–1697. [Google Scholar] [CrossRef]

- Karakuzu, R.; Kanlioǧlu, H.; Deniz, M.E. Effect of seawater on pin-loaded laminated composites. Mater. Test. 2018, 60, 85–92. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Scalici, T.; Valenza, A. Evolution of the bearing failure map of pinned flax composite laminates aged in marine environment. Compos. Part B Eng. 2020. submitted. [Google Scholar]

- Calabrese, L.; Fiore, V.; Bruzzaniti, P.G.; Scalici, T.; Valenza, A. An Aging Evaluation of the Bearing Performances of Glass Fiber Composite Laminate in Salt Spray Fog Environment. Fibers 2019, 7, 96. [Google Scholar] [CrossRef] [Green Version]

- Fiore, V.; Calabrese, L.; Scalici, T.; Bruzzaniti, P.; Valenza, A. Bearing strength and failure behavior of pinned hybrid glass-flax composite laminates. Polym. Test. 2018, 69, 310–319. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Calabrese, L.; Valenza, A.; Proverbio, E. Effect of external basalt layers on durability behaviour of flax reinforced composites. Compos. Part B Eng. 2016, 84, 258–265. [Google Scholar] [CrossRef]

- Sola, C.; Castanié, B.; Michel, L.; Lachaud, F.; Delabie, A.; Mermoz, E. On the role of kinking in the bearing failure of composite laminates. Compos. Struct. 2016, 141, 184–193. [Google Scholar] [CrossRef] [Green Version]

- Opelt, C.V.; Cândido, G.M.; Rezende, M.C. Compressive failure of fiber reinforced polymer composites–A fractographic study of the compression failure modes. Mater. Today Commun. 2018, 15, 218–227. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Scalici, T.; Bruzzaniti, P.; Valenza, A. Experimental design of the bearing performances of flax fiber reinforced epoxy composites by a failure map. Compos. Part B Eng. 2018, 148, 40–48. [Google Scholar] [CrossRef]

- Malmstein, M.; Chambers, A.R.; Blake, J.I.R. Hygrothermal ageing of plant oil based marine composites. Compos. Struct. 2013, 101, 138–143. [Google Scholar] [CrossRef]

- Abd-El-Naby, S.F.M.; Hollaway, L. The experimental behaviour of bolted joints in pultruded glass/ polyester material. Part 1: Single-bolt joints. Composites 1993, 24, 531–538. [Google Scholar]

- Turvey, G. Failure of single-lap single-bolt tension joints in pultruded glass fibre reinforced plate. In Proceedings of the 6th International Conference on Composites in Construction Engineering (CICE), Rome, Italy, 13–15 June 2012. [Google Scholar]

- Assarar, M.; Scida, D.; El Mahi, A.; Poilâne, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax-fibres and glass-fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Baley, C.; Le Duigou, A.; Bourmaud, A.; Davies, P. Influence of drying on the mechanical behaviour of flax fibres and their unidirectional composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1226–1233. [Google Scholar] [CrossRef]

- Bos, H.L.; Van Den Oever, M.J.A.; Peters, O.C.J.J. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Akil, H.M.; Cheng, L.W.; Mohd Ishak, Z.A.; Abu Bakar, A.; Abd Rahman, M.A. Water absorption study on pultruded jute fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2009, 69, 1942–1948. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Wei, B.; Cao, H.; Song, S. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater. Corros. Sci. 2011, 53, 426–431. [Google Scholar] [CrossRef]

- Ouarhim, W.; Zari, N.; Bouhfid, R.; Qaiss, A. el kacem Mechanical performance of natural fibers–based thermosetting composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 43–60. ISBN 978-0-08-102292-4. [Google Scholar]

- Fiore, V.; Scalici, T.; Badagliacco, D.; Enea, D.; Alaimo, G.; Valenza, A. Aging resistance of bio-epoxy jute-basalt hybrid composites as novel multilayer structures for cladding. Compos. Struct. 2017, 160, 1319–1328. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calabrese, L.; Fiore, V.; Bruzzaniti, P.; Scalici, T.; Valenza, A. Pinned Hybrid Glass-Flax Composite Laminates Aged in Salt-Fog Environment: Mechanical Durability. Polymers 2020, 12, 40. https://doi.org/10.3390/polym12010040

Calabrese L, Fiore V, Bruzzaniti P, Scalici T, Valenza A. Pinned Hybrid Glass-Flax Composite Laminates Aged in Salt-Fog Environment: Mechanical Durability. Polymers. 2020; 12(1):40. https://doi.org/10.3390/polym12010040

Chicago/Turabian StyleCalabrese, Luigi, Vincenzo Fiore, Paolo Bruzzaniti, Tommaso Scalici, and Antonino Valenza. 2020. "Pinned Hybrid Glass-Flax Composite Laminates Aged in Salt-Fog Environment: Mechanical Durability" Polymers 12, no. 1: 40. https://doi.org/10.3390/polym12010040

APA StyleCalabrese, L., Fiore, V., Bruzzaniti, P., Scalici, T., & Valenza, A. (2020). Pinned Hybrid Glass-Flax Composite Laminates Aged in Salt-Fog Environment: Mechanical Durability. Polymers, 12(1), 40. https://doi.org/10.3390/polym12010040