Structure and Properties of Polysulfone Filled with Modified Twill Weave Carbon Fabrics

Abstract

:1. Introduction

2. Materials and Methods

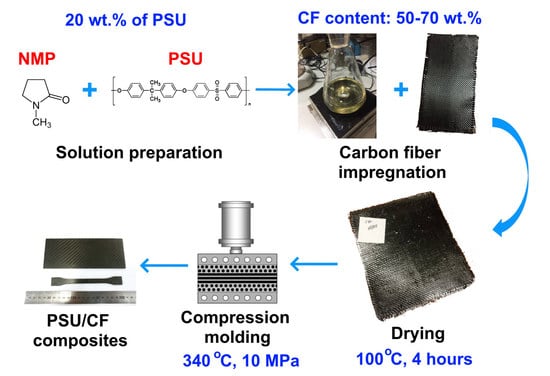

2.1. Preparation of Carbon Fiber/Polysulfone Composites

2.2. Carbon Fibers Surface Modification

2.3. Thermogravimetric Analysis

2.4. Fourier-Transform Infrared Spectroscopy Analysis

2.5. X-ray Photoelectron Spectroscopy

2.6. In-Plane Shear Strength Tests

2.7. Mechanical Tests

2.8. Dynamic Mechanical Analysis

3. Results and Discussion

3.1. Polysulfone Solution

3.2. Surface Modification of CFs

3.3. Interface Analysis of Carbon Fibers/Polysulfone Composites

3.4. Mechanical Tests of CF/PSU Composites

3.5. Dynamic Mechanical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chung, D.D.L. Processing-structure-property relationships of continuous carbon fiber polymer-matrix composites. Mater. Sci. Eng. R Rep. 2017, 113, 1–29. [Google Scholar] [CrossRef]

- Santulli, C. Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review. Materials 2019, 12, 517. [Google Scholar] [CrossRef] [Green Version]

- Alam, P.; Mamalis, D.; Robert, C.; Floreani, C.; Ó Brádaigh, C.M. The fatigue of carbon fibre reinforced plastics-A review. Compos. Part B Eng. 2019, 166, 555–579. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Lin, Y.; Zong, Z.; Sun, G.; Li, Q. Lightweight design of carbon twill weave fabric composite body structure for electric vehicle. Compos. Struct. 2013, 97, 231–238. [Google Scholar] [CrossRef]

- Wenbin, L.; Jianfeng, H.; Jie, F.; Liyun, C.; Chunyan, Y. Mechanical and wet tribological properties of carbon fabric/phenolic composites with different weave filaments counts. Appl. Surf. Sci. 2015, 353, 1223–1233. [Google Scholar] [CrossRef]

- Gao, J.; Chen, W.; Yu, B.; Fan, P.; Zhao, B.; Hu, J.; Zhang, D.; Fang, G.; Peng, F. Effect of temperature on the mechanical behaviours of a single-ply weave-reinforced shape memory polymer composite. Compos. Part B Eng. 2019, 159, 336–345. [Google Scholar] [CrossRef]

- Viana, S.T.; Scariot, V.K.; Provensi, A.; Barra, G.M.O.; Barbosa, J.R. Fabrication and thermal analysis of epoxy resin-carbon fiber fabric composite plate-coil heat exchangers. Appl. Therm. Eng. 2017, 127, 1451–1460. [Google Scholar] [CrossRef]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. Electromagnetic shielding effectiveness of carbon fibre reinforced composites. Compos. Part B Eng. 2019, 173, 106906. [Google Scholar] [CrossRef]

- Zulkifli, F.; Stolk, J.; Heisserer, U.; Yong, A.T.-M.; Li, Z.; Hu, X.M. Strategic positioning of carbon fiber layers in an UHMwPE ballistic hybrid composite panel. Int. J. Impact Eng. 2019, 129, 119–127. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Lee, J.K.Y.; Khorasani, S.N.; Ramakrishna, S. Towards the development of self-healing carbon/epoxy composites with improved potential provided by efficient encapsulation of healing agents in core-shell nanofibers. Polym. Test. 2017, 62, 79–87. [Google Scholar] [CrossRef]

- Wu, X.-F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Sinha-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toughening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Khorasani, S.N.; Naeimirad, M.; Lee, J.K.Y.; Ramakrishna, S. Improving Mechanical Properties of Carbon/Epoxy Composite by Incorporating Functionalized Electrospun Polyacrylonitrile Nanofibers. Macromol. Mater. Eng. 2017, 302, 1600551. [Google Scholar] [CrossRef]

- Capela, C.; Oliveira, S.E.; Ferreira, J.A.M. Fatigue behavior of short carbon fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 164, 191–197. [Google Scholar] [CrossRef]

- Chukov, D.I.; Stepashkin, A.A.; Tcherdyntsev, V.V.; Kaloshkin, S.D.; Danilov, V.D. Strength and thermophysical properties of composite polymer materials filled with discrete carbon fiber. Inorg. Mater. Appl. Res. 2014, 5, 386–391. [Google Scholar] [CrossRef]

- Chukov, D.I.; Stepashkin, A.A.; Salimon, A.I.; Kaloshkin, S.D. Highly filled elastomeric matrix composites: Structure and property evolution at low temperature carbonization. Mater. Des. 2018, 156, 22–31. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Zhang, C.-C.; Xue, Y.-D. Stiffness prediction of short fiber reinforced composites. Int. J. Mech. Sci. 2019, 161–162, 105068. [Google Scholar] [CrossRef]

- Dorigato, A.; Fredi, G.; Pegoretti, A. Application of the thermal energy storage concept to novel epoxy–short carbon fiber composites. J. Appl. Polym. Sci. 2019, 136, 47434. [Google Scholar] [CrossRef]

- Spoerk, M.; Savandaiah, C.; Arbeiter, F.; Traxler, G.; Cardon, L.; Holzer, C.; Sapkota, J. Anisotropic properties of oriented short carbon fibre filled polypropylene parts fabricated by extrusion-based additive manufacturing. Compos. Part A Appl. Sci. Manuf. 2018, 113, 95–104. [Google Scholar] [CrossRef]

- Zhang, G.; Rasheva, Z.; Schlarb, A.K. Friction and wear variations of short carbon fiber (SCF)/PTFE/graphite (10 vol.%) filled PEEK: Effects of fiber orientation and nominal contact pressure. Wear 2010, 268, 893–899. [Google Scholar] [CrossRef]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. A review of input data and modelling assumptions in longitudinal strength models for unidirectional fibre-reinforced composites. Compos. Struct. 2016, 150, 153–172. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, Y.; Sugahara, T.; Hamada, H. A study on the failure behavior and mechanical properties of unidirectional fiber reinforced thermosetting and thermoplastic composites. Compos. Part B Eng. 2016, 99, 162–172. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Zadorozhnyy, M.; Tcherdyntsev, V.; Stepashkin, A.; Zherebtsov, D. Structure, Mechanical and Thermal Properties of Polyphenylene Sulfide and Polysulfone Impregnated Carbon Fiber Composites. Polymers 2019, 11, 684. [Google Scholar] [CrossRef] [Green Version]

- Stepashkin, A.A.; Chukov, D.I.; Senatov, F.S.; Salimon, A.I.; Korsunsky, A.M.; Kaloshkin, S.D. 3D-printed PEEK-carbon fiber (CF) composites: Structure and thermal properties. Compos. Sci. Technol. 2018, 164, 319–326. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, H.; Gu, X. In-plane shear response of unidirectional fiber reinforced and fabric reinforced carbon/epoxy composites. Polym. Test. 2013, 32, 594–601. [Google Scholar] [CrossRef]

- Bilisik, K.; Karaduman, N.S.; Sapanci, E. Tensile properties of nanoprepreg/nanostitched 3D carbon/epoxy MWCNTs composites. Mech. Mater. 2019, 128, 11–23. [Google Scholar] [CrossRef]

- Bergmann, T.; Heimbs, S.; Maier, M. Mechanical properties and energy absorption capability of woven fabric composites under ±45° off-axis tension. Compos. Struct. 2015, 125, 362–373. [Google Scholar] [CrossRef]

- Bijwe, J.; Rattan, R. Influence of weave of carbon fabric in polyetherimide composites in various wear situations. Wear 2007, 263, 984–991. [Google Scholar] [CrossRef]

- Foroutan, R.; Nemes, J.; Ghiasi, H.; Hubert, P. Experimental investigation of high strain-rate behaviour of fabric composites. Compos. Struct. 2013, 106, 264–269. [Google Scholar] [CrossRef]

- Lundström, F.; Frogner, K.; Andersson, M. A method for inductive measurement of equivalent electrical conductivity in thin non-consolidated multilayer carbon fibre fabrics. Compos. Part B Eng. 2018, 140, 204–213. [Google Scholar] [CrossRef]

- Thompson, A.J.; El Said, B.; Ivanov, D.; Belnoue, J.P.-H.; Hallett, S.R. High fidelity modelling of the compression behaviour of 2D woven fabrics. Int. J. Solids Struct. 2018, 154, 104–113. [Google Scholar] [CrossRef] [Green Version]

- Gaurav, A.; Singh, K.K. Fatigue behavior of FRP composites and CNT-Embedded FRP composites: A review. Polym. Compos. 2018, 39, 1785–1808. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- de Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High performance polymer nanocomposites for additive manufacturing applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Mujika, F.; Benito, A.D.; Fernández, B.; Vázquez, A.; Llano-Ponte, R.; Mondragon, I. Mechanical properties of carbon woven reinforced epoxy matrix composites. A study on the influence of matrix modification with polysulfone. Polym. Compos. 2002, 23, 372–382. [Google Scholar] [CrossRef]

- Solodilov, V.I.; Korokhin, R.A.; Gorbatkina, Y.A.; Kuperman, A.M. Comparison of Fracture Energies of Epoxy-polysulfone Matrices and Unidirectional Composites Based on Them. Mech. Compos. Mater. 2015, 51, 177–190. [Google Scholar] [CrossRef]

- Cauich-Cupul, J.I.; Herrera-Franco, P.J.; García-Hernández, E.; Moreno-Chulim, V.; Valadez-González, A. Factorial design approach to assess the effect of fiber–matrix adhesion on the IFSS and work of adhesion of carbon fiber/polysulfone-modified epoxy composites. Carbon Lett. 2019, 29, 345–358. [Google Scholar]

- Brown, S.A.; Hastings, R.S.; Mason, J.J.; Moet, A. Characterization of short-fibre reinforced thermoplastics for fracture fixation devices. Biomaterials 1990, 11, 541–547. [Google Scholar] [CrossRef]

- Zimmerman, M.C.; Scalzo, H.L.; Parsons, J.R.; Torop, A.H.; Lin, T.S. Effects of environmental exposure on carbon polysulphone composites. Biomaterials 1991, 12, 424–430. [Google Scholar] [CrossRef]

- Mai, K.; Li, J.; Zeng, H. Mechanical property and fracture morphology of fiber-reinforced polysulfone plasticized with acetylene-terminated sulfone. J. Appl. Polym. Sci. 1994, 52, 1279–1291. [Google Scholar] [CrossRef]

- Antonov, A.V.; Zelenskii, E.S.; Kuperman, A.M.; Lebedeva, O.V.; Rybin, A.A. Behavior of reinforced plastics based on polysulfone matrix under impact loading. Mech. Compos. Mater. 1998, 34, 12–19. [Google Scholar] [CrossRef]

- Migacz, K.; Chłopek, J.; Morawska-Chochół, A.; Ambroziak, M. Gradient composite materials for artificial intervertebral discs. Acta Bioeng. Biomech. 2014, 16, 3–12. [Google Scholar]

- Sun, D.; Lin, G.; Sui, G.; Hao, Y.; Yang, R.; Zhang, K. Multi-gating injection molding to enhance the thermal conductivity of carbon fiber/polysulfone composite. Polym. Compos. 2017, 38, 185–191. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Torokhov, V.; Stepashkin, A.; Sherif, G.; Tcherdyntsev, V. Effect of carbon fiber surface modification on their interfacial interaction with polysulfone. Results Phys. 2019, 15, 102634. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Stepashkin, A.; Maksimkin, A.; Zherebtsov, D.; Tcherdyntsev, V. Novel carbon fibers reinforced composites based on polysulfone matrix. MATEC Web Conf. 2018, 242, 01004. [Google Scholar] [CrossRef]

- Iyer, S.R.; Drzal, L.T. Manufacture of Powder-Impregnated Thermoplastic Composites. J. Thermoplast. Compos. Mater. 1990, 3, 325–355. [Google Scholar] [CrossRef]

- Zheng, L.; Liao, G.X.; Jian, X.G. Preparation of Solution Impregnated Continuous Carbon Fibre Reinforced Poly (Phthalazinone Ether Sulfone Ketone) Composites. Adv. Compos. Lett. 2009, 18, 096369350901800101. [Google Scholar] [CrossRef] [Green Version]

- Wu, G.M.; Schultz, J.M. Processing and properties of solution impregnated carbon fiber reinforced polyethersulfone composites. Polym. Compos. 2000, 21, 223–230. [Google Scholar] [CrossRef]

- Masuelli, M.A. Synthesis Polysulfone-Acetylethanol Ultrafiltration Membranes. Application to Oily Wastewater Treatment. J. Mater. Phys. Chem. 2013, 1, 37–44. [Google Scholar]

- Kumar, M.; McGlade, D.; Ulbricht, M.; Lawler, J. Quaternized polysulfone and graphene oxide nanosheet derived low fouling novel positively charged hybrid ultrafiltration membranes for protein separation. RSC Adv. 2015, 5, 51208–51219. [Google Scholar] [CrossRef] [Green Version]

- Duchoslav, J.; Unterweger, C.; Steinberger, R.; Fürst, C.; Stifter, D. Investigation on the thermo-oxidative stability of carbon fiber sizings for application in thermoplastic composites. Polym. Degrad. Stab. 2016, 125, 33–42. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Effects of maleated polypropylene on the morphology, thermal and mechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Des. 2011, 32, 4069–4073. [Google Scholar] [CrossRef]

- Dilsiz, N.; Wightman, J.P. Surface analysis of unsized and sized carbon fibers. Carbon 1999, 37, 1105–1114. [Google Scholar] [CrossRef]

- Dai, Z.; Zhang, B.; Shi, F.; Li, M.; Zhang, Z.; Gu, Y. Effect of heat treatment on carbon fiber surface properties and fibers/epoxy interfacial adhesion. Appl. Surf. Sci. 2011, 257, 8457–8461. [Google Scholar] [CrossRef]

- Vautard, F.; Grappe, H.; Ozcan, S. Stability of carbon fiber surface functionality at elevated temperatures and its influence on interfacial adhesion. Appl. Surf. Sci. 2013, 268, 61–72. [Google Scholar] [CrossRef]

- Kundu, S.; Wang, Y.; Xia, W.; Muhler, M. Thermal Stability and Reducibility of Oxygen-Containing Functional Groups on Multiwalled Carbon Nanotube Surfaces: A Quantitative High-Resolution XPS and TPD/TPR Study. J. Phys. Chem. C 2008, 112, 16869–16878. [Google Scholar] [CrossRef]

- Dilsiz, N.; Wightman, J.P. Effect of acid–base properties of unsized and sized carbon fibers on fiber/epoxy matrix adhesion. Colloids Surf. A Physicochem. Eng. Asp. 2000, 164, 325–336. [Google Scholar] [CrossRef]

- Huang, S.-Y.; Wu, G.-P.; Chen, C.-M.; Yang, Y.; Zhang, S.-C.; Lu, C.-X. Electrophoretic deposition and thermal annealing of a graphene oxide thin film on carbon fiber surfaces. Carbon 2013, 52, 613–616. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, S.; Lu, C. Surface modification of carbon fibers by a polyether sulfone emulsion sizing for increased interfacial adhesion with polyether sulfone. Appl. Surf. Sci. 2014, 317, 737–744. [Google Scholar] [CrossRef]

- Li, N.; Wu, Z.; Huo, L.; Zong, L.; Guo, Y.; Wang, J.; Jian, X. One-step functionalization of carbon fiber using in situ generated aromatic diazonium salts to enhance adhesion with PPBES resins. RSC Adv. 2016, 6, 70704–70714. [Google Scholar] [CrossRef]

- Liu, L.; Yan, F.; Li, M.; Zhang, M.; Xiao, L.; Shang, L.; Ao, Y. A novel thermoplastic sizing containing graphene oxide functionalized with structural analogs of matrix for improving interfacial adhesion of CF/PES composites. Compos. Part A Appl. Sci. Manuf. 2018, 114, 418–428. [Google Scholar] [CrossRef]

| Sample | Concentration, at. % | |||||||

|---|---|---|---|---|---|---|---|---|

| C | O | N | Si | S | Na | Cl | F | |

| initial | 77.5 | 18.0 | 3.0 | 0.7 | 0.3 | 0.3 | 0.3 | - |

| TO 300 °C | 79.0 | 18.1 | 0.4 | 2.3 | 0.1 | 0.1 | ||

| TO 500 °C | 82.5 | 7.5 | 8.5 | 0.3 | - | - | 1.0 | |

| Sample | C | O | N | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 1 | 2 | 1 | 2 | 3 | ||

| Initial | EB, eV | 285.0 | 286.5 | 289.5 | - | - | 531.7 | 532.9 | 400.3 | ||

| % | 65 | 32 | 3 | - | - | 15 | 85 | 100 | |||

| TO 300 °C | EB, eV | 285.0 | 286.5 | 289.5 | - | 291.5 | 531.3 | 533.5 | 400.3 | ||

| % | 69 | 23 | 4 | - | 4 | 10 | 90 | 100 | |||

| TO 500 °C | EB, eV | 284.7 | 286.1 | 287.5 | 288.6 | 291.4 | 531.3 | 533.4 | 398.7 | 400.55 | 403.5 |

| % | 80 | 9 | 3 | 2 | 6 | 50 | 50 | 40 | 50 | 10 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chukov, D.I.; Nematulloev, S.G.; Tсherdyntsev, V.V.; Torokhov, V.G.; Stepashkin, A.A.; Zadorozhnyy, M.Y.; Zherebtsov, D.D.; Sherif, G. Structure and Properties of Polysulfone Filled with Modified Twill Weave Carbon Fabrics. Polymers 2020, 12, 50. https://doi.org/10.3390/polym12010050

Chukov DI, Nematulloev SG, Tсherdyntsev VV, Torokhov VG, Stepashkin AA, Zadorozhnyy MY, Zherebtsov DD, Sherif G. Structure and Properties of Polysulfone Filled with Modified Twill Weave Carbon Fabrics. Polymers. 2020; 12(1):50. https://doi.org/10.3390/polym12010050

Chicago/Turabian StyleChukov, Dilyus I., Sarvarkhodza G. Nematulloev, Viсtor V. Tсherdyntsev, Valerii G. Torokhov, Andrey A. Stepashkin, Mikhail Y. Zadorozhnyy, Dmitry D. Zherebtsov, and Galal Sherif. 2020. "Structure and Properties of Polysulfone Filled with Modified Twill Weave Carbon Fabrics" Polymers 12, no. 1: 50. https://doi.org/10.3390/polym12010050

APA StyleChukov, D. I., Nematulloev, S. G., Tсherdyntsev, V. V., Torokhov, V. G., Stepashkin, A. A., Zadorozhnyy, M. Y., Zherebtsov, D. D., & Sherif, G. (2020). Structure and Properties of Polysulfone Filled with Modified Twill Weave Carbon Fabrics. Polymers, 12(1), 50. https://doi.org/10.3390/polym12010050