The Transferability and Design of Commercial Printer Settings in PLA/PBAT Fused Filament Fabrication

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Filament Preparation and Printed Part Preparation with Reference Printer

2.3. Transferability for Two Commerical Printers

2.4. Characterization

2.4.1. Mass and Dimension Variation

2.4.2. Cross-Section Morphology

2.4.3. Rheometric Analysis

2.4.4. Differential Scanning Calorimeter

2.4.5. Mechanical Analysis

3. Results

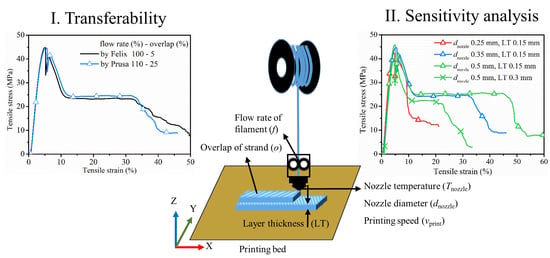

3.1. Evaluation of Transferability between Commercial Printer Felix and Prusa

3.2. Sensitivity Analysis for Prusa Printer after Transferibility Based on Tensile Strenght

3.2.1. Slicer Predictions

3.2.2. Dimension Stability and Morphology

3.2.3. Mechanical Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2020, 2, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the mechanical properties of FFF structures and materials: A review on the experimental, computational and theoretical approaches. Materials 2019, 16, 895. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Peterson, A.M. Review of acrylonitrile butadiene styrene in fused filament fabrication: A plastics engineering-focused perspective. Addit. Manuf. 2019, 27, 363–371. [Google Scholar] [CrossRef]

- Gomez-Gras, G.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Lluma-Fuentes, J. Fatigue performance of fused filament fabrication PLA specimens. Mater. Des. 2018, 140, 278–285. [Google Scholar] [CrossRef] [Green Version]

- Carlier, E.; Marquette, S.; Peerboom, C.; Denis, L.; Benali, S.; Raquez, J.M.; Amighi, K.; Goole, J. Investigation of the parameters used in fused deposition modeling of poly(lactic acid) to optimize 3D printing sessions. Int. J. Pharm. 2019, 565, 367–377. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhang, M.; Li, S.; Si, L.; Peng, J.; Hu, Y. Mechanical property parametric appraisal of fused deposition modeling parts based on the gray Taguchi method. Int. J. Adv. Manuf. Technol. 2017, 89, 2387–2397. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D Printing Biocompatible Polyurethane/Poly(lactic acid)/Graphene Oxide Nanocomposites: Anisotropic Properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef] [PubMed]

- Yao, T.; Ye, J.; Deng, Z.; Zhang, K.; Ma, Y.; Ouyang, H. Tensile failure strength and separation angle of FDM 3D printing PLA material: Experimental and theoretical analyses. Compos. Part B 2020, 188, 107894. [Google Scholar] [CrossRef]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef]

- Letcher, T.; Waytashek, M. Material Property Testing of 3D-Printed Specimen. Proc. ASME 2014 Int. Mech. Eng. Congr. Expo. 2016, 2A, 1–8. [Google Scholar] [CrossRef]

- Panda, S.K.; Padhee, S.; Sood, A.K.; Mahapatra, S.S. Optimization of Fused Deposition Modelling (FDM) Process Parameters Using Bacterial Foraging Technique. Intell. Inf. Manag. 2009, 01, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Rajpurohit, S.R.; Dave, H.K. Flexural strength of fused filament fabricated (FFF) PLA parts on an open-source 3D printer. Adv. Manuf. 2018, 6, 430–441. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [Green Version]

- Tsouknidas, A.; Pantazopoulos, M.; Katsoulis, I.; Fasnakis, D.; Maropoulos, S.; Michailidis, N. Impact absorption capacity of 3D-printed components fabricated by fused deposition modelling. Mater. Des. 2016, 102, 41–44. [Google Scholar] [CrossRef]

- Christiyan, K.G.J.; Chandrasekhar, U.; Venkateswarlu, K. A study on the influence of process parameters on the Mechanical Properties of 3D printed ABS composite. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114. [Google Scholar] [CrossRef]

- Wang, S.; Capoen, L.; D’hooge, D.R.; Cardon, L. Can the melt flow index be used to predict the success of fused deposition modelling of commercial poly(lactic acid) filaments into 3D printed materials? Plast. Rubber Compos. 2018, 47, 9–16. [Google Scholar] [CrossRef]

- Wang, L.; Sanders, J.E.; Gardner, D.J.; Han, Y. Effect of fused deposition modeling process parameters on the mechanical properties of a filled polypropylene. Prog. Addit. Manuf. 2018, 3, 205–214. [Google Scholar] [CrossRef]

- Seppala, J.E.; Hoon Han, S.; Hillgartner, K.E.; Davis, C.S.; Migler, K.B. Weld formation during material extrusion additive manufacturing. Soft Matter 2017, 13, 6761–6769. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical strength of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef] [PubMed]

- Bakrani Balani, S.; Chabert, F.; Nassiet, V.; Cantarel, A. Influence of printing parameters on the stability of deposited beads in fused filament fabrication of poly (lactic) acid. Addit. Manuf. 2019, 25, 112–121. [Google Scholar] [CrossRef] [Green Version]

- Spoerk, M.; Arbeiter, F.; Cajner, H.; Sapkota, J.; Holzer, C. Parametric optimization of intra- and inter-layer strengths in parts produced by extrusion-based additive manufacturing of poly (lactic acid). J. Appl. Polym. Sci. 2017, 134, 45401. [Google Scholar] [CrossRef]

- Spörk, M. Optimisation of the Mechanical Properties and Processing of Polypropylene and Poly (Lactic Acid) Parts Produced by Extrusion Based Additive Manufacturing; Montanuniversitaet Leoben: Leoben, Austria, 2018. [Google Scholar]

- Deshpande, A.; Ravi, A.; Kusel, S.; Churchwell, R.; Hsu, K. Interlayer thermal history modification for interface strength in fused filament fabricated parts. Prog. Addit. Manuf. 2019, 4, 63–70. [Google Scholar] [CrossRef]

- Faes, M.; Ferraris, E.; Moens, D. Influence of Inter-layer Cooling time on the Quasi-static Properties of ABS Components Produced via Fused Deposition Modelling. Procedia CIRP 2016, 42, 748–753. [Google Scholar] [CrossRef]

- Wang, L.; Gramlich, W.M.; Gardner, D.J. Improving the impact strength of Poly(lactic acid) (PLA) in fused layer modeling (FLM). Polymer 2017, 114, 242–248. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Y.; Wang, H. Additive manufacturing of carbon fiber-reinforced plastic composites using fused deposition modeling: Effects of process parameters on tensile properties. J. Compos. Mater. 2017, 51, 451–462. [Google Scholar] [CrossRef]

- Pan, A.; Huang, Z.; Guo, R.; Liu, J. Effect of FDM process on adhesive strength of polylactic acid(PLA) filament. Key Eng. Mater. 2016, 667, 181–186. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- D’Amico, A.; Peterson, A.M. An adaptable FEA simulation of material extrusion additive manufacturing heat transfer in 3D. Addit. Manuf. 2018, 21, 422–430. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Cheng, J.; Anstey, A.; Mohanty, A.K.; Misra, M. Development of Toughened Blends of Poly(lactic acid) (PLA) and Poly(butylene adipate-co-terephthalate) (PBAT) for 3D Printing Applications: Compatibilization Methods and Material Performance Evaluation. ACS Sustain. Chem. Eng. 2020. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Zhang, F.; Leng, J.; Pei, S.; Wang, L.; Jia, X.; Cotton, C.; Sun, B.; Chou, T.W. Microstructural design for enhanced shape memory behavior of 4D printed composites based on carbon nanotube/polylactic acid filament. Compos. Sci. Technol. 2019, 181, 107692. [Google Scholar] [CrossRef]

- Wang, S.; Pang, S.; Xu, N.; Pan, L. Isothermal crystallization behavior of PLA/PBAT blend and effects of isothermal heating treatment on mechanical performance of PLA/PBAT blend. Gaofenzi Cailiao Kexue Yu Gongcheng/Polym. Mater. Sci. Eng. 2016, 32. [Google Scholar] [CrossRef]

- Adrar, S.; Habi, A.; Ajji, A.; Grohens, Y. Synergistic effects in epoxy functionalized graphene and modified organo-montmorillonite PLA/PBAT blends. Appl. Clay Sci. 2018, 157, 65–75. [Google Scholar] [CrossRef]

- Correa, J.P.; Bacigalupe, A.; Maggi, J.; Eisenberg, P. Biodegradable PLA/PBAT/clay nanocomposites: Morphological, rheological and thermomechanical behavior. J. Renew. Mater. 2016, 4, 258–265. [Google Scholar] [CrossRef]

- Wang, S.; Daelemans, L.; Fiorio, R.; Gou, M.; D’hooge, D.R.; De Clerck, K.; Cardon, L. Improving Mechanical Properties for Extrusion-Based Additive Manufacturing of Poly (Lactic Acid) by Annealing and Blending with Poly (3-Hydroxybutyrate). Polymers 2019, 11, 1529. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fischer, E.W.; Sterzel, H.J.; Wegner, G. Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid-Z. Z. Polym. 1973, 251, 980–990. [Google Scholar] [CrossRef]

- Seppala, J.E.; Migler, K.D. Infrared thermography of welding zones produced by polymer extrusion additive manufacturing. Addit. Manuf. 2016, 12, 71–76. [Google Scholar] [CrossRef] [Green Version]

| Fixed Settings | Variable Settings for Translation | ||

|---|---|---|---|

| Infill rate (%) | 100 | (1) Flow rate—f (%) 1 | 100–105–110–120 |

| Shell thickness | 1.05 | (2) Overlap rate—o (%) | 5–15–25 |

| Strand orientation (°) | ±45 | (3) Printing speed—vprint (mm s−1) | 40–60–80–120 |

| Bed temperature (°C) | 50 | (4) Nozzle diameter—dnozzle (mm) | 0.25–0.35–0.5 |

| Bed material | PEI2 | (5) Nozzle temperature—Tprint (°C) | 210–230 |

| Nozzle material | copper | (6) Layer thickness—LT (mm) | 0.15/0.3 3 |

| No. | Printer | vprint (mm s−1) | f (%) | o (%) | Extrusion Length, LE (mm) | Line Count | Layer Count | Printing Time, t | Volumetric Flow Rate, Qflow, 1 (mm3 s−1) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Felix | 40 | 100 | 5 | 461 | 5638 | 13 | 9 m 44 s | 2.37 |

| 2 | Prusa | 40 | 100 | 5 | 446 | 5567 | 13 | 9 m 39 s | 2.31 |

| 3 | Prusa | 40 | 100 | 25 | 453 | 5581 | 13 | 9 m 50 s | 2.31 |

| 4 | Prusa | 40 | 105 | 25 | 475 | 5581 | 13 | 9 m 50 s | 2.42 |

| 5 | Prusa | 40 | 110 | 5 | 490 | 5567 | 13 | 9 m 39 s | 2.54 |

| 6 | Prusa | 40 | 110 | 15 | 493 | 5566 | 13 | 9 m 42 s | 2.54 |

| 7 | Prusa | 40 | 110 | 25 | 498 | 5581 | 13 | 9 m 50 s | 2.54 |

| 8 | Prusa | 40 | 120 | 5 | 535 | 5567 | 13 | 9 m 39 s | 2.78 |

| 9 | Prusa | 40 | 120 | 25 | 543 | 5581 | 13 | 9 m 50 s | 2.78 |

| No. | Mass (g) | Width 1 (mm) | Thickness 1 (mm) | Length 1 (mm) | E (GPa) | σY (MPa) | σM (MPa) | ε (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.27 ± 0.02 | 5.29 ± 0.01 | 2.06 ± 0.01 | 75.05 ± 0.26 | 2471 ± 110 | 37.2 ± 0.8 | 44.7 ± 3.7 | 38 ± 15 |

| 2 | 1.21 ± 0.01 | 5.01 ± 0.01 | 2.07 ± 0.05 | 74.97 ± 0.03 | 2456 ± 143 | 32.9 ± 0.1 | 43.2 ± 0.8 | 17 ± 2 |

| 3 | 1.26 ± 0.01 | 5.05 ± 0.01 | 2.04 ± 0.01 | 74.95 ± 0.03 | 2555 ± 44 | 32.6 ± 1.1 | 43. 2 ± 1.5 | 17 ± 1 |

| 4 | 1.30 ± 0.01 | 5.11 ± 0.01 | 2.08 ± 0.01 | 75.11 ± 0.03 | 2525 ± 72 | 35.1 ± 0.1 | 44.5 ± 0.1 | 14 ± 1 |

| 5 | 1.36 ± 0.01 | 5.12 ± 0.02 | 2.21 ± 0.02 | 74.99 ± 0.02 | 2573 ± 43 | 35.1 ± 0.4 | 44.1 ± 0.5 | 16 ± 8 |

| 6 | 1.34 ± 0.01 | 5.19 ± 0.01 | 2.12 ± 0.01 | 75.08 ± 0.02 | 2547 ± 55 | 35.3 ± 0.9 | 44.3 ± 0.3 | 20 ± 10 |

| 7 | 1.35 ± 0.01 | 5.27 ± 0.04 | 2.14 ± 0.04 | 75.12 ± 0.04 | 2513 ± 68 | 35.4 ± 1.4 | 44.8 ± 0.6 | 34 ± 9 |

| 8 | 1.45 ± 0.01 | 5.43 ± 0.06 | 2.25 ± 0.02 | 75.24 ± 0.03 | 2416 ± 105 | 35.3 ± 0.7 | 43.1 ± 0.3 | 10 ± 1 |

| 9 | 1.46 ± 0.01 | 5.46 ± 0.02 | 2.23 ± 0.02 | 75.27 ± 0.02 | 2359 ± 58 | 35.0 ± 0.4 | 43.0 ± 1.0 | 12 ± 1 |

| No. | dnozzle (mm) | LT (mm) | vprint (mm s−1) | Extrusion Length, LE (mm) | Line Count | Layer Count | Printing Time, t | Volumetric Flow Rate, Qflow 1 (mm3 s−1) |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.25 | 0.15 | 40 | 493 | 7395 | 13 | 12 m 52 s | 1.92 |

| 2 | 60 | 493 | 7395 | 13 | 9 m 41 s | 2.55 | ||

| 3 | 80 | 493 | 7395 | 13 | 7 m 56 s | 3.11 | ||

| 4 | 120 | 493 | 7395 | 13 | 6 m 31 s | 3.79 | ||

| 5 | 0.35 | 0.15 | 40 | 498 | 5581 | 13 | 9 m 50 s | 2.54 |

| 6 | 60 | 498 | 5581 | 13 | 7 m 28 s | 3.34 | ||

| 7 | 80 | 498 | 5581 | 13 | 6 m 8 s | 4.07 | ||

| 8 | 120 | 498 | 5581 | 13 | 5 m 4 s | 4.92 | ||

| 9 | 0.5 | 0.15 | 40 | 509 | 3779 | 13 | 6 m 47 s | 3.76 |

| 10 | 60 | 509 | 3779 | 13 | 5 m 11 s | 4.92 | ||

| 11 | 80 | 509 | 3779 | 13 | 4 m 18 s | 5.93 | ||

| 12 | 120 | 509 | 3779 | 13 | 3 m 34 s | 7.15 | ||

| 13 | 0.5 | 0.3 | 40 | 524 | 2069 | 7 | 3 m 54 s | 6.73 |

| 14 | 60 | 524 | 2069 | 7 | 3 m 10 s | 8.29 | ||

| 15 | 80 | 524 | 2069 | 7 | 2 m 44 s | 9.60 | ||

| 16 | 120 | 524 | 2069 | 7 | 2 m 22 s | 11.09 |

| Sample No.1 | vprint (mm s−1) | Mass (g) | Dimension | Tensile Property | |||||

|---|---|---|---|---|---|---|---|---|---|

| Width (mm) | Thickness (mm) | Length (mm) | E (MPa) | σY (MPa) | σM (MPa) | ε (%) | |||

| dnozzle = 0.25 mm, LT = 0.15 mm, Tnozzle = 210 °C | |||||||||

| A1 | 40 | 1.36 ± 0.00 | 5.15 ± 0.01 | 2.25 ± 0.00 | 75.02 ± 0.01 | 2409 ± 18 | 34.1 ± 0.1 | 42.7 ± 0.6 | 9 ± 1 |

| A2 | 60 | 1.35 ± 0.02 | 5.15 ± 0.03 | 2.19 ± 0.06 | 75.01 ± 0.03 | 2420 ± 72 | 32.8 ± 1.0 | 41.6 ± 0.5 | 8 ± 3 |

| A3 | 80 | 1.35 ± 0.02 | 5.17 ± 0.04 | 2.18 ± 0.04 | 75.11 ± 0.04 | 2523 ± 34 | 34.7 ± 0.7 | 43.7 ± 0.4 | 8 ± 4 |

| A4 | 120 | 1.36 ± 0.01 | 5.16 ± 0.05 | 2.21 ± 0.02 | 75.09 ± 0.04 | 2438 ± 31 | 35.0 ± 0.5 | 43.5 ± 0.0 | 9 ± 2 |

| dnozzle = 0.35 mm, LT = 0.15 mm, Tnozzle = 210 °C | |||||||||

| A5 | 40 | 1.36 ± 0.01 | 5.27 ± 0.04 | 2.14 ± 0.04 | 75.12 ± 0.04 | 2513 ± 68 | 35.4 ± 1.4 | 44.8 ± 0.6 | 34 ± 9 |

| A6 | 60 | 1.37 ± 0.01 | 5.32 ± 0.04 | 2.19 ± 0.02 | 75.51 ± 0.98 | 2499 ± 80 | 35.2 ± 1.2 | 44.6 ± 0.7 | 30 ± 12 |

| A7 | 80 | 1.37 ± 0.01 | 5.21 ± 0.06 | 2.16 ± 0.04 | 75.11 ± 0.06 | 2586 ± 58 | 36.0 ± 0.9 | 46.0 ± 0.8 | 16 ± 4 |

| A8 | 120 | 1.31 ± 0.01 | 5.14 ± 0.04 | 2.08 ± 0.03 | 75.17 ± 0.02 | 2664 ± 15 | 36.6 ± 0.3 | 46.1 ± 0.4 | 14 ± 6 |

| dnozzle = 0.5 mm, LT = 0.15 mm, Tnozzle = 210 °C | |||||||||

| A9 | 40 | 1.39 ± 0.02 | 5.31 ± 0.05 | 2.22 ± 0.05 | 75.17 ± 0.02 | 2443 ± 61 | 36.2 ± 0.6 | 45.3 ± 0.6 | 31 ± 10 |

| A10 | 60 | 1.38 ± 0.01 | 5.32 ± 0.04 | 2.17 ± 0.05 | 75.22 ± 0.02 | 2467 ± 64 | 36.5 ± 0.4 | 45.3 ± 0.8 | 43 ± 10 |

| A11 | 80 | 1.37 ± 0.03 | 5.18 ± 0.07 | 2.17 ± 0.07 | 75.15 ± 0.04 | 2498 ± 144 | 35.9 ± 0.8 | 44.7 ± 0.6 | 36 ± 11 |

| A12 | 120 | 1.35 ± 0.01 | 5.18 ± 0.02 | 2.13 ± 0.04 | 75.20 ± 0.04 | 2561 ± 54 | 35.9 ± 0.7 | 45.7 ± 0.8 | 33 ± 12 |

| dnozzle = 0.5 mm, LT = 0.3 mm, Tnozzle = 210 °C | |||||||||

| A13 | 40 | 1.40 ± 0.01 | 5.32 ± 0.04 | 2.38 ± 0.03 | 75.18 ± 0.04 | 2195 ± 18 | 33.5 ± 0.5 | 40.6 ± 0.6 | 26 ± 5 |

| A14 | 60 | 1.41 ± 0.00 | 5.36 ± 0.05 | 2.36 ± 0.02 | 75.20 ± 0.07 | 2236 ± 26 | 33.6 ± 0.1 | 40.6 ± 0.5 | 14 ± 5 |

| A15 | 80 | 1.38 ± 0.01 | 5.29 ± 0.01 | 2.31 ± 0.01 | 75.21 ± 0.01 | 2276 ± 13 | 34.1 ± 0.8 | 41.7 ± 0.7 | 22 ± 5 |

| A16 | 120 | 1.40 ± 0.01 | 5.30 ± 0.02 | 2.35 ± 0.03 | 75.17 ± 0.04 | 2217 ± 39 | 34.2 ± 1.3 | 40.9 ± 1.2 | 20 ± 5 |

| dnozzle = 0.25 mm, LT = 0.15 mm, Tnozzle = 230 °C | |||||||||

| B1 | 40 | 1.38 ± 0.01 | 5.21 ± 0.06 | 2.25 ± 0.04 | 75.09 ± 0.05 | 2354 ± 43 | 34.2 ± 0.4 | 42.1 ± 0.7 | 10 ± 2 |

| B2 | 60 | 1.37 ± 0.00 | 5.26 ± 0.03 | 2.24 ± 0.03 | 75.12 ± 0.04 | 2339 ± 82 | 35.0 ± 0.7 | 42.8 ± 1.1 | 9 ± 1 |

| B3 | 80 | 1.37 ± 0.02 | 5.19 ± 0.03 | 2.24 ± 0.03 | 75.09 ± 0.02 | 2331 ± 90 | 35.3 ± 0.2 | 42.9 ± 0.7 | 12 ± 4 |

| B4 | 120 | 1.37 ± 0.01 | 5.26 ± 0.03 | 2.21 ± 0.04 | 75.17 ± 0.02 | 2387 ± 10 | 36.3 ± 0.4 | 43.8 ± 0.0 | 9 ± 2 |

| dnozzle = 0.35 mm, LT = 0.15 mm, Tnozzle = 230 °C | |||||||||

| B5 | 40 | 1.39 ± 0.02 | 5.27 ± 0.10 | 2.17 ± 0.07 | 75.11 ± 0.08 | 2591 ± 105 | 36.5 ± 1.5 | 46.8 ± 0.8 | 49 ± 10 |

| B6 | 60 | 1.38 ± 0.01 | 5.36 ± 0.02 | 2.18 ± 0.02 | 75.20 ± 0.04 | 2550 ± 79 | 35.9 ± 1.4 | 46.2 ± 1.6 | 51 ± 5 |

| B7 | 80 | 1.39 ± 0.01 | 5.22 ± 0.08 | 2.22 ± 0.05 | 75.12 ± 0.08 | 2570 ± 58 | 36.6 ± 1.1 | 46.5 ± 0.9 | 44 ± 5 |

| B8 | 120 | 1.34 ± 0.01 | 5.20 ± 0.02 | 2.16 ± 0.01 | 75.13 ± 0.07 | 2535 ± 39 | 36.0 ± 0.5 | 46.0 ± 0.6 | 21 ± 8 |

| dnozzle = 0.5 mm, LT = 0.15 mm, Tnozzle = 230 °C | |||||||||

| B9 | 40 | 1.40 ± 0.04 | 5.26 ± 0.05 | 2.21 ± 0.04 | 75.15 ± 0.05 | 2510 ± 42 | 37.1 ± 1.1 | 46.2 ± 0.5 | 41 ± 8 |

| B10 | 60 | 1.40 ± 0.05 | 5.30 ± 0.04 | 2.22 ± 0.03 | 75.18 ± 0.02 | 2421 ± 72 | 36.6 ± 0.4 | 45.2 ± 0.7 | 37 ± 4 |

| B11 | 80 | 1.40 ± 0.00 | 5.28 ± 0.05 | 2.05 ± 0.21 | 75.17 ± 0.05 | 2470 ± 108 | 36.4 ± 0.6 | 45.3 ± 0.8 | 44 ± 9 |

| B12 | 120 | 1.39 ± 0.02 | 5.19 ± 0.07 | 2.27 ± 0.09 | 75.13 ± 0.04 | 2495 ± 10 | 35.8 ± 0.7 | 44.6 ± 0.1 | 37 ± 1 |

| dnozzle = 0.5 mm, LT = 0.3 mm, Tnozzle = 230 °C | |||||||||

| B13 | 40 | 1.44 ± 0.01 | 5.33 ± 0.05 | 2.40 ± 0.03 | 75.14 ± 0.07 | 2201 ± 52 | 33.9 ± 1.1 | 40.1 ± 1.2 | 19 ± 4 |

| B14 | 60 | 1.39 ± 0.03 | 5.27 ± 0.06 | 2.37 ± 0.06 | 75.16 ± 0.03 | 2222 ± 10 | 34.1 ± 0.5 | 40.8 ± 0.5 | 23 ± 8 |

| B15 | 80 | 1.43 ± 0.02 | 5.34 ± 0.04 | 2.38 ± 0.03 | 75.17 ± 0.06 | 2214 ± 61 | 35.1 ± 0.8 | 41.0 ± 0.6 | 16 ± 3 |

| B16 | 120 | 1.42 ± 0.01 | 5.29 ± 0.03 | 2.39 ± 0.05 | 75.19 ± 0.10 | 2160 ± 35 | 34.2 ± 0.7 | 39.9 ± 0.5 | 21 ± 7 |

| Sample | Notched Impact | Flexural | |||

|---|---|---|---|---|---|

| No. | dnozzle (mm) | vprint (mm s−1) | Strength (kJ m−2) | Modulus, EF (MPa) | Strength, σF (MPa) |

| A1 | 0.25 | 40 | 6.4 ± 0.4 | 2451 ± 166 | 68.4 ± 0.8 |

| A3 | 80 | 5.7 ± 0.5 | 2380 ± 236 | 65.1 ± 3.3 | |

| A4 | 120 | 6.4 ± 0.7 | 2299 ± 85 | 61.6 ± 3.5 | |

| A5 | 0.35 | 40 | 5.5 ± 0.5 | 2557 ± 193 | 71.5 ± 1.0 |

| A7 | 80 | 5.7 ± 0.6 | 2515 ± 80 | 71.7 ± 1.5 | |

| A8 | 120 | 6.0 ± 0.8 | 2462 ± 90 | 69.1 ± 1.5 | |

| A9 | 0.5 | 40 | 6.8 ± 0.1 | 2438 ± 60 | 72.6 ± 0.8 |

| A11 | 80 | 7.4 ± 1.2 | 2515 ± 80 | 73.2 ± 0.5 | |

| A12 | 120 | 7.4 ± 1.7 | 2462 ± 90 | 71.8 ± 0.2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; D’hooge, D.R.; Daelemans, L.; Xia, H.; Clerck, K.D.; Cardon, L. The Transferability and Design of Commercial Printer Settings in PLA/PBAT Fused Filament Fabrication. Polymers 2020, 12, 2573. https://doi.org/10.3390/polym12112573

Wang S, D’hooge DR, Daelemans L, Xia H, Clerck KD, Cardon L. The Transferability and Design of Commercial Printer Settings in PLA/PBAT Fused Filament Fabrication. Polymers. 2020; 12(11):2573. https://doi.org/10.3390/polym12112573

Chicago/Turabian StyleWang, Sisi, Dagmar R. D’hooge, Lode Daelemans, Hesheng Xia, Karen De Clerck, and Ludwig Cardon. 2020. "The Transferability and Design of Commercial Printer Settings in PLA/PBAT Fused Filament Fabrication" Polymers 12, no. 11: 2573. https://doi.org/10.3390/polym12112573

APA StyleWang, S., D’hooge, D. R., Daelemans, L., Xia, H., Clerck, K. D., & Cardon, L. (2020). The Transferability and Design of Commercial Printer Settings in PLA/PBAT Fused Filament Fabrication. Polymers, 12(11), 2573. https://doi.org/10.3390/polym12112573