Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Surface Modification of JFs

2.2.1. Alkali Treatment

2.2.2. Combined Alkali/Stearic Acid Treatment

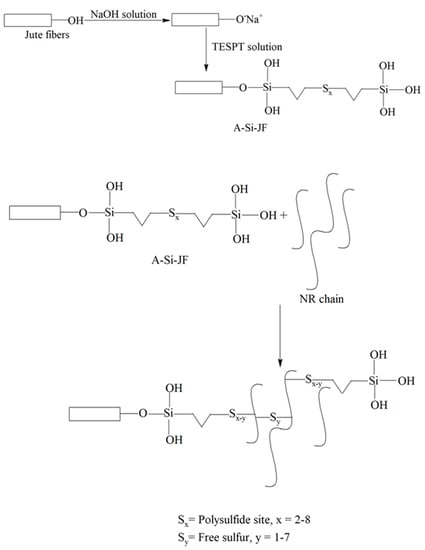

2.2.3. Combined Alkali/Silane Treatment

2.3. Preparation of NR Composites

2.4. Characterization Techniques

3. Results and Discussion

3.1. Confirmation of Surface Modification of JFs

3.2. Cure Characteristics

3.3. Mechanical Properties

3.4. Crosslink Density

3.5. Morphology of Composite Fracture Surfaces

3.6. Solvent Uptake Behaviour of JFs Filled NR Composites

3.7. Thermal Properties of JFs Filled NR Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Andideh, M.; Naderi, G.; Ghoreishy, M.H.R.; Soltani, S. Effects of Nanoclay and Short Nylon Fiber on Morphology and Mechanical Properties of Nanocomposites Based on NR/SBR. Fibers Polym. 2014, 15, 814–822. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Das, A.; Heinrich, G.; Potiyaraj, P. Exploring the synergistic effect of short jute fiber and nanoclay on the mechanical, dynamic mechanical and thermal properties of natural rubber composites. Polym. Test. 2018, 67, 487–493. [Google Scholar] [CrossRef]

- Soltani, S.; Naderi, G.; Mohseniyan, S. Mechanical, Morphological and Rheological Properties of Short Nylon Fiber Reinforced Acrylonitrile-Butadiene Rubber Composites. Fibers Polym. 2014, 15, 2360–2369. [Google Scholar] [CrossRef]

- Rana, A.K.; Mandal, A.; Bandyopadhyay, S. Short jute fiber reinforced polypropylene composites: Effect of compatibiliser, impact modifier and fiber loading. Compos. Sci. Technol. 2003, 63, 801–806. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Murty, V.M.; De, S.K. Short jute fiber reinforced rubber composites. Rubber Chem. Technol. 1982, 55, 287–308. [Google Scholar] [CrossRef]

- Zaman, H.U.; Khan, R.A.; Haque, M.E.; Khan, M.A.; Khan, A.; Huq, T.; Noor, N.; Rahman, M.; Rahman, K.M.; Huq, D.; et al. Preparation and mechanical characterization of jute reinforced polypropylene/natural rubber composite. J. Reinforc. Plast. Compos. 2010, 29, 3064–3065. [Google Scholar] [CrossRef]

- Pantamanatsopa, P.; Ariyawiriyanan, W.; Meekeaw, T.; Suthamyong, R.; Arrub, K.; Hamada, H. Effect of modified jute fiber on mechanical properties of Green rubber composite. Energy Procedia 2014, 56, 641–647. [Google Scholar] [CrossRef] [Green Version]

- Tzounis, L.; Debnath, S.; Rooj, S.; Fischer, D.; Mäder, E.; Das, A.; Stamm, M.; Heinrich, G. High performance natural rubber composites with a hierarchical reinforcement structure of carbon nanotube modified natural fibers. Mater. Des. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Ismail, H.; Shuhelmy, S.; Edyham, M.R. The effects of a silane coupling agent on curing characteristics and mechanical properties of bamboo fibre filled natural rubber composites. Eur. Polym. J. 2002, 38, 39–47. [Google Scholar] [CrossRef]

- Ismail, H. The effects of filler loading and a silane coupling agent on the dynamic properties and swelling behaviour of bamboo filled natural rubber compounds. J. Elastom. Plast. 2003, 35, 149–159. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Mathew, K.T.; Lakshminarayanan, R.; Thomas, S. Composite of short coir fibres and natural rubber: Effect of chemical modification, loading and orientation of fibre. Polymer 1998, 39, 1483–1491. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Kalaprasad, G.; Groeninckx, G.; Thomas, S. Dynamic mechanical behavior of short coir fiber reinforced natural rubber composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1499–1506. [Google Scholar] [CrossRef]

- Xu, Z.H.; Kong, Z.N. Mechanical and thermal properties of short-coirfiber-reinforced natural rubber/polyethylene composites. Mech. Compos. Mater. 2014, 50, 353–358. [Google Scholar] [CrossRef]

- Jacob, M.; Thomas, S.; Varughese, K.T. Mechanical properties of sisal/oil palm hybrid fiber reinforced natural rubber composites. Compos. Sci. Technol. 2004, 64, 955–965. [Google Scholar] [CrossRef]

- John, M.J.; Varughese, K.T.; Thomas, S. Green composites from natural fibers and natural rubber: Effect of fiber ratio on mechanical and swelling characteristics. J. Nat. Fibers 2008, 5, 47–60. [Google Scholar] [CrossRef]

- Joseph, S.; Joseph, K.; Thomas, S. Green composites from natural rubber and oil palm fiber: Physical and mechanical properties. Int. J. Polym. Mater. 2006, 55, 925–945. [Google Scholar] [CrossRef]

- Azammi, A.M.N.; Sapuan, S.M.; Ishak, M.R.; Sultan, M.T.H. Mechanical and Thermal Properties of Kenaf Reinforced Thermoplastic Polyurethane (TPU)-Natural Rubber (NR) Composites. Fiber. Polymer 2018, 19, 446–451. [Google Scholar]

- De, D.; De, D.; Adhikari, B. The effect of grass fiber filler on curing characteristics and mechanical properties of natural rubber. Polym. Adv. Technol. 2004, 15, 708–715. [Google Scholar] [CrossRef]

- De, D.; De, D.; Adhikari, B. Curing characteristics and mechanical properties of alkali-treated grass-fiber-filled natural rubber composites and effects of bonding agent. J. Appl. Polym. Sci. 2006, 101, 3151–3160. [Google Scholar] [CrossRef]

- Manaila, E.; Stelescu, M.D.; Doroftei, F. Polymeric composites based on natural rubber and hemp fibers. Iran. Polym. J. 2015, 24, 135–148. [Google Scholar] [CrossRef]

- Moonart, U.; Utara, S. Effect of surface treatments and filler loading on the properties of hemp fiber/natural rubber composites. Cellulose 2019, 26, 7271–7295. [Google Scholar] [CrossRef]

- Hariwongsanupab, N.; Thanawan, S.; Amornsakchai, T.; Vallat, M.F.; Mougin, K. Improving the mechanical properties of short pineapple leaf fiber reinforced natural rubber by blending with acrylonitrile butadiene rubber. Polym. Test. 2017, 57, 94–100. [Google Scholar] [CrossRef]

- Yantaboot, K.; Amornsakchai, T. Effect of preparation methods and carbon black distribution on mechanical properties of short pineapple leaf fiber-carbon black reinforced natural rubber hybrid composites. Polym. Test. 2017, 61, 223–228. [Google Scholar] [CrossRef]

- Rahman, M.R.; Huque, M.M.; Islam, M.N.; Hasan, M. Improvement of physico-mechanical properties of jute fiber reinforced polypropylene composites by post-treatment. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1739–1747. [Google Scholar] [CrossRef]

- Roy, K.; Potiyaraj, P. Development of high performance microcrystalline cellulose based natural rubber composites using maleated natural rubber as compatibilizer. Cellulose 2018, 25, 1077–1087. [Google Scholar] [CrossRef]

- Liu, X.; Hao, S.J.; Cui, Y.H.; Chen, H. Improvement on the interfacial compatibility of jute fiber-reinforced polypropylene composites by different surface treatments. J. Ind. Text. 2018. [Google Scholar] [CrossRef]

- Dilfi, K.F.A.; Balan, A.; Bin, H.; Xian, G.; Thomas, S. Effect of Surface Modification of Jute Fiber on the Mechanical Properties and Durability of Jute Fiber-Reinforced Epoxy Composites. Polym. Compos. 2018, 39, E2519–E2528. [Google Scholar] [CrossRef]

- Roy, K.; Alam, M.N.; Mandal, S.K.; Debnath, S.C. Surface modification of sol–gel derived nano zinc oxide (ZnO) and the study of its effect on the properties of styrene–butadiene rubber (SBR) nanocomposites. J. Nanostruct. Chem. 2014, 4, 133–142. [Google Scholar] [CrossRef] [Green Version]

- Roy, K.; Potiyaraj, P. Exploring the comparative effect of silane coupling agents with different functional groups on the cure, mechanical and thermal properties of nano-alumina (Al2O3)-based natural rubber (NR) compounds. Polym. Bull. 2019, 76, 883–902. [Google Scholar] [CrossRef]

- Ismail, H.; Shaari, S.M. Curing characteristics, tensile properties and morphology of palm ash/halloysite nanotubes/ethylene-propylene-diene monomer (EPDM) hybrid composites. Polym. Test. 2010, 29, 872–878. [Google Scholar] [CrossRef]

- Intiya, W.; Thepsuwan, U.; Sirisinha, C.; Sae-Oui, P. Possible use of sludge ash as filler in natural rubber. J. Mater. Cycles Waste Manag. 2017, 19, 774–781. [Google Scholar] [CrossRef]

- Ismail, H.; Rusli, A.; Rashid, A.A. Maleated natural rubber as a coupling agent for paper sludge filled natural rubber composites. Polym. Test. 2005, 24, 856–862. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A critical review on the utilization of various reinforcement modifiers in filled rubber composites. J. Elastom. Plast. 2019. [Google Scholar] [CrossRef]

- Visakh, P.M.; Thomas, S.; Oksman, K.; Mathew, A.P. Crosslinked natural rubber nanocomposites reinforced with cellulose whiskers isolated from bamboo waste: Processing and mechanical/thermal properties. Compos. Part A Appl. Sci. Manuf. 2012, 43, 735–741. [Google Scholar] [CrossRef]

| Ingredients | Compound Designation | ||||

|---|---|---|---|---|---|

| Unfilled NR | NR/JFun | NR/A-JF | NR/A-St-JF | NR/A-Si-JF | |

| NR | 100 | 100 | 100 | 100 | 100 |

| ZnO | 5 | 5 | 5 | 5 | 5 |

| Stearic acid | 2 | 2 | 2 | 2 | 2 |

| TMTD | 2.16 | 2.16 | 2.16 | 2.16 | 2.16 |

| Sulfur | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| JFun | - | 10 | - | - | - |

| A-JF | - | - | 10 | - | - |

| A-St-JF | - | - | - | 10 | - |

| A-Si-JF | - | - | - | - | 10 |

| Formulation | Maximum Torque (Nm) | Torque Difference (Nm) | Scorch Time, t2 (min) | Optimum Cure Time, t90 (min) |

|---|---|---|---|---|

| Unfilled NR | 4.48 | 4.07 | 1.85 | 3.17 |

| NR/JFun | 4.88 | 4.73 | 1.66 | 2.48 |

| NR/A-JF | 4.94 | 4.77 | 1.55 | 2.34 |

| NR/A-St-JF | 4.96 | 4.78 | 1.6 | 2.4 |

| NR/A-Si-JF | 5.23 | 4.98 | 1.5 | 2.26 |

| Formulation | M100 (MPa) | Hardness (Shore A) | Tensile Strength (MPa) | Elongation at Break (%) | Crosslink Density × 105 (mol cm−3) |

|---|---|---|---|---|---|

| Unfilled NR | 0.83 ± 0.04 | 47 ± 2 | 12.07 ± 0.58 | 835 ± 15 | 7.21 |

| NR/JFun | 1.20 ± 0.09 | 55 ± 2 | 10.52 ± 0.69 | 765 ± 15 | 8.54 |

| NR/A-JF | 1.49 ± 0.07 | 58 ± 1 | 14.21 ± 0.89 | 750 ± 20 | 8.76 |

| NR/A-St-JF | 1.63 ± 0.12 | 59 ± 1 | 15.91 ± 0.44 | 750 ± 20 | 9.01 |

| NR/A-Si-JF | 1.77 ± 0.11 | 62 ± 2 | 17.04 ± 0.52 | 770 ± 20 | 10.88 |

| Formulation | Temperature (°C) | |||

|---|---|---|---|---|

| T10% | T20% | T50% | T80% | |

| Unfilled NR | 343 | 359 | 381 | 413 |

| NR/JFun | 341 | 359 | 382 | 420 |

| NR/A-JF | 335 | 355 | 381 | 417 |

| NR/A-St-JF | 338 | 357 | 382 | 419 |

| NR/A-Si-JF | 342 | 361 | 387 | 421 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roy, K.; Debnath, S.C.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P. Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites. Polymers 2020, 12, 369. https://doi.org/10.3390/polym12020369

Roy K, Debnath SC, Tzounis L, Pongwisuthiruchte A, Potiyaraj P. Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites. Polymers. 2020; 12(2):369. https://doi.org/10.3390/polym12020369

Chicago/Turabian StyleRoy, Kumarjyoti, Subhas Chandra Debnath, Lazaros Tzounis, Aphiwat Pongwisuthiruchte, and Pranut Potiyaraj. 2020. "Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites" Polymers 12, no. 2: 369. https://doi.org/10.3390/polym12020369

APA StyleRoy, K., Debnath, S. C., Tzounis, L., Pongwisuthiruchte, A., & Potiyaraj, P. (2020). Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites. Polymers, 12(2), 369. https://doi.org/10.3390/polym12020369