Effect of PEW and CS on the Thermal, Mechanical, and Shape Memory Properties of UHMWPE

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Analytical Methods

3. Results and Discussion

3.1. FTIR Analyses

3.2. Thermal Properties

3.2.1. DSC Analyses

3.2.2. TGA Analyses

3.2.3. VST Analyses

3.3. Thermomechanical Properties

3.4. Mechanical Properties

3.4.1. Tensile Test Analyses

3.4.2. Three-Point Bending Test Analyses

3.4.3. Notched Impact Test Analyses

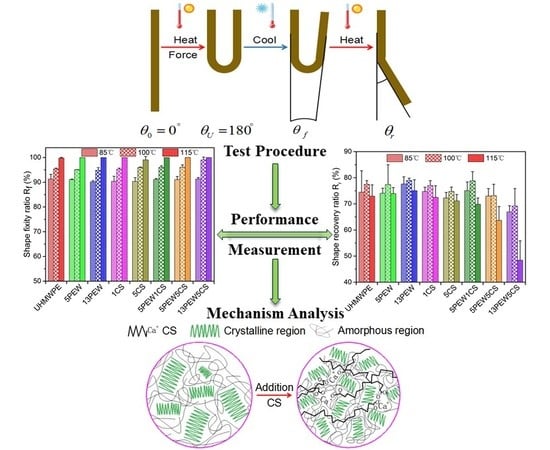

3.5. Shape Memory Behaviors

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, W.; Kwok, K.S.; Gracias, D.H. Ultrathin shape change smart materials. Acc. Chem. Res. 2018, 51, 436–444. [Google Scholar] [CrossRef]

- Lendlein, A.; Jiang, H.; Jünger, O.; Langer, R. Light-induced shape-memory polymers. Nature 2005, 434, 879–882. [Google Scholar] [CrossRef] [PubMed]

- Scott, T.F.; Schneider, A.D.; Cook, W.D.; Bowman, C.N. Photoinduced Plasticity in Cross-Linked Polymers. Science 2005, 308, 1615–1617. [Google Scholar] [CrossRef] [PubMed]

- Scott, T.; Draughon, R.B.; Bowman, C.N. Actuation in Crosslinked Polymers via Photoinduced Stress Relaxation. Adv. Mater. 2006, 18, 2128–2132. [Google Scholar] [CrossRef]

- Guo, W.; Lu, C.H.; Orbach, R.; Wang, F.; Qi, X.J.; Cecconello, A.; Seliktar, D.; Willner, I. pH-Stimulated DNA Hydrogels Exhibiting Shape-Memory Properties. Adv. Mater. 2015, 27, 73–78. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.; Correia, V.; Castro, H.; Martins, P.; Lanceros-Mendez, S. Polymer-based smart materials by printing technologies: Improving application and integration. Addit. Manuf. 2018, 21, 269–283. [Google Scholar] [CrossRef]

- Tan, Y.J.; Wu, J.; Li, H.; Benjamin, T.C.K. Self-Healing Electronic Materials for a Smart and Sustainable Future. ACS Appl. Mater. Interfaces 2018, 10, 15331–15345. [Google Scholar] [CrossRef]

- Wu, H.; Xu, Z.C.; Wu, J.B.; Wen, W.J. Research progress of field-induced soft smart materials. Int. J. Mod. Phys. B 2018, 32, 1840010. [Google Scholar] [CrossRef]

- Buffington, S.L.; Paul, J.E.; Ali, M.M.; Macios, M.M.; Mather, P.T.; Henderson, J.H. Enzymatically Triggered Shape Memory Polymers. Acta. Biomater. 2019, 84, 88–97. [Google Scholar] [CrossRef]

- Vernon, L.B.; Vernon, H.M. Process of Manufacturing Articles of Thermoplastic Synthetic Resins. U.S. Patent 2,234,993, 18 March 1941. [Google Scholar]

- Rainer, W.C.; Redding, E.M.; Hitov, J.J.; Sloan, A.W.; Stewart, W.D. Polyethylene Product and Process. U.S. Patent 3,144,398, 11 August 1964. [Google Scholar]

- Perrone, R.J. Silicone-Rubber, Polyethylene Composition; Heat Shrinkable Articles Made Therefrom and Process Therefor. U.S. Patent 3,326,869, 20 June 1967. [Google Scholar]

- Arditti, S.J.; Avedikian, S.Z.; Bernstein, B.S. Articles with Polymeric Memory and Method of Constructing Same. U.S. Patent 3,563,973, 16 February 1971. [Google Scholar]

- Hager, M.D.; Bode, S.; Weber, C.; Schubert, U.S. Shape memory polymers: Past, present and future developments. Prog. Polym. Sci. 2015, 49, 3–33. [Google Scholar] [CrossRef]

- Santo, L.; Quadrini, F.; Accettura, A.; Villadei, W. Shape memory composites for self-deployable structures in aerospace applications. Procedia Eng. 2014, 88, 42–47. [Google Scholar] [CrossRef]

- Liu, Y.; Du, H.; Liu, L.; Leng, J. Shape memory polymers and their composites in aerospace applications: A review. Smart Mater. Struct. 2014, 23, 023001. [Google Scholar] [CrossRef]

- Beavers, F.L.; Munshi, N.A.; Lake, M.S.; Maji, A.; Qassim, K.; Carpenter, B.F.; Suraj, P.R. Design and testing of an elastic memory composite deployment hinge for spacecraft. In Proceedings of the 43rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Denver, CO, USA, 22–25 April 2002. [Google Scholar]

- Seffen, K.A.; Pellegrino, S. Deployment dynamics of tape springs. R. Soc. A Math. Phys. 1999, 455, 1003–1048. [Google Scholar] [CrossRef] [Green Version]

- Park, J.; Kim, J.K.; Park, S.A.; Lee, D.W. Biodegradable polymer material based smart stent: Wireless pressure sensor and 3D printed stent. Microelectron. Eng. 2019, 206, 1–5. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, L.; Zhang, F.; Leng, J.; Liu, Y. Shape memory polymers and their composites in biomedical applications. Mater. Sci. Eng. C 2019, 97, 864–883. [Google Scholar] [CrossRef]

- Gu, L.; Jiang, Y.; Hu, J. Synthesis and properties of shape memory poly (γ-benzyl-L-glutamate)-b-poly (propylene glycol)-b-poly (γ-benzyl-L-glutamate). Appl. Sci. 2017, 7, 1258. [Google Scholar] [CrossRef] [Green Version]

- Sokolowski, W.; Metcalfe, A.; Hayashi, S.; Yahia, L.; Raymond, J. Medical applications of shape memory polymers. Biomed. Mater. 2007, 2, S23–S27. [Google Scholar] [CrossRef]

- Cardoso, V.F.; Correia, D.M.; Ribeiro, C.; Fernandes, M.M.; Lanceros-Méndez, S. Fluorinated polymers as smart materials for advanced biomedical applications. Polymers 2018, 10, 161. [Google Scholar] [CrossRef] [Green Version]

- Vats, G.; Vaish, R. Smart Materials Selection for Thermal Energy Efficient Architecture. Proc. Natl. Acad. Sci. USA 2019, 89, 11–21. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of progress in shape-memory polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Mu, T.; Liu, L.; Lan, X.; Liu, Y.; Leng, J. Shape memory polymers for composites. Compos. Sci. Technol. 2018, 160, 169–198. [Google Scholar] [CrossRef]

- Maksimkin, A.; Kaloshkin, S.; Zadorozhnyy, M.; Tcherdyntsev, V. Comparison of shape memory effect in UHMWPE for bulk and fiber state. J. Alloys Compd. 2014, 586, S214–S217. [Google Scholar] [CrossRef]

- Rezanejad, S.; Kokabi, M. Shape memory and mechanical properties of cross-linked polyethylene/clay nanocomposites. Eur. Polym. J. 2007, 43, 2856–2865. [Google Scholar] [CrossRef]

- Xu, L.; Chen, C.; Zhong, G.J.; Lei, J.; Xu, J.Z.; Hsiao, B.S.; Li, Z.M. Tuning the superstructure of ultrahigh-molecular-weight polyethylene/low-molecular-weight polyethylene blend for artificial joint application. ACS Appl. Mater. Interfaces 2012, 4, 1521–1529. [Google Scholar] [CrossRef] [PubMed]

- Reinitz, S.D.; Carlson, E.M.; Levine, R.A.C.; Franklin, K.J.; Van Citters, D.W. Dynamical mechanical analysis as an assay of cross-link density of orthopaedic ultra high molecular weight polyethylene. Polym. Test. 2015, 45, 174–178. [Google Scholar] [CrossRef]

- Kaloshkin, S.; Maksimkin, A.; Kaloshkina, M.; Zadorozhnyy, M.; Churyukanova, M. Shape memory behavior of ultra-high molecular weight polyethylene. Mater. Res. Soc. Symp. Proc. 2012, 1403, 91–97. [Google Scholar] [CrossRef]

- Bastiaansen, C.W.M.; Meyer, H.E.H.; Lemstra, P.J. Memory effects in polyethylenes: Influence of processing and crystallization history. Polymer 1990, 31, 1435–1440. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Li, Q.; Fu, Z.; Sun, L.; Guo, W.; Wu, C. The shape memory effect of crosslinked ultra-high-molecular-weight polyethylene prepared by silane-induced crosslinking method. Polym. Bull. 2018, 75, 2181–2196. [Google Scholar] [CrossRef]

- Li, Q.; Chen, T.; Sun, L.; Guo, W.; Wu, C. Cross-linked ultra-high-molecular-weight polyethylene prepared by silane-induced cross-linking under in situ development of water. Adv. Polym. Technol. 2018, 37, 2859–2865. [Google Scholar] [CrossRef]

- Takahashi, Y.; Shishido, T.; Yamamoto, K.; Masaoka, T.; Kubo, K.; Tateiwa, T.; Pezzotti, G. Mechanisms of plastic deformation in highly cross-linked UHMWPE for total hip components—The molecular physics viewpoint. J. Mech. Behav. Biomed. 2015, 42, 43–53. [Google Scholar] [CrossRef]

- Pucci, A.; Liuzzo, V.; Ruggeri, G.; Ciardel, F. Conferring Smart Behavior to Polyolefins through Blending with Organic Dyes and Metal Derivatives. ACS Symp. Ser. 2005, 916, 18–33. [Google Scholar] [CrossRef]

- Reddy, S.K.; Kumar, S.; Varadarajan, K.M.; Marpu, P.R.; Gupta, T.K.; Choosri, M. Strain and damage-sensing performance of biocompatible smart CNT/UHMWPE nanocomposites. Mater. Sci. Eng. C 2018, 92, 957–968. [Google Scholar] [CrossRef] [PubMed]

- Alam, F.; Choosri, M.; Gupta, T.K.; Varadarajan, K.M.; Choi, D.; Kumar, S. Electrical, mechanical and thermal properties of graphene nanoplatelets reinforced UHMWPE nanocomposites. Mater. Sci. Eng. B 2019, 241, 82–91. [Google Scholar] [CrossRef]

- Lahiri, D.; Dua, R.; Zhang, C.; de Socarraz-Novoa, I.; Bhat, A.; Ramaswamy, S.; Agarwal, A. Graphene nanoplatelet-induced strengthening of ultrahigh molecular weight polyethylene and biocompatibility in vitro. ACS Appl. Mater. Interfaces 2012, 4, 2234–2241. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Eyler, A.; Zhong, W.H. Simultaneous improvements in wear resistance and mechanical properties of UHMWPE nanocomposite fabricated via a facile approach. Mater. Latt. 2016, 177, 17–20. [Google Scholar] [CrossRef]

- Xie, M.; Li, H. Viscosity reduction and disentanglement in ultrahigh molecular weight polyethylene melt: Effect of blending with polypropylene and poly (ethylene glycol). Eur. Polym. J. 2007, 43, 3480–3487. [Google Scholar] [CrossRef]

- Shen, L.; Severn, J.; Bastiaansen, C.W.M. Drawing behavior and mechanical properties of ultra-high molecular weight polyethylene blends with a linear polyethylene wax. Polymer 2018, 153, 354–361. [Google Scholar] [CrossRef]

- Utsumi, M.; Nagata, K.; Suzuki, M.; Mori, A.; Sakuramoto, I.; Torigoe, Y.; Kaneeda, T.; Moriya, H. Effects of calcium stearate addition of ultrahigh molecular weight polyethylene in direct compression molding. J. Appl. Polym. Sci. 2003, 87, 1602–1609. [Google Scholar] [CrossRef]

- Panin, C.V.; Kornienko, L.A.; Nguyen, S.T.; Ivanova, L.R.; Poltaranin, M.A. The effect of adding calcium stearate on wear-resistance of ultra-high molecular weight polyethylene. Procedia Eng. 2015, 113, 490–498. [Google Scholar] [CrossRef] [Green Version]

- Zhong, F.; Schwabe, J.; Hofmann, D.; Meier, J.; Thomann, R.; Enders, M.; Mülhaupt, R. All-polyethylene composites reinforced via extended-chain UHMWPE nanostructure formation during melt processing. Polymer 2018, 140, 107–116. [Google Scholar] [CrossRef]

- Maksimkin, A.V.; Kaloshkin, S.D.; Zadorozhnyy, M.V.; Senatov, F.S.; Salimon, A.I.; Dayyoub, T. Artificial muscles based on coiled UHMWPE fibers with shape memory effect. Express Polym. Lett. 2018, 12, 1072–1080. [Google Scholar] [CrossRef]

- Fan, L.F.; Huang, Y.N.; Rong, M.Z.; Zhang, M.Q.; Chen, X. Imparting External Stress-Free Two-Way Shape Memory Effect to Commodity Polyolefins by Manipulation of Their Hierarchical Structures. ACS Macro Lett. 2019, 8, 1141–1146. [Google Scholar] [CrossRef]

- Senatov, F.S.; Kopylov, A.N.; Anisimova, N.Y.; Kiselevsky, M.V.; Maksimkin, A.V. UHMWPE-based nanocomposite as a material for damaged cartilage replacement. Mater. Sci. Eng. C 2014, 48, 566–571. [Google Scholar] [CrossRef] [PubMed]

- Varley, R.J.; van der Zwaag, S. Towards an understanding of thermally activated self-healing of an ionomer system during ballistic penetration. Acta Mater. 2008, 56, 5737–5750. [Google Scholar] [CrossRef]

- Wu, X.L.; Huang, W.M.; Ding, Z.; Tan, H.X.; Yang, W.G.; Sun, K.Y. Characterization of the Thermoresponsive Shape-Memory Effect in Poly (ether ether ketone) (PEEK). J. Appl. Polym. Sci. 2014, 131, 39844. [Google Scholar] [CrossRef]

- Memarian, F.; Fereidoon, A.; Ahangari, M.G.; Khonakdar, H.A. Shape memory and mechanical properties of TPU/ABS blends: The role of pristine versus organo-modified carbon nanotubes. Polym. Compos. 2018, 39, E984–E995. [Google Scholar] [CrossRef]

| Content (wt %) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| UHMWPE | 5PEW | 13PEW | 1CS | 5CS | 5PEW1CS | 5PEW5CS | 13PEW5CS | ||

| UHMWPE | 100 | 95 | 87 | 99 | 95 | 94 | 90 | 82 | |

| PEW | -- | 5 | 13 | -- | -- | 5 | 5 | 13 | |

| CS | -- | -- | -- | 1 | 5 | 1 | 5 | 5 | |

| Sample | DSC | TGA | |||||

|---|---|---|---|---|---|---|---|

| Tmon (°C) | Tmmax (°C) | Tmoff (°C) | Crystallinity (%) | T1 (°C) | T50 (°C) | Ash Content (%) | |

| UHMWPE | 125.3 | 136.9 | 141.9 | 49.62 | 464.3 | 480.7 | 0.256 |

| 5PEW | 122.9 | 136.9 | 142.3 | 52.16 | 466.2 | 481.6 | 0.013 |

| 13PEW | 120.2 | 138.1 | 144.3 | 60.29 | 465.9 | 481.1 | 0.105 |

| 1CS | 125.1 | 136.4 | 141.3 | 49.08 | 463.9 | 479.4 | 0.352 |

| 5CS | 124.5 | 137.4 | 143.3 | 43.51 | 461.9 | 481.8 | 0.988 |

| 5PEW1CS | 123.9 | 137.9 | 144.1 | 57.52 | 465.1 | 482.7 | 1.814 |

| 5PEW5CS | 123.4 | 138.3 | 144.9 | 55.24 | 462.6 | 482.6 | 2.586 |

| 13PEW5CS | 122.8 | 137.5 | 143.0 | 60.96 | 460.1 | 480.6 | 0.331 |

| UHMWPE | 5PEW | 13PEW | 1CS | 5CS | 5PEW1CS | 5PEW5CS | 13PEW5CS | ||

|---|---|---|---|---|---|---|---|---|---|

| E′ (MPa) | 4.587 | 4.755 | 4.603 | 4.971 | 5.060 | 5.907 | 5.607 | 4.761 | |

| Me (g/mol) | 2066 | 1993 | 2059 | 1907 | 1873 | 1605 | 1690 | 1991 | |

| υe (mol/m3) | 453 | 469 | 454 | 490 | 499 | 583 | 553 | 470 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Wang, S.; Tian, J.; Chen, K.; Xue, P.; Wu, Y.; Chou, W. Effect of PEW and CS on the Thermal, Mechanical, and Shape Memory Properties of UHMWPE. Polymers 2020, 12, 483. https://doi.org/10.3390/polym12020483

Zhang R, Wang S, Tian J, Chen K, Xue P, Wu Y, Chou W. Effect of PEW and CS on the Thermal, Mechanical, and Shape Memory Properties of UHMWPE. Polymers. 2020; 12(2):483. https://doi.org/10.3390/polym12020483

Chicago/Turabian StyleZhang, Run, Suwei Wang, Jing Tian, Ke Chen, Ping Xue, Yihui Wu, and Weimin Chou. 2020. "Effect of PEW and CS on the Thermal, Mechanical, and Shape Memory Properties of UHMWPE" Polymers 12, no. 2: 483. https://doi.org/10.3390/polym12020483

APA StyleZhang, R., Wang, S., Tian, J., Chen, K., Xue, P., Wu, Y., & Chou, W. (2020). Effect of PEW and CS on the Thermal, Mechanical, and Shape Memory Properties of UHMWPE. Polymers, 12(2), 483. https://doi.org/10.3390/polym12020483