Properties of Poplar Fiber/PLA Composites: Comparison on the Effect of Maleic Anhydride and KH550 Modification of Poplar Fiber

Abstract

:1. Introduction

2. Experimental

2.1. Materials

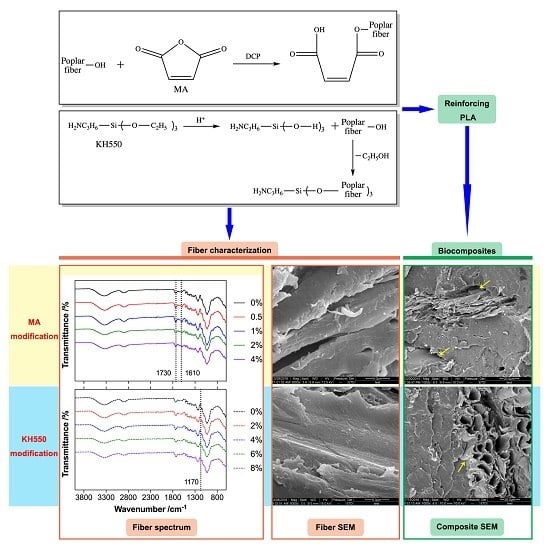

2.2. Modification of Poplar Fiber

2.3. Preparation of Poplar Fiber/PLA Composites

2.4. Characterizations

3. Results and Discussions

3.1. Chemical and Structural Properties of Modified Poplar Fiber

3.2. Thermal Properties of Composites

3.3. Mechanical Properties of Composites

3.4. Rheological Properties of Composites

3.5. Physical Properties of Composites

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part. A Appl. S 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Lee, S.H.; Wang, S.Q. Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos. Part. A Appl. S 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Effect of maleated compatibilizer on performance of PLA/wheat straw-based green composites. Macromol. Mater. Eng. 2011, 296, 710–718. [Google Scholar] [CrossRef]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Yang, Z.; Bi, H.; Bi, Y.; Rodrigue, D.; Xu, M.; Feng, X. Comparison between polyethylene glycol and tributyl citrate to modify the properties of wood fiber/polylactic acid biocomposites. Polym. Compos. 2019, 40, 1384–1394. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, X.; Bi, Y.; Zhou, Z.; Yue, J.; Xu, M. Bleached extruder chemi-mechanical pulp fiber-PLA composites: Comparison of mechanical, thermal, and rheological properties with those of wood flour-PLA bio-composites. J. Appl. Polym. Sci. 2016, 133, 1–9. [Google Scholar] [CrossRef]

- Kang, J.T.; Kim, S.H. Improvement in the mechanical properties of polylactide and bamboo fiber biocomposites by fiber surface modification. Macromol. Res. 2011, 19, 789–796. [Google Scholar] [CrossRef]

- Wang, Y.; Tong, B.; Hou, S.; Li, M.; Shen, C. Transcrystallization behavior at the poly(lactic acid)/sisal fibre biocomposite interface. Compos. Part. A Appl. S 2011, 42, 66–74. [Google Scholar] [CrossRef]

- Birnin-Yauri, A.U.; Ibrahim, N.A.; Zainuddin, N.; Abdan, K.; Then, Y.Y.; Chieng, B.W. Effect of maleic anhydride-modified poly(lactic acid) on the properties of Its hybrid fiber biocomposites. Polymers 2017, 9, 165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Behera, K.; Chang, Y.-H.; Chiu, F.-C.; Yang, J.-C. Characterization of poly(lactic acid)s with reduced molecular weight fabricated through an autoclave process. Polym. Test. 2017, 60, 132–139. [Google Scholar] [CrossRef]

- Behera, K.; Chang, Y.-H.; Yadav, M.; Chiu, F.-C. Enhanced thermal stability, toughness, and electrical conductivity of carbon nanotube-reinforced biodegradable poly(lactic acid)/poly(ethylene oxide) blend-based nanocomposites. Polymer 2020, 186, 122002. [Google Scholar] [CrossRef]

- Behera, K.; Sivanjineyulu, V.; Chang, Y.-H.; Chiu, F.-C. Thermal properties, phase morphology and stability of biodegradable PLA/PBSL/HAp composites. Polym. Degrad. Stabil. 2018, 154, 248–260. [Google Scholar] [CrossRef]

- Zhou, C.; Shi, Q.; Guo, W.; Terrell, L.; Qureshi, A.T.; Hayes, D.J.; Wu, Q. Electrospun bio-nanocomposite scaffolds for bone tissue engineering by cellulose nanocrystals reinforcing maleic anhydride grafted PLA. ACS Appl. Mater. Interfaces 2013, 5, 3847–3854. [Google Scholar] [CrossRef]

- Saenghirunwattana, P.; Noomhorm, A.; Rungsardthong, V. Mechanical properties of soy protein based “green” composites reinforced with surface modified cornhusk fiber. Ind. Crop. Prod. 2014, 60, 144–150. [Google Scholar] [CrossRef]

- Hong, H.; Xiao, R.; Guo, Q.; Liu, H.; Zhang, H. Quantitively characterizing the chemical composition of tailored bagasse fiber and its effect on the thermal and mechanical properties of polylactic acid-based composites. Polymers 2019, 11, 1567. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.; Han, G.; Li, Q.; Gao, X.; Cheng, W. High-Temperature Hot Air/Silane Coupling Modification of Wood Fiber and Its Effect on Properties of Wood Fiber/HDPE Composites. Materials 2017, 10, 286. [Google Scholar] [CrossRef] [Green Version]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of fibre treatments on interfacial shear strength of hemp fibre reinforced polylactide and unsaturated polyester composites. Compos. Part. A-Appl. S 2011, 42, 1189–1196. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.H.; Ohkita, T.; Kitagawa, K. Eco-composite from poly(lactic acid) and bamboo fiber. Holzforschung 2004, 58, 529–536. [Google Scholar] [CrossRef]

- Xu, Y.; Kawata, S.; Hosoi, K.; Kawai, T.; Kuroda, S. Thermomechanical properties of the silanized-kenaf/polystyrene composites. Express Polym. Lett. 2009, 3, 657–664. [Google Scholar] [CrossRef]

- Lee, B.-H.; Kim, H.-S.; Lee, S.; Kim, H.-J.; Dorgan, J.R. Bio-composites of kenaf fibers in polylactide: Role of improved interfacial adhesion in the carding process. Compos. Sci. Technol. 2009, 69, 2573–2579. [Google Scholar] [CrossRef]

- Liua, S.-Q.; Yua, J.-J.; Wu, G.-H.; Wang, P.; Liu, M.-F.; Zhang, Y.; Zhang, J.; Yin, X.-L.; Li, F.; Zhang, M. Effect of silane KH550 on interface of basalt fibers (BFs)/poly (lactic acid) (PLA) composites. Ind. Text. 2019, 70, 408–412. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.F.; Li, Z.P.; Yang, X.L.; Hou, W.B. Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. Part. B-Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, Z.; Leng, X.; Shen, K.; Li, Y. Highly toughened polylactide with epoxidized polybutadiene by in-situ reactive compatibilization. Polymer 2016, 92, 74–83. [Google Scholar] [CrossRef] [Green Version]

- Stenstad, P.; Andresen, M.; Tanem, B.S.; Stenius, P. Chemical surface modifications of microfibrillated cellulose. Cellulose 2008, 15, 35–45. [Google Scholar] [CrossRef]

- Dun, M.; Hao, J.; Wang, W.; Wang, G.; Cheng, H. Sisal fiber reinforced high density polyethylene pre-preg for potential application in filament winding. Compos. Part. B-Eng. 2019, 159, 369–377. [Google Scholar] [CrossRef]

- Kruglikov, A.; Vasilchenko, A.; Kasprzhitskii, A.; Lazorenko, G. Atomic-level understanding of interface interactions in a halloysite nanotubes-PLA nanocomposite. RSC Adv. 2019, 9, 39505–39514. [Google Scholar] [CrossRef] [Green Version]

- Xu, C.; Lv, Q.; Wu, D.; Wang, Z. Polylactide/cellulose nanocrystal composites: A comparative study on cold and melt crystallization. Cellulose 2017, 24, 2163–2175. [Google Scholar] [CrossRef]

- Cervantes-Uc, J.M.; Cauich-Rodriguez, J.V.; Vazquez-Torres, H.; Licea-Claverie, A. TGA/FTIR study on thermal degradation of polymethacrylates containing carboxylic groups. Polym. Degrad. Stabil. 2006, 91, 3312–3321. [Google Scholar] [CrossRef]

- Li, Y.; Yu, J.; Guo, Z.X. The influence of interphase on nylon-6/nano-SiO2 composite materials obtained from in situ polymerization. Polym. Int. 2003, 52, 981–986. [Google Scholar] [CrossRef]

- Lee, K.Y.; Blaker, J.J.; Bismarck, A. Surface functionalisation of bacterial cellulose as the route to produce green polylactide nanocomposites with improved properties. Compos. Sci. Technol. 2009, 69, 2724–2733. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Mo, X.; Pang, J.; Yang, F. Effects of silica on the morphology, structure, and properties of thermoplastic cassava starch/poly(vinyl alcohol) blends. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Wang, Y.; Mei, Y.; Wang, Q.; Wei, W.; Huang, F.; Li, Y.; Li, J.Y.; Zhou, Z.W. Improved fracture toughness and ductility of PLA composites by incorporating a small amount of surface-modified helical carbon nanotubes. Compos. Part. B Eng. 2019, 162, 54–61. [Google Scholar] [CrossRef]

- Tidjani, A.; Wald, O.; Pohl, M.M.; Hentschel, M.P.; Schartel, B. Polypropylene-graft-maleic anhydride-nanocomposites: I—Characterization and thermal stability of nanocomposites produced under nitrogen and in air. Polym. Degrad. Stabil. 2003, 82, 133–140. [Google Scholar] [CrossRef]

- Chen, H.; Lu, H.; Zhou, Y.; Zheng, M.; Ke, C.; Zeng, D. Study on thermal properties of polyurethane nanocomposites based on organo-sepiolite. Polym. Degrad. Stabil. 2012, 97, 242–247. [Google Scholar] [CrossRef]

- Shang, X.; Zhu, Y.; Li, Z. Surface modification of silicon carbide with silane coupling agent and hexadecyl iodiele. Appl. Surf. Sci. 2017, 394, 169–177. [Google Scholar] [CrossRef]

- Luo, Y.F.; Wang, Y.L.; Niu, X.F.; Pan, J.; Shi, L.P. Synthesis and characterization of a novel biomaterial: Maleic anhydride-modified poly(dl-lactic acid). Chin. Chem. Lett. 2004, 15, 521–524. [Google Scholar]

| Modifier Content /% | T5%/°C | Tmax/°C | T90%/°C | |

|---|---|---|---|---|

| 0 | 250 | 301 | 352 | |

| MA | 0.5 | 251 | 299 | 333 |

| 1 | 251 | 300 | 340 | |

| 2 | 253 | 300 | 340 | |

| 4 | 255 | 302 | 343 | |

| KH550 | 2 | 253 | 305 | 355 |

| 4 | 259 | 317 | 366 | |

| 6 | 254 | 309 | 381 | |

| 8 | 256 | 316 | 369 | |

| Modifier Content /% | Tg/°C | Tc/°C | Tm/°C | ΔHc/(J/g) | ΔHm/(J/g) | Xc/% | |

|---|---|---|---|---|---|---|---|

| 0 | 61.7 | 108.5 | 167.5 | 20.4 | 31.1 | 37.7 | |

| MA | 0.5 | 61.9 | 109.1 | 168.2 | 22.0 | 35.3 | 35.2 |

| 1 | 61.4 | 108.7 | 167.8 | 19.1 | 29.7 | 36.2 | |

| 2 | 61.6 | 107.9 | 167.9 | 19.5 | 29.5 | 36.3 | |

| 4 | 61.3 | 106.9 | 167.7 | 19.6 | 29.2 | 34.9 | |

| KH550 | 2 | 61.5 | 106.9 | 168.3 | 20.4 | 30.6 | 34.9 |

| 4 | 61.4 | 109.4 | 168.9 | 22.6 | 31.0 | 31.4 | |

| 6 | 61.8 | 108.9 | 168.5 | 21.2 | 30.3 | 32.1 | |

| 8 | 61.7 | 108.3 | 168.8 | 23.8 | 32.8 | 33.7 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Feng, X.; Xu, M.; Rodrigue, D. Properties of Poplar Fiber/PLA Composites: Comparison on the Effect of Maleic Anhydride and KH550 Modification of Poplar Fiber. Polymers 2020, 12, 729. https://doi.org/10.3390/polym12030729

Yang Z, Feng X, Xu M, Rodrigue D. Properties of Poplar Fiber/PLA Composites: Comparison on the Effect of Maleic Anhydride and KH550 Modification of Poplar Fiber. Polymers. 2020; 12(3):729. https://doi.org/10.3390/polym12030729

Chicago/Turabian StyleYang, Zhaozhe, Xinhao Feng, Min Xu, and Denis Rodrigue. 2020. "Properties of Poplar Fiber/PLA Composites: Comparison on the Effect of Maleic Anhydride and KH550 Modification of Poplar Fiber" Polymers 12, no. 3: 729. https://doi.org/10.3390/polym12030729

APA StyleYang, Z., Feng, X., Xu, M., & Rodrigue, D. (2020). Properties of Poplar Fiber/PLA Composites: Comparison on the Effect of Maleic Anhydride and KH550 Modification of Poplar Fiber. Polymers, 12(3), 729. https://doi.org/10.3390/polym12030729