Influence of MgO-Lignin Dual Component Additives on Selected Properties of Low Density Polyethylene

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MgO-Lignin Hybrid Fillers

2.3. Polyethylene/PE-g-MAH/MgO-Lignin Formulation and Processing

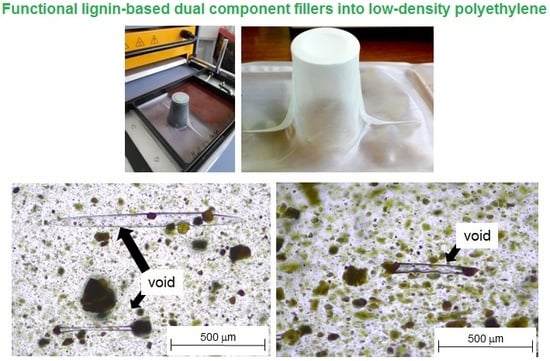

2.4. Microstructural Investigations

2.5. Tensile Test of Composites

2.6. Thermoforming of Polyethylene Composites

2.7. Concact Angle Measurements

3. Results and Discussion

3.1. Microstructural Observations

3.2. Mechanical and Technological Properties of Thermoformed Polyethylene/Hybrid Composites

3.3. Analysis of Wettability for Obtained LDPE Films

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Norgren, M.; Edlund, H. Lignin: Recent advances and emerging applications. Curr. Opin. Colloid Interface Sci. 2014, 19, 409–416. [Google Scholar] [CrossRef]

- Stiubianu, G.; Cazacu, M.; Cristea, M.; Vlad, A. Polysiloxane-lignin composites. J. Appl. Polym. Sci. 2009, 113, 2313–2321. [Google Scholar] [CrossRef]

- Guilhen, A.; Gadioli, R.; Fernandes, F.C.; Waldman, W.R.; De Paoli, M.A. High-density green polyethylene biocomposite reinforced with cellulose fibers and using lignin as antioxidant. J. Appl. Polym. Sci. 2017, 134, 45219–45229. [Google Scholar] [CrossRef]

- Ramos de Sousa Junior, R.; Gouveia, J.R.; Nacas, A.M.; Tavares, L.B.; Ito, N.M.; Nascimento de Moura, E.; Gaia, F.; Pereira, R.F.; Jackson dos Santos, D. Improvement of polypropylene adhesion by kraft lignin incorporation. Mater. Res. 2019, 22, e20180123. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Naegele, H.; Pfitzer, J.; Ziegler, L.; Inone-Kauffmann, E.R.; Eisenreich, N. Applications of Lignin Materials and Their Composites (Lignin Applications in Various Industrial Sectors, Future Trends of Lignin and Their Composites). In Lignin in Polymer Composites, 1st ed.; Faruk, O., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 233–244. [Google Scholar]

- Satheesh Kumar, M.N.; Mohanty, A.K.; Erickson, L.; Misra, M. Lignin and its applications with polymers. J. Biobased Mater. Bioenergy 2009, 3, 1–24. [Google Scholar] [CrossRef]

- Ghozali, M.; Triwulandri, E.; Haryono, A.; Yuanita, E. Effect of lignin on morphology, biodegradability, mechanical and thermal properties of low linear density polyethylene/lignin biocomposites. In Proceedings of the Innovation in Polymer Science and Technology, Medan, Indonesia, 7–10 November 2016; p. 223. [Google Scholar]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Xanthos, M. Functional Fillers for Plastics; Wiley-VCH Verlag GmbH & Co KGaA: Weinheim, Germany, 2005. [Google Scholar]

- Diop, A.; Mijiyawa, F.; Koffi, D.; Kokta, B.V.; Montplaisir, D. Study of lignin dispersion in low-density polyethylene. J. Thermoplast. Compos. Mater. 2015, 28, 1662–1674. [Google Scholar] [CrossRef]

- Sailaja, R.R.N.; Deepthi, M.V. Mechanical and thermal properties of compatibilized composites of polyethylene and esterified lignin. Mater. Des. 2010, 31, 4369–4379. [Google Scholar] [CrossRef]

- Gregorova, A.; Cibulkova, Z.; Kosıkova, B.; Simon, P. Stabilization effect of lignin in polypropylene and recycled polypropylene. Polym. Degr. Stab. 2005, 89, 553–558. [Google Scholar] [CrossRef]

- Bozsódi, B.; Romhányi, V.; Pataki, P.; Kun, D.; Renner, K.; Pukánszky, B. Modification of interactions in polypropylene/lignosulfonate blends. Mater. Des. 2016, 103, 32–39. [Google Scholar] [CrossRef] [Green Version]

- El-Zawawy, W.K.; Ibrahim, M.M.; Belgacem, M.N.; Dufresne, A. Characterization of the effects of lignin and lignin complex particles as filler on a polystyrene film. Mater. Chem. Phys. 2011, 131, 348–357. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Dominici, F.; Giovanale, G.; Mazzaglia, A.; Balestra, G.M.; Kenny, J.M.; Puglia, D. Effect of cellulose and lignin on disintegration, antimicrobial and antioxidant properties of PLA active films. Int. J. Biol. Macromol. 2016, 89, 360–368. [Google Scholar] [CrossRef] [PubMed]

- Domenek, S.; Louaifi, A.; Guinault, A.; Baumberger, S. Potential of lignins as antioxidant additive in active biodegradable packaging materials. J. Polym. Environ. 2013, 21, 692–701. [Google Scholar] [CrossRef] [Green Version]

- Le Digabel, F.; Avérous, L. Effects of lignin content on the properties of lignocellulose-based biocomposites. Carbohydr. Polym. 2006, 66, 537–545. [Google Scholar] [CrossRef]

- Canetti, M.; Bertini, F.; De Chirico, A.; Audisio, G. Thermal degradation behaviour of isotactic polypropylene blended with lignin. Polym. Degrad. Stab. 2006, 91, 494–498. [Google Scholar] [CrossRef]

- Brebu, M.; Vasile, C. Thermal degradation of lignin—A review. Cellul. Chem. Technol. 2010, 44, 353–363. [Google Scholar]

- Poletto, M.; Zattera, A.J.; Forte, M.M.C.; Santana, R.M.C. Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Biores. Technol. 2012, 109, 148–153. [Google Scholar] [CrossRef]

- Borysiak, S.; Klapiszewski, Ł.; Bula, K.; Jesionowski, T. Nucleation ability of advanced functional silica/lignin hybrid fillers in polypropylene composites. J. Therm. Anal. Calorim. 2016, 126, 251–262. [Google Scholar] [CrossRef] [Green Version]

- Klapiszewski, Ł.; Jamrozik, A.; Strzemiecka, B.; Koltsov, I.; Borek, B.; Matykiewicz, D.; Voelkel, A.; Jesionowski, T. Characteristics of multifunctional, eco-friendly lignin-Al2O3 hybrid fillers and their influence on the properties of composites for the abrasive tools. Molecules 2017, 22, 1920–1939. [Google Scholar] [CrossRef] [Green Version]

- Klapiszewski, Ł.; Bula, K.; Dobrowolska, A.; Czaczyk, K.; Jesionowski, T. A high-density polyethylene container based on ZnO/lignin dual fillers with potential antimicrobial activity. Polym. Test. 2019, 73, 51–59. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Bula, K.; Sobczak, M.; Jesionowski, T. Influence of processing conditions on the thermal stability and mechanical properties of PP/silica-lignin composites. Int. J. Polym. Sci. 2016, 1, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Bula, K.; Kubicki, G.; Jesionowski, T.; Klapiszewski, Ł. MgO–lignin dual phase filler as an effective modifier of polyethylene film properties. Materials 2020, 13, 809. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grząbka-Zasadzińska, A.; Klapiszewski, Ł.; Jesionowski, T.; Borysiak, S. Functional MgO—Lignin hybrids and their application as fillers for polypropylene composites. Molecules 2020, 25, 864. [Google Scholar] [CrossRef] [Green Version]

- Pilarska, A.; Klapiszewski, Ł.; Jesionowski, T. Recent development in the synthesis, modification and application of Mg(OH)2 and MgO: A review. Powder Technol. 2017, 319, 373–407. [Google Scholar] [CrossRef]

- Choudhury, B.; Choudhury, A. Microstructural, optical and magnetic properties study of nanocrystalline MgO. Mater. Res. Express 2014, 1, 025026. [Google Scholar] [CrossRef]

- Sailaja, R.R.N. Low density polyethylene and grafted lignin polyblends using epoxy-functionalized compatibilizer: Mechanical and thermal properties. Polym. Int. 2005, 54, 1589–1598. [Google Scholar] [CrossRef]

- Liu, R.; Peng, Y.; Cao, J.; Chen, Y. Comparison on properties of lignocelulosic flour/polymer composites by using wood, cellulose, and lignin as a fillers. Compos. Sci. Technol. 2014, 103, 1–7. [Google Scholar] [CrossRef]

- Polat, Y.; Stojanovska, E.; Negawo, T.A.; Doner, E.; Kilic, A. Lignin as an Additive for Advanced Composites. In Green Biocomposites: Manufacturing and Properties; Jawaid, M., Sapuan, S.M., Alothman, O.Y., Eds.; Springer International Publishing: New York, NY, USA, 2017; pp. 71–89. [Google Scholar]

- Iyer, K.A.; Torkelson, J.M. Sustainable green hybrids of polyolefins and lignin yield major improvements in mechanical properties when prepared via solid-state shear pulverization. ACS Sustain. Chem. Eng. 2015, 3, 959–968. [Google Scholar] [CrossRef]

- Park, C.W.; Youe, W.-J.; Kim, S.J.; Han, S.Y.; Park, J.S.; Lee, E.A.; Kwon, G.J.; Kim, Y.S.; Kim, N.H.; Lee, S.H. Effect of lignin plasticization on physico-mechanical properties of lignin/poly(lactic acid). Comp. Polym. 2019, 11, 2089. [Google Scholar] [CrossRef] [Green Version]

- Gregorova, A.; Kosikova, B.; Stasko, A.J. Radical scavenging capacity of lignin and its effect on processing stabilization of virgin and recycled polypropylene. Appl. Polym. Sci. 2007, 106, 1626–1631. [Google Scholar] [CrossRef]

- Pucciariello, R.; Villani, V.; Bonini, C.; D’Auria, M.; Vetere, T. Physical properties of straw lignin-based polymer blends. Polymer 2004, 45, 4159–4169. [Google Scholar] [CrossRef]

- Levon, K.; Huhtala, J.; Maim, B.; Lindberg, J.J. Improvement of the thermal stabilization of polyethylene with lignosulphonate. Polymer 1987, 28, 745–750. [Google Scholar] [CrossRef]

- Cazacu, G.; Pascu, M.C.; Profire, L.; Kowarski, A.I.; Mihaes, M.; Vasile, C. Lignin role in a complex polyolefin blend. Ind. Crops Prod. 2004, 20, 261–273. [Google Scholar] [CrossRef]

- Stewart, D. Lignin as a base material for materials applications: Chemistry, application and economics. Ind. Crops Prod. 2008, 27, 202–207. [Google Scholar] [CrossRef]

- Bula, K.; Klapiszewski, Ł.; Jesionowski, T. A novel functional silica/lignin hybrid material as a potential bio-based polypropylene filler. Polym. Compos. 2016, 36, 913–922. [Google Scholar] [CrossRef]

- Bula, K.; Klapiszewski, Ł.; Jesionowski, T. Effect of processing conditions and functional silica/lignin content on the properties of bio-based composite thin sheet films. Polym. Test. 2019, 77, 105911. [Google Scholar] [CrossRef]

- Kaelble, D.H. Dispersion-polar surface tension properties of organic solids. J. Adhes. 1970, 2, 66–81. [Google Scholar] [CrossRef]

- Wendt, D.K.; Ownens, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar]

- Toriz, G.; Denes, F.; Young, R.A. Lignin-polypropylene composites. Part 1: Composites from unmodified lignin and polypropylene. Polym. Compos. 2002, 23, 806–813. [Google Scholar] [CrossRef]

- Parizek, M.; Slepickova Kasalkova, N.; Bacakova, L.; Svindrych, Z.; Slepicka, P.; Bacakova, M.; Lisa, V.; Svorcik, V. Adhesion, growth, and maturation of vascular smooth muscle cells on low-density polyethylene grafted with bioactive substances. BioMed Res. Int. 2013, 2013, 371430. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wysokowski, M.; Materna, K.; Walter, J.; Petrenko, I.; Stelling, A. L.; Bazhenov, V. V.; Klapiszewski, Ł.; Szatkowski, T.; Lewandowska, O.; Stawski, D. Solvothermal synthesis of hydrophobic chitin-polyhedral oligomeric silsesquioxane (POSS) nanocomposites. Int. J. Biol. Macromol. 2015, 78, 224–229. [Google Scholar] [CrossRef] [PubMed]

- Sulym, I.; Kubiak, A.; Jankowska, K.; Sternik, D.; Terpilowski, K.; Sementsov, Y.; Borysenko, M.; Derylo-Marczewska, A.; Jesionowski, T. Superhydrophobic MWCNTs/PDMS-nanocomposite materials: Preparation and characterization. Physicochem. Probl. Miner. Process. 2019, 55, 1394–1400. [Google Scholar]

- Kasalkova, S.N.; Slepicka, P.; Kolska, Z.; Svorcik, V. Wettability and other surface properties of modified polymers. In Wetting and Wettability; Aliofkhazraei, M., Ed.; IntechOpen: London, UK, 2015; pp. 323–355. [Google Scholar]

- Howarter, J.A.; Youngblood, J.P. Surface modification of polymers with 3-aminopropyltriethoxysilane as a general pretreatment for controlled wettability. Macromolecules 2007, 40, 1128–1132. [Google Scholar] [CrossRef]

- Notley, S. M.; Norgren, M. Surface energy and wettability of spin-coated thin films of lignin isolated from wood. Langmuir 2010, 26, 5484–5490. [Google Scholar] [CrossRef] [PubMed]

- Chizallet, C.; Costentin, G.; Che, M.; Delbecq, F.; Sautet, P. Infrared characterization of hydroxyl groups on MgO: A periodic and cluster density functional theory study. J. Am. Chem. Soc. 2007, 129, 6442–6452. [Google Scholar] [CrossRef]

- Foster, M.; Furse, M.; Passno, D. An FTIR study of water thin films on magnesium oxide. Surf. Sci. 2002, 502–503, 102–108. [Google Scholar] [CrossRef]

| Sample Description | Tensile Strength (MPa) | Stand. Dev. (MPa) | Young’s Modulus (MPa) | Stand. Dev. (MPa) |

|---|---|---|---|---|

| LDPE | 11.1 | 1.2 | 105 | 8.7 |

| MgO | 9.1 | 0.8 | 150 | 11.2 |

| MgO-L 5:1 wt./wt. | 10.5 | 1.1 | 176 | 15.4 |

| MgO-L 1:1 wt./wt. | 10.3 | 0.7 | 180 | 12.0 |

| MgO-L 1:5 wt./wt. | 8.4 | 0.9 | 188 | 14.1 |

| Lignin | 7.8 | 0.6 | 196 | 26.9 |

| Measurement Points | Samples Used for Thermoforming | |||||

|---|---|---|---|---|---|---|

| LDPE | MgO | MgO-L 5:1 wt./wt. | MgO-L 1:1 wt./wt. | MgO-L 1:5 wt./wt. | Lignin | |

| Relative Wall Thickness (%) | ||||||

| 1 | 49.0 | 45.7 | 39.6 | 48.7 | 55.3 | 47.6 |

| 2 | 48.0 | 49.0 | 29.3 | 42.7 | 54.5 | 39.8 |

| 3 | 63.3 | 42.4 | 24.4 | 37.3 | 49.6 | 42.2 |

| 4 Reference point | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| 5 | 50.7 | 49.5 | 46.3 | 52.0 | 65.7 | 66.5 |

| 6 | 64.0 | 47.6 | 43.3 | 64.0 | 61.9 | 56.8 |

| 7 | 60.1 | 37.1 | 40.2 | 81.3 | 59.3 | 47.1 |

| 8 | 46.3 | 53.8 | 50.6 | 49.3 | 65.2 | 43.2 |

| 9 | 48.0 | 48.1 | 41.5 | 43.3 | 64.8 | 41.3 |

| 10 | 30.0 | 37.1 | 40.9 | 27.3 | 35.8 | 26.2 |

| 11 | 33.5 | 29.5 | 31.1 | 30.7 | 35.0 | 38.8 |

| Mean relative wall thickness | 49.3 | 44.0 | 38.7 | 47.7 | 54.7 | 45.0 |

| Sample | Contact Angle (°) | SFE (mN/m2) | |

|---|---|---|---|

| Diiodomethane | Water | ||

| LDPE | 44.91 (±0.44) | 102.24 (±0.36) | 37.19 (±1.27) |

| LDPE/MgO | 59.21 (±0.74) | 92.08 (±0.18) | 30.97 (±1.06) |

| LDPE/MgO-L (5:1 wt./wt.) | 48.8 (±0.63) | 90.59 (±0.47) | 34.25 (±1.41) |

| LDPE/MgO-L (1:1 wt./wt.) | 52.77 (±0.67) | 89.64 (±0.56) | 36.92 (±0.96) |

| LDPE/MgO-L (1:5 wt./wt.) | 32.23 (±0.97) | 53.91 (±0.44) | 42.33 (±0.92) |

| LDPE/lignin | 44.91 (±0.55) | 74.06 (±0.26) | 41.19 (±1.13) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bula, K.; Kubicki, G.; Kubiak, A.; Jesionowski, T.; Klapiszewski, Ł. Influence of MgO-Lignin Dual Component Additives on Selected Properties of Low Density Polyethylene. Polymers 2020, 12, 1156. https://doi.org/10.3390/polym12051156

Bula K, Kubicki G, Kubiak A, Jesionowski T, Klapiszewski Ł. Influence of MgO-Lignin Dual Component Additives on Selected Properties of Low Density Polyethylene. Polymers. 2020; 12(5):1156. https://doi.org/10.3390/polym12051156

Chicago/Turabian StyleBula, Karol, Grzegorz Kubicki, Adam Kubiak, Teofil Jesionowski, and Łukasz Klapiszewski. 2020. "Influence of MgO-Lignin Dual Component Additives on Selected Properties of Low Density Polyethylene" Polymers 12, no. 5: 1156. https://doi.org/10.3390/polym12051156

APA StyleBula, K., Kubicki, G., Kubiak, A., Jesionowski, T., & Klapiszewski, Ł. (2020). Influence of MgO-Lignin Dual Component Additives on Selected Properties of Low Density Polyethylene. Polymers, 12(5), 1156. https://doi.org/10.3390/polym12051156