System Performance and Process Capability in Additive Manufacturing: Quality Control for Polymer Jetting

Abstract

:1. Introduction

- Vat photo-polymerization (VP) process with the stereolithography (SLA) technology;

- Binder jetting (BJ) process with 3D inkjet printing (3DP) technology;

- Material extrusion (ME) process with the fused deposition modeling (FDM) technology;

- Material jetting (MJ) process with polymer jetting (PolyJet) and multi-jet printing (MJM) technologies;

- Sheet lamination (SL) process with the laminated object manufacturing (LOM) technology;

- Powder bed fusion (PBF) process with selective laser sintering/melting (SLS/SLM) and electron beam melting (EBM) technologies; and

- Directed energy deposition (DED) process with laser engineered net shaping (LENS) technology.

- The AM artifacts are intended to investigate the strengths and weaknesses of additive manufacturing processes and they allow the comparison of the performances of different AM systems.

- The AM process control has an important role on the part quality, but there is a lack of adequate AM control methods and standards. There is still no AM standard for machine performance and process capability determination in mass production.

- Only a few research studies have focused on the repeatability, ISO IT grades, and process capability of polymer based AM systems.

2. Materials and Methods

2.1. New Methodology for Statistical Quality Tools in AM Production

- Methods applied to demonstrate that the process is in control;

- Technical conditions (input batches, operators, tools, etc.);

- Measurement process (resolution, repeatability, reproducibility, etc.); and

- Data collection (duration, frequency).

2.2. Process Specifications. Materials, Artifact, and Manufacturing Method

2.3. The Variability of the Measurement System

- The amount of measurement system variation compared with the process variation;

- The amount of variation in the measurement system that is due to operator influence; and

- The measurement system’s capability to discriminate between different parts.

- A Mitutoyo 500-196-30 digital scale caliper with advanced onsite sensor (AOS), a measuring range from 0 to 150 mm, and resolution 0.001 mm was used;

- The method that describes the way to keep the part in hand and the area to be measured for the height and for the diameter;

- A sample of 10 parts was used to be measured by three operators, twice, for each characteristic, the height, and the diameter. The parts were measured randomly;

- Circular 3D printed parts were made of polymers; and

- A controlled laboratory temperature of 20 °C and relative humidity of 30%.

2.4. System and Process Capability for PolyJet Technology

- 50 parts are printed at once;

- One operator manages the 3D printing process;

- The variation of the material batch or the printer user variation is not included in the total variation of the process; and

- The parts are measured and the data statistically analyzed.

- The specimens are 3D printed in three batches, each batch containing 50 specimens;

- Different operators manage the 3D printing process of the three batches based on the established parameters; and

- The parts are measured and the data transposed into the Destra software (Q-DAS GmbH, Weinheim, Germany), with the order of the measurements not being important.

2.5. Capable Tolerance Specification for PolyJet Technology

3. Results and Discussion

3.1. The Variability of the Measurement System

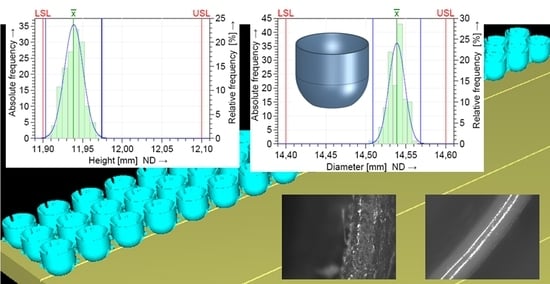

3.2. System Performance of Objet EDEN 350 PolyJet

3.3. Process Capability of PolyJet

3.4. Capable Tolerance and Its Limits Deviation for PolyJet Process

3.5. Determination of Tolerance Grade (ISO IT grade)

3.6. Quality Inspection through Microscopy Analysis

4. Conclusions

- The properties of the polymers used in additive manufacturing processes are relevant to the dimensional accuracy of the parts and require different evaluation and quantification of geometrical tolerances in comparison to metal materials and other plastics.

- The implementation of AM for pre-production series and short series production mainly depends on the repeatability, machine capability, and process capability.

- The values of the system and process capability indices (Cm, Cmk, Cp, and Cpk) of the circular parts produced with Objet VeroBlue RGD840 material by PolyJet technology were greater than 1.67 within the capable tolerance interval of 0.22 mm. The capable lower limit deviation and capable upper limit deviation of the circular artifact were −0.13 mm and +0.09 mm, respectively.

- From the statistical analysis conducted on the geometrical dimensions of the circular parts, the distribution of the measurements showed that they were not centered on the nominal value. These were located near the upper tolerance limits for the dimension of diameter (D) and near the lower tolerance limits for the dimension of height (H), respectively.

- The roundness of the artifact edges detected through the microscopy investigations explains why the distribution of the height measurements was located near the lower tolerance limits and was lower than the nominal value. Additionally, the height values resulting from the measurements were lower than the nominal value.

- The International Tolerance Grade for polymer manufactured circular parts was found to be between IT8 to IT10, which is in-line as per the ISO-286 for materials. The IT Grade of the height dimension was IT10 for 86% of specimens and 58% for the diameter dimension, respectively.

- A small size specimen, built in a minimum of 50 pieces, should be used for AM system capability determination to minimize material consumption and related costs. Three batches of 50 specimens should be built for the process capability study.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kang, H.S.; Lee, J.-Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- International Organization for Standardization. Standard Terminology for Additive Manufacturing—General Principles—Terminology; ISO/ASTM 52900-15; ISO/ASME International: Geneva, Switzerland, 2015. [Google Scholar]

- Eyers, D.; Potter, A. Industrial Additive Manufacturing: A manufacturing systems perspective. Comput. Ind. 2017, 92, 208–218. [Google Scholar] [CrossRef]

- Tofail, S.A.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C.A. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- International Organization for Standardization. Additive Manufacturing—Test Artifacts—Geometric Capability Assessment of Additive Manufacturing Systems; ISO/ASTM 52902-19; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar] [CrossRef]

- Cazón-Martín, A.; Morer, P.; Matey, L. PolyJet technology for product prototyping: Tensile strength and surface roughness properties. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 2014, 228, 1664–1675. [Google Scholar] [CrossRef]

- Mueller, J.; Shea, K.; Daraio, C. Mechanical properties of parts fabricated with inkjet 3D printing through efficient experimental design. Mater. Des. 2015, 86, 902–912. [Google Scholar] [CrossRef]

- Leach, R. Metrology for Additive Manufacturing. Meas. Control 2016, 49, 132–135. [Google Scholar] [CrossRef] [Green Version]

- Krolczyk, G.; Raos, P.; Legutko, S. Experimental analysis of surface roughness and surface texture of machined and fused deposition modelled parts. Tehnički Vjesnik 2014, 21, 217–221. [Google Scholar]

- García-Plaza, E.; López, P.J.N.; Caminero, M.Á.; Muñoz, J.M.C. Analysis of PLA Geometric Properties Processed by FFF Additive Manufacturing: Effects of Process Parameters and Plate-Extruder Precision Motion. Polymers 2019, 11, 1581. [Google Scholar] [CrossRef] [Green Version]

- Moylan, S. Progress Toward standardized additive manufacturing test artifacts. In Proceedings of the ASPE 2015 Spring Topical Meeting Achieving Precision Tolerances in Additive Manufacturing, Raleigh, NC, USA, 26–29 April 2015; pp. 100–105. [Google Scholar]

- Ameta, G.; Lipman, R.; Moylan, S.P.; Witherell, P. Investigating the Role of Geometric Dimensioning and Tolerancing in Additive Manufacturing. J. Mech. Des. 2015, 137, 111401. [Google Scholar] [CrossRef] [Green Version]

- Reverte, J.; Caminero, M.Á.; Chacón, J.; García-Plaza, E.; Núñez, P.; Becar, J. Mechanical and Geometric Performance of PLA-Based Polymer Composites Processed by the Fused Filament Fabrication Additive Manufacturing Technique. Materials 2020, 13, 1924. [Google Scholar] [CrossRef] [Green Version]

- Chacón, J.; Caminero, M.Á.; Núñez, P.; García-Plaza, E.; García-Moreno, I.; Reverte, J. Additive manufacturing of continuous fibre reinforced thermoplastic composites using fused deposition modelling: Effect of process parameters on mechanical properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.; García-Plaza, E.; Núñez, P.; Reverte, J.; Becar, J. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Montgomery, D.C. Introduction to Statistical Quality Control, 6th ed.; John Wiley & Sons Inc.: New York, NY, USA, 2009. [Google Scholar]

- Guoqing, W. Statistical Process Control Analysis Based on Software Q-Das. Am. J. Theor. Appl. Stat. 2014, 3, 90. [Google Scholar] [CrossRef] [Green Version]

- Singh, J.; Singh, R.; Singh, H. Repeatability of linear and radial dimension of ABS replicas fabricated by fused deposition modelling and chemical vapor smoothing process: A case study. Measurement 2016, 94, 5–11. [Google Scholar] [CrossRef]

- Automotive Industry Action Group. Statistical Process Control, Reference Manual, 2nd ed.; Automotive Industry Action Group: Detroit, MI, USA, 2005. [Google Scholar]

- Akandeac, S.O.; Dalgarnoa, K.W.; Munguiaa, J.; Pallarib, J. Statistical Process Control Application to Polymer based SLS process. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015; pp. 1634–1643. [Google Scholar]

- International Organization for Standardization. Statistical Methods in Process Management—Capability and Performance—Part 2: Process Capability and Performance of Time-Dependent Process Models; ISO 22514-2; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- International Organization for Standardization. Geometrical Product Specifications (GPS)—Inspection by Measurement of Workpieces and Measuring Equipment—Part 1: Decision Rules for Verifying Conformity or Nonconformity with Specifications; ISO 14253-1; ISO: Geneva, Switzerland, 2017. [Google Scholar]

- Baturynska, I. Statistical analysis of dimensional accuracy in additive manufacturing considering STL model properties. Int. J. Adv. Manuf. Technol. 2018, 97, 2835–2849. [Google Scholar] [CrossRef]

- George, E.; Liacouras, P.; Rybicki, F.J.; Mitsouras, D. Measuring and Establishing the Accuracy and Reproducibility of 3D Printed Medical Models. RadioGraphics 2017, 37, 1424–1450. [Google Scholar] [CrossRef]

- Preißler, M.; Rosenberger, M.; Notni, G. An Investigation for Process Capability in Additive Manufacturing. In Proceedings of the 59th Ilmenau Scientific Colloquium, Ilmenau, Germany, 11–15 September 2017. [Google Scholar]

- Singh, R. Process capability study of polyjet printing for plastic components. J. Mech. Sci. Technol. 2011, 25, 1011–1015. [Google Scholar] [CrossRef]

- International Organization for Standardization. Statistical Methods in Process Management—Capability and Performance—Part 3: Machine Performance Studies for Measured Data on Discrete Parts; ISO 22514-3; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- Kitsakis, K.; Kechagias, J.; Vaxevanidis, N.; Giagkopoulos, D. Tolerance Analysis of 3d-MJM Parts According to IT Grade; IOP Conf. Series: Materials Science and Engineering; IOP Science: Kozani, Greece, 2016; Volume 161. [Google Scholar] [CrossRef] [Green Version]

- Yap, Y.L.; Wang, C.; Sing, S.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Minetola, P.; Calignano, F.; Galati, M. Comparing geometric tolerance capabilities of additive manufacturing systems for polymers. Addit. Manuf. 2020, 32, 101103. [Google Scholar] [CrossRef]

- International Organization for Standardization. Additive Manufacturing—General Principles—Requirements for Purchased AM Parts; ISO/ASTM 52901-17; ISO/ASME International: Geneva, Switzerland, 2017. [Google Scholar]

- International Organization for Standardization. Geometrical Product Specifications (GPS)—ISO Code System for Tolerances on Linear Sizes—Part 1: Basis of Tolerances, Deviations and Fits; ISO 286-1:2010; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- German Institute for Standardisation. Plastics Moulded Parts—Tolerances and Acceptance Conditions; DIN 16742-13; DIN: Berlin, Germany, 2013. [Google Scholar]

- International Organization for Standardization. General Tolerances—Part 1: Tolerances for Linear and Angular Dimensions without Individual Tolerance Indications; ISO 2768-1:1989; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- International Organization for Standardization. Statistical Methods in Process Management. Capability and Performance—Part 1: General Principles and Concepts; ISO 22514-1; ISO: Geneva, Switzerland, 2014. [Google Scholar]

- International Organization for Standardization. Quality Management Systems. Particular Requirements for the Application of ISO 9001:2000 for Automotive Production and Relevant Service Part Organizations; ISO/TS 16949; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Arcidiacono, G.; Nuzzi, S. A Review of the Fundamentals on Process Capability, Process Performance, and Process Sigma, and an Introduction to Process Sigma Split. Int. J. Appl. Eng. Res. 2017, 12, 4556–4570. [Google Scholar]

- Objet Geometries. Eden 500V/350V/350 3-D Printer System. User Guide; Objet Geometries Ltd.: Rehovot, Israel, 2007. [Google Scholar]

- Stratasys. PolyJet Materials Data Sheet. Available online: http://www.stratasys.com (accessed on 10 September 2015).

- Udroiu, R.; Nedelcu, A. Optimization of additive manufacturing processes focused on 3D Printing. In Rapid Prototyping Technology—Principles and Functional Requirements; Hoque, M.E., Ed.; InTechOpen: Rijeka, Croatia, 2011; pp. 1–28. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Lü, J. RP part surface quality versus build orientation: When the layers are getting thinner. Int. J. Adv. Manuf. Technol. 2012, 67, 377–385. [Google Scholar] [CrossRef] [Green Version]

- Udroiu, R.; Braga, I.C.; Nedelcu, A. Evaluating the Quality Surface Performance of Additive Manufacturing Systems: Methodology and a Material Jetting Case Study. Materials 2019, 12, 995. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Derby, B. Inkjet Printing of Functional and Structural Materials: Fluid Property Requirements, Feature Stability, and Resolution. Annu. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- Du Plessis, A.; Sperling, P.; Beerlink, A.; Tshabalala, L.; Hoosain, S.; Mathe, N.; Le Roux, S.G. Standard method for microCT-based additive manufacturing quality control 2: Density measurement. MethodsX 2018, 5, 1117–1123. [Google Scholar] [CrossRef] [PubMed]

- Sabău, E.; Udroiu, R.; Bere, P.; Buranský, I.; Miron-Borzan, C.-Ş. A Novel Polymer Concrete Composite with GFRP Waste: Applications, Morphology, and Porosity Characterization. Appl. Sci. 2020, 10, 2060. [Google Scholar] [CrossRef] [Green Version]

- Automotive Industry Action Group: MSA-4. Measurement Systems Analysis—Reference Manual, 4nd ed.; Automotive Industry Action Group: Southfield, MI, USA, 2010. [Google Scholar]

- Zanobini, A.; Sereni, B.; Catelani, M.; Ciani, L. Repeatability and Reproducibility techniques for the analysis of measurement systems. Measurement 2016, 86, 125–132. [Google Scholar] [CrossRef]

- Minitab. Getting Started with Minitab 19. Available online: https://www.minitab.com (accessed on 21 September 2019).

- Q-DAS Statistical Software (Q-DAS). Available online: https://www.q-das.com/en/ (accessed on 10 February 2020).

- Sambrani, V.N. Process Capability—A Managers Tool for 6 Sigma Quality Advantage. Glob. J. Manag. Bus. Res.: G Interdiscip. 2016, 16, 63–69. [Google Scholar]

- Galve, J.E.; Elduque, D.; Pina, C.; Clavería, I.; Acero, R.; Fernández, Á.; Javierre, C. Dimensional Stability and Process Capability of an Industrial Component Injected with Recycled Polypropylene. Polymers 2019, 11, 1063. [Google Scholar] [CrossRef] [Green Version]

- Maurya, N.K.; Rastogi, V.; Singh, P. Comparative Study and Measurement of Form Errors for the Component Printed by FDM and PolyJet Process. Instrum. Mes. Métrol. 2019, 18, 353–359. [Google Scholar] [CrossRef]

| Property | ASTM | Metric |

|---|---|---|

| Tensile Strength | D-638-03 | 50–60 MPa |

| Elongation at Break | D-638-05 | 15%–25% |

| Flexural Strength | D-790-03 | 60–70 MPa |

| Rockwell Hardness | Scale M | 73–76 Scale M |

| Water Absorption | D-570-98 24hr | 1.5%–2.2% |

| Source | VarComp 1 | Contribution 1 | VarComp 2 | Contribution 2 |

|---|---|---|---|---|

| Total Gage R&R | 0.0000032 | 0.88% | 0.0000029 | 0.54% |

| Repeatability | 0.0000031 | 0.86% | 0.0000028 | 0.52% |

| Reproducibility | 0.0000001 | 0.02% | 0.0000001 | 0.01% |

| Operators | 0.0000001 | 0.02% | 0.0000001 | 0.01% |

| Part-To-Part | 0.0003585 | 99.12% | 0.0005336 | 99.46% |

| Total Variation | 0.0003617 | 100% | 0.0005365 | 100% |

| Study Var | %Study Var | %Tolerance | ||

|---|---|---|---|---|

| Source | StdDev (SD) | (6 × SD) | (SV) | (SV/Toler) |

| Total Gage R&R | 0.0017829 | 0.010698 | 9.37% | 5.35 |

| Repeatability | 0.0017611 | 0.010566 | 9.26% | 5.28 |

| Reproducibility | 0.0002783 | 0.00167 | 1.46% | 0.83 |

| Operators | 0.0002783 | 0.00167 | 1.46% | 0.83 |

| Part-To-Part | 0.0189344 | 0.113606 | 99.56% | 56.8 |

| Total Variation | 0.0190181 | 0.114109 | 100% | 57.05 |

| Number of Distinct Categories = 14 | ||||

| Study Var | %Study Var | %Tolerance | ||

|---|---|---|---|---|

| Source | StdDev (SD) | (6 × SD) | (SV) | (SV/Toler) |

| Total Gage R&R | 0.0016968 | 0.010181 | 7.33% | 5.09 |

| Repeatability | 0.0016783 | 0.01007 | 7.25% | 5.03 |

| Reproducibility | 0.00025 | 0.0015 | 1.08% | 0.75 |

| Operators | 0.00025 | 0.0015 | 1.08% | 0.75 |

| Part-To-Part | 0.0231008 | 0.138605 | 99.73% | 69.3 |

| Total Variation | 0.0231631 | 0.138978 | 100% | 69.49 |

| Number of Distinct Categories = 16 | ||||

| Drawing Values | Collected Values | Statistics | |||

|---|---|---|---|---|---|

| Tm | 12 | n | 50 | StDev | 0.0116 |

| LSL | 11.9 | xmin | 11.918 | X0.135% | 11.90378 |

| USL | 12.1 | xmax | 11.966 | X99.865% | 11.97358 |

| T | 0.2 | xmean | 11.939 | X50% | 11.93868 |

| Drawing Values | Collected Values | Statistics | |||

|---|---|---|---|---|---|

| Tm | 14.5 | n | 50 | StDev | 0.0114 |

| LSL | 14.4 | xmin | 14.514 | X0.135% | 14.50363 |

| USL | 14.6 | xmax | 11.561 | X99.865% | 14.57205 |

| T | 0.2 | xmean | 14.54 | X50% | 14.53784 |

| Drawing Values | Collected Values | Statistics | |||

|---|---|---|---|---|---|

| Tm | 12 | n | 150 | StDev | 0.0118 |

| LSL | 11.9 | xmin | 11.910 | X0.135% | 11.90335 |

| USL | 12.1 | xmax | 11.969 | X99.865% | 11.97406 |

| T | 0.2 | xmean | 11.939 | X50% | 11.93871 |

| Drawing Values | Collected Values | Statistics | |||

|---|---|---|---|---|---|

| Tm | 14.5 | n | 150 | StDev | 0.00994 |

| LSL | 14.4 | xmin | 14.510 | X0.135% | 14.50893 |

| USL | 14.6 | xmax | 14.562 | X99.865% | 14.56854 |

| T | 0.2 | xmean | 14.540 | X50% | 14.53873 |

| ISO 286 Standard Requirements | IT8 | IT9 | IT10 | IT11 | |

|---|---|---|---|---|---|

| Max magnitude of the tolerance zone | 25 i | 40 i | 64 i | 100 i | |

| Size range (10–18 mm), i = 1.083 μm | 27 μm | 43 μm | 70 μm | 109 μm | |

| Collected values | |||||

| n | Linear dimension (Height = 12 mm) | - | (32–42) μm | (44–69) μm | (73–75) μm |

| Radial dimension (Diameter = 14.5 mm) | (19–24) μm | (28–41) μm | (47–57) μm | - | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Udroiu, R.; Braga, I.C. System Performance and Process Capability in Additive Manufacturing: Quality Control for Polymer Jetting. Polymers 2020, 12, 1292. https://doi.org/10.3390/polym12061292

Udroiu R, Braga IC. System Performance and Process Capability in Additive Manufacturing: Quality Control for Polymer Jetting. Polymers. 2020; 12(6):1292. https://doi.org/10.3390/polym12061292

Chicago/Turabian StyleUdroiu, Razvan, and Ion Cristian Braga. 2020. "System Performance and Process Capability in Additive Manufacturing: Quality Control for Polymer Jetting" Polymers 12, no. 6: 1292. https://doi.org/10.3390/polym12061292

APA StyleUdroiu, R., & Braga, I. C. (2020). System Performance and Process Capability in Additive Manufacturing: Quality Control for Polymer Jetting. Polymers, 12(6), 1292. https://doi.org/10.3390/polym12061292