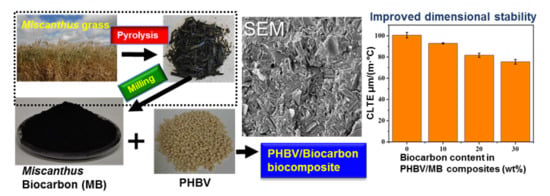

Thermal and Mechanical Properties of the Biocomposites of Miscanthus Biocarbon and Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) (PHBV)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Preparation

2.3. Characterization

3. Results

3.1. Mechanical Properties

3.2. Fracture Surfaces

3.3. Thermal Behavior

3.4. Thermal Stability

3.5. Heat Deflection Temperature (HDT)

3.6. Coefficient of Linear Thermal Expansion (CLTE)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chanprateep, S. Current trends in biodegradable polyhydroxyalkanoates. J. Biosci. Bioeng. 2010, 110, 621–632. [Google Scholar] [CrossRef] [PubMed]

- Arrieta, M.P.; Castro-López, M.d.M.; Rayón, E.; Barral-Losada, L.F.; López-Vilariño, J.M.; López, J.; González-Rodríguez, M.V. Plasticized poly(lactic acid)−poly(hydroxybutyrate) (PLA−PHB) blends incorporated with catechin intended for active food-packaging applications. J. Agric. Food Chem. 2014, 62, 10170–10180. [Google Scholar] [CrossRef] [PubMed]

- Misra, S.K.; Ansari, T.I.; Valappil, S.P.; Mohne, D.; Philip, S.E.; Stark, W.J.; Roy, I.; Knowles, J.C.; Salih, V. Poly(3-hydroxybutyrate) multifunctional composite scaffolds for tissue engineering applications. Biomaterials 2010, 31, 2806–2815. [Google Scholar] [CrossRef]

- Che, X.-M.; Ye, H.-M.; Chen, G.-Q. Effects of uracil on crystallization and rheological property of poly(R-3-hydroxybutyrate-co-4-hydroxybutyrate). Compos. Part A Appl. Sci. Manuf. 2018, 109, 141–150. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A.K.; Sugie, T.; Takai, Y.; Hamada, H. Renewable resource based biocomposites from natural fiber and polyhydroxybutyrate-co-valerate (PHBV) bioplastic. Compos. Part A Appl. Sci. Manuf. 2008, 39, 875–886. [Google Scholar] [CrossRef]

- Rivera-Briso, A.L.; Serrano-Aroca, Á. Poly(3-hydroxybutyrate-co-3-hydroxyvalerate): Enhancement strategies for advanced applications. Polymers 2018, 10, 732. [Google Scholar] [CrossRef] [Green Version]

- Zaverl, M.; Seydibeyoğlu, M.Ö.; Misra, M.; Mohanty, A. Studies on recyclability of polyhydroxybutyrate-co-valerate bioplastic: Multiple melt processing and performance evaluations. J. Appl. Polym. Sci. 2012, 125, E324–E331. [Google Scholar] [CrossRef]

- Xiang, H.; Wen, X.; Miu, X.; Li, Y.; Zhou, Z.; Zhu, M. Thermal depolymerization mechanisms of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Prog. Nat. Sci. Mater. Int. 2016, 26, 58–64. [Google Scholar] [CrossRef] [Green Version]

- Sridhar, V.; Lee, I.; Chun, H.H.; Park, H. Graphene reinforced biodegradable poly(3-hydroxybutyrate-co-4-hydroxybutyrate) nano-composites. eXPRESS Polym. Lett. 2013, 7, 320–328. [Google Scholar] [CrossRef]

- Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Sustainable carbonaceous biofiller from miscanthus: Size reduction, characterization, and potential bio-composites applications. BioResources 2018, 13, 3720–3739. [Google Scholar] [CrossRef] [Green Version]

- Snowdon, M.R.; Mohanty, A.K.; Misra, M.A.K. A study of carbonized lignin as an alternative to carbon black. ACS Sustain. Chem. Eng. 2014, 2, 1257–1263. [Google Scholar] [CrossRef]

- Gregory, S.J.; Anderson, C.W.N.; Camps Arbestain, M.; McManus, M.T. Response of plant and soil microbes to biochar amendment of an arsenic-contaminated soil. Agric. Ecosyst. Environ. 2014, 191, 133–141. [Google Scholar] [CrossRef]

- Kouchachvili, L.; Maffei, N.; Entchev, E. Infested ash trees as a carbon source for supercapacitor electrodes. J. Porous Mater. 2015, 22, 979–988. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The effect of bio-carbon addition on the electrical, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. J. Compos. Mater. 2016, 50, 1161–1168. [Google Scholar] [CrossRef]

- Liu, W.-J.; Jiang, H.; Yu, H.-Q. Development of biochar-based functional materials: Toward a sustainable platform carbon material. Chem. Rev. 2015, 115, 12251–12285. [Google Scholar] [CrossRef]

- Anstey, A.; Vivekanandhan, S.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Oxidative acid treatment and characterization of new biocarbon from sustainable Miscanthus biomass. Sci. Total Environ. 2016, 550, 241–247. [Google Scholar] [CrossRef]

- Modi, S.; Koelling, K.; Vodovotz, Y. Miscibility of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with high molecular weight poly(lactic acid) blends determined by thermal analysis. J. Appl. Polym. Sci. 2012, 124, 3074–3081. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef]

- Ho, M.-P.; Lau, K.-T.; Wang, H.; Hui, D. Improvement on the properties of polylactic acid (PLA) using bamboo charcoal particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Picard, M.; Thakur, S.; Misra, M.; Mielewski, D.F.; Mohanty, A.K. Biocarbon from peanut hulls and their green composites with biobased poly(trimethylene terephthalate) (PTT). Sci. Rep. 2020, 10, 3310. [Google Scholar] [CrossRef] [PubMed]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly(lactic acid)–biochar biocomposites: Effect of processing and filler content on rheological, thermal, and mechanical properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Sustainable green composites: Value addition to agricultural residues and perennial grasses. ACS Sustain. Chem. Eng. 2013, 1, 325–333. [Google Scholar] [CrossRef]

- Janus, A.; Pelfrêne, A.; Heymans, S.; Deboffe, C.; Douay, F.; Waterlot, C. Elaboration, characteristics and advantages of biochars for the management of contaminated soils with a specific overview on Miscanthus biochars. J. Environ. Manag. 2015, 162, 275–289. [Google Scholar] [CrossRef] [PubMed]

- Major, I.; Pin, J.-M.; Behazin, E.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A. Graphitization of Miscanthus grass biocarbon enhanced by in situ generated FeCo nanoparticles. Green Chem. 2018, 20, 2269–2278. [Google Scholar] [CrossRef] [Green Version]

- You, X.; Misra, M.; Gregori, S.; Mohanty, A.K. Preparation of an electric double layer capacitor (EDLC) using Miscanthus-derived biocarbon. ACS Sustain. Chem. Eng. 2018, 6, 318–324. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Misra, M.; Mohanty, A.K. Sustainable biocomposites from biobased polyamide 6,10 and biocarbon from pyrolyzed miscanthus fibers. J. Appl. Polym. Sci. 2017, 134, 44221. [Google Scholar] [CrossRef]

- Codou, A.; Misra, M.; Mohanty, A.K. Sustainable biocarbon reinforced nylon 6/polypropylene compatibilized blends: Effect of particle size and morphology on performance of the biocomposites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 1–10. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Sustainable biocarbon from pyrolyzed perennial grasses and their effects on impact modified polypropylene biocomposites. Compos. Part B Eng. 2017, 118, 116–124. [Google Scholar] [CrossRef]

- Snowdon, M.R.; Mohanty, A.K.; Misra, M. Examination of a biobased carbon nucleating agent on poly(lactic acid) crystallization. J. Renew. Mater. 2017, 5, 94–105. [Google Scholar] [CrossRef]

- Snowdon, M.R.; Wu, F.; Mohanty, A.K.; Misra, M. Comparative study of the extrinsic properties of poly(lactic acid)-based biocomposites filled with talc versus sustainable biocarbon. RSC Adv. 2019, 9, 6752–6761. [Google Scholar] [CrossRef] [Green Version]

- Ten, E.; Jiang, L.; Wolcott, M.P. Crystallization kinetics of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/cellulose nanowhiskers composites. Carbohydr. Polym. 2012, 90, 541–550. [Google Scholar] [CrossRef] [PubMed]

- Chea, V.; Angellier-Coussy, H.; Peyron, S.; Kemmer, D.; Gontard, N. Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) films for food packaging: Physical–chemical and structural stability under food contact conditions. J. Appl. Polym. Sci. 2016, 133, 41850. [Google Scholar] [CrossRef]

- Poulose, A.M.; Elnour, A.Y.; Anis, A.; Shaikha, H.; Al-Zahrani, S.M.; George, J.; Al-Wabel, M.I.; Usmanc, A.R.; Ok, Y.S.; Tsang, D.C.W.; et al. Date palm biochar-polymer composites: An investigation of electrical, mechanical, thermal and rheological characteristics. Sci. Total Environ. 2018, 619–620, 311–318. [Google Scholar] [CrossRef] [PubMed]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Structure–mechanics property relationship of waste derived biochars. Sci. Total Environ. 2015, 538, 611–620. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.R.; Huque, M.M.; Islam, M.N.; Hasan, M. Mechanical properties of polypropylene composites reinforced with chemically treated abaca. Compos. Part A Appl. Sci. Manuf. 2019, 40, 511–517. [Google Scholar] [CrossRef]

- Kim, G.-M.; Michler, G.H. Micromechanical deformation processes in toughened and particle-filled semicrystalline polymers: Part 1. Characterization of deformation processes in dependence on phase morphology. Polymer 1998, 39, 5689–5697. [Google Scholar] [CrossRef]

- Kfoury, G.; Raquez, J.-M.; Hassouna, F.; Odent, J.; Toniazzo, V.; Ruch, D.; Dubois, P. Recent advances in high performance poly(lactide): From “green” plasticization to super-tough materials via (reactive) compounding. Front. Chem. 2013, 1, 32. [Google Scholar] [CrossRef] [Green Version]

- Zarrinbakhsh, N.; Misra, M.; Mohanty, A.K. Biodegradable green composites from distiller’s dried grains with solubles (DDGS) and a polyhydroxy(butyrate-co-valerate) (PHBV)-based bioplastic. Macromol. Mater. Eng. 2011, 296, 1035–1045. [Google Scholar] [CrossRef]

- Mimmoa, T.; Panzacchi, P.; Baratieri, M.; Davies, C.A.; Tonon, G. Effect of pyrolysis temperature on miscanthus (Miscanthus × giganteus) biochar physical, chemical and functional properties. Biomass Bioenergy 2014, 62, 149–157. [Google Scholar] [CrossRef]

- Oginnia, O.; Singha, K.; Zondlo, J.W. Pyrolysis of dedicated bioenergy crops grown on reclaimed mine landin West Virginia. J. Anal. Appl. Pyrolysis 2017, 123, 319–329. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.-Y.; Qin, Z.-Y.; Sun, B.; Yang, X.-G.; Yao, J.-M. Reinforcement of transparent poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by incorporation of functionalized carbon nanotubes as a novel bionanocomposite for food packaging. Compos. Sci. Technol. 2014, 94, 96–104. [Google Scholar] [CrossRef]

- Berthet, M.-A.; Angellier-Coussy, H.; Machado, D.; Hilliou, L.; Staebler, A.; Vicente, A.; Gontard, N. Exploring the potentialities of using lignocellulosic fibres derived from three food by-products as constituents of biocomposites for food packaging. Ind. Crops Prod. 2015, 69, 110–122. [Google Scholar] [CrossRef]

- Reddy, K.R.; Sato, H.; Takahashi, I.; Ozaki, Y. Intermolecular hydrogen bondings in the poly(3-hydroxybutyrate) and chitin blends: Their effects on the crystallization behavior and crystal structure of poly(3-hydroxybutyrate). Polymer 2015, 75, 141–150. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, Y.; Liu, S.; Zeng, G.; Hu, X.; Hu, X.; Guo, Z.; Tan, X.; Wang, L.; Wu, Z. Adsorption of estrogen contaminants by graphene nanomaterials under natural organic matter preloading: Comparison to carbon nanotube, biochar, and activated carbon. Environ. Sci. Technol. 2017, 51, 6352–6359. [Google Scholar] [CrossRef]

- Ikram, S.; Das, O.; Bhattacharyya, D. A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 177–188. [Google Scholar] [CrossRef]

- Jakic´, M.; Vrandecˇic´, N.S.; Erceg, M. Thermal degradation of poly(3-hydroxybutyrate)/poly(ethyleneoxide) blends: Thermogravimetric and kinetic analysis. Eur. Polym. J. 2016, 81, 376–385. [Google Scholar] [CrossRef]

- Qian, S.; Sheng, K.; Yao, W.; Yu, H. Poly(lactic acid) biocomposites reinforced with ultrafine bamboo-char: Morphology, mechanical, thermal, and water absorption properties. J. Appl. Polym. Sci. 2016, 133, 43425. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. ZnO-reinforced poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bionanocomposites with antimicrobial function for food packaging. ACS Appl. Mater. Interfaces 2014, 6, 9822–9834. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Ju, D.; Han, L.; Dong, L. Formation of more efficient thermally conductive pathways due to the synergistic effect of boron nitride and alumina in poly(3-hydroxylbutyrate). Thermochim. Acta 2017, 652, 9–16. [Google Scholar] [CrossRef]

- Ma, P.M.; Wang, R.Y.; Wang, S.F.; Zhang, Y.; Zhang, Y.X.; Hristova, D. Effects of fumed silica on the crystallization behavior and thermal properties of poly(hydroxybutyrate-co-hydroxyvalerate. J. Appl. Polym. Sci. 2008, 108, 1770–1777. [Google Scholar] [CrossRef]

- Bruzaud, S.; Bourmaud, A. Thermal degradation and (nano)mechanical behavior of layered silicate reinforced poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites. Polym. Test. 2007, 26, 652–659. [Google Scholar] [CrossRef]

- Achilias, D.S.; Panayotidou, E.; Zuburtikudis, I. Thermal degradation kinetics and isoconversional analysis of biodegradable poly(3-hydroxybutyrate)/organomodified montmorillonite nanocomposites. Thermochim. Acta 2011, 514, 58–66. [Google Scholar] [CrossRef]

- Lee, C.; Pang, M.M.; Koay, S.C.; Choo, H.L.; Tshai, K.Y. Talc filled polylactic-acid biobased polymer composites: Tensile, thermal and morphological properties. SN Appl. Sci. 2020, 2, 354. [Google Scholar] [CrossRef] [Green Version]

- Akkapeddi, M.K. Glass fiber reinforced polyamide-6 nanocomposites. Polym. Compos. 2000, 21, 576–585. [Google Scholar] [CrossRef]

- Fasanella, N.; Sundararaghavan, V. Atomistic modeling of thermomechanical properties of SWNT/Epoxy nanocomposites. Model. Simul. Mater. Sci. Eng. 2015, 23, 065003. [Google Scholar] [CrossRef]

| Young’s Modulus (MPa) (S.D. 1) | Tensile Strength (MPa) (S.D.) | Elongation-at-Break (%) (S.D.) | |

|---|---|---|---|

| PHBV | 3587 (311) | 38.3 (1.1) | 2.01 (0.37) |

| PHBV/MB10 | 3741 (231) | 32.2 (1.6) | 1.12 (0.08) |

| PHBV/MB20 | 4691 (272) | 33.1 (2.4) | 0.99 (0.19) |

| PHBV/MB30 | 5240 (164) | 32.8 (0.8) | 0.89 (0.07) |

| Tm1 (°C) | Tm2 (°C) | χc (%) | Tc (°C) | |

|---|---|---|---|---|

| PHBV | n.a. | 174 | 61.4 | 124 |

| PHBV/MB10 | 172 | 175 | 61.3 | 121 |

| PHBV/MB20 | 171 | 174 | 50.0 | 122 |

| PHBV/MB30 | 170 | 174 | 56.6 | 124 |

| T5% (°C) | Tmax (°C) | |

|---|---|---|

| PHBV | 262 | 285 |

| PHBV/MB10 | 257 | 279 |

| PHBV/MB20 | 246 | 266 |

| PHBV/MB30 | 250 | 264 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Reimer, C.; Wang, T.; Mohanty, A.K.; Misra, M. Thermal and Mechanical Properties of the Biocomposites of Miscanthus Biocarbon and Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) (PHBV). Polymers 2020, 12, 1300. https://doi.org/10.3390/polym12061300

Li Z, Reimer C, Wang T, Mohanty AK, Misra M. Thermal and Mechanical Properties of the Biocomposites of Miscanthus Biocarbon and Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) (PHBV). Polymers. 2020; 12(6):1300. https://doi.org/10.3390/polym12061300

Chicago/Turabian StyleLi, Zonglin, Christoff Reimer, Tao Wang, Amar K. Mohanty, and Manjusri Misra. 2020. "Thermal and Mechanical Properties of the Biocomposites of Miscanthus Biocarbon and Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) (PHBV)" Polymers 12, no. 6: 1300. https://doi.org/10.3390/polym12061300

APA StyleLi, Z., Reimer, C., Wang, T., Mohanty, A. K., & Misra, M. (2020). Thermal and Mechanical Properties of the Biocomposites of Miscanthus Biocarbon and Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) (PHBV). Polymers, 12(6), 1300. https://doi.org/10.3390/polym12061300