Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

3.1. Rheological Measurements

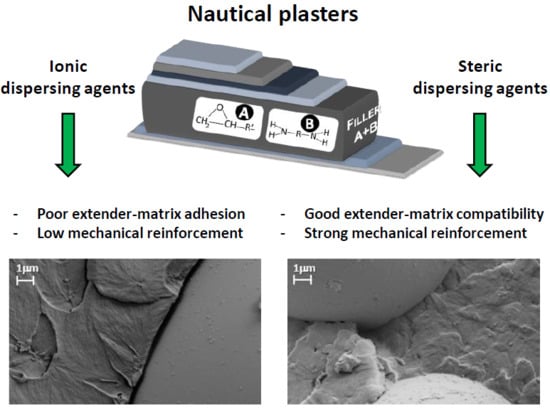

3.2. Mechanical Tests

3.3. Morphological Characterization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wallström, E.; Jespersen, H.T.; Schaumburg, K. A new concept for anti-fouling paint for Yachts. In Proceedings of the Progress in Organic Coatings; Elsevier: Amsterdam, The Netherlands, 2011; Volume 72, pp. 109–114. [Google Scholar]

- Böß, V.; Denkena, B.; Dittrich, M.A.; Kenneweg, R. Mathematical description of aesthetic criteria for process planning and quality control of luxury yachts. In Proceedings of the Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2019; Volume 79, pp. 478–483. [Google Scholar]

- Armendáriz-Ontiveros, M.M.; Fimbres Weihs, G.A.; de los Santos Villalobos, S.; Salinas-Rodriguez, S.G. Biofouling of FeNP-Coated SWRO Membranes with Bacteria Isolated after Pre-Treatment in the Sea of Cortez. Coatings 2019, 9, 462. [Google Scholar] [CrossRef] [Green Version]

- Akuzov, D.; Franca, L.; Grunwald, I.; Vladkova, T. Sharply Reduced Biofilm Formation from Cobetia marina and in Black Sea Water on Modified Siloxane Coatings. Coatings 2018, 8, 136. [Google Scholar] [CrossRef] [Green Version]

- Delucchi, M.; Castellano, M.; Vicini, S.; Vita, S.; Finocchio, E.; Ricotti, R.; Cerisola, G. A methodological approach for monitoring the curing process of fairing compounds based on epoxy resins. Prog. Org. Coat. 2018, 123, 20–26. [Google Scholar] [CrossRef]

- Boote, D.; Vergassola, G.; Giannarelli, D.; Ricotti, R. Thermal load effects on side plates of superyachts. Mar. Struct. 2017, 56, 39–68. [Google Scholar] [CrossRef]

- Strong, A.B. Fundamentals of Composites Manufacturing: Materials, Methods and Applications; Society of Manufacturing Engineers: Dearborn, MI, USA, 2008; ISBN 9781613449677. [Google Scholar]

- Delucchi, M.; Finocchio, E.; Castellano, M.; Vicini, S.; Vita, S.; Cerisola, G.; Ricotti, R. Application of DSC and FTIR techniques for monitoring the curing process of epoxy fillers used for yacht application. Metall. Ital. 2017, 109, 107–110. [Google Scholar]

- Sharma, S.; Wetzel, K.K. Process Development Issues of Glass—Carbon Hybrid-reinforced Polymer Composite Wind Turbine Blades. J. Compos. Mater. 2010, 44, 437–456. [Google Scholar] [CrossRef]

- Delucchi, M.; Ricotti, R.; Cerisola, G. Influence of micro- and nano-fillers on chemico-physical properties of epoxy-based materials. In Proceedings of the Progress in Organic Coatings; Elsevier: Amsterdam, The Netherlands, 2011; Volume 72, pp. 58–64. [Google Scholar]

- Donnelly, B.; Bedwell, I.; Dimas, J.; Scardino, A.; Tang, Y.; Sammut, K. Effects of Various Antifouling Coatings and Fouling on Marine Sonar Performance. Polymers (Basel) 2019, 11, 663. [Google Scholar] [CrossRef] [Green Version]

- Santos, T.; Nunes, L.; Faria, P. Production of eco-efficient earth-based plasters: Influence of composition on physical performance and bio-susceptibility. J. Clean. Prod. 2017, 167, 55–67. [Google Scholar] [CrossRef] [Green Version]

- Bochen, J.; Labus, M. Study on physical and chemical properties of external lime-sand plasters of some historical buildings. Constr. Build. Mater. 2013, 45, 11–19. [Google Scholar] [CrossRef]

- Graham-Jones, J.; Summerscales, J. Marine Applications of Advanced Fibre-Reinforced Composites; Woodhead Publishing: Cambridge, UK, 2015; ISBN 9780081002001. [Google Scholar]

- Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Environmental impacts of natural and conventional building materials: A case study on earth plasters. J. Clean. Prod. 2014, 80, 179–186. [Google Scholar] [CrossRef]

- Micó-Vicent, B.; Jordán, J.; Perales, E.; Martínez-Verdú, F.M.; Cases, F. Finding the Additives Incorporation Moment in Hybrid Natural Pigments Synthesis to Improve Bioresin Properties. Coatings 2019, 9, 34. [Google Scholar] [CrossRef] [Green Version]

- Viesca, J.-L.; Anand, M.; Blanco, D.; Fernández-González, A.; García, A.; Hadfield, M. Tribological Behaviour of PVD Coatings Lubricated with a FAP− Anion-Based Ionic Liquid Used as an Additive. Lubricants 2016, 4, 8. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez-González, S.; Alonso, M.M.; Gadea, J.; Rodríguez, A.; Calderón, V. Rheological behaviour of gypsum plaster pastes with polyamide powder wastes. Constr. Build. Mater. 2013, 38, 407–412. [Google Scholar] [CrossRef]

- Patton, T.C. Paint Flow and Pigment Dispersion: A Rheological Approach to Coating and Ink; Wiley: Hoboken, NJ, USA, 1966; Volume 68, ISBN 978-0-471-03272-4. [Google Scholar]

- Tracton, A.A. Coatings Materials and Surface Coatings; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Shukla, S.; Seal, S. Thermodynamic tetragonal phase stability in sol-gel derived nanodomains of pure zirconia. J. Phys. Chem. B 2004, 108, 3395–3399. [Google Scholar] [CrossRef]

- Fujibayashi, T.; Okubo, M. Preparation and thermodynamic stability of micron-sized, monodisperse composite polymer particles of disc-like shapes by seeded dispersion polymerization. Langmuir 2007, 23, 7958–7962. [Google Scholar] [CrossRef]

- Jaglinski, T.; Kochmann, D.; Stone, D.; Lakes, R.S. Composite materials with viscoelastic stiffness greater than diamond. Science 2007, 315, 620–622. [Google Scholar] [CrossRef] [Green Version]

- Lova, P.; Giusto, P.; Di Stasio, F.; Manfredi, G.; Paternò, G.M.; Cortecchia, D.; Soci, C.; Comoretto, D. All-polymer methylammonium lead iodide perovskite microcavities. Nanoscale 2019, 11, 8978–8983. [Google Scholar] [CrossRef]

- Tsai, Y.T.; Chiou, J.Y.; Liao, C.Y.; Chen, P.Y.; Tung, S.H.; Lin, J.J. Organically modified clays as rheology modifiers and dispersing agents for epoxy packing of white LED. Compos. Sci. Technol. 2016, 132, 9–15. [Google Scholar] [CrossRef]

- Boccalero, G.; Jean-Mistral, C.; Castellano, M.; Boragno, C. Soft, hyper-elastic and highly-stable silicone-organo-clay dielectric elastomer for energy harvesting and actuation applications. Compos. Part B Eng. 2018, 146, 13–19. [Google Scholar] [CrossRef]

- Castellano, M.; Turturro, A.; Riani, P.; Montanari, T.; Finocchio, E.; Ramis, G.; Busca, G. Bulk and surface properties of commercial kaolins. Appl. Clay Sci. 2010, 48, 446–454. [Google Scholar] [CrossRef]

- Holmberg, K. Natural surfactants. Curr. Opin. Colloid Interface Sci. 2001, 6, 148–159. [Google Scholar] [CrossRef]

- Shinoda, W.; Devane, R.; Klein, M.L. Coarse-grained molecular modeling of non-ionic surfactant self-assembly. Soft Matter 2008, 4, 2454–2462. [Google Scholar] [CrossRef]

- Solè, I.; Maestro, A.; González, C.; Solans, C.; Gutiérrez, J.M. Optimization of nano-emulsion preparation by low-energy methods in an ionic surfactant system. Langmuir 2006, 22, 8326–8332. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Migas, D.B.; Panahandeh-Fard, M.; Chen, S.; Wang, Z.; Lova, P.; Soci, C. Charge redistribution at GaAs/P3HT heterointerfaces with different surface polarity. J. Phys. Chem. Lett. 2013, 4, 3303–3309. [Google Scholar] [CrossRef]

- Castellano, M.; Alloisio, M.; Darawish, R.; Dodero, A.; Vicini, S. Electrospun composite mats of alginate with embedded silver nanoparticles. J. Therm. Anal. Calorim. 2019, 137, 767–778. [Google Scholar] [CrossRef]

- Shamsuri, A.A.; Md. Jamil, S.N.A. Compatibilization Effect of Ionic Liquid-Based Surfactants on Physicochemical Properties of PBS/Rice Starch Blends: An Initial Study. Materials (Basel) 2020, 13, 1885. [Google Scholar] [CrossRef] [Green Version]

- Bertora, A.; Castellano, M.; Marsano, E.; Alessi, M.; Conzatti, L.; Stagnaro, P.; Colucci, G.; Priola, A.; Turturro, A. A new modifier for silica in reinforcing SBR elastomers for the tyre industry. Macromol. Mater. Eng. 2011, 296, 455–464. [Google Scholar] [CrossRef]

- Castellano, M.; Marsano, E.; Turturro, A.; Conzatti, L.; Busca, G. Dependence of surface properties of silylated silica on the length of silane arms. Adsorption 2012, 18, 307–320. [Google Scholar] [CrossRef]

- Tarsi, G.; Caputo, P.; Porto, M.; Sangiorgi, C. A Study of Rubber-REOB Extender to Produce Sustainable Modified Bitumens. Appl. Sci. 2020, 10, 1204. [Google Scholar] [CrossRef] [Green Version]

- Dörr, D.; Standau, T.; Murillo Castellón, S.; Bonten, C.; Altstädt, V. Rheology in the Presence of Carbon Dioxide (CO2) to Study the Melt Behavior of Chemically Modified Polylactide (PLA). Polymers (Basel) 2020, 12, 1108. [Google Scholar] [CrossRef]

- Shira, S.; Buller, C. Hollow Glass Microspheres for Plastics, Elastomers, and Adhesives Compounds; Elsevier: Amsterdam, The Netherlands, 2015; pp. 241–271. [Google Scholar] [CrossRef]

- ASTM D790 - 17 Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. Available online: https://www.astm.org/Standards/D790 (accessed on 8 June 2020).

- Glória, G.O.; Teles, M.C.A.; Neves, A.C.C.; Vieira, C.M.F.; Lopes, F.P.D.; de Gomes, M.A.; Margem, F.M.; Monteiro, S.N. Bending test in epoxy composites reinforced with continuous and aligned PALF fibers. J. Mater. Res. Technol. 2017, 6, 411–416. [Google Scholar] [CrossRef]

- Linhares, F.N.; Gabriel, C.F.S.; de Sousa, A.M.F.; Nunes, R.C.R. Mechanical and rheological properties of nitrile rubber/fluoromica composites. Appl. Clay Sci. 2018, 162, 165–174. [Google Scholar] [CrossRef]

- Senff, L.; Ascensão, G.; Ferreira, V.M.; Seabra, M.P.; Labrincha, J.A. Development of multifunctional plaster using nano-TiO2 and distinct particle size cellulose fibers. Energy Build. 2018, 158, 721–735. [Google Scholar] [CrossRef]

- Ochoa, R.E.; Gutiérrez, C.A.; López-Cuevas, J.; Rendón, J.; Rodríguez-Galicia, J.L.; Cruz-Álvarez, J. Effect of Water/Plaster Ratio on Preparing Molds for Slip Casting of Sanitaryware; Rheology of the Initial Plaster Slurry, Microstructure and Mold Properties. Trans. Indian Ceram. Soc. 2018, 77, 84–89. [Google Scholar] [CrossRef]

- Dodero, A.; Alloisio, M.; Vicini, S.; Castellano, M. Preparation of composite alginate-based electrospun membranes loaded with ZnO nanoparticles. Carbohydr. Polym. 2020, 227, 115371. [Google Scholar] [CrossRef]

- Chaudhary, A.K.; Jayaraman, K. Extrusion of linear polypropylene-clay nanocomposite foams. Polym. Eng. Sci. 2011, 51, 1749–1756. [Google Scholar] [CrossRef]

- Brunengo, E.; Castellano, M.; Conzatti, L.; Canu, G.; Buscaglia, V.; Stagnaro, P. PVDF-based composites containing PZT particles: How processing affects the final properties. J. Appl. Polym. Sci. 2020, 137, 48871. [Google Scholar] [CrossRef]

- Payne, A.R. The dynamic properties of carbon black loaded natural rubber vulcanizates. Part II. J. Appl. Polym. Sci. 1962, 6, 368–372. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Sensem, Z.; Surya, I.; Sahakaro, K.; Ismail, H. Synergistic Effect of Maleated Natural Rubber and Modified Palm Stearin as Dual Compatibilizers in Composites based on Natural Rubber and Halloysite Nanotubes. Polymers (Basel) 2020, 12, 766. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, S.; Mishra, Y. Nanocarbon Reinforced Rubber Nanocomposites: Detailed Insights about Mechanical, Dynamical Mechanical Properties, Payne, and Mullin Effects. Nanomaterials 2018, 8, 945. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramier, J.; Gauthier, C.; Chazeau, L.; Stelandre, L.; Guy, L. Payne effect in silica-filled styrene–butadiene rubber: Influence of surface treatment. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 286–298. [Google Scholar] [CrossRef]

- Castellano, M.; Turturro, A.; Marsano, E.; Conzatti, L.; Vicini, S. Hydrophobation of silica surface by silylation with new organo-silanes bearing a polybutadiene oligomer tail. Polym. Compos. 2014, 35, 1603–1613. [Google Scholar] [CrossRef]

- Hentschke, R. The payne effect revisited. Express Polym. Lett. 2017, 11, 278–292. [Google Scholar] [CrossRef]

- Xu, H.; Fan, T.; Ye, N.; Wu, W.; Huang, D.; Wang, D.; Wang, Z.; Zhang, L. Plasticization Effect of Bio-Based Plasticizers from Soybean Oil for Tire Tread Rubber. Polymers (Basel) 2020, 12, 623. [Google Scholar] [CrossRef] [Green Version]

- Aranguren, M.I.; Mora, E.; DeGroot, J.V.; Macosko, C.W. Effect of reinforcing fillers on the rheology of polymer melts. J. Rheol. 1992, 36, 1165–1182. [Google Scholar] [CrossRef]

- Cassagnau, P. Melt rheology of organoclay and fumed silica nanocomposites. Polymer 2008, 49, 2183–2196. [Google Scholar] [CrossRef] [Green Version]

- Vallittu, P.K. High-aspect ratio fillers: Fiber-reinforced composites and their anisotropic properties. Dent. Mater. 2015, 31, 1–7. [Google Scholar] [CrossRef]

- Dybowska-Sarapuk, L.; Kielbasinski, K.; Arazna, A.; Futera, K.; Skalski, A.; Janczak, D.; Sloma, M.; Jakubowska, M. Efficient Inkjet Printing of Graphene-Based Elements: Influence of Dispersing Agent on Ink Viscosity. Nanomaterials 2018, 8, 602. [Google Scholar] [CrossRef] [Green Version]

- Ng, S.; Justnes, H. Influence of dispersing agents on the rheology and early heat of hydration of blended cements with high loading of calcined marl. Cem. Concr. Compos. 2015, 60, 123–134. [Google Scholar] [CrossRef]

- Zhan, Z.; He, H.; Zhu, Z.; Xue, B.; Wang, G.; Chen, M.; Xiong, C. Blends of rABS and SEBS: Influence of In-Situ Compatibilization on the Mechanical Properties. Materials (Basel) 2019, 12, 2352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.; Wang, Y.; Gu, C.; Liu, J.; Liu, Y.; Li, M.; Lu, Y. Enhancement of the Mechanical Properties of Basalt Fiber-Wood-Plastic Composites via Maleic Anhydride Grafted High-Density Polyethylene (MAPE) Addition. Materials (Basel) 2013, 6, 2483–2496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quitadamo, A.; Massardier, V.; Santulli, C.; Valente, M. Optimization of Thermoplastic Blend Matrix HDPE/PLA with Different Types and Levels of Coupling Agents. Materials (Basel) 2018, 11, 2527. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Label | Component A | Dispersing Agent | Microspheres | Anti-Foam Agent |

|---|---|---|---|---|

| Sample 0 (without dispersing agent) | 81.2 | 0.0 | 18.3 | 0.5 |

| Sample 1 (with additive 1) | 80.0 | 1.5 | 18.0 | 0.5 |

| Sample 2 (with additive 2) | 80.0 | 1.5 | 18.0 | 0.5 |

| Sample 3 (with additive 3) | 80.0 | 1.5 | 18.0 | 0.5 |

| Sample 4 (with additive 4) | 81.0 | 0.1 | 18.4 | 0.5 |

| Dispersing Agent | Nature | Label |

|---|---|---|

| Additive 1 | Ionic dispersants | Self-emulsifying soy lecithin |

| Additive 2 | N-tallow alkyl trimethylene diamine dioleate | |

| Additive 3 | Steric dispersants | Hyperbranched polyester |

| Additive 4 | Tetra(2,2-diallyloxymethylene-1-butyl)bis(ditridecyl phosphite) titanate |

| Sample. | G0* (Pa) | G∞* (Pa) | ΔG* (Pa) |

|---|---|---|---|

| Matrix | 15 ± 1 | 11 ± 0.5 | 4.8 ± 0.9 |

| Sample 0 | 3812 ± 11 | 119 ± 1 | 3693 ± 11 |

| Sample 1 | 1733 ± 70 | 104 ± 9 | 1629 ± 61 |

| Sample 2 | 3951 ± 4 | 148 ± 1 | 3803 ± 4 |

| Sample 3 | 193 ± 4 | 101 ± 3 | 91 ± 1 |

| Sample 4 | 169 ± 2 | 83 ± 4 | 87 ± 3 |

| Sample | Eb (MPa) | σb (MPa) | εb (%) | Extender–Matrix Distance (μm) |

|---|---|---|---|---|

| Sample 0 | 1454 ± 90 | 24.9 ± 1.8 | 1.80 ± 0.17 | 0.254 ± 0.047 |

| Sample 1 | 1444 ± 31 | 17.7 ± 0.9 | 1.34 ± 0.11 | 0.235 ± 0.023 |

| Sample 2 | 1490 ± 53 | 18.0 ± 0.7 | 1.26 ± 0.07 | 0.249 ± 0.051 |

| Sample 3 | 1866 ± 32 | 24.9 ± 1.3 | 1.38 ± 0.13 | - |

| Sample 4 | 1857 ± 59 | 24.4 ± 1.5 | 1.36 ± 0.14 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vita, S.; Ricotti, R.; Dodero, A.; Vicini, S.; Borchardt, P.; Pinori, E.; Castellano, M. Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials. Polymers 2020, 12, 1339. https://doi.org/10.3390/polym12061339

Vita S, Ricotti R, Dodero A, Vicini S, Borchardt P, Pinori E, Castellano M. Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials. Polymers. 2020; 12(6):1339. https://doi.org/10.3390/polym12061339

Chicago/Turabian StyleVita, Silvia, Rico Ricotti, Andrea Dodero, Silvia Vicini, Per Borchardt, Emiliano Pinori, and Maila Castellano. 2020. "Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials" Polymers 12, no. 6: 1339. https://doi.org/10.3390/polym12061339

APA StyleVita, S., Ricotti, R., Dodero, A., Vicini, S., Borchardt, P., Pinori, E., & Castellano, M. (2020). Rheological, Mechanical and Morphological Characterization of Fillers in the Nautical Field: The Role of Dispersing Agents on Composite Materials. Polymers, 12(6), 1339. https://doi.org/10.3390/polym12061339