Epoxy Based Blends for Additive Manufacturing by Liquid Crystal Display (LCD) Printing: The Effect of Blending and Dual Curing on Daylight Curable Resins

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Method

2.1.1. Materials

2.1.2. Epoxy-Based Blend Preparation

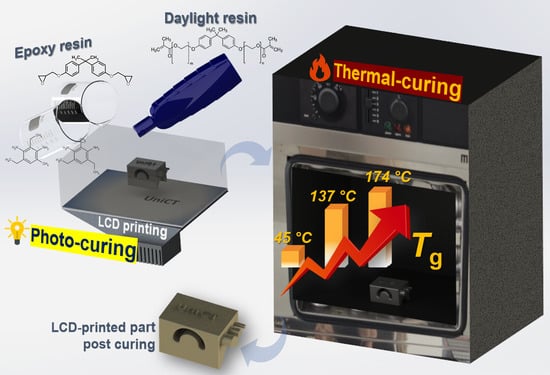

2.1.3. Resin LCD Printing and Thermal Curing

2.2. Characterization

2.2.1. Dynamic Mechanical Analysis (DMA)

2.2.2. Differential Scanning Calorimetry (DSC)

2.2.3. Rheology Testing

3. Results and Discussion

3.1. DSC Testing Results

3.2. Rheology Testing

3.3. Printing Test

3.4. DMA Testing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| * | Complex viscosity |

| DETDA | Diethyltoluene diamine |

| DGEBA | Diglycidyl ether of bisphenol A |

| DMA | Dynamic Mechanical Analysis |

| DSC | Differential Scanning Calorimetry |

| E’ | Storage modulus |

| cp | Heat capacity increment |

| LCD | Liquid Crystal Display |

| Glass-transition temperature |

References

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Xinyu, G.U.; Poelma, J.; Rolland, J.P. Methods Of Making Three Dimensional Objects From Dual Cure Resins With Supported Second Cure; WO 2017/040890 A1; World Intellectual Property Organization: Geneva, Switzerland, 2017. [Google Scholar]

- Obst, P.; Riedelbauch, J.; Oehlmann, P.; Rietzel, D.; Launhardt, M.; Schmölzer, S.; Osswald, T.A.; Witt, G. Investigation of the influence of exposure time on the dual-curing reaction of RPU 70 during the DLS process and the resulting mechanical part properties. Addit. Manuf. 2020, 32, 101002. [Google Scholar] [CrossRef]

- Redmann, A.; Oehlmann, P.; Scheffler, T.; Kagermeier, L.; Osswald, T.A. Thermal curing kinetics optimization of epoxy resin in Digital Light Synthesis. Addit. Manuf. 2020, 32, 101018. [Google Scholar] [CrossRef]

- Konuray, O.; Fernández-Francos, X.; Ramis, X.; Serra, À. State of the Art in Dual-Curing Acrylate Systems. Polymers 2018, 10, 178. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Griffini, G.; Invernizzi, M.; Levi, M.; Natale, G.; Postiglione, G.; Turri, S. 3D-printable CFR polymer composites with dual-cure sequential IPNs. Polymer 2016, 91, 174–179. [Google Scholar] [CrossRef]

- Lantean, S.; Roppolo, I.; Sangermano, M.; Pirri, C.F.; Chiappone, A. Development of New Hybrid Acrylic/Epoxy DLP-3D Printable Materials. Inventions 2018, 3, 29. [Google Scholar] [CrossRef] [Green Version]

- Holt, P.; Zaregadeh, H.; Karmel, S. Methods for Making a Metal, Sand Or Ceramic Object by Additive Manufacture and Formulations for Use in Said Methods; US 2020/0079966 A1; United States Patent Application Publication: Peterborough, Great Britain, UK, 2017.

- Zhu, J.; Zhang, Q.; Yang, T.; Liu, Y.; Liu, R. 3D printing of multi-scalable structures via high penetration near-infrared photopolymerization. Nat. Commun. 2020, 11, 3462. [Google Scholar] [CrossRef] [PubMed]

- Cairone, F.; Davi, S.; Stella, G.; Guarino, F.; Recca, G.; Cicala, G.; Bucolo, M. 3D-Printed micro-optofluidic device for chemical fluids and cells detection. Biomed. Microdev. 2020, 22, 37. [Google Scholar] [CrossRef]

- Richard, C.; Neild, A.; Cadarso, V.J. The emerging role of microfluidics in multi-material 3D bioprinting. Lab Chip. 2020, 20, 2044–2056. [Google Scholar] [CrossRef] [PubMed]

- Waheed, S.; Cabot, J.M.; Macdonald, N.P.; Lewis, T.; Guijt, R.M.; Paull, B.; Breadmore, M.C. 3D printed microfluidic devices: Enablers and barriers. Lab Chip 2016, 16, 1993–2013. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tosto, C.; Latteri, A.; Pergolizzi, E.; Giordano, D.; Abramo, G.; Catenaro, R.; Pignotti, N.; Cicala, G. Additive Manufacturing of Plastics: An Efficient Approach for Composite Tooling. Macromol. Symp. 2020, 389. [Google Scholar] [CrossRef]

- Li, H.; Taylor, G.; Bheemreddy, V.; Iyibilgin, O.; Leu, M.; Chandrashekhara, K. Modeling and characterization of fused deposition modeling tooling for vacuum assisted resin transfer molding process. Addit. Manuf. 2015, 7, 64–72. [Google Scholar] [CrossRef]

- Kampker, A.; Ayvaz, P.; Lukas, G. Direct Polymer Additive Tooling—Economic Analysis of Additive Manufacturing Technologies for Fabrication of Polymer Tools for Injection Molding. Key Eng. Mater. 2020, 843, 9–18. [Google Scholar] [CrossRef]

- Cicala, G.; Recca, G.; Carciotto, S.; Restuccia, C. Development of epoxy/hyperbranched blends for resin transfer molding and vacuum assisted resin transfer molding applications: Effect of a reactive diluent. Polym. Eng. Sci. 2009, 49, 577–584. [Google Scholar] [CrossRef]

- Cicala, G.; Mamo, A.; Recca, G.; Restuccia, C.L. Study on epoxy/thermoplastic blends based on the addition of a novel aromatic block copolymer. Polym. Eng. Sci. 2007, 47, 2027–2033. [Google Scholar] [CrossRef]

- Sapuppo, F.; Bucolo, M.; Intaglietta, M.; Fortuna, L.; Arena, P. A cellular nonlinear network: Real-time technology for the analysis of microfluidic phenomena in blood vessels. Nanotechnology 2006, 17, S54–S63. [Google Scholar] [CrossRef]

- Cairone, F.; Gagliano, S.; Bucolo, M. Experimental study on the slug flow in a serpentine microchannel. Exp. Ther. Fluid Sci. 2016, 76, 34–44. [Google Scholar] [CrossRef]

- Maffezzoli, A.; Terzi, R.; Nicolais, L. Cure behaviour of visible light activated dental composites. J. Mater. Sci. Mater. Med. 1995, 6, 155–160. [Google Scholar] [CrossRef]

- Menard, H.P. Dynamic Mechanical Analysis: A Practical Introduction, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar] [CrossRef]

- Campbell, J.A.; Inglis, H.; Ng WeiLong, E.; McKinley, C.; Lewis, D.A. Morphology Control in a Dual-Cure System for Potential Applications in Additive Manufacturing. Polymers 2019, 11, 420. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| ID Sample | Cream [wt%] | Epoxy [wt%] |

|---|---|---|

| C | 100 | 0 |

| CE7030 | 70 | 30 |

| CE5050 | 50 | 50 |

| E | 0 | 100 |

| ID Sample | Exposure Time [s] | Z Lift Distance [mm] | Z Lift Speed [mm/min] | Z Retract Speed [mm/min] | Top Time [s] |

|---|---|---|---|---|---|

| C | 25 | 3 | 15 | 50 | 5 |

| CE7030 | 30 | 10 | 10 | 10 | 10 |

| CE5050 | 30 | 10 | 10 | 10 | 10 |

| ID Sample | Uncured | Photocured | Postcured in Oven | Isothermal [C] | Peak [C] | Onset [C] | Heat [J/g] | Peak [C] | Onset [C] | Heat [J/g] |

|---|---|---|---|---|---|---|---|---|---|---|

| E | • | 171.79 | 129.59 | 264.52 | - | - | - | |||

| CE5050 | • | 183.23 | 148.69 | 174.53 | 259.3 | 253 | 9.88 | |||

| CE7030 | • | 186.56 | 143.7 | 227.98 | 261.06 | 243.93 | 9.31 | |||

| C | • | 181 | 150.24 | 168.35 | 264.83 | 245.33 | 41.4 | |||

| C | • | 185.56 | 183.25 | 115.71 | - | - | - | |||

| C | • | • | 100 | 188.22 | 184.52 | 55.16 | - | - | - | |

| C | • | • | 140 | 189.54 | 185.71 | 12.05 | - | - | - | |

| C | • | • | 150 | - | - | - | - | - | - |

| Exposure Time [s] | Thickness [m] | Width Overcure [%] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | CE7030 | CE5050 | C | CE7030 | CE5050 | |||||||

| Mean | Std Dev | Mean | Std Dev | Mean | Std Dev | Mean | Std Dev | Mean | Std Dev | Mean | Std Dev | |

| 5 | - | - | - | - | - | - | - | - | - | - | - | - |

| 10 | 32 | 1.0 | - | - | - | - | −9.4% | 0.14% | - | - | - | - |

| 15 | 46 | 0.7 | 41 | 1.0 | - | - | −8.1% | 0.15% | −9.0% | 0.17% | - | - |

| 20 | 82 | 1.0 | 73 | 1.2 | - | - | −4.7% | 0.19% | −5.3% | 0.20% | - | - |

| 25 | 105 | 0.9 | 95 | 1.3 | 88 | 0.8 | 0.0% | 0.14% | −2.0% | 0.15% | −4.0% | 0.13% |

| 30 | 117 | 1.0 | 108 | 1.2 | 102 | 1.0 | 1.1% | 0.20% | 1.5% | 0.12% | 1.0% | 0.19% |

| 35 | 137 | 0.7 | 125 | 1.2 | 118 | 0.9 | 1.1% | 0.16% | 1.6% | 0.16% | 1.5% | 0.12% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tosto, C.; Pergolizzi, E.; Blanco, I.; Patti, A.; Holt, P.; Karmel, S.; Cicala, G. Epoxy Based Blends for Additive Manufacturing by Liquid Crystal Display (LCD) Printing: The Effect of Blending and Dual Curing on Daylight Curable Resins. Polymers 2020, 12, 1594. https://doi.org/10.3390/polym12071594

Tosto C, Pergolizzi E, Blanco I, Patti A, Holt P, Karmel S, Cicala G. Epoxy Based Blends for Additive Manufacturing by Liquid Crystal Display (LCD) Printing: The Effect of Blending and Dual Curing on Daylight Curable Resins. Polymers. 2020; 12(7):1594. https://doi.org/10.3390/polym12071594

Chicago/Turabian StyleTosto, Claudio, Eugenio Pergolizzi, Ignazio Blanco, Antonella Patti, Paul Holt, Sarah Karmel, and Gianluca Cicala. 2020. "Epoxy Based Blends for Additive Manufacturing by Liquid Crystal Display (LCD) Printing: The Effect of Blending and Dual Curing on Daylight Curable Resins" Polymers 12, no. 7: 1594. https://doi.org/10.3390/polym12071594

APA StyleTosto, C., Pergolizzi, E., Blanco, I., Patti, A., Holt, P., Karmel, S., & Cicala, G. (2020). Epoxy Based Blends for Additive Manufacturing by Liquid Crystal Display (LCD) Printing: The Effect of Blending and Dual Curing on Daylight Curable Resins. Polymers, 12(7), 1594. https://doi.org/10.3390/polym12071594