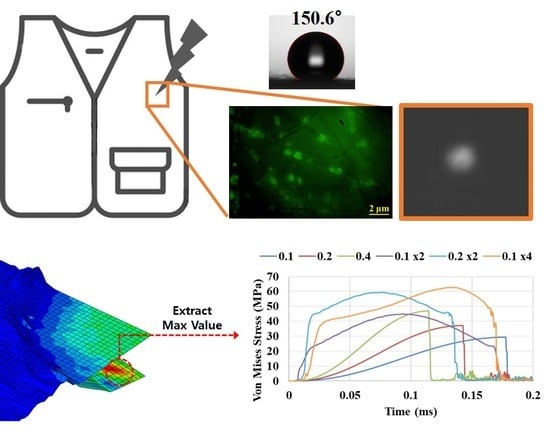

Water-Resistant Mechanoluminescent Electrospun Fabrics with Protected Sensitivity in Wet Condition via Plasma-Enhanced Chemical Vapor Deposition Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of ML/PVDF and ML/PAN

2.3. Measurement of Mechanoluminescence by the Ball Drop Test

2.4. Microscopic Analysis

2.5. Measurement of Water Vapor Transmission Rate (WVTR)

- P: water vapor transmission rate (g/m2·h);

- a1–a2: mass change of water-permeable cup with CaCl2 after 1 h (g/h);

- S: area (m2) of the sample exposed to the moisture absorbent.

2.6. Finite Element Analysis for Normal Stress

3. Results and Discussion

3.1. Microscopic Observation of ML-Incorporated Composite Fabrics

3.2. Light Emission of ML-Incorporated Electrospun Composites

3.3. Simulation on Layering Effect

3.4. Effect of Composite Wettability on ML Intensity

3.5. Water Vapor Transmission Rate (WVTR) of Composite Fabrics

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef] [Green Version]

- Suga, T.; Konishi, H.; Nishide, H. Photocrosslinked nitroxide polymer cathode-active materials for application in an organic-based paper battery. Chem. Commun. 2007, 17, 1730–1732. [Google Scholar] [CrossRef] [PubMed]

- Pushparaj, V.L.; Shaijumon, M.M.; Kumar, A.; Murugesan, S.; Ci, L.; Vajtai, R.; Linhardt, R.J.; Nalamasu, O.; Ajayan, P.M. Flexible energy storage devices based on nanocomposite paper. PNAS. 2007, 104, 13574–13577. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaltenbrunner, M.; Kettlgruber, G.; Siket, C.; Schwödiauer, R.; Bauer, S. Stretchable batteries: Arrays of ultracompliant electrochemical dry gel cells for stretchable electronics. Adv. Mater. 2010, 22, 2065–2067. [Google Scholar] [CrossRef]

- Futaba, D.N.; Hata, K.; Yamada, T.; Hiraoka, T.; Hayamizu, Y.; Kakudate, Y.; Tanaike, O.; Hatori, H.; Yumura, M.; Iijima, S. Shape-engineerable and highly densely packed single-walled carbon nanotubes and their application as super-capacitor electrodes. Nat. Mater. 2006, 5, 987–994. [Google Scholar] [CrossRef]

- Bedeloglu, A.; Demir, A.; Bozkurt, Y.; Sariciftci, N.S. A photovoltaic fiber design for smart textiles. Text. Res. J. 2010, 80, 1065–1074. [Google Scholar] [CrossRef]

- Pope, J.; Lekakou, C. Thermoelectric polymer composite yarns and an energy harvesting wearable textile. Smart. Mater. Struct. 2019, 28, 095006. [Google Scholar] [CrossRef]

- Hanson, M.A.; Powell Jr, H.C.; Barth, A.T.; Ringgenberg, K.; Calhoun, B.H.; Aylor, J.H.; Lach, J. Body area sensor networks: Challenges and opportunities. J. Comput. 2009, 42, 58–65. [Google Scholar] [CrossRef]

- Thomas, J.P.; Qidwai, M.A.; Kellogg, J.C. Energy scavenging for small-scale unmanned systems. J. Power Sources 2006, 159, 1494–1509. [Google Scholar] [CrossRef]

- Jeong, S.M.; Song, S.; Lee, S.K.; Ha, N.Y. Color manipulation of mechanoluminescence from stress-activated composite films. Adv. Mater. 2013, 25, 6194–6200. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Yu, R.; Dong, L.; Peng, D.; Zhang, A.; Zhang, Y.; Liu, H.; Pan, C.; Wang, Z.L. Dynamic pressure mapping of personalized handwriting by a flexible sensor matrix based on the mechanoluminescence process. Adv. Mater. 2015, 27, 2324–2331. [Google Scholar] [CrossRef] [PubMed]

- Azad, A.I.; Rahimi, M.R.; Yun, G.J. Quantitative full-field strain measurements by SAOED (SrAl2O4: Eu2+, Dy3+) mechanoluminescent materials. Smart. Mat. Struct. 2016, 25, 095032. [Google Scholar] [CrossRef]

- Li, C.; Xu, C.; Imai, Y.; Bu, N. Real-time visualisation of the Portevin–Le Chatelier effect with mechanoluminescent-sensing film. Strain 2011, 47, 483–488. [Google Scholar] [CrossRef]

- Gnidakouong, J.R.N.; Yun, G.J. Dislocation density level induced divergence between stress-free afterglow and mechanoluminescence in SrAl2O4: Eu2+, Dy3+. Ceram. Int. 2019, 45, 1794–1802. [Google Scholar] [CrossRef]

- Webbe, T.; You, H.; Hemmatian, T.; Kim, J.; Yun, G. Enhancement of mechanoluminescence sensitivity of SrAl2O4: Eu2+, Dy3+/Epoxy composites by ultrasonic curing treatment method. Compos. Interfaces. 2020, 2020, 1–23. [Google Scholar]

- Peng, D.; Chen, B.; Wang, F. Recent advances in doped mechanoluminescent phosphors. ChemPlusChem 2015, 80, 1209. [Google Scholar] [CrossRef]

- Yamamoto, H.; Matsuzawa, T. Mechanism of long phosphorescence of SrAl2O4: Eu2+, Dy3+ and CaAl2O4:Eu2+, Nd3+. J. Lumin. 1997, 72–74, 287–289. [Google Scholar] [CrossRef]

- Clabau, F.; Rocquefelte, X.; Jobic, X.; Deniard, P.; Whangbo, M.-H.; Garcia, A.; Le Mercier, T. Mechanism of phosphorescence appropriate for the long-lasting phosphors Eu2+-doped SrAl2O4 with codopants Dy3+ and B3+. Chem. Mater. 2005, 17, 3904–3912. [Google Scholar] [CrossRef]

- Someya, S.; Ishii, K.; Munakata, T.; Saeki, M. Lifetime-based measurement of stress during cyclic elastic deformation using mechanoluminescence of SrAl2O4: Eu2+. Opt. Express. 2014, 22, 21991–21998. [Google Scholar] [CrossRef]

- Yun, G.J.; Rahimi, M.R.; Gandomi, A.H.; Lim, G.-C.; Choi, J.-S. Stress sensing performance using mechanoluminescence of SrAl2O4: Eu(SAOE) and SrAl2O4: Eu, Dy (SAOED) under mechanical loadings. Smart. Mater. Struct. 2013, 22, 055006. [Google Scholar] [CrossRef]

- Fu, X.; Yamada, H.; Xu, C.-N. Property of highly oriented SrAl2O4: Eu: Eu film on quartz glass substrates and its potential application in stress sensor. J. Electrochem. Soc. 2009, 156, J249. [Google Scholar] [CrossRef]

- Zhang, J.-C.; Fan, X.-H.; Yan, X.; Xia, F.; Kong, W.; Long, Y.-Z.; Wang, X. Sacrificing trap density to achieve short-delay and high-contrast mechanoluminescence for stress imaging. Acta Mater. 2018, 152, 148–154. [Google Scholar] [CrossRef]

- Kim, J.S.; Kwon, Y.-N.; Sohn, K.-S. Dynamic visualization of crack propagation and bridging stress using the mechano-luminescence of SrAl2O4: Eu:(Eu, Dy, Nd). Acta Mater. 2003, 51, 6437–6442. [Google Scholar] [CrossRef]

- Kim, J.S.; Sohn, K.S.; Kwon, Y.N.; Ban, G.S.; Lee, K.H. Detection of crack propagation in alumina using SrAl2O4: Eu:(Eu, Dy) luminescent paint. Mater. Sci. Forum. 2007, 539–543, 2264–2268. [Google Scholar] [CrossRef]

- Jang, I.Y.; Kim, S.K.; Kim, J.S.; Ann, K.Y.; Cho, C.G. Detection of reinforced concrete crack using mechano-luminescence paint. Appl. Mech. Mater. 2013, 316–317, 1049–1054. [Google Scholar] [CrossRef]

- Calderón-Olvera, R.; Albanés-Ojeda, E.; García-Hipólito, M.; Hernández-Alcántara, J.; Álvarez-Perez, M.; Falcony, C.; Alvarez-Fregoso, O. Characterization of luminescent SrAl2O4 films doped with terbium and europium ions deposited by ultrasonic spray pyrolysis technique. Ceram. Int. 2018, 44, 7917–7925. [Google Scholar]

- Yamada, H.; Fu, X.Y.; Xu, C.N. Triboluminescence of SrAl2O4: Eu film with strong adhesion fabricated by a combination of RF magnetron sputtering and post-annealing treatment. Key Eng. Mater 2008, 368–372, 1362–1365. [Google Scholar] [CrossRef]

- Fujio, Y.; Xu, C.-N.; Nishibori, M.; Teraoka, Y.; Kamitani, K.; Terasaki, N.; Ueno, N. Development of highly sensitive mechanoluminescent sensor aiming at small strain measurement. J. Adv. Dielectr. 2014, 4, 1450016. [Google Scholar] [CrossRef] [Green Version]

- Fujio, Y.; Xu, C.-N.; Terasawa, Y.; Sakata, Y.; Yamabe, J.; Ueno, N.; Terasaki, N.; Yoshida, A.; Watanabe, S.; Murakami, Y. Sheet sensor using SrAl2O4: Eu mechanoluminescent material for visualizing inner crack of high-pressure hydrogen vessel. Int. J. Hydrog. Energy. 2016, 41, 1333–1340. [Google Scholar] [CrossRef] [Green Version]

- Sohn, K.-S.; Cho, M.Y.; Kim, M.; Kim, J.S. A smart load-sensing system using standardized mechano-luminescence measurement. Opt. Express. 2015, 23, 6073–6082. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.-C.; Xu, C.-N.; Kamimura, S.; Terasawa, Y.; Yamada, H.; Wang, X. An intense elastico-mechanoluminescence material CaZnOS: Mn 2+ for sensing and imaging multiple mechanical stresses. Opt. Express. 2013, 21, 12976–12986. [Google Scholar] [CrossRef] [PubMed]

- Nance, J.; Sparks, T.D. Comparison of coatings for SrAl2O4: Eu2+, Dy3+ powder in waterborne road striping paint under wet conditions. Prog. Org. Coat. 2020, 144, 105637. [Google Scholar] [CrossRef]

- Sikandar, M.A.; Ahmad, W.; Khan, M.H.; Ali, F.; Waseem, M. Effect of water resistant SiO2 coated SrAl2O4: Eu2+, Dy3+ persistent luminescence phosphor on the properties of Portland cement pastes. Constr. Build. Mater. 2019, 228, 116823. [Google Scholar] [CrossRef]

- Qu, Y.; Liu, Y.; Yu, C.; Zhu, G.; Sha, L.; Yang, Y.; Zheng, M.; Lei, B. Rapid combustion method for surface modification of strontium aluminate phosphors with high water resistance. Appl. Surf. Sci. 2012, 258, 6814–6818. [Google Scholar] [CrossRef]

- Zhu, Y.; Zeng, J.; Li, W.; Xu, L.; Guan, Q.; Liu, Y. Encapsulation of strontium aluminate phosphors to enhance water resistance and luminescence. Appl. Surf. Sci. 2009, 255, 7580–7585. [Google Scholar] [CrossRef]

- Chang, S.; Wang, M.; Zhang, F.; Liu, Y.; Liu, X.; Yu, D.G.; Shen, H. Sheath-separate-core nanocomposites fabricated using a trifluid electrospinning. Mater. Des. 2020, 192, 108782. [Google Scholar] [CrossRef]

- Wang, M.; Hou, J.; Yu, D.G.; Li, S.; Zhu, J.; Chen, Z. Electrospun tri-layer nanodepots for sustained release of acyclovir. J. Alloys Compd. 2020, 2020, 156471. [Google Scholar] [CrossRef]

- Park, S.; Yuan, Y.; Choi, K.; Choi, S.O.; Kim, J. Doxorubicin Release Controlled by Induced Phase Separation and Use of a Co-Solvent. Materials 2018, 11, 681. [Google Scholar] [CrossRef] [Green Version]

- Song, K.; Lee, J.; Choi, S.-O.; Kim, J. Interaction of surface energy components between solid and liquid on wettability, and its application to textile anti-wetting finish. Polymers 2019, 11, 498. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Choi, K.; Choi, S.-O.; Kim, J. Early stage release control of an anticancer drug by drug-polymer miscibility in a hydrophobic fiber-based drug delivery system. RSC Adv. 2018, 8, 19791–19803. [Google Scholar] [CrossRef] [Green Version]

- Roh, S.; Kim, S.; Kim, J. Facile functionalization via plasma-enhanced chemical vapor deposition for the effective filtration of oily aerosol. Polymers 2019, 11, 1490. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jung, S.; An, J.; Na, H.; Kim, J. Surface energy of filtration media influencing the filtration performance against solid particles, oily aerosol, and bacterial aerosol. Polymers 2019, 11, 935. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rueden, C.T.; Eliceiri, K.W. ImageJ for the next generation of scientific image data. Microsc. Microanal. 2019, 25, 142–143. [Google Scholar] [CrossRef] [Green Version]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods. 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Bazhin, D.N.; Kudyakova, Y.S.; Bogomyakov, A.S.; Slepukhin, P.A.; Kim, G.A.; Burgart, Y.V.; Saloutin, V.I. Dinuclear lanthanide–lithium complexes based on fluorinated β-diketonate with acetal group: Magnetism and effect of crystal packing on mechanoluminescence. Inorg. Chem. Front. 2019, 6, 40–49. [Google Scholar] [CrossRef]

- Kim, J.S.; Kibble, K.; Kwon, Y.N.; Sohn, K.S. Rate-equation model for the loading-rate-dependent mechanoluminescence of SrAl2O4: Eu2+, Dy3+. Opt. Lett. 2009, 34, 1915–1917. [Google Scholar] [CrossRef]

- Kim, J.S.; Kwon, Y.N.; Shin, N.; Sohn, K.S. Visualization of fractures in alumina ceramics by mechanoluminescence. Acta Mater. 2005, 53, 4337–4343. [Google Scholar] [CrossRef]

- Li, C.; Xu, C.N.; Zhang, L.; Yamada, H.; Imai, Y. Dynamic visualization of stress distribution on metal by mechanoluminescence images. J. Vis.-Jap. 2008, 11, 329–335. [Google Scholar] [CrossRef]

- Huang, S.; Park, H.; Park, Y.K.; Jo, Y.M. Dynamic trajectory and capture of fine dust by magnetic mesh filters based on a particle velocity model. Aerosol Sci. Technol. 2015, 49, 633–642. [Google Scholar] [CrossRef] [Green Version]

- ABAQUS User’s Manual; Version 6.14; ABAQUS Inc.: Palo Alto, CA, USA, 2014.

- Wang, Y.Y.; Lu, C.; Li, J.; Tan, X.M.; Tse, Y.C. Simulation of drop/impact reliability for electronic devices. Finite Elem. Anal. Des. 2005, 41, 667–680. [Google Scholar] [CrossRef]

- Zukas, J.A.; Scheffler, D.R. Impact effects in multilayered plates. Int. J. Solids. Struct. 2001, 38, 3321–3328. [Google Scholar] [CrossRef]

- Wang, L.; Shang, Z.; Shi, M.; Cao, P.; Yang, B.; Zou, J. Preparing and testing the reliability of long-afterglow SrAl2O4:Eu2+, Dy3+ phosphor flexible films for temperature sensing. RSC Adv. 2020, 10, 11418–11425. [Google Scholar] [CrossRef] [Green Version]

- Guo, C.; Luan, L.; Huang, D.; Su, Q.; Lv, Y. Study on the stability of phosphor SrAl2O4: Eu2+, Dy3+ in water and method to improve its moisture resistance. Mater. Chem. Phys. 2007, 106, 268–272. [Google Scholar] [CrossRef]

- Midha, V.K.; Dakuri, A.; Midha, V. Studies on the properties of nonwoven surgical gowns. J. Ind. Text. 2013, 43, 174–190. [Google Scholar] [CrossRef]

- Anatoly, C.; Pavel, Z.; Tatiana, C.; Alexei, R.; Svetlana, Z. Water vapor permeability through porous polymeric membranes with various hydrophilicity as synthetic and natural barriers. Polymers 2020, 12, 282. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Lai, P.-C.; Syu, S.H.; Leu, J. Effects of CF4 plasma treatment on the moisture uptake, diffusion, and WVTR of poly(ethylene terephthalate) flexible films. Surf. Coat. Technol. 2011, 206, 318–324. [Google Scholar] [CrossRef]

| Part | Density (kg/m3) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|

| Composites | 1780 | 2.27 | 0.225 |

| Support | 2700 | 70.0 | 0.330 |

| Measurement | ML/PVDF | ML/PAN | ||||

|---|---|---|---|---|---|---|

| Untreated | O2 Treated | Fluorinated | Untreated | O2 Treated | Fluorinated | |

| Contact angle (°) | 140 | 0 | 151 | 63.5 | 0 | 143 |

| Water add-on (%) | 6.27 | 239 | 2.38 | 569 | 708 | 11.2 |

| PIV in dry state | 162 | 163 | 167 | 141 | 150 | 145 |

| PIV in wet state | 150 | 97 | 150 | 100 | 110 | 157 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Cho, E.; Kerekes, T.W.; Kwon, S.L.; Yun, G.J.; Kim, J. Water-Resistant Mechanoluminescent Electrospun Fabrics with Protected Sensitivity in Wet Condition via Plasma-Enhanced Chemical Vapor Deposition Process. Polymers 2020, 12, 1720. https://doi.org/10.3390/polym12081720

Lee H, Cho E, Kerekes TW, Kwon SL, Yun GJ, Kim J. Water-Resistant Mechanoluminescent Electrospun Fabrics with Protected Sensitivity in Wet Condition via Plasma-Enhanced Chemical Vapor Deposition Process. Polymers. 2020; 12(8):1720. https://doi.org/10.3390/polym12081720

Chicago/Turabian StyleLee, Halim, Eunjin Cho, Tomas Webbe Kerekes, Seung Lee Kwon, Gun Jin Yun, and Jooyoun Kim. 2020. "Water-Resistant Mechanoluminescent Electrospun Fabrics with Protected Sensitivity in Wet Condition via Plasma-Enhanced Chemical Vapor Deposition Process" Polymers 12, no. 8: 1720. https://doi.org/10.3390/polym12081720

APA StyleLee, H., Cho, E., Kerekes, T. W., Kwon, S. L., Yun, G. J., & Kim, J. (2020). Water-Resistant Mechanoluminescent Electrospun Fabrics with Protected Sensitivity in Wet Condition via Plasma-Enhanced Chemical Vapor Deposition Process. Polymers, 12(8), 1720. https://doi.org/10.3390/polym12081720