Composite Fiber Networks Based on Polycaprolactone and Bioactive Glass-Ceramics for Tissue Engineering Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Inorganic Powders Synthesis

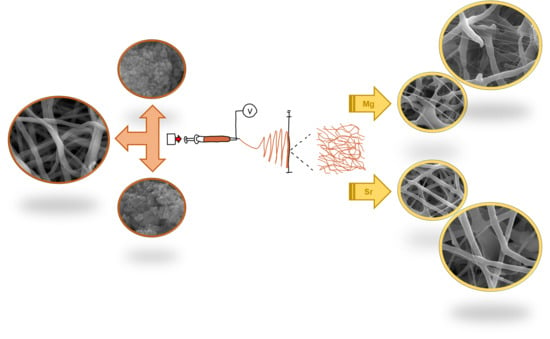

2.2. Composite Scaffolds Fabrication

2.3. Materials Characterization

2.4. Cellular Evaluation

3. Results and Discussion

3.1. Inorganic Powders Characterization

3.2. Composite Scaffolds Characterization

3.3. Biological Evaluation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gerhardt, L.C.; Boccaccini, A.R. Bioactive glass and glass-ceramic scaffolds for bone tissue engineering. Materials 2010, 3, 3867–3910. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koons, G.L.; Diba, M.; Mikos, A.G. Materials design for bone-tissue engineering. Nat. Rev. Mater. 2020, 5, 584–603. [Google Scholar] [CrossRef]

- Zamfirescu, A.I.; Baciu, A.; Banciu, D.; Jinga, S.I.; Busuioc, C. Composite fibrous scaffolds designed for bone regeneration. Rom. J. Mater. 2020, 50, 161–165. [Google Scholar]

- Ahmed, M.K.; Ramadan, R.; El-Dek, S.I.; Uskokovic, V. Complex relationship between alumina and selenium-doped carbonated hydroxyapatite as the ceramic additives to electrospun polycaprolactone scaffolds for tissue engineering applications. J. Alloys Compd. 2019, 801, 70–81. [Google Scholar] [CrossRef]

- Dwivedi, R.; Kumar, S.; Pandey, R.; Mahajan, A.; Nandana, D.; Katti, D.S.; Mehrotra, D. Polycaprolactone as biomaterial for bone scaffolds: Review of literature. J. Oral Biol. Craniofac. Res. 2020, 10, 381–388. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Fujihara, K.; Teo, W.E.; Lim, T.C.; Ma, Z. An Introduction to Electrospinning and Nanofibers; World Scientific Publishing: Singapore, 2005. [Google Scholar]

- Jinga, S.I.; Zamfirescu, A.I.; Voicu, G.; Enculescu, M.; Evanghelidis, A.; Busuioc, C. PCL-ZnO/TiO2/HAp elecstrospun composite fibres with applications in tissue engineering. Polymers 2019, 11, 1793. [Google Scholar] [CrossRef] [Green Version]

- Beregoi, M.; Busuioc, C.; Evanghelidis, A.; Matei, E.; Iordache, F.; Radu, M.; Dinischiotu, A.; Enculescu, I. Electrochromic properties of polyaniline-coated fiber webs for tissue engineering applications. Int. J. Pharm. 2016, 510, 465–473. [Google Scholar] [CrossRef]

- Busuioc, C.; Olaret, E.; Stancu, I.C.; Nicoara, A.I.; Jinga, S.I. Electrospun fibre webs templated synthesis of mineral scaffolds based on calcium phosphates and barium titanate. Nanomaterials 2020, 10, 772. [Google Scholar] [CrossRef] [Green Version]

- Matei, E.; Busuioc, C.; Evanghelidis, A.; Zgura, I.; Enculescu, M.; Beregoi, M.; Enculescu, I. Hierarchical functionalization of electrospun fibers by electrodeposition of zinc oxide nanostructures. Appl. Surf. Sci. 2018, 458, 555–563. [Google Scholar] [CrossRef]

- Busuioc, C.; Evanghelidis, A.; Enculescu, M.; Enculescu, I. Optical and photocatalytic properties of electrospun ZnO fibers. Dig. J. Nanomater. Bios. 2015, 10, 957–965. [Google Scholar]

- Busuioc, C.; Evanghelidis, A.; Galatanu, A.; Enculescu, I. Direct and contactless electrical control of temperature of paper and textile foldable substrates using electrospun metallic-web transparent electrodes. Sci. Rep. 2016, 6, 34584. [Google Scholar] [CrossRef] [Green Version]

- Busuioc, C.; Evanghelidis, A.; Florica, C.; Enculescu, I. Influence of preparation steps on the properties of electrospun ZnO fibers. Dig. J. Nanomater. Bios. 2014, 9, 1569–1578. [Google Scholar]

- Enculescu, M.; Evanghelidis, A.; Busuioc, C.; Florica, C.; Costas, A.; Oancea, M.; Preda, N.; Matei, E.; Enculescu, I. Dependence on the dye’s type and concentration of the emissive properties of electrospun dye-doped beaded nanofibers. Dig. J. Nanomater. Bios. 2014, 9, 809–816. [Google Scholar]

- Chen, Q.; Baino, F.; Spriano, S.; Pugno, N.M.; Vitale-Brovarone, C. Modelling of the strength–porosity relationship in glass-ceramic foam scaffolds for bone repair. J. Eur. Ceram. Soc. 2014, 34, 2663–2673. [Google Scholar] [CrossRef] [Green Version]

- Jones, J.R. Review of bioactive glass: From Hench to hybrids. Acta Biomater. 2013, 9, 4457–4486. [Google Scholar] [CrossRef]

- Voicu, G.; Ene, V.L.; Sava, D.F.; Surdu, V.A.; Busuioc, C. Sol-gel derived vitroceramic materials for biomedical applications. J. Non-Cryst. Solids 2016, 449, 75–82. [Google Scholar] [CrossRef]

- Rezaei, Y.; Moztarzadeh, F.; Shahabi, S.; Tahriri, M. Synthesis, characterization, and in vitro bioactivity of sol-gel-derived SiO2–CaO–P2O5–MgO-SrO bioactive glass. Synth. React. Inorg. Met. Org. Chem. 2013, 44, 692–701. [Google Scholar] [CrossRef]

- Kaur, G.; Pandey, O.P.; Singh, K.; Homa, D.; Scott, B.; Pickrell, G. A review of bioactive glasses: Their structure, properties, fabrication and apatite formation. J. Biomed. Mater. Res. A 2013, 102, 254–274. [Google Scholar] [CrossRef]

- Jinga, S.I.; Draghici, A.D.; Mocanu, A.; Nicoara, A.I.; Iordache, F.; Busuioc, C. Bacterial cellulose-assisted synthesis of glass-ceramic scaffolds with TiO2 crystalline domains. Int. J. Appl. Ceram. Technol. 2020, 17, 2017–20124. [Google Scholar] [CrossRef]

- Jinga, S.I.; Constantinoiu, I.; Surdu, V.A.; Iordache, F.; Busuioc, C. Sol-gel-derived mineral scaffolds within SiO2–P2O5–CaO–MgO–ZnO–CaF2 Ssystem. J. Sol-Gel Sci. Technol. 2019, 90, 411–421. [Google Scholar] [CrossRef]

- Schitea, R.I.; Nitu, A.; Ciobota, A.A.; Munteanu, A.L.; David, I.M.; Miu, D.; Raileanu, M.; Bacalum, M.; Busuioc, C. Pulsed laser deposition derived bioactive glass-ceramic coatings for enhancing the biocompatibility of scaffolding materials. Materials 2020, 13, 2615. [Google Scholar] [CrossRef] [PubMed]

- Jinga, S.I.; Skokin, M.; Vasile, B.S.; Constantinoiu, I.; Miu, D.; Bacalum, M.; Busuioc, C. Development of vitroceramic coatings and analysis of their suitability for biomedical applications. Coatings 2019, 9, 671. [Google Scholar] [CrossRef] [Green Version]

- Trakoolwannachai, V.; Kheolamai, P.; Ummartyotin, S. Characterization of hydroxyapatite from eggshell waste and polycaprolactone (PCL) composite for scaffold material. Compos. B Eng. 2019, 173, 106974. [Google Scholar] [CrossRef]

- Ji, L.; Wang, W.; Jin, D.; Zhou, S.; Song, X. In vitro bioactivity and mechanical properties of bioactive glass nanoparticles/polycaprolactone composites. Mater. Sci. Eng. C 2015, 46, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Hu, Q.; Gao, X.; Dong, Y. Characteristics and effects on dental pulp cells of a polycaprolactone/submicron bioactive glass composite scaffold. J. Endod. 2016, 42, 1070–1075. [Google Scholar] [CrossRef]

- Shaltooki, M.; Dini, G.; Mehdikhani, M. Fabrication of chitosan-coated porous polycaprolactone/strontium-substituted bioactive glass nanocomposite scaffold for bone tissue engineering. Mater. Sci. Eng. C 2019, 105, 110138. [Google Scholar] [CrossRef]

- Gomez-Cerezo, N.; Casarrubios, L.; Saiz-Pardo, M.; Ortega, L.; de Pablo, D.; Diaz-Guemes, I.; Fernandez-Tome, B.; Enciso, S.; Sanchez-Margallo, F.M.; Portoles, M.T.; et al. Mesoporous bioactive glass/ε-polycaprolactone scaffolds promote bone regeneration in osteoporotic sheep. Acta Biomater. 2019, 90, 393–402. [Google Scholar] [CrossRef]

- Yang, Y.; Michalczyk, C.; Singer, F.; Virtanen, S.; Boccaccini, A.R. In vitro study of polycaprolactone/bioactive glass composite coatings on corrosion and bioactivity of pure Mg. Appl. Surf. Sci. 2015, 355, 832–841. [Google Scholar] [CrossRef]

- Naghizadeh, F.; Sultana, N.; Kadir, M.R.A.; Shihabudin, T.M.T.M.; Hussain, R.; Kamarul, T. The Fabrication and characterization of PCL/rice husk derived bioactive glass-ceramic composite scaffolds. J. Nanomater. 2014, 2014, 253185. [Google Scholar] [CrossRef] [Green Version]

- Santocildes-Romero, M.E.; Crawford, A.; Hatton, P.V.; Goodchild, R.L.; Reaney, I.M.; Miller, C.A. The osteogenic response of mesenchymal stromal cells to strontium-substituted bioactive glasses. J. Tissue Eng. Regen. Med. 2015, 9, 619–631. [Google Scholar] [CrossRef]

- He, F.; Lu, T.; Fang, X.; Li, Y.; Zuo, F.; Deng, X.; Ye, J. Effects of strontium amount on the mechanical strength and cell-biological performance of magnesium-strontium phosphate bioceramics for bone regeneration. Mater. Sci. Eng. C 2020, 112, 110892. [Google Scholar] [CrossRef] [PubMed]

- Negrea, R.; Busuioc, C.; Constantinoiu, I.; Miu, D.; Enache, C.; Iordache, F.; Jinga, S.I. Akermanite based coatings grown by pulsed laser deposition for metallic implants employed in orthopaedics. Surf. Coat. Technol. 2019, 357, 1015–1026. [Google Scholar] [CrossRef]

- Kokubo, T.; Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef]

- Amudha, S.; Ramana Ramya, J.; Thanigai Arul, K.; Deepika, A.; Sathiamurthi, P.; Mohana, B.; Asokan, K.; Dong, C.L.; Narayana Kalkura, S. Enhanced mechanical and biocompatible properties of strontium ions doped mesoporous bioactive glass. Compos. B Eng. 2020, 196, 108099. [Google Scholar] [CrossRef]

- Plewinski, M.; Schickle, K.; Lindner, M.; Kirsten, A.; Weber, M.; Fischer, H. The effect of crystallization of bioactive bioglass 45S5 on apatite formation and degradation. Dent. Mater. 2013, 29, 1256–1264. [Google Scholar] [CrossRef] [PubMed]

- Voicu, G.; Miu, D.; Dogaru, I.; Jinga, S.I.; Busuioc, C. Vitroceramic interface deposited on titanium substrate by pulsed laser deposition method. Int. J. Pharm. 2016, 510, 449–456. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.H.; Kao, C.T.; Shen, Y.F.; Lin, Y.T.; Liu, Y.T.; Yen, S.Y.; Ho, C.C. Substitutions of strontium in bioactive calcium silicate bone cements stimulate osteogenic differentiation in human mesenchymal stem cells. J. Mater. Sci. Mater. Med. 2019, 30, 68. [Google Scholar] [CrossRef]

- No, Y.J.; Roohaniesfahani, S.; Lu, Z.; Shi, J.; Zreiqat, H. Strontium-doped calcium silicate bioceramic with enhanced in vitro osteogenic properties. Biomed. Mater. 2017, 12, 035003. [Google Scholar] [CrossRef]

- Chen, Q.Z.; Thouas, G.A. Fabrication and characterization of sol-gel derived 45S5 Bioglass®-ceramic scaffolds. Acta Biomater. 2011, 7, 3616–3626. [Google Scholar] [CrossRef]

- Meenarathi, B.; Chen, H.H.; Chen, P.H.; Anbarasan, R. Synthesis and characterization of fluorescent bio-degradable Poly (ε-Caprolactone). Int. J. Plast. Technol. 2014, 18, 135–145. [Google Scholar] [CrossRef]

| Oxide | Concentration (mol%) | Precursor | |

|---|---|---|---|

| Powder-Mg | Powder-Sr | ||

| SiO2 | 60 | 60 | Si(OC2H5)4 (TEOS) (Aldrich, St. Louis, MO, USA) |

| P2O5 | 5 | 5 | PO(OC2H5)3 (TEP) (Merck, St. Louis, MO, USA) |

| CaO | 25 | 25 | Ca(NO3)2·4H2O (Merck, St. Louis, MO, USA) |

| ZnO | 5 | 5 | Zn(NO3)2·6H2O (Sigma-Aldrich, St. Louis, MO, USA) |

| MgO | 5 | - | Mg(NO3)2·6H2O (Merck, St. Louis, MO, USA) |

| SrO | - | 5 | Sr(NO3)2 (Sigma-Aldrich, St. Louis, MO, USA) |

| Solution | Components | |||

|---|---|---|---|---|

| PCL (g) | Solvent Mixture (CF:DMF = 4:1) (mL) | Powder-Mg (g) | Powder-Sr (g) | |

| PCL | 1.6 | 10 | - | - |

| PCL-Mg-1 | 1.6 | 10 | 0.1 | - |

| PCL-Mg-5 | 1.6 | 10 | 0.5 | - |

| PCL-Sr-1 | 1.6 | 10 | - | 0.1 |

| PCL-Sr-5 | 1.6 | 10 | - | 0.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jinga, S.-I.; Costea, C.-C.; Zamfirescu, A.-I.; Banciu, A.; Banciu, D.-D.; Busuioc, C. Composite Fiber Networks Based on Polycaprolactone and Bioactive Glass-Ceramics for Tissue Engineering Applications. Polymers 2020, 12, 1806. https://doi.org/10.3390/polym12081806

Jinga S-I, Costea C-C, Zamfirescu A-I, Banciu A, Banciu D-D, Busuioc C. Composite Fiber Networks Based on Polycaprolactone and Bioactive Glass-Ceramics for Tissue Engineering Applications. Polymers. 2020; 12(8):1806. https://doi.org/10.3390/polym12081806

Chicago/Turabian StyleJinga, Sorin-Ion, Claudiu-Constantin Costea, Andreea-Ioana Zamfirescu, Adela Banciu, Daniel-Dumitru Banciu, and Cristina Busuioc. 2020. "Composite Fiber Networks Based on Polycaprolactone and Bioactive Glass-Ceramics for Tissue Engineering Applications" Polymers 12, no. 8: 1806. https://doi.org/10.3390/polym12081806

APA StyleJinga, S. -I., Costea, C. -C., Zamfirescu, A. -I., Banciu, A., Banciu, D. -D., & Busuioc, C. (2020). Composite Fiber Networks Based on Polycaprolactone and Bioactive Glass-Ceramics for Tissue Engineering Applications. Polymers, 12(8), 1806. https://doi.org/10.3390/polym12081806