Interfacial Compatibility on the Crystal Transformation of Isotactic Poly (1-Butene)/Herb Residue Composite

Abstract

:1. Introduction

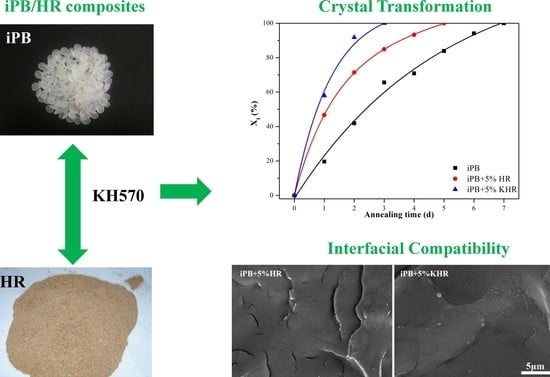

2. Materials and Methods

2.1. Materials

2.2. The Modification of HR

2.3. Characterization of the KHR

2.4. Preparation of the iPB/HR Composite

2.5. Characterization of iPB/HR Composite

2.5.1. The Crystal Transformation Rate of the iPB/HR Composite

2.5.2. The Interfacial Compatibility of the iPB/HR Composite

2.5.3. The Physical Properties of the iPB/HR Composite

3. Result and Discussion

3.1. FTIR Spectra of the HR and KHR

3.2. The Water Contact Angle of the HR and KHR

3.3. The Crystal Transformation Rate of the iPB/HR Composite

3.4. The Interfacial Compatibility of the iPB/HR Composite

3.5. The Physical Properties of the iPB/HR Composite

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luciani, L.; Seppälä, J.; Löfgren, B. Poly-1-butene: Its preparation, properties and challenges. Prog. Polym. Sci. 1988, 13, 37–62. [Google Scholar] [CrossRef]

- Shieh, Y.T.; Lee, M.S.; Chen, S.A. Crystallization behavior, crystal transformation, and morphology of polypropylene/polybutene-1 blends. Polymer 2001, 42, 4439–4448. [Google Scholar] [CrossRef]

- Danusso, F.; Gianotti, G. Isotactic polybutene-1: Formation and transformation of modification 2. Macromol. Chem. Phys. 2010, 88, 149–158. [Google Scholar] [CrossRef]

- Qiao, Y.; Wang, H.; Men, Y. Retardance of Form II to Form I Transition in Polybutene-1 at Late Stage: A Proposal of a New Mechanism. Macromolecules 2018, 51, 2232–2239. [Google Scholar] [CrossRef]

- Nakafuku, C.; Miyaki, T. Effect of pressure on the melting and crystallization behaviour of isotactic polybutene-1. Polymer 1983, 24, 141–148. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, K.; Tian, N.; Zhou, W.; Meng, L.; Li, L.; Ma, Z.; Wang, X. Stretch-Induced Crystal–Crystal Transition of Polybutene-1: An in situ Synchrotron Radiation Wide-Angle X-ray Scattering Study. Macromolecules 2012, 45, 2764–2772. [Google Scholar] [CrossRef]

- Yamashita, M.; Ueno, S. Direct melt crystal growth of isotactic polybutene-1 trigonal phase. Cryst. Res. Technol. 2007, 42, 1222–1227. [Google Scholar] [CrossRef]

- Wang, Y.T.; Liu, P.R.; Lu, Y.; Men, Y.F. Mechanism of polymorph selection during crystallization of random butene-1/ethylene copolymer. Chin. J. Polym. Sci. 2016, 34, 1014–1020. [Google Scholar] [CrossRef]

- Ljungberg, N.; Cavaillé, J.; Heux, L. Nanocomposites of isotactic polypropylene reinforced with rod-like cellulose whiskers. Polymer 2006, 47, 6285–6292. [Google Scholar] [CrossRef]

- Girones, J.; Vo, L.; Haudin, J.M.; Freire, L.; Navard, P. Crystallization of polypropylene in the presence of biomass-based fillers of different compositions. Polymer 2017, 127, 220–231. [Google Scholar] [CrossRef]

- Mi, Y.; Chen, X.; Guo, Q. Bamboo fiber-reinforced polypropylene composites: Crystallization and interfacial morphology. J. Appl. Polym. Sci. 1997, 64, 1267–1273. [Google Scholar] [CrossRef]

- Yang, J.; Qiu, K. Development of high surface area mesoporous activated carbons from herb residues. Chem. Eng. J. 2011, 167, 148–154. [Google Scholar] [CrossRef]

- Pan, W.; Zhan, S.; Yu, H.; Xue, X.; Hong, N. The effects of temperature and catalysts on the pyrolysis of industrial wastes (herb residue). Bioresour. Technol. 2010, 101, 3236–3241. [Google Scholar]

- Tripathy, V.; Basak, B.B.; Varghese, T.S.; Saha, A. Residues and contaminants in medicinal herbs-A review. Phytochem. Lett. 2015, 14, 67–78. [Google Scholar] [CrossRef]

- Wang, M.; Li, W.; Liu, S.; Liu, D.; Yin, L.; Yuan, H. Biogas Production from Chinese Herb-extraction Residues: Influence of Biomass Composition on Methane Yield. Bioresources 2013, 8, 3732–3740. [Google Scholar] [CrossRef]

- Guo, F.; Dong, Y.; Dong, L.; Jing, Y. An innovative example of herb residues recycling by gasification in a fluidized bed. Waste Manag. 2013, 33, 825–832. [Google Scholar] [CrossRef]

- Li, W.Y.; Cheng, H.T.; Zhang, S.B. Methods of Improving the Interfacial Compatibility of the Bamboo Fiber/Thermoplastic. Adv. Mater. Res. 2013, 602, 1130–1134. [Google Scholar] [CrossRef]

- Wang, Y.N.; Weng, Y.X.; Wang, L. Characterization of interfacial compatibility of polylactic acid and bamboo flour (PLA/BF) in biocomposites. Polym. Test. 2014, 36, 119–125. [Google Scholar] [CrossRef]

- Li, J. Effect of Silane Coupling Agent on the Tensile Properties of Carbon Fiber-Reinforced Thermoplastic Polyimide Composites. Polym. Plast. Technol. Eng. 2010, 49, 337–340. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, H.; Dong, X.; Qu, J.; He, H.; Xu, B.; Zhang, Y. Polyvinyl alcohol-modified Pithecellobium Clypearia Benth herbal residue fiber/polypropylene composites. Polym. Compos. 2016, 37, 915–924. [Google Scholar] [CrossRef]

- Feng, Y.-H.; Li, X.-L.; Jin, G.; Qu, J.-P.; He, H.-Z. Preparation and properties of several Chinese herbal residue/polylactic acid composites. J. Thermoplast. Compos. 2015, 28, 214–224. [Google Scholar]

- Bledzki, A.K.; Reihmane, S.; Gassan, J.J. Properties and modification methods for vegetable fibers for natural fiber composites. J. Appl. Polym. Sci. 1996, 59, 1329–1336. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2010, 84, 2222–2234. [Google Scholar] [CrossRef]

- Cantero, G.; Arbelaiz, A.; Mugika, F.; Valea, A.; Mondragon, I. Mechanical Behavior of Wood/Polypropylene Composites: Effects of Fibre Treatments and Ageing Processes. J. Reinf. Plast. Comp. 2003, 22, 37–50. [Google Scholar] [CrossRef]

- Wang, B.; Yang, D.; Zhang, H.R.; Huang, C.; Xiong, L.; Luo, J.; Chen, X.D. Preparation of Esterified Bacterial Cellulose for Improved Mechanical Properties and the Microstructure of Isotactic Polypropylene/Bacterial Cellulose Composites. Polymers 2016, 8, 129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nuñez, A.; Sturm, P.C.; Kenny, J.M.; Aranguren, M.I.; Marcovich, N.E.; Reboredo, M.M. Mechanical characterization of polypropylene–wood flour composites. J. Appl. Polym. Sci. 2010, 88, 1420–1428. [Google Scholar] [CrossRef]

- Wang, B.; Lin, F.H.; Zhao, Y.Y.; Li, X.Y.; Liu, Y.C.; Li, J.B.; Han, X.J.; Liu, S.X.; Ji, X.R.; Luo, J.; et al. Isotactic Polybutene-1/Bamboo Powder Composites with Excellent Properties at Initial Stage of Molding. Polymers 2019, 11, 1981. [Google Scholar] [CrossRef] [Green Version]

- Park, S.J.; Jin, J.S. Effect of silane coupling agent on mechanical interfacial properties of glass fiber-reinforced unsaturated polyester composites. J. Polym. Sci. Polym. Phys. 2003, 41, 55–62. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, H.R.; Huang, C.; Xiong, L.; Luo, J.; Chen, X.D. Mechanical and Rheological Properties of Isotactic Polypropylene/Bacterial Cellulose Composites. Polym. Korea 2017, 41, 460–464. [Google Scholar] [CrossRef]

- Wang, B.; Nie, K.; Xue, X.R.; Lin, F.H.; Li, X.Y.; Xue, Y.B.; Luo, J. Preparation of Maleic Anhydride Grafted Polybutene and Its Application in Isotactic Polybutene-1/Microcrystalline Cellulose Composites. Polymers 2018, 10, 393. [Google Scholar] [CrossRef] [Green Version]

- Arbelaiz, A.; Cantero, G.; Fernandez, B.; Mondragon, I.; Ganan, P.; Kenny, J.M. Flax fiber surface modifications: Effects on fiber physico mechanical and flax/polypropylene interface properties. Polym. Compos. 2010, 26, 324–332. [Google Scholar] [CrossRef]

- Li, Y.K.; Sun, Z.Y. Acceleration of crystal transformation from crystal form II to form I in Polybutene-1 induced by nanoparticles. Polymer 2018, 150, 119–129. [Google Scholar]

- Alfonso, G.C.; Azzurri, F.; Castellano, M. Analysis of Calorimetric Curves Detected During the Polymorphic Transformation of Isotactic Polybutene-1. J. Therm. Anal. Calorim. 2001, 66, 197–207. [Google Scholar] [CrossRef]

- Qu, P.; Zhou, Y.; Zhang, X.; Yao, S.; Zhang, L. Surface modification of cellulose nanofibrils for poly(lactic acid) composite application. J. Appl. Polym. Sci. 2012, 125, 3084–3091. [Google Scholar] [CrossRef]

- Xue, L.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar]

- Stiubianu, G.; Racles, C.; Cazacu, M.; Simionescu, B.C. Silicone-modified cellulose. Crosslinking of cellulose acetate with poly[dimethyl(methyl-H)siloxane] by Pt-catalyzed dehydrogenative coupling. J. Mater. Sci. 2010, 45, 4141–4150. [Google Scholar] [CrossRef]

- Lu, J.; Askeland, P.; Drzal, L.T. Surface modification of microfibrillated cellulose for epoxy composite applications. Polymer 2008, 49, 1285–1296. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Mao, S.; Lin, F.; Zhang, M.; Zhao, Y.; Zheng, X.; Wang, H.; Luo, J. Interfacial Compatibility on the Crystal Transformation of Isotactic Poly (1-Butene)/Herb Residue Composite. Polymers 2021, 13, 1654. https://doi.org/10.3390/polym13101654

Wang B, Mao S, Lin F, Zhang M, Zhao Y, Zheng X, Wang H, Luo J. Interfacial Compatibility on the Crystal Transformation of Isotactic Poly (1-Butene)/Herb Residue Composite. Polymers. 2021; 13(10):1654. https://doi.org/10.3390/polym13101654

Chicago/Turabian StyleWang, Bo, Shuangdan Mao, Fuhua Lin, Mi Zhang, Yuying Zhao, Xiuhong Zheng, Hui Wang, and Jun Luo. 2021. "Interfacial Compatibility on the Crystal Transformation of Isotactic Poly (1-Butene)/Herb Residue Composite" Polymers 13, no. 10: 1654. https://doi.org/10.3390/polym13101654

APA StyleWang, B., Mao, S., Lin, F., Zhang, M., Zhao, Y., Zheng, X., Wang, H., & Luo, J. (2021). Interfacial Compatibility on the Crystal Transformation of Isotactic Poly (1-Butene)/Herb Residue Composite. Polymers, 13(10), 1654. https://doi.org/10.3390/polym13101654