3D Printing of High Viscosity Reinforced Silicone Elastomers

Abstract

:1. Introduction

2. Materials and Methods

2.1. SLA-Paste Printing

2.2. Materials

2.3. Instrumentation

3. Results

3.1. DLP-SLA Paste Printer Design and Build

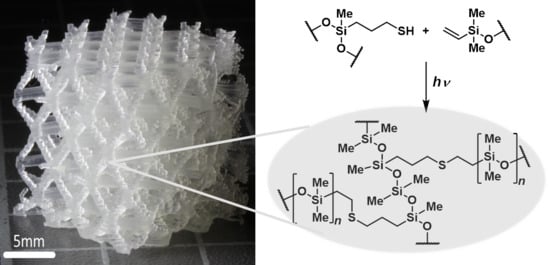

3.2. Formulation of UV-Curable Silicone Elastomers

3.3. Mechanical Properties and Testing

3.4. Optimization of SLA-Paste Printing

3.5. Negative Stiffness Behavior in Printed Lattices

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mulhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- O’Neill, M.R.; Acome, E.; Bakarich, S.; Mitchell, S.K.; Timko, J.; Keplinger, C.; Shepherd, R.F. Rapid 3D Printing of Electrohydraulic (HASEL) Tentacle Actuators. Adv. Funct. Mater. 2020, 30, 2005244. [Google Scholar] [CrossRef]

- Duoss, E.B.; Weisgraber, T.H.; Hearon, K.; Zhu, C.; Small, W., IV; Metz, T.R.; Vericella, J.J.; Barth, H.D.; Kuntz, J.D.; Maxwell, R.S.; et al. Three-Dimensional Printing of Elastomeric, Cellular Architectures with Negative Stiffness. Adv. Funct. Mater. 2014, 24, 4905–4913. [Google Scholar] [CrossRef]

- Jin, L.; Forte, A.E.; Deng, B.; Rafsanjani, A.; Bertoldi, K. Kirigami-Inspired Inflatables with Programmable Shapes. Adv. Mater. 2020, 32, 2001863. [Google Scholar] [CrossRef] [PubMed]

- Unkovskiy, A.; Spintzyk, S.; Brom, J.; Huettig, D.; Kuetel, C. Direct 3D printing of silicone facial prostheses: A preliminary experience in digital workflow. J. Prosthet. Dent. 2018, 120, 303–308. [Google Scholar] [CrossRef] [PubMed]

- Martín-Montal, J.; Pernas-Sánchez, J.; Varas, D. Experimental Characterization Framework for SLA Additive Manufacturing Materials. Polymers 2021, 13, 1147. [Google Scholar] [CrossRef] [PubMed]

- Lay, M.; Thajudina, N.L.N.; Hamida, Z.A.A.; Ruslia, A.; Abdullaha, M.K.; Shuiba, R.K. Comparison of physical and mechanical properties of PLA, ABS and nylon 6 fabricated using fused deposition modeling and injection molding. Compos. Part B Eng. 2019, 176, 107341. [Google Scholar] [CrossRef]

- Wicks, J.; Jue, M.L.; Beck, V.A.; Oakdale, J.S.; Dudukovic, N.A.; Clemens, A.L.; Liang, S.; Ellis, M.E.; Lee, G.; Baker, S.E.; et al. 3D-Printable Fluoropolymer Gas Diffusion Layers for CO2 Electroreduction. Adv. Mater. 2021, 33, 2003855. [Google Scholar] [CrossRef] [PubMed]

- Durban, M.M.; Lenhardt, J.M.; Wu, A.S.; Small, W., IV; Bryson, T.M.; Perez-Perez, L.; Nguyen, D.T.; Gammon, S.; Smay, J.E.; Duoss, E.B.; et al. Custom 3D Printable Silicones with Tunable Stiffness. Macromol. Rapid Commun. 2017, 1700563. [Google Scholar] [CrossRef]

- Shit, S.C.; Shah, P. A Review on Silicone Rubber. Natl. Acad. Sci. Lett. 2013, 36, 355–365. [Google Scholar] [CrossRef]

- Mazurek, P.; Vudayagiri, S.; Skov, A.L. How to tailor flexible silicone elastomers with mechanical integrity: A tutorial review. Chem. Soc. Rev. 2019, 48, 1448–1464. [Google Scholar] [CrossRef] [Green Version]

- Paul, D.R.; Mark, J.E. Fillers for polysiloxane (“silicone”) elastomers. Prog. Polym. Sci. 2010, 35, 893–901. [Google Scholar] [CrossRef]

- Thomas, D.K.; Moore, B.B. Filler reinforcement in silicone polymers. Polymer 1972, 13, 109–114. [Google Scholar] [CrossRef]

- For an Example of Commercial 3D Printing of Silicones See ACEO Technology. Available online: https://www.aceo3d.com/ (accessed on 1 June 2021).

- Liravi, F.; Toyserkani, E. Additive manufacturing of silicone structures: A review and prospective. Addit. Manuf. 2018, 24, 232–242. [Google Scholar] [CrossRef]

- Wong, B.H. Invisalign A to Z. Am. J. Orthod. Dentofac. Orthop. 2002, 121, 540–541. [Google Scholar] [CrossRef]

- Wang, K.; Pan, W.; Liu, Z.; Wallin, T.J.; van Dover, G.; Li, S.; Giannelis, E.P.; Mengüç, Y.; Shepherd, R.F. 3D Printing of Viscoelastic Suspensions via Digital Light Synthesis for Tough Nanoparticle–Elastomer Composites. Adv. Mater. 2020, 32, 2001646. [Google Scholar] [CrossRef]

- Wallin, T.J.; Simonsen, L.E.; Pan, W.; Wang, K.; Giannelis, E.; Shepherd, R.F.; Mengüç, Y. 3D printable tough silicone double networks. Nat. Commun. 2020, 11, 4000. [Google Scholar] [CrossRef]

- Liu, Z.; Hong, P.; Huang, Z.; Zhang, T.; Xu, R.; Chen, L.; Xiang, H.; Liu, X. Self-healing, reprocessing and 3D printing of transparent and hydrolysis-resistant silicone elastomers. Chem. Eng. J. 2020, 387, 124142. [Google Scholar] [CrossRef]

- Zhao, T.; Yu, R.; Li, S.; Li, X.; Zhang, Y.; Yang, X.; Zhao, X.; Wang, C.; Liu, Z.; Dou, R.; et al. Superstretchable and Processable Silicone Elastomers by Digital Light Processing 3D Printing. ACS Appl. Mater. Interfaces 2019, 11, 14391–14398. [Google Scholar] [CrossRef]

- Xiang, H.; Wang, X.; Ou, Z.; Lin, G.; Yin, J.; Liu, Z.; Zhang, L.; Liu, X. UV-curable, 3D printable and biocompatible silicone elastomers. Prog. Org. Coat. 2019, 137, 105372. [Google Scholar] [CrossRef]

- Sirrine, J.M.; Zlatanic, A.; Meenakshisundaram, V.; Messman, J.M.; Williams, C.B.; Dvornic, P.R.; Long, T.E. 3D Printing Amorphous Polysiloxane Terpolymers via Vat Photopolymerization. Macromol. Chem. Phys. 2019, 220, 1800425. [Google Scholar] [CrossRef]

- Sirrine, J.M.; Meenakshisundaram, V.; Moon, N.G.; Scott, P.J.; Mondschein, R.J.; Weiseman, T.F.; Williams, C.B.; Long, T.E. Functional siloxanes with photo-activated, simultaneous chain extension and crosslinking for lithography-based 3D printing. Polymer 2018, 152, 25–34. [Google Scholar] [CrossRef]

- Schmidt, J.; Colombo, P. Digital light processing of ceramic components from polysiloxanes. J. Eur. Ceram. Soc. 2018, 38, 57–66. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Parra-Cabrera, C.; Kim, Y.T.; Kuo, A.P.; Folch, A. Desktop—Stereolithography 3D—Printing of a Poly(dimethylsiloxane)—Based Material with Sylgard—184 Properties. Adv. Mater. 2018, 30, 1800001. [Google Scholar] [CrossRef] [PubMed]

- Wallin, T.J.; Pikul, J.H.; Bodkhe, S.; Peele, B.N.; MacMurry, B.C.; Therriault, D.; McEnerney, B.W.; Dillon, R.P.; Giannelis, E.P.; Shepherd, R.F. Click chemistry stereolithography for soft robots that self-heal. J. Mater. Chem. B 2017, 5, 6249–6255. [Google Scholar] [CrossRef]

- Femmer, T.; Kuehne, A.J.C.; Wessling, M. Print your own membrane: Direct rapid prototyping of polydimethylsiloxane. Lab Chip 2014, 14, 2610–2613. [Google Scholar] [CrossRef]

- Thrasher, C.J.; Schwartz, J.J.; Boydston, A.J. Modular Elastomer Photoresins for Digital Light Processing Additive Manufacturing. ACS Appl. Mater. Interfaces 2017, 9, 39708–39716. [Google Scholar] [CrossRef]

- Zanchetta, E.; Cattaldo, M.; Franchin, G.; Schwentenwein, M.; Homa, J.; Brusatin, G.; Colombo, P. Stereolithography of SiOC Ceramic Microcomponents. Adv. Mater. 2015, 28, 370–376. [Google Scholar] [CrossRef]

- Wu, X.; Xu, C.; Zhang, Z. Flexible film separation analysis of LCD based mask stereolithography. J. Mater. Process. Technol. 2021, 288, 116916. [Google Scholar] [CrossRef]

- Pan, Y.; Zhao, X.; Zhou, C.; Chen, Y. Smooth surface fabrication in mask projection based stereolithography. J. Manuf. Process. 2012, 14, 460–470. [Google Scholar] [CrossRef]

- Introducing the Form 3 and Form 3L, Powered by Low Force Stereolithography. Available online: https://formlabs.com/blog/introducing-form-3-form-3l-low-force-stereolithography/ (accessed on 3 April 2019).

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef]

- FlexVat: DIY and Technical Information. Available online: https://flexvat.com/pages/diy-and-technical-information (accessed on 1 June 2021).

- Flagg, D.H.; McCarthy, T.J. Rediscovering Silicones: MQ Copolymers. Macromolecules 2016, 49, 8581–8592. [Google Scholar] [CrossRef]

- Xu, X.; Wu, C.; Zhang, B.; Dong, H. Preparation, structure characterization, and thermal performance of phenyl-modified MQ silicone resins. J. Appl. Polym. Sci. 2013, 128, 4189–4200. [Google Scholar] [CrossRef]

- MacDowell, A.A.; Parkinson, D.Y.; Haboub, A.; Schaible, E.; Nasiatka, J.R.; Yee, C.A.; Jameson, J.R.; Ajo-Franklin, J.B.; Brodersen, C.R.; McElrone, A.J. X-ray micro-tomography at the Advanced Light Source. In Proceedings of the Volume 8506, Developments in X-Ray Tomography VIII, San Diego, CA, USA, 12–16 August 2012; p. 850618. [Google Scholar] [CrossRef]

- Champley, K.M. Livermore Tomography Tools (LTT) User’s Manual, Version 1.6; LLNL-SM-744257; Lawrence Livermore National Laboratory: Livermore, CA, USA, 2021. [Google Scholar]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, C.R.; Saalfeld, S.; Schmid, B.; Tinevez, J.Y.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [Green Version]

- Kikinis, R.; Pieper, S.D.; Vosburgh, K.G. 3D Slicer: A Platform for Subject-Specific Image Analysis, Visualization, and Clinical Support. In Intraoperative Imaging and Image-Guided Therapy; Springer: New York, NY, USA, 2014; pp. 277–289. [Google Scholar] [CrossRef]

- CloudCompare (Version 2.12) [GPL Software]. 2021. Available online: http://www.cloudcompare.org/ (accessed on 1 June 2021).

- Michael, K.W.; Mink, A.E.; Mitchell, D.D. Fast Curing Mercaptoalkyl Vinyl Siloxane Resins. US Patent 3873499, 25 March 1975. [Google Scholar]

- Perju, E.; Dünki, S.J.; Opris, D.M. A versatile synthetic path to thiol containing polysiloxanes. J. Polym. Sci. Part A Polym. Chem. 2016, 54, 2940–2948. [Google Scholar] [CrossRef]

- Robeyns, C.; Picard, L.; Ganachaud, F. Synthesis, characterization and modification of silicone resins: An “Augmented Review”. Prog. Org. Coat. 2018, 125, 287–315. [Google Scholar] [CrossRef]

- Tatarinova, E.; Vasilenko, N.; Muzafarov, A. Synthesis and Properties of MQ Copolymers: Current State of Knowledge. Molecules 2017, 22, 1768. [Google Scholar] [CrossRef] [Green Version]

- Vinogradov, S.V.; Polivanov, A.N.; Chuprova, E.A. Vinyl-functional MQ-resins (review). Plast. Massy 2019, 3–4, 59–65. [Google Scholar] [CrossRef]

- Kishi, H.; Nakamura, T.; Hagiwara, S.; Urahama, Y. Thermo-reversible phase structures of lightly cross-linked PDMS/MQ silicone polymer blends. Polymer 2020, 200, 122574. [Google Scholar] [CrossRef]

- Ito, T.; Hagiwara, T.; Ozai, T.; Miyao, T. Rapid Prototyping Resin Compositions. US Patent US20070049652A1, 1 March 2007. [Google Scholar]

| Sample | Ingredients (phr) | ||||||

|---|---|---|---|---|---|---|---|

| VTS-1 | VTS-2 | VTS-3 | MFS-1 | MFS-2 | Fumed Silica | MQ Resin | |

| TEFS-1 | - | 80 | - | 20 | - | - | - |

| TEFS-2 | - | 80 | - | 20 | - | 10 | - |

| TEFS-3 | - | 80 | - | 20 | 25 | ||

| TEFS-4 | - | 80 | - | 20 | - | 33 | - |

| TEFS-5 | 55 | - | - | 45 | - | 33 | - |

| TEFS-6 | - | - | 86 | 14 | - | 33 | - |

| TEMQ-1 | 70 | 30 | - | 17.5 | 17.5 | ||

| TEMQ-2 | - | - | 73 | 17 | 10 | 17 | 33 |

| TEMQ-3 | - | - | 73 | 17 | 10 | - | 37 |

| TEMQ-4 | - | - | 77 | - | 23 | 15 | 54 |

| Sample | G′ (kPa) a | σmax (MPa) b | εmax c | Ε (MPa) d | Shore A e |

|---|---|---|---|---|---|

| TEFS-1 | 0.001 | 0.14 ± 0.04 | 1.12 ± 0.27 | 0.20 ± 0.02 | 12 |

| TEFS-2 | 0.15 | 0.36 ± 0.05 | 1.55 ± 0.16 | 0.37 ± 0.02 | 21 |

| TEFS-3 | 8 | 0.56 ± 0.09 | 1.81 ± 0.25 | 0.57 ± 0.03 | 22 |

| TEFS-4 | 64 | 0.93 ± 0.07 | 2.80 ± 0.15 | 0.62 ± 0.09 | 23 |

| TEFS-5 | --- | 0.27 ± 0.04 | 0.57 ± 0.02 | 0.65 ± 0.05 | 22 |

| TEFS-6 | --- | 0.92 ± 0.08 | 3.64 ± 0.24 | 0.45 ± 0.01 | 25 |

| TEMQ-1 | 13 | 1.77 ± 0.36 | 3.81 ± 0.79 | 0.79 ± 0.04 | 35 |

| TEMQ-2 | 64 | 1.64 ± 0.29 | 2.01 ± 0.42 | 1.17 ± 0.11 | 39 |

| TEMQ-3 | 0.0076 | 0.43 ± 0.08 | 1.41 ± 0.10 | 0.38 ± 0.01 | 29 |

| TEMQ-4 | 160 | 2.43 ± 0.11 | 1.58 ± 0.11 | 2.25 ± 0.16 | 54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez, N.; Ruelas, S.; Forien, J.-B.; Dudukovic, N.; DeOtte, J.; Rodriguez, J.; Moran, B.; Lewicki, J.P.; Duoss, E.B.; Oakdale, J.S. 3D Printing of High Viscosity Reinforced Silicone Elastomers. Polymers 2021, 13, 2239. https://doi.org/10.3390/polym13142239

Rodriguez N, Ruelas S, Forien J-B, Dudukovic N, DeOtte J, Rodriguez J, Moran B, Lewicki JP, Duoss EB, Oakdale JS. 3D Printing of High Viscosity Reinforced Silicone Elastomers. Polymers. 2021; 13(14):2239. https://doi.org/10.3390/polym13142239

Chicago/Turabian StyleRodriguez, Nicholas, Samantha Ruelas, Jean-Baptiste Forien, Nikola Dudukovic, Josh DeOtte, Jennifer Rodriguez, Bryan Moran, James P. Lewicki, Eric B. Duoss, and James S. Oakdale. 2021. "3D Printing of High Viscosity Reinforced Silicone Elastomers" Polymers 13, no. 14: 2239. https://doi.org/10.3390/polym13142239

APA StyleRodriguez, N., Ruelas, S., Forien, J. -B., Dudukovic, N., DeOtte, J., Rodriguez, J., Moran, B., Lewicki, J. P., Duoss, E. B., & Oakdale, J. S. (2021). 3D Printing of High Viscosity Reinforced Silicone Elastomers. Polymers, 13(14), 2239. https://doi.org/10.3390/polym13142239