Recent Progress of Rice Husk Reinforced Polymer Composites: A Review

Abstract

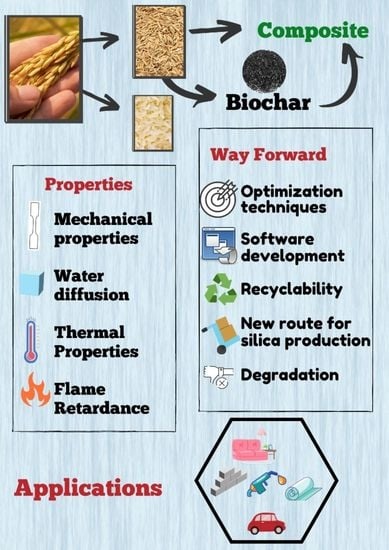

:1. Introduction

2. Tensile Strength of RH Composites

3. Flexural Strength of RH Composites

4. Impact Strength of RH Composites

5. Water Diffusion Behavior of RH Composites

6. Thermal Properties of RH Composites

7. Flame Retardance of RH Composites

8. RH Composites Applications

9. A Way Forward: RH Composites

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cherubin, M.R.; Oliveira, D.M.D.S.; Feigl, B.J.; Pimentel, L.G.; Lisboa, I.P.; Gmach, M.R.; Varanda, L.L.; Morais, M.C.; Satiro, L.S.; Popin, G.V. Crop residue harvest for bioenergy production and its implications on soil functioning and plant growth: A review. Sci. Agric. 2018, 75, 255–272. [Google Scholar] [CrossRef] [Green Version]

- Jittin, V.; Bahurudeen, A.; Ajinkya, S. Utilisation of rice husk ash for cleaner production of different construction products. J. Clean. Prod. 2020, 263, 121578. [Google Scholar] [CrossRef]

- Beidaghy Dizaji, H.; Zeng, T.; Hartmann, I.; Enke, D.; Schliermann, T.; Lenz, V.; Bidabadi, M. Generation of high quality biogenic silica by combustion of rice husk and rice straw combined with pre-and post-treatment strategies—A review. Appl. Sci. 2019, 9, 1083. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.; Moghadam, M.J.; Moayedi, H. Agricultural wastes preparation, management, and applications in civil engineering: A review. J. Mater. Cycles Waste Manag. 2019, 21, 1039–1051. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Sun, W.; Zhao, Y.; Wang, X.; Liu, X.; Li, Y. Bamboo flattening technique: A literature and patent review. Eur. J. Wood Wood Prod. 2021, 1–14. [Google Scholar]

- Mohamed Rashidi, A.H.; Jamal, M.H.; Hassan, M.Z.; Mohd Sendek, S.S.; Mohd Sopie, S.L.; Abd Hamid, M.R. Coastal structures as beach erosion control and sea level rise adaptation in malaysia: A review. Water 2021, 13, 1741. [Google Scholar] [CrossRef]

- Tan, M.L.; Samat, N.; Chan, N.W.; Lee, A.J.; Li, C. Analysis of precipitation and temperature extremes over the Muda River Basin, Malaysia. Water 2019, 11, 283. [Google Scholar] [CrossRef] [Green Version]

- Roslan, S.; Rasid, Z.; Hassan, M. The natural fiber composites based on bamboo fibers: A review. ARPN J. Eng. Appl. Sci. 2015, 10, 6279–6288. [Google Scholar]

- Hassan, M.Z.; Sapuan, S.; A Rasid, Z.; Nor, A.F.M.; Dolah, R.; Md Daud, M.Y. Impact damage resistance and post-impact tolerance of optimum banana-pseudo-stem-fiber-reinforced epoxy sandwich structures. Appl. Sci. 2020, 10, 684. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, M.I.; Hassan, M.Z.; Dolah, R.; Yusoff, M.Z.M.; Salit, M.S. Tensile behaviour for mercerization of single kenaf fiber. Malays. J. Fundam. Appl. Sci. 2018, 14, 437–439. [Google Scholar] [CrossRef]

- Mekhilef, S.; Saidur, R.; Safari, A.; Mustaffa, W. Biomass energy in Malaysia: Current state and prospects. Renew. Sustain. Energy Rev. 2011, 15, 3360–3370. [Google Scholar] [CrossRef]

- Goh, C.S.; Tan, K.T.; Lee, K.T.; Bhatia, S. Bio-ethanol from lignocellulose: Status, perspectives and challenges in Malaysia. Bioresour. Technol. 2010, 101, 4834–4841. [Google Scholar] [CrossRef] [PubMed]

- FAOSTAT. Available online: http://www.fao.org/faostat (accessed on 15 July 2021).

- Manickam, T.; Cornelissen, G.; Bachmann, R.T.; Ibrahim, I.Z.; Mulder, J.; Hale, S.E. Biochar application in Malaysian sandy and acid sulfate soils: Soil amelioration effects and improved crop production over two cropping seasons. Sustainability 2015, 7, 16756–16770. [Google Scholar] [CrossRef] [Green Version]

- Athira, G.; Bahurudeen, A.; Appari, S. Sustainable alternatives to carbon intensive paddy field burning in India: A framework for cleaner production in agriculture, energy, and construction industries. J. Clean. Prod. 2019, 236, 117598. [Google Scholar] [CrossRef]

- Abdulkareem, S.A.; Adeniyi, A.G. Tensile and water absorbing properties of natural fibre reinforced plastic composites from waste polystyrene and rice husk. J. Eng. Res. Dev. 2018, 1, 199–204. [Google Scholar]

- Zafar, M.F.; Siddiqui, M.A. Raw natural fiber reinforced polystyrene composites: Effect of fiber size and loading. Mater. Today Proc. 2018, 5, 5908–5917. [Google Scholar] [CrossRef]

- Zhang, Q.; Yi, W.; Li, Z.; Wang, L.; Cai, H. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers 2018, 10, 286. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Li, Y.; Cai, H.; Lin, X.; Yi, W.; Zhang, J. Properties comparison of high density polyethylene composites filled with three kinds of shell fibers. Results Phys. 2019, 12, 1542–1546. [Google Scholar] [CrossRef]

- Xue, B.; Wang, X.; Sui, J.; Xu, D.; Zhu, Y.; Liu, X. A facile ball milling method to produce sustainable pyrolytic rice husk bio-filler for reinforcement of rubber mechanical property. Ind. Crops Prod. 2019, 141, 111791. [Google Scholar] [CrossRef]

- Fernandes, I.J.; Santos, R.V.; Santos, E.C.A.d.; Rocha, T.L.A.C.; Domingues, N.S., Jr.; Moraes, C.A.M. Replacement of commercial silica by rice husk ash in epoxy composites: A comparative analysis. Mater. Res. 2018, 21. [Google Scholar] [CrossRef] [Green Version]

- Pongdong, W.; Kummerlöwe, C.; Vennemann, N.; Thitithammawong, A.; Nakason, C. A comparative investigation of rice husk ash and siliceous earth as reinforcing fillers in dynamically cured blends of epoxidized natural rubber (ENR) and thermoplastic polyurethane (TPU). J. Polym. Environ. 2018, 26, 1145–1159. [Google Scholar] [CrossRef]

- Chen, R.S.; Ahmad, S.; Gan, S. Rice husk bio-filler reinforced polymer blends of recycled HDPE/PET: Three-dimensional stability under water immersion and mechanical performance. Polym. Compos. 2018, 39, 2695–2704. [Google Scholar] [CrossRef]

- Raghu, N.; Kale, A.; Chauhan, S.; Aggarwal, P.K. Rice husk reinforced polypropylene composites: Mechanical, morphological and thermal properties. J. Indian Acad. Wood Sci. 2018, 15, 96–104. [Google Scholar] [CrossRef]

- Rajendran Royan, N.R.; Sulong, A.B.; Yuhana, N.Y.; Chen, R.S.; Ab Ghani, M.H.; Ahmad, S. UV/O3 treatment as a surface modification of rice husk towards preparation of novel biocomposites. PLoS ONE 2018, 13, e0197345. [Google Scholar] [CrossRef]

- Bisht, N.; Gope, P. Effect of alkali treatment on mechanical properties of rice husk flour reinforced epoxy bio-Composite. Mater. Today Proc. 2018, 5, 24330–24338. [Google Scholar] [CrossRef]

- Santiagoo, R.; Ismail, H.; Suharty, N. Comparison of processing and mechanical properties of polypropylene/recycled acrylonitrile butadiene rubber/rice husk powder composites modified with silane and acetic anhydride compound. In Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2018; pp. 333–347. [Google Scholar]

- Zhang, Q.; Zhang, D.; Lu, W.; Khan, M.U.; Xu, H.; Yi, W.; Lei, H.; Huo, E.; Qian, M.; Zhao, Y. Production of high-density polyethylene biocomposites from rice husk biochar: Effects of varying pyrolysis temperature. Sci. Total Environ. 2020, 738, 139910. [Google Scholar] [CrossRef]

- Moreno, D.D.P.; de Camargo, R.V.; dos Santos Luiz, D.; Branco, L.T.P.; Grillo, C.C.; Saron, C. Composites of recycled polypropylene from cotton swab waste with pyrolyzed rice husk. J. Polym. Environ. 2021, 29, 350–362. [Google Scholar] [CrossRef]

- Boonsuk, P.; Sukolrat, A.; Bourkaew, S.; Kaewtatip, K.; Chantarak, S.; Kelarakis, A.; Chaibundit, C. Structure-properties relationships in alkaline treated rice husk reinforced thermoplastic cassava starch biocomposites. Int. J. Biol. Macromol. 2021, 167, 130–140. [Google Scholar] [CrossRef] [PubMed]

- Olcay, H.; Kocak, E.D. Rice plant waste reinforced polyurethane composites for use as the acoustic absorption material. Appl. Acoust. 2021, 173, 107733. [Google Scholar] [CrossRef]

- Shubbar, S.D.A. Experimental investigation of rice husk particles as filler in hybrid composites. J. Univ. Babylon Eng. Sci. 2018, 26, 307–315. [Google Scholar]

- Awang, M.; Mohd, W.W. Comparative studies of Titanium Dioxide and Zinc Oxide as a potential filler in Polypropylene reinforced rice husk composite. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Pekan, Malayzia, 1–2 March 2018; p. 012046. [Google Scholar]

- Kumar, S.; Mer, K.K.S.; Gangil, B.; Patel, V.K. Synergy of rice-husk filler on physico-mechanical and tribological properties of hybrid Bauhinia-vahlii/sisal fiber reinforced epoxy composites. J. Mater. Res. Technol. 2019, 8, 2070–2082. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, M.A.; Salinas, E. Mechanical, thermal, viscoelastic performance and product application of PP-rice husk Colombian biocomposites. Compos. Part. B Eng. 2019, 176, 107135. [Google Scholar] [CrossRef]

- Singh, T.; Gangil, B.; Patnaik, A.; Biswas, D.; Fekete, G. Agriculture waste reinforced corn starch-based biocomposites: Effect of rice husk/walnut shell on physicomechanical, biodegradable and thermal properties. Mater. Res. Express 2019, 6, 045702. [Google Scholar] [CrossRef]

- Sun, J.; Pang, Y.; Yang, Y.; Zhao, J.; Xia, R.; Li, Y.; Liu, Y.; Guo, H. Improvement of rice husk/HDPE bio-composites interfacial properties by silane coupling agent and compatibilizer complementary modification. Polymers 2019, 11, 1928. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Běhálek, L.; Borůvka, M.; Brdlík, P.; Habr, J.; Lenfeld, P.; Kroisová, D.; Veselka, F.; Novák, J. Thermal properties and non-isothermal crystallization kinetics of biocomposites based on poly (lactic acid), rice husks and cellulose fibres. J. Therm. Anal. Calorim. 2020, 142, 629–649. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Rather, M.H.; Giridharan, B.; Prajwal, B.; Krishna, K.V.; Venkatesh, K.; Reddy, N. Groundnut shell/rice husk agro-waste reinforced polypropylene hybrid biocomposites. J. Build. Eng. 2020, 27, 100991. [Google Scholar] [CrossRef]

- Petchwattana, N.; Sanetuntikul, J. Static and Dynamic Mechanical Properties of Poly (vinyl chloride) and Waste Rice Husk Ash Composites Compatibilized with γ-aminopropyltrimethoxysilane. Silicon 2018, 10, 287–292. [Google Scholar] [CrossRef]

- Jiang, L.; Fu, J.; Liu, L.; Du, P. Wear and thermal behavior of basalt fiber reinforced rice husk/polyvinyl chloride composites. J. Appl. Polym. Sci. 2021, 138, 50094. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Johar, N.; Ahmad, I. Starch biocomposite film reinforced by multiscale rice husk fiber. Compos. Sci. Technol. 2017, 151, 147–155. [Google Scholar] [CrossRef]

- Yap, S.Y.; Sreekantan, S.; Hassan, M.; Sudesh, K.; Ong, M.T. Characterization and Biodegradability of Rice Husk-Filled Polymer Composites. Polymers 2021, 13, 104. [Google Scholar] [CrossRef]

- Spada, J.C.; Seibert, S.F.; Tessaro, I.C. Impact of PLA Poly (Lactic Acid) and PBAT Poly (butylene adipate-co-terephthalate) coating on the properties of composites with high content of rice husk. J. Polym. Environ. 2021, 29, 1324–1331. [Google Scholar] [CrossRef]

- Deo, C.; Acharya, S. Effect of moisture absorption on mechanical properties of chopped natural fiber reinforced epoxy composite. J. Reinf. Plast. Compos. 2010, 29, 2513–2521. [Google Scholar] [CrossRef]

- Shakeri, A.; Ghasemian, A. Water absorption and thickness swelling behavior of polypropylene reinforced with hybrid recycled newspaper and glass fiber. Appl. Compos. Mater. 2010, 17, 183–193. [Google Scholar] [CrossRef]

- Miao, J.; Tsige, M.; Taylor, P.L. Generalized model for the diffusion of solvents in glassy polymers: From fickian to super case II. J. Chem. Phys. 2017, 147, 044904. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Siriwardena, S.; Ismail, H.; Ishiaku, U. A comparison of the mechanical properties and water absorption behavior of white rice husk ash and silica filled polypropylene composites. J. Reinf. Plast. Compos. 2003, 22, 1645–1666. [Google Scholar] [CrossRef]

- Melo, R.Q.; Lia Fook, M.V.; de Lima, A.G. Non-Fickian Moisture Transport in Vegetable-Fiber-Reinforced Polymer Composites Using a Langmuir-Type Model. Polymers 2020, 12, 2503. [Google Scholar] [CrossRef]

- Lee, S.-H.; Ohkita, T.; Kitagawa, K. Eco-composite from poly (lactic acid) and bamboo fiber. Walter de Gruyter 2004, 58, 529–536. [Google Scholar] [CrossRef]

- Chen, R.S.; Ahmad, S. Mechanical performance and flame retardancy of rice husk/organoclay-reinforced blend of recycled plastics. Mater. Chem. Phys. 2017, 198, 57–65. [Google Scholar] [CrossRef]

- Sheykh, M.J.; Tarmian, A.; Doosthoseini, K. Wear resistance and friction coefficient of nano-SiO2 and ash-filled HDPE/lignocellulosic fiber composites. Polym. Bull. 2017, 74, 4537–4547. [Google Scholar] [CrossRef]

- Huner, U. Effect of chemical treatment and maleic anhydride grafted polypropylene coupling agent on rice husk and rice husk reinforced composite. Mater. Express 2017, 7, 134–144. [Google Scholar] [CrossRef]

- Saidi, M.A.; Ahmad, M.; Arjmandi, R.; Hassan, A.; Rahmat, A.R. The effect of titanate coupling agent on water absorption and mechanical properties of rice husk filled poly (vinyl chloride) composites. In Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2018; pp. 197–210. [Google Scholar]

- Mohamed, R.; Mohamed, M.M.F.; Norizan, M.N.; Mohamed, R.R.R. Physical and morphological properties of filled calcium carbonate/kenaf fibre/rice husk polypropylene hybrid composite. In Proceedings of the AIP Conference Proceedings, Selangor, Malaysia, 21–22 October 2017; p. 050003. [Google Scholar]

- Battegazzore, D.; Alongi, J.; Frache, A.; Wågberg, L.; Carosio, F. Layer by Layer-functionalized rice husk particles: A novel and sustainable solution for particleboard production. Mater. Today Commun. 2017, 13, 92–101. [Google Scholar] [CrossRef]

- Prapruddivongs, C.; Apichartsitporn, M.; Wongpreedee, T. Effect of silica resources on the biodegradation behavior of poly (lactic acid) and chemical crosslinked poly (lactic acid) composites. Polym. Test. 2018, 71, 87–94. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Husney, N.A.A.b.; Ismail, N.H.; Mariatti, M. Structure and performance of poly (lactic acid)/poly (butylene succinate-co-L-lactate) blend reinforced with rice husk and coconut shell filler. Polym. Polym. Compos. 2020, 0967391120954047. [Google Scholar] [CrossRef]

- Daramola, O.O. Flesural properties and water absorotion characteristics of high density polyethylene-based siliceous composites. Acta Tech. Corviniensis-Bull. Eng. 2019, 12, 57–62. [Google Scholar]

- Hamid, N.H.; Hisan, W.S.I.W.B.; Abdullah, U.H.; Azim, A.A.A.; Tahir, P.M. Mechanical properties and moisture absorption of epoxy composites mixed with amorphous and crystalline silica from rice husk. BioResources 2019, 14, 7363–7374. [Google Scholar]

- Chalapud, M.C.; Herdt, M.; Nicolao, E.S.; Ruseckaite, R.A.; Ciannamea, E.M.; Stefani, P.M. Biobased particleboards based on rice husk and soy proteins: Effect of the impregnation with tung oil on the physical and mechanical behavior. Constr. Build. Mater. 2020, 230, 116996. [Google Scholar] [CrossRef]

- Norhasnan, N.H.A.; Hassan, M.Z.; Nor, A.F.M.; Zaki, S.; Dolah, R.; Jamaludin, K.R.; Aziz, S.A.A. Physicomechanical properties of rice husk/coco peat reinforced acrylonitrile butadiene styrene blend composites. Polymers 2021, 13, 1171. [Google Scholar] [CrossRef]

- Chen, R.S.; Ab Ghani, M.H.; Ahmad, S.; Mou’ad, A.T.; Gan, S. Tensile, thermal degradation and water diffusion behaviour of gamma-radiation induced recycled polymer blend/rice husk composites: Experimental and statistical analysis. Compos. Sci. Technol. 2021, 207, 108748. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: Elaboration and performances evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef] [Green Version]

- Yusuf, T.A. Characterization of selected properties of composites of waste paper with untreated bamboo stem fibre and rice husk. Acta Polytech. 2017, 57, 295–303. [Google Scholar] [CrossRef] [Green Version]

- Antunes, A.; Faria, P.; Silva, V.; Brás, A. Rice husk-earth based composites: A novel bio-based panel for buildings refurbishment. Constr. Build. Mater. 2019, 221, 99–108. [Google Scholar] [CrossRef]

- Nabinejad, O.; Debnath, S.; Ying, T.J.; Liew, W.Y.; Davies, I.J. Influence of alkali treatment and nanoclay content on the properties of rice husk filled polyester composites. Mater. Sci. Forum 2017, 882, 89–100. [Google Scholar] [CrossRef]

- Zulkipli, A.H.; Romli, A.Z. Thermal characterization of low density polyethylene (LDPE)/rice husk ash and rice husk ash derived silica aerogel composites. In Proceedings of the AIP Conference Proceedings, Selangor, Malaysia, 21–22 October 2017; p. 030011. [Google Scholar]

- Majeed, K.; Ahmed, A.; Abu Bakar, M.S.; Indra Mahlia, T.M.; Saba, N.; Hassan, A.; Jawaid, M.; Hussain, M.; Iqbal, J.; Ali, Z. Mechanical and thermal properties of montmorillonite-reinforced polypropylene/rice husk hybrid nanocomposites. Polymers 2019, 11, 1557. [Google Scholar] [CrossRef] [Green Version]

- Krishnadevi, K.; Devaraju, S.; Sriharshitha, S.; Alagar, M.; Priya, Y.K. Environmentally sustainable rice husk ash reinforced cardanol based polybenzoxazine bio-composites for insulation applications. Polym. Bull. 2020, 77, 2501–2520. [Google Scholar] [CrossRef] [Green Version]

- Tipachan, C.; Gupta, R.K.; Agarwal, S.; Kajorncheappunngam, S. Flame retardant properties and thermal stability of polylactic acid filled with layered double hydroxide and rice husk ash silica. J. Polym. Environ. 2020, 28, 948–961. [Google Scholar] [CrossRef]

- Arjmandi, R.; Ismail, A.; Hassan, A.; Bakar, A.A. Effects of ammonium polyphosphate content on mechanical, thermal and flammability properties of kenaf/polypropylene and rice husk/polypropylene composites. Constr. Build. Mater. 2017, 152, 484–493. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, Y.; Yu, H.; Wang, Q. Study on Modified Rice Husk Ash and Its Filling Natural Rubber Composite. DEStech Trans. Eng. Technol. Res. 2018. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jadhav, A.; Qureshi, S.S.; Baloch, H.A.; Siddiqui, M.; Mubarak, N.; Griffin, G.; Madapusi, S.; Tanksale, A.; Ahamed, M.I. Synthesis and characterization of polylactide/rice husk hydrochar composite. Sci. Rep. 2019, 9, 1–11. [Google Scholar]

- Dutta, N.; Maji, T.K. Valorization of waste rice husk by preparing nanocomposite with polyvinyl chloride and montmorillonite clay. J. Thermoplast. Compos. Mater. 2019, 34, 801–806. [Google Scholar] [CrossRef]

- Dutta, N.; Maji, T.K. Synergic effect of montmorillonite and microcrystalline cellulose on the physicochemical properties of rice husk/PVC composite. SN Appl. Sci. 2020, 2, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Phan, H.T.; Nguyen, B.T.; Pham, L.H.; Pham, C.T.; Do, T.V.V.; Hoang, C.N.; Nguyen, N.N.; Kim, J.; Hoang, D. Excellent fireproof characteristics and high thermal stability of rice husk-filled polyurethane with halogen-free flame retardant. Polymers 2019, 11, 1587. [Google Scholar] [CrossRef] [Green Version]

- Oleiwi, J.K.; Hamad, Q.A.; Rahman, H.J.A. Study thermal behavior of heat cure poly (methyl methacrylate) reinforced by bamboo and rice husk powders for denture applications. Al-Qadisiyah J. Eng. Sci. 2018, 11, 417–425. [Google Scholar] [CrossRef]

- Lai, S.M.; Han, J.L.; Yu, Y.F. Properties of rice husk/epoxy composites under different interfacial treatments. Polym. Compos. 2017, 38, 1992–2000. [Google Scholar] [CrossRef]

- Almirón, J.; Roudet, F.; Duquesne, S. Influence of volcanic ash, rice husk ash, and solid residue of catalytic pyrolysis on the flame-retardant properties of polypropylene composites. J. Fire Sci. 2019, 37, 434–451. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, S.; Chen, Y.; Li, D. Thermal properties of wood-plastic composites with different compositions. Materials 2019, 12, 881. [Google Scholar] [CrossRef] [Green Version]

- Das, O.; Hedenqvist, M.S.; Prakash, C.; Lin, R.J. Nanoindentation and flammability characterisation of five rice husk biomasses for biocomposites applications. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105566. [Google Scholar] [CrossRef]

- Attia, N.F.; Saleh, B.K. Novel synthesis of renewable and green flame-retardant, antibacterial and reinforcement material for styrene–butadiene rubber nanocomposites. J. Therm. Anal. Calorim. 2020, 139, 1817–1827. [Google Scholar] [CrossRef]

- Vu, C.M.; Nguyen, V.-H.; Bach, Q.-V. Phosphorous-jointed epoxidized soybean oil and rice husk-based silica as the novel additives for improvement mechanical and flame retardant of epoxy resin. J. Fire Sci. 2020, 38, 3–27. [Google Scholar] [CrossRef]

- Vu, C.M.; Bach, Q.-V. Effects of DOPO-grafted epoxidized soybean oil on fracture toughness and flame retardant of epoxy resin/rice husk silica hybrid. Macromol. Res. 2020, 28, 826–834. [Google Scholar] [CrossRef]

- Son, T.; Nguyen, H.T.; Phan, H.T.; Pham, C.T.; Nguyen, B.T.; Pham, L.H.; Do, T.V.V.; Vothi, H.; Kim, J.; Hoang, D.Q. Phosphorus/phosphorus-nitrogen flame retardants applied to polyurethane/rice husk eco-composites: Thermal behavior, flame retardancy, and physico-mechanical properties. Polym. Bull. 2021, 78, 2727–2743. [Google Scholar] [CrossRef]

- Wu, W.; He, H.; Liu, T.; Wei, R.; Cao, X.; Sun, Q.; Venkatesh, S.; Yuen, R.K.; Roy, V.A.; Li, R.K. Synergetic enhancement on flame retardancy by melamine phosphate modified lignin in rice husk ash filled P34HB biocomposites. Compos. Sci. Technol. 2018, 168, 246–254. [Google Scholar] [CrossRef]

- Xu, Y.; Li, J.; Shen, R.; Wang, Z.; Hu, P.; Wang, Q. Experimental study on the synergistic flame retardant effect of bio-based magnesium phytate and rice husk ash on epoxy resins. J. Therm. Anal. Calorim. 2021, 1–12. [Google Scholar] [CrossRef]

- Kavitha, D.; Murugavel, S.C.; Thenmozhi, S. Flame retarding cardanol based novolac-epoxy/rice husk composites. Mater. Chem. Phys. 2021, 263, 124225. [Google Scholar] [CrossRef]

- Bakari, R.; Kivevele, T.; Huang, X.; Jande, Y.A. Simulation and optimisation of the pyrolysis of rice husk: Preliminary assessment for gasification applications. J. Anal. Appl. Pyrolysis 2020, 150, 104891. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, H.; Chen, P.; Fang, X.; Du, T. Synthesis of La and Ce modified X zeolite from rice husk ash for carbon dioxide capture. J. Mater. Res. Technol. 2020, 9, 4368–4378. [Google Scholar] [CrossRef]

- He, S.; Chen, G.; Xiao, H.; Shi, G.; Ruan, C.; Ma, Y.; Dai, H.; Yuan, B.; Chen, X.; Yang, X. Facile preparation of N-doped activated carbon produced from rice husk for CO2 capture. J. Colloid Interface Sci. 2021, 582, 90–101. [Google Scholar] [CrossRef] [PubMed]

- Panda, D.; Saini, C.; Kumar, E.A.; Singh, S.K. In situ casting of rice husk ash in metal organic frameworks induces enhanced CO2 capture performance. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Tiwari, S.; Pradhan, M. Effect of rice husk ash on properties of aluminium alloys: A review. Mater. Today Proc. 2017, 4, 486–495. [Google Scholar] [CrossRef]

- Okoya, A.A.; Adegbaju, O.S.; Akinola, O.E.; Akinyele, A.B.; Amuda, O.S. Comparative assessment of the efficiency of rice husk biochar and conventional water treatment method to remove chlorpyrifos from pesticide polluted water. Curr. J. Appl. Sci. Technol. 2020, 39, 1–11. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, Z.; Su, J.; Li, J.; Gao, B.; Fu, J.; Zhang, X.; Huo, K.; Chu, P.K. Large-scale and low-cost synthesis of in situ generated SiC/C nano-composites from rice husks for advanced electromagnetic wave absorption applications. Surf. Coat. Technol. 2021, 406, 126641. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, F.; Liu, J.-C.; Wang, S. Eco-friendly high strength, high ductility engineered cementitious composites (ECC) with substitution of fly ash by rice husk ash. Cem. Concr. Res. 2020, 137, 106200. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Application of rice husk biochar as filler in cenosphere modified mortar: Preparation, characterization and performance under elevated temperature. Constr. Build. Mater. 2020, 253, 119083. [Google Scholar] [CrossRef]

- Marques, B.; António, J.; Almeida, J.; Tadeu, A.; de Brito, J.; Dias, S.; Pedro, F.; Sena, J.D. Vibro-acoustic behaviour of polymer-based composite materials produced with rice husk and recycled rubber granules. Constr. Build. Mater. 2020, 264, 120221. [Google Scholar] [CrossRef]

- Abdelmagid, A.A.; Feng, C.P. Laboratory evaluation of the effects of short-term aging on high temperature performance of asphalt binder modified with crumb rubber and rice husk ash. Pet. Sci. Technol. 2019, 37, 1557–1565. [Google Scholar] [CrossRef]

- Abdelmagid, A.A.; Pei Feng, C. Evaluating the effect of rice-husk ash and crumb-rubber powder on the high-temperature performance of asphalt binder. J. Mater. Civ. Eng. 2019, 31, 04019296. [Google Scholar] [CrossRef]

- Bodie, A.R.; Micciche, A.C.; Atungulu, G.G.; Rothrock, M.J., Jr.; Ricke, S.C. Current trends of rice milling byproducts for agricultural applications and alternative food production systems. Front. Sustain. Food Syst. 2019, 3, 47. [Google Scholar] [CrossRef]

- De Silva, G.S.; Vishvalingam, S.; Etampawala, T. Effect of waste rice husk ash from rice husk fuelled brick kilns on strength, durability and thermal performances of mortar. Constr. Build. Mater. 2021, 268, 121794. [Google Scholar] [CrossRef]

- Thang, N.H. Novel Porous Refractory Synthesized from Diatomaceous Earth and Rice Husk Ash. J. Polym. Compos. 2020, 8, 128–137. [Google Scholar]

- SEAT Uses Recycled Rice Husks to Reduce Plastics in New Leon. Available online: https://blog.swanswaygarages.com/seat-uses-recycled-rice-husks-to-reduce-plastics-in-new-leon. (accessed on 16 July 2021).

- Primaningtyas, W.; Sakura, R.; Syafi’i, I.; Adhyaksa, A. Asbestos-free Brake Pad Using Composite Polymer Strengthened with Rice Husk Powder. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Surabaya, Indonesia, 29 September 2019; p. 012015. [Google Scholar]

- Paramasivam, K.; Jayaraj, J.J.; Ramar, K.; Subramani, Y.; Ajithkumar, K.; Kabilan, N. Evaluation of natural fibers for the production of automotive brake pads replacement for asbestos brake pad. In Proceedings of the AIP Conference Proceedings, Chennai, India, 7–9 August 2020; p. 040005. [Google Scholar]

- Eddy, D.R.; Noviyanti, A.R.; Solihudin, S.; Ishmayana, S.; Tjokronegoro, R.-A. Rice Husk for Photocatalytic Composite Material Fabrication. In Visible-Light Photocatal. Carbon-Based Mater; IntechOpen: London, UK, 2018; pp. 19–28. [Google Scholar]

- Chen, H.; Zhao, L.; Wang, G.; He, X.; Wang, X.; Fang, W.; Du, X. Direct growth of ZnO nanorods on biogenic hierarchical rice husk SiO2 and their application to dye degradation. Clean Technol. Environ. Policy 2017, 19, 1335–1345. [Google Scholar] [CrossRef]

- Vu, D.-L.; Seo, J.-S.; Lee, H.-Y.; Lee, J.-W. Activated carbon with hierarchical micro–mesoporous structure obtained from rice husk and its application for lithium–sulfur batteries. RSC Adv. 2017, 7, 4144–4151. [Google Scholar] [CrossRef] [Green Version]

- Suwanprateeb, J.; Hatthapanit, K. Rice-husk-ash-based silica as a filler for embedding composites in electronic devices. J. Appl. Polym. Sci. 2002, 86, 3013–3020. [Google Scholar] [CrossRef]

- Chen, J.-P.; Song, G.; Liu, Z.; Kong, Q.-Q.; Zhang, S.-C.; Chen, C.-M. Preparation of SiC whiskers using graphene and rice husk ash and its photocatalytic property. J. Alloys Compd. 2020, 833, 155072. [Google Scholar] [CrossRef]

- Nicolao, E.; Leiva, P.; Chalapud, M.; Ruseckaite, R.A.; Ciannamea, E.M.; Stefani, P.M. Flexural and tensile properties of biobased rice husk-jute-soybean protein particleboards. J. Build. Eng. 2020, 30, 101261. [Google Scholar] [CrossRef]

- Pratheep, V.; Priyanka, E.; Prasad, P.H. Characterization and Analysis of Natural Fibre-Rice Husk with Wood Plastic Composites. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tamil Nady, India, 12–13 April 2019; p. 012066. [Google Scholar]

- Sadik, W.A.A.; El Demerdash, A.G.M.; Abbas, R.; Bedir, A. Effect of Nanosilica and Nanoclay on the Mechanical, Physical, and Morphological Properties of Recycled Linear Low Density Polyethylene/Rice Husk Composites. J. Polym. Environ. 2021, 29, 1600–1615. [Google Scholar] [CrossRef]

- Gupta, H.; Kumar, H.; Kumar, M.; Gehlaut, A.K.; Gaur, A.; Sachan, S.; Park, J.-W. Synthesis of biodegradable films obtained from rice husk and sugarcane bagasse to be used as food packaging material. Environ. Eng. Res. 2020, 25, 506–514. [Google Scholar] [CrossRef]

- Datta, D.; Halder, G. Blending of phthalated starch and surface functionalized rice husk extracted nanosilica with LDPE towards developing an efficient packaging substitute. Environ. Sci. Pollut. Res. 2020, 27, 1533–1557. [Google Scholar] [CrossRef]

- Datta, D.; Samanta, S.; Halder, G. Surface functionalization of extracted nanosilica from rice husk for augmenting mechanical and optical properties of synthesized LDPE-Starch biodegradable film. Polym. Test. 2019, 77, 105878. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Sapuan, S.; Roslan, S.A.; Sarip, S. Optimization of tensile behavior of banana pseudo-stem (Musa acuminate) fiber reinforced epoxy composites using response surface methodology. J. Mater. Res. Technol. 2019, 8, 3517–3528. [Google Scholar] [CrossRef]

- Hassan, M.Z.; Roslan, S.A.; Sapuan, S.; Rasid, Z.A.; Mohd Nor, A.F.; Md Daud, M.Y.; Dolah, R.; Mohamed Yusoff, M.Z. Mercerization optimization of bamboo (Bambusa vulgaris) fiber-reinforced epoxy composite structures using a box–behnken design. Polymers 2020, 12, 1367. [Google Scholar] [CrossRef]

- Nor, A.F.M.; Hassan, M.Z.; Rasid, Z.A.; Sarip, S.; Daud, M.Y.M. Optimization on Tensile Properties of Kenaf/Multi-walled CNT Hybrid Composites with Box-Behnken Design. Appl. Compos. Mater. 2021, 28, 607–632. [Google Scholar] [CrossRef]

- Bisht, N.; Gope, P.C.; Rani, N. Rice husk as a fibre in composites: A review. J. Mech. Behav. Mater. 2020, 29, 147–162. [Google Scholar] [CrossRef]

- Motlagh, E.K.; Asasian-Kolur, N.; Sharifian, S.; Pirbazari, A.E. Sustainable rice straw conversion into activated carbon and nano-silica using carbonization-extraction process. Biomass Bioenergy 2021, 144, 105917. [Google Scholar] [CrossRef]

- Adebajo, S.; Akintokun, P.; Ojo, A.; Akintokun, A.; Badmos, O. Recovery of Biosurfactant Using Different Extraction Solvent by Rhizospheric Bacteria Isolated from Rice-husk and Poultry Waste Biochar Amended Soil. Egypt. J. Basic Appl. Sci. 2020, 7, 252–266. [Google Scholar] [CrossRef]

| Types | Quantity (kt) | Source | Source (kt) |

|---|---|---|---|

| Agricultural waste | |||

| Oil palm fronds | 46,837 | Oil palm FFB | 81.92 |

| EPFB | 18,022 | ||

| Oil palm fibers | 11,059 | ||

| Oil palm shells | 4506 | ||

| Oil palm trunks | 10,827 | ||

| Paddy straw | 880 | Replanting paddy | 2375 |

| RH | 484 | ||

| Banana residues | 265 | Banana | 530 |

| Sugarcane bagasse | 234 | Sugarcane | 730 |

| Coconut husk | 171 | Coconut | 505 |

| Pineapple waste | 48 | Pineapples for factories | 69 |

| Forest residues | |||

| Logging residues | 2649 | Logs | 2649 |

| Plywood residues | 2492 | Plywood | 2492 |

| Sawmill residues | 1.16 | Sawn timber | 1418 |

| Municipal solid waste | |||

| Organic waste | 4653 | MSW | 6744 |

| Matrix | Parametric Study | Tensile Strength (MPa) | Flexural (MPa) | Impact Strength (kJ/m2) | References |

|---|---|---|---|---|---|

| HDPE | Matrix modification | 22.5 ± 0.5 | 49.6 ± 1.2 | Abdulkarem et al. [16] | |

| PP | Filler loading | 19.7 | 39.2 | Zafar et al. [17] | |

| HDPE | Filler modification | 20 | 53.7 | 13 | Zhang et al. [18] |

| HDPE | Hybrid | 15.8 | 25.7 | 15.2 | Zhang et al. [19] |

| Natural rubber | Filler modification | 21.3 ± 0.7 | Xue et al. [20] | ||

| Epoxy | Filler modification | 120 | Fernandes et al. [21] | ||

| Epoxidized natural rubber | Filler modification | 18.5 ± 0.5 | Pongdong et al. [22] | ||

| HDPE/PET | Matrix modification | 22.2 ± 0.1 | 48 ± 2 | 3 ± 0.1 | Chen et al. [23] |

| Epoxidized natural rubber | Matrix modification | 35 | 45 | 22 | Raghu et al. [24] |

| rHDPE | Filler treatment | 18.37 | Rajendran et al. [25] | ||

| Epoxy | Filler treatment | 46 ± 1 | 87 ± 2 | 2.7 ± 0.1 | Bisht et al. [26] |

| rABS/PP | Matrix modification | 21 ± 1 | Santiago et al. [27] | ||

| HDPE | Filler treatment | 26.3 ± 0.50 | Zhang et al. [28] | ||

| rPP | Filler treatment | 28 ± 0.25 | 3.0 ± 0.5 | Moreno et al. [29] | |

| TPS | Filler treatment | 2.43 ± 0.25 | Boonsuk et al. [30] | ||

| PU | Filler treatment | 0.25 ± 0.11 | Olcay et al. [31] | ||

| Epoxy | Hybrid | 43 | Shubbar [32] | ||

| PP | Hybrid | 40 ± 2 | Awang et al. [33] | ||

| Epoxy | Hybrid | 30 ± 2 | 25 ± 2 | Kumar et al. [34] | |

| PP | Filler loading | 33.2 ± 0.5 | 39.8 ± 0.3 | Hidalgo-Salazar et al. [35] | |

| Corn starch | Hybrid | 10.7 | 19.6 | Singh et al. [36] | |

| HDPE | Matrix modification | 30 ± 2 | Sun et al. [37] | ||

| PLA | Matrix modification | 5254 ± 25 | Běhálek et al. [38] | ||

| PP | Hybrid | 15.6 ± 0.25 | 37.6 ± 1.88 | Guna et al. [39] | |

| PVC | Matrix modification | 51.9 ± 2.54 | 74.9 ± 5.81 | Petchwattana et al. [40] | |

| PVC | Hybrid | 5.5 ± 0.80 | Jiang et al. [41] | ||

| Cassava starch | Filler modification | 3.3 ± 0.5 | Kargarzadeh et al. [42] | ||

| Corn starch | Matrix modification | 14.3 ± 1.13 | Yap et al. [43] | ||

| PLA and PBAT | Matrix modification | 10.0 ± 1.0 | Spada et al. [44] |

| Matrix | Parametric Study | M∞(%) | Thickness Swelling (%) | Diffusion Coefficients (D × 10–5 mm2/s) | References |

|---|---|---|---|---|---|

| rHDPE | Hybrid | 1.8–4.0 | 4.8–6.8 | Chen and Ahmad [51] | |

| HDPE | Filler content | 12.0–13.0 | 8.5–10.0 | Sheykh et al. [52] | |

| PE | Filler treatment | 3.0–7.0 | Nabinejad et al. 2017 | ||

| Cassava starch | Hybrid | 0.5–2.7 | Huner [53] | ||

| PVC | Coupling agent | 0.4–2.4 | Saidi et al. [54] | ||

| PE | Hybrid | 2.5–13.0 | Mohamed et al. [55] | ||

| Corn starch | Filler content | 5.1–11.9 | Battegazzore et al. [56] | ||

| PVC | Coupling agent | 4.2–6.3 | Petchwattana et al. [40] | ||

| Epoxy | Hybrid | 1.2–2.4 | Shubbar [32] | ||

| rHDPE | Filler treatment | 1.7–4.0 | Rajendran et al. [25] | ||

| rPE | Filler content | 2.8–1.6 | Abdulkareem et al. [16] | ||

| rHDPE/rPET | Hybrid | 3.0–9.5 | 4.0–8.8 | Chen et al. [23] | |

| Epoxy | Filler content | 0.06–0.17 | Fernandes et al. [21] | ||

| PLA | Filler treatment | 2.5–3.5 | Prappuddivongs et al. [57] | ||

| PLA/PLB | Blending effect | 0.8–5.2 | Akindoyo et al. [58] | ||

| HDPE | Filler content | 0.12–0.28 | Daramola [59] | ||

| Epoxy | Filler content | 0.08–0.13 | Hamid et al. [60] | ||

| Soy bean | Coating | 4.0–11.0 | 3.2–15.9 | Chalapud et al. [61] | |

| ABS | Hybrid | 6.9–9.1 | 1.1–1.4 | Norhasnan et al. [62] | |

| rHDPE | Filler treatment | 3.7–26.6 | 0.63 | Chen et al. [63] |

| Matrix | Parametric Study | Tg, °C | 5% Weight Loss, °C | 10% Weight Loss, °C | Tm, °C | Char Yield at (600–900 °C), % | References |

|---|---|---|---|---|---|---|---|

| Cardanol based polybenzoxazine | Filler content | 145 | 319 | 370 | 470 | 47 | Krishnadevi et al. [70] |

| PLA | Matrix modification | 335 | 521 | 6.1 | Tipachan et al. [71] | ||

| Organic paraffin | Filler content | 51.5 | 341 | 7.46 | Lai et al. [79] | ||

| PLA | Filler treatment | 472 | 3 | Chen and Ahmad [51] | |||

| PP | Filler content | 449.5 | 3 | Arjmandi et al. [72] | |||

| Epoxy | Filler treatment | 140 | 156.5 | Fernandes et al. [21] | |||

| PMMA | Filler content | 129 | 453 | Oleiwi et al. [78] | |||

| LDPE | Filler comparison | 112.9 | Zulkipli and Romli [68] | ||||

| Natural rubber | Coupling agent | 447.2 | Zeng et al. [73] | ||||

| PBAT/PLA | Filler content | 40 | Muthuraj et al. [64] | ||||

| PP | Filler content | 166 | Hidalgo and Salinas [35] | ||||

| rHDPE | Filler content | 131 | Guo et al. [81] | ||||

| Corn starch | Filler content | 139 | 166 | 3.5 | Singh et al. [36] | ||

| PP | Filler content | 356.3 | 422.4 | 489.8 | 9.2 | Awang et al. [33] | |

| PP | Filler content | 403 | 22.8 | Almiron et al. [80] | |||

| PP | Filler content | 350 | 30 | Das et al. [82] | |||

| PET | Flame retardant effect | 234 | 1.3 | Phan et al. [77] | |||

| PVC | Clay addition | 455 | 11 | Dutta and Maji [75] | |||

| PP | Clay addition | 311 | 162.9 | Majeed et al. [69] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suhot, M.A.; Hassan, M.Z.; Aziz, S.A.; Md Daud, M.Y. Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymers 2021, 13, 2391. https://doi.org/10.3390/polym13152391

Suhot MA, Hassan MZ, Aziz SA, Md Daud MY. Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymers. 2021; 13(15):2391. https://doi.org/10.3390/polym13152391

Chicago/Turabian StyleSuhot, Mohamed Azlan, Mohamad Zaki Hassan, Sa’ardin Abdul Aziz, and Mohd Yusof Md Daud. 2021. "Recent Progress of Rice Husk Reinforced Polymer Composites: A Review" Polymers 13, no. 15: 2391. https://doi.org/10.3390/polym13152391

APA StyleSuhot, M. A., Hassan, M. Z., Aziz, S. A., & Md Daud, M. Y. (2021). Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymers, 13(15), 2391. https://doi.org/10.3390/polym13152391